|

시장보고서

상품코드

1714100

기어박스 및 회전기구 시험 시장(2025-2035년)Global Gearbox and rotary testing Market 2025-2035 |

||||||

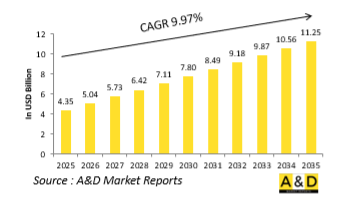

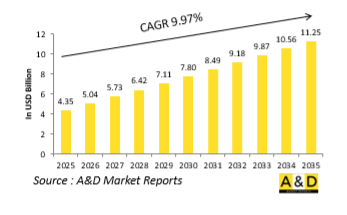

세계의 기어박스 및 회전기구 시험 시장 규모는 2025년 43억 5,000만 달러에서 예측 기간 중 9.97%의 CAGR로 추이하며, 2035년에는 112억 5,000만 달러로 성장할 것으로 예측됩니다.

기어박스 및 회전기구 테스트 시장 : 소개

기어박스 및 회전기구 시험은 군용 항공기, 함정, 육상 차량의 동력 전달 시스템 평가에 있으며, 매우 중요한 분야입니다. 국방 분야에서 기어박스 및 회전 메커니즘은 헬리콥터와 같은 회전익 항공기, 틸트로터, 무인항공시스템(UAS), 함정 추진 시스템, 장갑차 및 기타 미션 크리티컬한 플랫폼에서 필수적인 구성 요소입니다. 이러한 구성 요소는 기계적 에너지를 변환하고 제어하여 극한의 작동 조건에서 각 하위 시스템에 공급합니다. 높은 토크, 빠른 회전, 가혹한 열 환경에 노출되므로 미션 실패를 방지하고 장기적인 운영 신뢰성을 보장하기 위해 이러한 시스템에 대한 엄격한 테스트가 필수적입니다. 군용 기어박스는 특히 전투 행동이나 급격한 기동 중에 심한 진동, 충격, 고주파 하중 변동에도 안정적으로 작동해야 합니다. 회전 메커니즘의 테스트는 베어링(베어링), 샤프트, 커플링 시스템 등을 대상으로하며 내구성, 소음 수준, 기어 마모, 윤활유 흐름, 열 거동, 시스템의 공진 거동(고조파)에 중점을 둡니다. 현대의 국방 시스템이 고효율, 저소음으로 진화하는 가운데, 회전 메커니즘의 고정밀 시험은 더 이상 부차적인 과제가 아니라 임무 성공의 핵심 요소로 자리 잡고 있습니다. 이러한 시험은 기어박스의 기계적 내구성뿐만 아니라 현대의 비행 및 기동 제어 시스템과의 통합성을 검증하는 역할을 하며, 방위 플랫폼의 개발에서 유지 및 운용에 이르는 전체 수명주기에서 필수적인 역할을 합니다.

기어박스 및 회전기구 시험 시장 : 기술의 영향력

최근 수년간의 기술 혁신으로 인해 방위 산업에서 기어박스 및 회전 메커니즘의 테스트 방법이 크게 변화하여 보다 예측적이고, 데이터베이스적이며, 효율적인 평가 방법을 실현하고 있습니다. 특히 주목할 만한 발전 중 하나는 자동화된 폐쇄 루프 테스트 벤치의 도입입니다. 이를 통해 토크 변동, 엔진 출력 사이클, 환경적 스트레스와 같은 복잡한 부하 조건을 실시간으로 충실하게 재현할 수 있게 되었습니다. 이러한 시스템에서는 서보 유압 액추에이터를 사용하여 비행 및 운용시 스트레스를 시뮬레이션하고, 동적 동력 입출력 조건을 장시간에 걸쳐 재현할 수 있습니다. 또한 고정밀 토크 센서, 음향 방사 모니터, 오일 파편(이물질) 센서와 같은 첨단 센서의 도입으로 실시간 상태 모니터링 및 부품 수준의 마모 감지가 가능해졌습니다. 열화상 및 적외선 센서도 이제 표준 장비가 되어 마찰로 인한 열 발생과 윤활 효과를 평가하는 데 도움이 되고 있습니다. 또 다른 큰 발전은 전산 모델링과 디지털 트윈 기술의 적용입니다. 이를 통해 기어의 치면에 가해지는 응력, 진동 특성, 공진 거동 등을 물리 시험 전에 가상으로 시뮬레이션할 수 있게 되어, 실제 시험 데이터와 연계하여 설계 검증 및 개선이 매우 효율적으로 이루어집니다. 또한 AI와 머신러닝 알고리즘이 시험 장비에서 얻은 방대한 센서 데이터 분석에 활용되어 기어 마모, 소음 발생, 윤활유 열화 등의 미세한 패턴을 파악할 수 있게 되었습니다. 이는 기어박스의 고장 모드를 예측하는 데 매우 중요합니다. 또한 모듈식 테스트 플랫폼은 다양한 기어 구성을 위한 퀵 체인지 인터페이스를 제공하여 다양한 차량 및 항공기 등급에서 테스트의 유연성과 처리 시간을 단축하는 데 기여하고 있습니다.

