|

연간정보 서비스

상품코드

1585848

OEM 수소 전해조 프로젝트 데이터베이스Global OEM Electrolyzer Projects Database |

||||||

"Global OEM Electrolyzer Projects Database"는 Global Insight Services의 새로운 구독 서비스로, 새로운 수소 전해조 프로젝트에 대한 추적 정보를 제공합니다. 이 서비스에 가입하면 매월 업데이트되는 최신 프로젝트 데이터베이스에 액세스할 수 있습니다.

INFOGRAPHICS

전해질은 전기를 이용하여 비자발적인 화학반응을 촉진하는 장치로, 일반적으로 물을 전기분해하여 수소와 산소로 만드는 장치입니다. 이 과정에서 물에 전류를 흐르게 하여 물을 한쪽 전극의 수소가스(H2)와 다른 쪽 전극의 산소가스(O2)로 분해합니다. 전해조는 각종 산업 응용, 에너지 저장, 자동차의 청정 연료 공급원으로서 수소 생산에 중요한 역할을 하고 있습니다.

"Global OEM Electrolyzer Projects Database"는 빠르게 변화하고 진화하는 프로젝트 상황에서 수소 가치사슬 전반에 걸친 시장 진출기업들에게 필수적인 시장 정보원이 되고 있습니다.

이 데이터베이스는 300개 이상의 제조시설을 대상으로 전해조 용량, 생산량, 기술, 자금조달, 참여기업, 프로젝트 현황, 타임라인에 대한 상세한 데이터를 제공하여 각 산업분야의 효율적인 수소 프로젝트 계획 수립 및 분석을 지원합니다.

- 제조업체에 대한 종합적인 정보 : 다양한 지역 및 기술에 걸친 주요 OEM의 상세한 프로파일

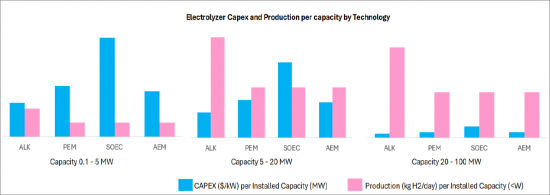

- 성과지표: 용량, 효율성, 설비투자, 프로젝트 비용에 관한 상세한 데이터

- 프로젝트 추적 정보 : 세계에서 진행 중이거나 계획 중인 전해조 프로젝트 관련 데이터

- 경쟁사 벤치마킹: 기술, 가격 및 용량에 대한 OEM 간 비교

- 기술 발전: 신기술(PEM, 알칼리, 고체산화물 등)의 동향을 추적하고, 그 동향과 혁신을 파악합니다.

- 지역별 시장 분석 : 지역별 수소 보급 추세에 따라 고객이 특정 시장을 타겟팅할 수 있습니다.

- 사업 제휴 및 협력 데이터: OEM 및 기타 이해관계자와의 전략적 제휴 및 합작 투자에 대한 정보.

- 자금 조달 및 인센티브: 전해질 프로젝트에 대한 정부 보조금, 인센티브 및 자금 조달 옵션에 대한 정보

데이터베이스의 대상 범위

| 프로젝트 | 250건 이상 |

| 대상 지역 | 세계 |

| 전해질 제조업체 | 100개사 이상 |

| 프로젝트 정보 | 프로젝트명, 프로젝트 소재지, 프로젝트 카테고리, 프로젝트 참여기업, 플랜트 현황, 자금 제공업체, 자금 조달 금액, 프로젝트 비용, 재생에너지 유형, 전해조 제조업체, 기술, 전해조 용량, 수소 생산능력, 수소 최종 사용자, 공급원 자산 용량, 프로젝트 발표 년도, 프로젝트 건설 시작 년도, 프로젝트 건설 종료 년도 |

| 전해질 기술 | 알칼리성 물 전기 분해, 양성자 교환막, 고체 산화물 전해 전지, 음이온 교환막, 모세관 전기 분해, Membrane-Free 전기 분해 |

