|

시장보고서

상품코드

1709976

항공우주 및 툴링 시장(2025-2035년)Global Aerospace and tooling Market 2025-2035 |

||||||

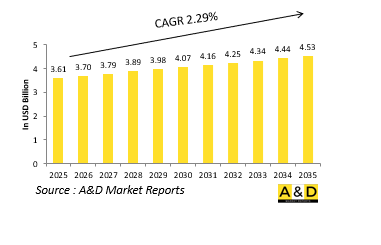

세계 항공우주 및 툴링 시장 규모는 2025년에 36억 1,000만 달러, 2035년에는 45억 3,000만 달러로 성장할 것으로 예상되며, 2025년부터 2035년까지 예측 기간 동안 연평균 성장률(CAGR)은 2.29%를 나타낼 것으로 예상됩니다.

항공우주 및 툴링 시장 소개:

세계 국방 항공우주 및 툴링 시장은 정교한 군용기 및 관련 시스템을 생산, 조립, 유지보수하기 위한 중요한 기반입니다. 여기서 말하는 툴링은 기체, 엔진, 탑재시스템의 수명주기 동안 사용되는 정밀기기, 지그, 금형, 금형, 맞춤형 장비 등 광범위한 것을 포괄합니다. 스텔스 기술, 고성능 소재, 디지털 통합 시스템으로 국방 항공우주 분야가 발전함에 따라 툴링 공정의 복잡성도 그에 따라 확대되고 있습니다. 이러한 툴링은 제조 시 치수 정확도, 구조적 무결성, 반복성을 보장하며, 이는 모두 엄격한 군사 표준을 충족하는 데 필수적인 요소입니다. 5세대 전투기, 대형 수송기, 무인 항공기 시스템을 조립할 때 맞춤형 툴링 솔루션은 필수적입니다. 또한, 툴링은 새로운 항공전자 및 미션 시스템을 탑재한 플랫폼의 신속한 개조를 가능하게 하는 개조 및 오버홀에도 중요한 역할을 합니다. 방위 항공 프로그램은 종종 수십 년에 걸쳐 진행되기 때문에 내구성, 적응성, 확장성이 뛰어난 툴링의 필요성은 장기적인 전략적 우선순위가 되고 있습니다. 이 시장은 주요 항공기 제조업체뿐만 아니라 공급업체와 유지보수 제공업체의 복잡한 네트워크의 관점에서 운영되고 있으며, 광범위한 방위 산업 기반에서 중요하고 상호 연결된 부문입니다.

항공우주 및 툴링 시장에서 기술의 영향:

기술은 생산과 유지보수 작업 모두에서 더 높은 정확성, 유연성 및 효율성을 가능하게 함으로써 항공우주 및 툴링 시장을 변화시키고 있습니다. 컴퓨터 지원 설계 및 컴퓨터 지원 제조와 같은 첨단 디지털 제조 도구는 복잡한 형상의 개발 및 부품 공차 최적화를 간소화합니다. 적층 가공(3D 프린팅)는 경량 맞춤형 금형과 일부 구조 부품의 제조에 사용되어 리드 타임과 재료 낭비를 줄이고 있습니다. 로봇 공학 및 자동 가이드 시스템은 특히 드릴링, 체결 및 표면 처리와 같은 반복적인 작업에서 금형 워크플로우에 점점 더 통합되어 일관성과 작업자 안전을 향상시키고 있습니다. 센서가 장착된 공구와 실시간 피드백 시스템을 통해 보다 스마트한 품질 관리가 가능해져 공정 초기에 편차를 감지하고 재작업을 최소화할 수 있습니다. 가상현실과 증강현실의 적용은 공구 정렬과 기술자 교육에 영향을 미치기 시작하여 조립 및 검사 절차의 정확성을 높이고 있습니다. 툴링 데이터베이스는 디지털화되어 보다 광범위한 항공우주 플랫폼에 연결되고 있으며, 전 세계 운영에서 추적성 및 구성 관리가 더욱 효과적으로 이루어지고 있습니다. 이러한 기술 개발은 납기를 단축하고, 플랫폼의 즉각적인 대응력을 높이고, 점점 더 복잡해지는 항공기 시스템을 최소의 오류와 최대의 일관성으로 지원한다는 국방 분야의 광범위한 목표에 부합합니다.