기어박스 및 회전기구 시험 시장 : 주요 촉진요인

현대 국방 플랫폼의 복잡성 증가와 고성능에 대한 요구는 보다 진보된 기어박스 및 회전 메커니즘에 대한 시험을 필요로 하는 요인으로 작용하고 있습니다. 가장 중요한 원동력 중 하나는 회전익 및 틸트로터 항공기의 전술적 및 병참적 역할에 대한 활용이 증가하고 있다는 점입니다. 예를 들어 V-22 오스프리나 차세대 수직 이착륙 프로그램과 같은 플랫폼은 매우 높은 기계적 부하를 견디고 엄격한 중량 및 크기 제약을 충족하는 고성능 기어박스에 크게 의존하고 있습니다. 이러한 기어박스의 경우, 이중화, 고장 허용성 및 장시간 작동 신뢰성에 대한 테스트가 전략적으로 필수적입니다. 또 다른 중요한 요소는 하이브리드 전기 추진 및 분산 추진 시스템으로의 전환입니다. 이로 인해 기존과 다른 기계 구성과 비기존형 기어박스 설계가 도입되고 있으며, 복잡하고 비선형적인 하중 조건에서 검증이 필요하므로 첨단 회전 시험이 필수적입니다. 또한 스텔스성 및 저소음이 강조되는 플랫폼에서는 고조파 노이즈 및 진동 발생원을 식별하고 제거하기 위해 정밀한 회전 테스트가 요구됩니다. 최근에는 수명 연장과 유지보수성 향상이 국방 계획의 주요 과제로 떠오르고 있습니다. 군 예산이 수명주기 비용의 효율성을 중시하는 가운데, 기어박스 시스템은 마모 패턴 예측, 유지보수 간격 및 재정비 필요성을 평가하기 위해 철저한 테스트를 거쳐야 합니다. 또한 노후화된 기체 및 함대를 유지하기 위해서는 교체 부품 및 개조 구성을 검증하기 위한 지속적인 테스트가 필수적입니다. 또한 전장에서의 자동화 및 무인화 시스템 증가로 인해 소형 및 고출력 기어박스에 대한 수요가 증가하고 있으며, 이에 대한 소형화 및 열 관리에 특화된 전용 시험 체계가 필요합니다.

세계의 기어박스 및 회전기구 시험 시장을 조사했으며, 시장의 현황, 기술 동향, 시장 영향요인의 분석, 시장 규모 추이·예측, 지역별 상세 분석, 경쟁 구도, 주요 기업의 개요 등을 정리하여 전해드립니다.

목차

세계의 방위 부문용 기어박스 및 회전기구 시험 : 목차

세계의 방위 부문용 기어박스 및 회전기구 시험 : 리포트의 정의

세계의 방위 부문용 기어박스 및 회전기구 시험

지역별

유형별

용도별

컴포넌트별

향후 10년간의 세계 방위 부문용 기어박스 및 회전기구 시험의 분석

세계의 방위 부문용 기어박스 및 회전기구 시험 시장 : 기술

세계의 방위 부문용 기어박스 및 회전기구 시험 시장 : 예측

방위 동향과 예측

북미

촉진요인, 제약, 과제

억제요인

시장 예측·시나리오 분석

주요 기업

공급업체 Tier의 상황

기업 벤치마킹

유럽

중동

아시아태평양

남미

세계의 방위 부문용 기어박스 및 회전기구 시험 : 국가별 분석

미국

방위 프로그램

최신 뉴스

특허

현재 기술 성숙도

시장 예측·시나리오 분석

캐나다

이탈리아

프랑스

독일

네덜란드

벨기에

스페인

스웨덴

그리스

호주

남아프리카공화국

인도

중국

러시아

한국

일본

말레이시아

싱가포르

브라질

세계의 방위 부문용 기어박스 및 회전기구 시험 : 기회 매트릭스

세계의 방위 부문용 기어박스 및 회전기구 시험 : 전문가의 의견

결론

항공·방위 시장 보고서 소개

KSA 25.05.16The Global Gearbox and rotary testing market is estimated at USD 4.35 billion in 2025, projected to grow to USD 11.25 billion by 2035 at a Compound Annual Growth Rate (CAGR) of 9.97% over the forecast period 2025-2035.