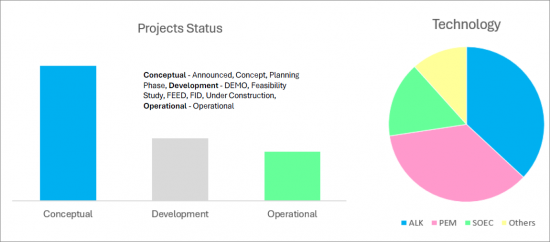

| 프로젝트 현황 | 건설 중, 발표, 운영 중, 계획 단계, 컨셉, FID, FID, 타당성 분석, DEMO, FEED |

| 수소 최종사용자 | 암모니아, 시멘트, 화학, 전자상거래, 전자 연료, 전기자동차, 에너지, 에너지 저장, 비료 생산, 식품 밸류체인, 연료전지, 난방, 수소 연료 공급 시스템, 물류, 제조, 메탄올, 모빌리티, 정유소, 철강, 합성 연료, 통신 |

| 주요 수소 관련 기업 | H2 Energy, Orsted, ENGIE, BP, Infinite Green Energy Ltd, Fortescue Future Industries, ScottishPower |

| 주요 전해조 제조업체 | Nel ASA, Siemens, McPhy Energy, ITM Power Plc, Gaztransport & Technigaz(Elogen), Green Hydrogen Systems, iGas Energy GmbH, Next Hydrogen, Asahi Kasei, thyssenkrupp, Cummins(Hydrogenics), Toshiba Corporation, Plug Power, John Cockerill, Enagas(H2Greem), Sunfire GmbH, Bloom Energy, Air Liquide, Volkswagen AG(H-TEC SYSTEMS), Enapter AG |

월간 뉴스 레터

이 서비스 가입자에게는 이 분야의 주요 동향을 정리한 뉴스레터를 매월 보내드립니다.

- 프로젝트 발표 및 승인 동향

- 투자 및 자금 조달

- 사업 협력/합작투자/사업 제휴

- 수소 정책

- 전해질 제조 동향

인도 OEM 전해조 데이터베이스 : 애널리스트의 통찰력

2024년 10월 현재, "OEM Electrolyzer Projects Database 2024"에는 인도에서 약 41개의 수소 전해조 프로젝트가 기록되어 있습니다. 이 프로젝트들은 아직은 미미한 수준이지만, 미래가 유망한 상태입니다:

- 가동 중인 프로젝트 : 이 중 약 15%의 설비가 가동 중이며, 상업용 및 산업용으로 수소를 생산하여 벤치마킹 대상이 되고 있습니다.

- 신규 발표 : 2024년에만 11개의 신규 프로젝트가 발표되었으며, 그 용량은 총 6,600MW가 넘습니다. 이 프로젝트의 급증은 이 분야의 개발 및 투자 속도가 빨라지고 있음을 보여줍니다.

이 프로젝트의 주요 참여자로는 Sterling and Wilson Private Limited, Tecnicas Reunidas, S.A., HET Hydrogen(Horizon Fuel Cell Technologies의 자회사), Avaada Group 등이 있으며, 각각 2024년에 2개의 중요한 프로젝트를 발표하였습니다. 이들 전해조에서 생산되는 수소의 약 55%는 에너지 분야용이며, 36%는 산업용입니다.

인도 수소 전해조 시장의 기술 분포는 현재 알칼리 기술이 선두를 달리고 있으며, 프로젝트의 32%를 차지하고 있습니다. 양성자 교환막(PEM) 기술이 24.4%로 근소한 차이로 뒤를 이었고, 고체 산화물 전해조 셀(SOEC) 기술은 아직 초기 단계에 있지만 시장의 7.3%를 차지합니다.

"Hydrogen Electrolyzer Market Report 2024-2033"는 다음과 같은 내용을 담고 있습니다.

- 알칼리 전해조 : 2023년 시장 규모는 1,110만 달러로 평가되어쏙, 2024-2033년간 33.3%의 연평균 복합 성장률(CAGR)로 성장할 것으로 예상됩니다.

- PEM 전해조 : 이 분야는 더 높은 수익 성장을 보일 것으로 예상되며, 같은 기간 동안 38.2%의 연평균 복합 성장률(CAGR)로 성장하여 2033년에는 2억 2,490만 달러에 달할 것으로 예상됩니다.