항공우주 및 툴링 시장의 주요 촉진요인:

몇 가지 강력한 트렌드가 국방 항공우주 및 툴링 시장의 지속적인 성장에 박차를 가하고 있습니다. 주요 요인 중 하나는 최신 군용 항공기 및 무인 시스템에 대한 세계 수요 증가로, 이러한 시스템은 개발 초기부터 유지보수까지 고도의 툴링이 필요합니다. 각국이 공권력과 다중 도메인 작전을 추구함에 따라 항공기 시스템이 엄격한 성능과 내구성 요건을 충족시키기 위해서는 금형이 필수적입니다. 또한, 수명주기 유지 및 수명 중반의 업그레이드, 특히 오래된 플랫폼을 디지털 항공전자 및 새로운 구조 부품으로 현대화할 때 툴링에 대한 투자를 촉진합니다. 또한, 신속한 프로토타이핑과 빠른 개발 주기의 중요성이 강조됨에 따라 설계 요구사항의 변화에 대응할 수 있는 민첩하고 재구성 가능한 툴링이 요구되고 있습니다. 세계 공급망 전략도 조달 의사결정에 영향을 미치고 있으며, 방산업체들은 취약한 무역 경로에 대한 의존도를 줄이기 위해 보다 현지화되고 탄력적인 툴링 지원을 요구하고 있습니다. 지속가능성이 새로운 고려사항으로 떠오르고 있으며, 친환경 소재와 에너지 효율이 높은 제조 방식이 지지를 받고 있습니다. 특히, 국가 안보의 요구로 인해 금형 시스템은 생산 라인이든 현장 수리가든, 금형 시스템은 압력 하에서 최대의 신뢰성과 반복성을 제공해야 합니다. 이러한 배경은 국방 항공우주 역량을 대규모로 신속하게 지원하는 데 있어 툴링이 전략적으로 중요하다는 것을 뒷받침합니다.

항공우주 및 툴링 시장의 지역 동향 :

세계 국방 항공우주 및 툴링 시장은 국방 우선순위, 산업 역량, 첨단 제조에 대한 투자로 인해 뚜렷한 지역적 역학이 형성되고 있습니다. 북미, 특히 미국은 방대한 항공기 생산 프로그램과 성숙한 방산 제조 생태계로 인해 강력한 선두를 유지하고 있습니다. 이 지역은 군사 계약자, 공구 전문가, 연구 기관 간의 깊은 통합이 특징이며, 지속적인 기술 혁신을 촉진하고 있습니다. 유럽에서는 국방 관련 공동 이니셔티브가 동맹국 간의 금형 시스템 표준화를 촉진하고 있으며, 특히 항공기 공동 개발 및 유지보수 프로그램을 지원하고 있습니다. 독일, 프랑스, 영국과 같은 국가들은 자국 플랫폼과 대서양 횡단 프로젝트를 지원하기 위해 고정밀 툴링 인프라에 투자하고 있습니다. 아시아태평양은 빠르게 부상하고 있으며, 인도, 한국, 일본과 같은 국가들이 자국 항공우주 역량에 중점을 두고 있습니다. 이들 국가는 자국 전투기를 생산할 뿐만 아니라 외국 공급망에 대한 의존도를 낮추기 위해 금형 제조 시설을 설립하고 있습니다. 중동에서는 산업화 노력이 국방 오프셋과 결합되어 국내 생산과 현지화된 금형 능력을 장려하고 있습니다. 라틴아메리카와 아프리카의 일부 지역에서는 이 분야의 개발이 늦었지만, 공동 제조 허브에 관심을 보이고 있습니다. 각 지역은 금형 개발에서 혁신, 역량 구축 및 전략적 자율성의 독특한 균형을 반영합니다.

주요 항공우주 및 공구 프로그램:

DARPA와의 연구개발 계약에 따라 보잉과 록히드마틴은 각각 차세대 항공 우세(NGAD) 플랫폼의 위험 감소 노력을 지원하기 위해 X-플레인을 개발했습니다. 이 실험용 비행기는 각각 2019년과 2022년에 첫 비행을 완료했으며, 이후 각각 수백 시간의 비행 시간을 축적했습니다.

세계의 항공우주 및 툴링 시장에 대해 조사했으며, 향후 10년간의 분야별 시장 예측, 기술 동향, 기회 분석, 기업 프로파일, 국가별 데이터 등의 정보를 정리하여 전해드립니다.

목차

세계의 항공우주 및 툴링 시장-목차

세계의 항공우주 및 툴링 시장 보고서 정의

세계의 항공우주 및 툴링 시장 세분화

- 소재별

- 제조 공정별

- 용도별

- 지역별

향후 10년간 세계의 항공우주 및 툴링 시장 분석

이 장에서는 10년간 세계의 항공우주 및 툴링 시장 분석에 의해 세계 항공우주 및 툴링 시장 성장, 변화하는 동향, 기술 채택 개요 및 전체적인 시장의 매력 상세한 개요가 제공됩니다.

세계의 항공우주 및 툴링 시장 시장 기술

이 부문에서는 이 시장에 영향을 미치는으로 예상되는 상위 10기술과 이러한 기술이 시장 전체에 미칠 가능성이 있는 영향에 대해 설명합니다.

세계의 항공우주 및 툴링 시장 예측

이 시장 10년간 세계의 항공우주 및 툴링 시장 예측은 상기 부문 전체로 상세하게 설명되고 있습니다.

세계의 항공우주 및 툴링 시장 지역 동향과 예측

이 부문에서는 지역별 대 드론 시장 동향, 촉진요인, 억제요인, 과제, 그리고 정치, 경제, 사회, 기술이라고 하는 측면을 망라하고 있습니다. 또한 지역별 시장 예측과 시나리오 분석도 상세하게 채택하고 있습니다.지역 분석 마지막에는 주요 기업 프로파일링, 공급업체 상황, 기업 벤치마킹가 포함되어 있습니다.현재 시장 규모는 통상 시나리오에 근거하고 추정되고 있습니다.

- 북미

- 성장 촉진요인, 억제요인, 과제

- PEST

시장 예측과 시나리오 분석

- 주요 기업

- 공급업체 계층 상황

- 기업 벤치마킹

- 유럽

- 중동

- 아시아태평양

- 남미

세계의 항공우주 및 툴링 시장 국가별 분석

이 장에서는 이 시장 주요 방위 프로그램을 채택해 이 시장에서 신청된 최신 뉴스나 특허에 대해도 해설합니다. 또한 국가 레벨 10년간 시장 예측과 시나리오 분석에 대해도 해설합니다.

- 미국

- 방위 프로그램

- 최신 뉴스

- 특허

- 이 시장의 현재 기술 성숙도

시장 예측과 시나리오 분석

캐나다

이탈리아

프랑스

독일

네덜란드

벨기에

스페인

스웨덴

그리스

호주

남아프리카공화국

인도

중국

러시아

한국

일본

말레이시아

싱가포르

브라질

세계의 항공우주 및 툴링 시장 기회 매트릭스

세계의 항공우주 및 툴링 시장 보고서에 관한 전문가 의견

결론

항공 및 방위 시장 보고서에 대해

LSH 25.05.07The Global Aerospace and Tooling Market is estimated at USD 3.61 billion in 2025, projected to grow to USD 4.53 billion by 2035 at a Compound Annual Growth Rate (CAGR) of 2.29% over the forecast period 2025-2035.

Introduction to Aerospace and Tooling Market:

The global defense aerospace and tooling market represents a critical foundation for producing, assembling, and maintaining sophisticated military aircraft and related systems. Tooling in this context encompasses an extensive array of precision equipment, jigs, fixtures, molds, and custom-built instruments used throughout the lifecycle of airframes, engines, and onboard systems. As the defense aerospace sector advances, driven by stealth technology, high-performance materials, and digitally integrated systems, the complexity of tooling processes has expanded accordingly. These tools ensure dimensional accuracy, structural integrity, and repeatability in manufacturing, all of which are essential to meet strict military standards. Whether it's the assembly of fifth-generation fighter jets, heavy-lift transport aircraft, or unmanned aerial systems, customized tooling solutions are indispensable. Additionally, tooling plays a key role in modifications and overhauls, enabling rapid retrofitting of platforms with new avionics or mission systems. With defense aviation programs often spanning decades, the need for durable, adaptive, and scalable tooling has become a long-term strategic priority. This market operates not only at the level of major airframe manufacturers but also within a complex web of suppliers and maintenance providers, making it a vital and interconnected segment of the broader defense industrial base.