지역 리더 : 구자라트와 카르나타카가 인도 수소 전해조 시장을 독점하고 있으며, 이는 지역의 전략적 우선순위와 에너지 자원의 가용성을 반영

- 구자라트(Gujarat) : 구자라트주는 문서화된 프로젝트의 27%를 차지하고 약 1,500MW에 달하는 설비용량을 보유한 수소 생산의 중요한 거점입니다.

- 카르나타카 주: 인도에서 가장 큰 총 설비용량을 보유하고 있으며, 총 12,500MW 이상의 전해조가 설치되어 있고, 그 중 83%가 PEM 기술을 활용하고 있습니다. 이 중 주목할 만한 것은 Ceres Power와 Shell이 공동 개발한 대규모 SOEC 기술 프로젝트입니다. 이 프로젝트는 2022년에 발표되었으며, Ceres Power에서 1억 달러의 자금을 지원받아 2024년에 건설을 시작하여 2026년까지 가동될 예정입니다.

인도 전체 프로젝트의 전해조 용량은 총 35,000MW를 넘어섰으며, 이는 인도의 수소 생산 확대와 탈탄소화를 적극 추진하겠다는 의지를 보여줍니다.

LSH"Global OEM Electrolyzer Projects Database" is a new subscription offering from Global Insight Services that offers tracking of new hydrogen electrolyzer projects. Subscribers to this service receive access to updates to projects database on a monthly basis.

INFOGRAPHICS

An electrolyzer is a device that uses electricity to drive a non-spontaneous chemical reaction, typically the electrolysis of water into hydrogen and oxygen. In this process, an electric current is passed through water, causing it to decompose into its constituent elements: hydrogen gas (H2) at one electrode and oxygen gas (O2) at the other electrode. Electrolyzers play a key role in the production of hydrogen for various industrial applications, energy storage, and as a clean fuel source for vehicles.

Given the rapidly changing and evolving nature of project landscape, Global OEM Electrolyzer Projects Database is an essential source of market information for participants across the hydrogen value chain.

Covering 300+ manufacturing facilities, this database delivers detailed data on electrolyzer capacity, production volumes, technology, funding details, participants, project status, and timelines for efficient hydrogen project planning and analysis across industries, aiding clients in tracking manufacturing progress from inception to completion for informed decision-making.

- Comprehensive Manufacturer Coverage: Detailed profiles of leading OEMs across regions and technologies

- Performance Metrics: In-depth data on capacity, efficiency, Capex and project costs

- Project Tracking: Data on ongoing and planned Electrolyzer projects globally

- Competitive Benchmarking: Comparisons across OEMs for technology, price, and production capacity

- Technology Advancements: Tracks emerging technologies, such as PEM, Alkaline, and Solid Oxide, to identify trends and innovations

- Geographic Analysis: Regional breakdowns, enabling clients to target specific markets based on hydrogen adoption trends.

- Partnership and Collaboration Data: Information on strategic alliances and joint ventures between OEMs and other stakeholders.

- Financing and Incentives: Information on government subsidies, incentives, and financing options for Electrolyzer projects.

Database Coverage:

| Projects | 250+ |

| Region | Global |

| Electrolyzer Manufacturers | 100+ |

| Project Information | Project name, Project location, Project category, Project participants, Plant status, Funding provider, Funding value, Project cost, Type of renewable energy, Electrolyzer manufacturer, Technology, Electrolyzer Capacity, Hydrogen Production Capacity, Hydrogen End-Users, Supply Source Asset Capacity, Project Announcement Year, Project Construction Start Year, Project Construction End Year |

| Electrolyzer Technology | Alkaline Water Electrolysis, Proton Exchange Membrane, Solid Oxide Electrolysis Cell, Anion Exchange Membrane, Capillary-fed Electrolysis and Membrane-Free Electrolysis |

| Project Status | Under Construction, Announced, Operational, Planning Phase, Concept, FID, Feasibility Study, DEMO, FEED |

| Hydrogen End-Users | Ammonia, Cement, Chemicals, E-commerce, e-fuels, Electric Vehicles, Energy, Energy Storage, Fertilizer Production, Food Value Chain, Fuel Cells, Heating, Hydrogen Fuelling System, Logistics, Manufacturing, Methanol, Mobility, Refineries, Steel, Synfuels, Telecommunications |