Technology Impact in Aerospace and Tooling Market:

Technology is transforming the defense aerospace and tooling market by enabling higher precision, flexibility, and efficiency in both production and maintenance operations. Advanced digital manufacturing tools, such as computer-aided design and computer-aided manufacturing, have streamlined the development of complex geometries and optimized part tolerances. Additive manufacturing, or 3D printing, is now being used to produce lightweight, custom tooling and even some structural components, reducing lead times and material waste. Robotics and automated guided systems are increasingly being integrated into tooling workflows, especially in repetitive tasks like drilling, fastening, and surface treatment, improving consistency and worker safety. Sensor-equipped tools and real-time feedback systems allow for smarter quality control, detecting deviations early in the process and minimizing rework. Virtual reality and augmented reality applications are beginning to influence tool alignment and technician training, enhancing accuracy during assembly and inspection procedures. Tooling databases are being digitized and connected to broader aerospace platforms, making traceability and configuration management more effective across global operations. These technological developments are aligning with broader goals in defense: faster delivery schedules, enhanced platform readiness, and the ability to support increasingly complex aircraft systems with minimal error and maximum consistency.

Key Drivers in Aerospace and Tooling Market:

Several powerful trends are fueling sustained growth in the defense aerospace and tooling market. One major factor is the increased global demand for modern military aircraft and unmanned systems, which require sophisticated tooling from the outset of development through to sustainment. As nations pursue air dominance and multi-domain operations, tooling becomes essential to ensure that aircraft systems meet stringent performance and durability requirements. Lifecycle sustainment and mid-life upgrades also drive tooling investments, especially when older platforms are being modernized with digital avionics or new structural components. Additionally, the growing emphasis on rapid prototyping and short-turnaround development cycles demands agile and reconfigurable tooling that can keep up with shifting design requirements. Global supply chain strategies are also influencing procurement decisions, as defense manufacturers seek more localized and resilient tooling support to reduce dependency on vulnerable trade routes. Sustainability is emerging as a new consideration, with eco-friendly materials and energy-efficient manufacturing practices gaining traction. Above all, national security imperatives require that tooling systems deliver maximum reliability and repeatability under pressure, whether on the production line or during in-field repairs. These drivers collectively underscore tooling's strategic importance in supporting defense aerospace capabilities at scale and speed.

Regional Trends in Aerospace and Tooling Market:

The global defense aerospace and tooling market exhibits distinct regional dynamics shaped by national defense priorities, industrial capacity, and investment in advanced manufacturing. North America, particularly the United States, maintains a strong lead due to its expansive aircraft production programs and mature defense manufacturing ecosystem. The region is marked by deep integration between military contractors, tooling specialists, and research institutions, fostering continuous innovation. In Europe, collaborative defense initiatives are prompting standardization of tooling systems across allied nations, especially in support of joint aircraft development and maintenance programs. Countries like Germany, France, and the UK are investing in high-precision tooling infrastructure to support both indigenous platforms and transatlantic projects. Asia-Pacific is emerging rapidly, with countries such as India, South Korea, and Japan focusing on indigenous aerospace capabilities. These nations are not only producing their own combat aircraft but are also establishing tooling facilities to reduce reliance on foreign supply chains. In the Middle East, industrialization efforts are being tied to defense offsets, encouraging domestic production and localized tooling capabilities. Latin America and parts of Africa are slower to develop in this sector but are showing interest in collaborative manufacturing hubs. Each region reflects a unique balance of innovation, capability-building, and strategic autonomy in tooling development.

Key Aerospace and Tooling Program:

Under research and development contracts with DARPA, Boeing and Lockheed Martin each developed an X-plane to support risk reduction efforts for the Next Generation Air Dominance (NGAD) platform. These experimental aircraft completed their first flights in 2019 and 2022, respectively, and have since accumulated several hundred flight hours each.

Table of Contents

Global Aerospace and tooling market - Table of Contents

Global Aerospace and tooling market Report Definition

Global Aerospace and tooling market Segmentation

By Material

By Manufacturing Process

By Application

By Region

Global Aerospace and tooling market Analysis for next 10 Years

The 10-year Global Aerospace and tooling market analysis would give a detailed overview of Global Aerospace and tooling market growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Global Aerospace and tooling market

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global Aerospace and tooling market Forecast

The 10-year Global Aerospace and tooling market forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Global Aerospace and tooling market Trends & Forecast

The regional counter drone market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Global Aerospace and tooling market

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Global Aerospace and tooling market

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Global Aerospace and tooling market Report

Hear from our experts their opinion of the possible analysis for this market.