| Key Hydrogen Companies | H2 Energy, orsted, ENGIE, BP, Infinite Green Energy Ltd, Fortescue Future Industries, ScottishPower |

| Key Electrolyzer Manufacturers | Nel ASA, Siemens, McPhy Energy, ITM Power Plc, Gaztransport & Technigaz (Elogen), Green Hydrogen Systems, iGas Energy GmbH, Next Hydrogen, Asahi Kasei, thyssenkrupp, Cummins (Hydrogenics), Toshiba Corporation, Plug Power, John Cockerill, Enagas (H2Greem), Sunfire GmbH, Bloom Energy, Air Liquide, Volkswagen AG (H-TEC SYSTEMS), Enapter AG |

Monthly Newsletter

Subscribers to the service also receive a monthly newsletter summarizing key developments in the sector by:

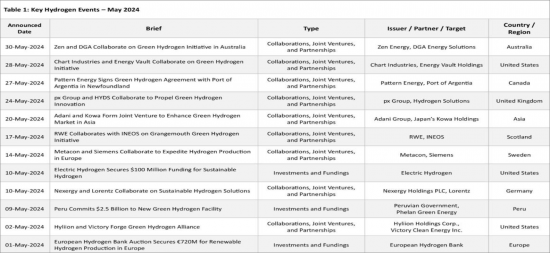

- Project Announcements & Approvals

- Investments and Fundings

- Collaborations, Joint Ventures, and Partnerships

- Hydrogen Policy

- Electrolyzer Manufacturing

Analyst Insights on India OEM Electrolyzers Database

As of October 2024, the "OEM Electrolyzer Projects Database 2024" records around 41 hydrogen electrolyzer projects in India. The status of these projects is a mixed but promising landscape:

- Operational Projects: Approximately 15% of these facilities are active, producing hydrogen and setting the benchmark for commercial and industrial applications.

- New Announcements: In 2024 alone, 11 new projects were announced, collectively exceeding a capacity of 6,600 MW. This influx of projects highlights the accelerated pace of development and investment in the sector.

Major participants in these projects include Sterling and Wilson Private Limited, Tecnicas Reunidas, S.A., HET Hydrogen (a subsidiary of Horizon Fuel Cell Technologies), and the Avaada Group, each of which has announced two significant projects in 2024. Approximately 55% of the hydrogen produced from these electrolyzers is dedicated to energy sector applications, while 36% is earmarked for industrial use, emphasizing the diverse potential of hydrogen across different sectors.

The technological distribution in India's hydrogen electrolyzer market is currently led by Alkaline technology, which accounts for 32% of projects. Proton Exchange Membrane (PEM) technology follows closely at 24.4%, and Solid Oxide Electrolyzer Cell (SOEC) technology, while still in its nascent stage, makes up 7.3% of the market.

The "Hydrogen Electrolyzer Market Report 2024-2033" reveals that:

- Alkaline Electrolyzers: Valued at $11.1 million in 2023, this segment is expected to grow at a CAGR of 33.3% from 2024 to 2033.

- PEM Electrolyzers: With a higher revenue growth potential, this segment is forecasted to grow at a CAGR of 38.2% over the same period, reaching $224.9 million by 2033.

Regional Leaders: The states of Gujarat and Karnataka dominate India's hydrogen electrolyzer landscape, reflecting regional strategic priorities and energy resource availability:

- Gujarat: With 27% of documented projects, Gujarat is a critical hub for hydrogen production, supported by an installed capacity of approximately 1,500 MW.

- Karnataka: This state leads in total capacity, with over 12,500 MW of electrolyzers, 83% of which are based on PEM technology. Notable among these is a significant SOEC technology project, jointly developed by Ceres Power and Shell. Announced in 2022 and supported with $100 million in funding from Ceres Power, construction commenced in 2024, with operations expected by 2026.

The combined electrolyzer capacity from all projects in India exceeds 35,000 MW, a testament to the country's aggressive push to scale hydrogen production and support decarbonization.

(주말 및 공휴일 제외)