Introduction to Gearbox and rotary testing Market:

Gearbox and rotary system testing occupy a critical niche in the evaluation of power transmission systems within military aircraft, naval vessels, and land vehicles. In the defense context, gearboxes and rotary mechanisms are integral to rotorcraft (such as helicopters), tiltrotors, unmanned aerial systems (UAS), naval propulsion systems, armored vehicles, and other mission-critical platforms. These components are responsible for converting and managing mechanical power across subsystems under extreme operational conditions. Given the high torque loads, rotational speeds, and thermal stresses involved, rigorous testing of these systems is imperative to prevent mission failure and ensure long-term operational reliability. Military gearboxes must function under intense vibration, shock, and high-frequency load variations, particularly during combat operations or rapid maneuvers. Rotary testing also encompasses bearings, shafts, and coupling systems, with emphasis on durability, noise levels, gear wear, oil flow, thermal behavior, and system harmonics. As defense systems evolve toward higher efficiency and reduced acoustic signatures, precision in rotary testing is no longer a secondary consideration-it is a cornerstone of mission assurance. These tests validate not only the mechanical endurance of gearboxes but also their integration with modern flight and mobility control systems, making them essential throughout the development and sustainment lifecycle of defense platforms.

Technology Impact in Gearbox and rotary testing Market:

Recent technological advancements have transformed the landscape of gearbox and rotary testing in defense, leading to more predictive, data-rich, and efficient evaluation methodologies. One of the most notable developments is the incorporation of automated, closed-loop test benches that replicate complex load conditions in real time, simulating torque fluctuations, engine power cycles, and environmental stressors with high fidelity. These systems often use servo-hydraulic actuators to mimic flight or operational stresses and are capable of replicating dynamic power input/output conditions for extended durations. The advent of advanced sensors, including high-precision torque sensors, acoustic emission monitors, and oil-debris sensors, has enabled real-time health monitoring and wear detection down to the component level. Thermal imaging and infrared sensors are now standard in rotary testing setups, helping engineers assess frictional heating and lubrication efficacy. Another significant leap is the application of computational modeling and digital twin technology, which allows engineers to simulate gear tooth stress, vibration signatures, and resonance behavior before physical testing even begins. When combined with real test data, digital twins offer a powerful tool for validation and design iteration. AI and machine learning algorithms are increasingly being used to interpret large volumes of sensor data from test rigs, identifying subtle patterns in gear wear, noise generation, or lubricant degradation-factors critical for predicting gearbox failure modes. Additionally, modular test platforms now offer quick-change interfaces for multi-gear configurations, improving turnaround time and testing flexibility across different vehicle or aircraft classes.

Key Drivers in Gearbox and rotary testing Market:

The growing complexity and performance demands of modern defense platforms are driving the need for more advanced gearbox and rotary testing. One of the foremost drivers is the increased use of rotorcraft and tiltrotor aircraft in both tactical and logistical military roles. These platforms, such as the V-22 Osprey or next-gen vertical lift programs, rely heavily on robust, high-performance gearboxes that must endure extreme mechanical stress while meeting strict weight and size constraints. Testing these gearboxes for redundancy, fault tolerance, and long-duration reliability is a strategic imperative. Another key driver is the shift toward hybrid-electric and distributed propulsion systems, which introduce novel mechanical layouts and non-traditional gearbox designs. These configurations require validation under complex, non-linear load scenarios, making advanced rotary testing essential. The growing emphasis on stealth and low acoustic signature platforms also demands refined rotary testing to identify and eliminate sources of harmonic noise and vibration. Additionally, longevity and maintainability goals have come to the forefront in defense planning. As military budgets prioritize lifecycle cost efficiency, gearbox systems must be thoroughly tested to predict wear patterns, maintenance intervals, and refurbishment needs. Sustainment of aging fleets-including helicopters and naval vessels that rely on legacy gear systems-further necessitates ongoing testing to validate replacement parts and retrofit configurations. Moreover, increasing automation and unmanned systems in the battlefield push the boundaries of miniature yet powerful gearboxes, necessitating dedicated testing regimes focused on miniaturization and thermal management.

Regional Trends in Gearbox and rotary testing Market:

The regional dynamics in gearbox and rotary testing reflect national defense priorities, industrial base capabilities, and technological investment levels. In North America, particularly in the United States, gearbox testing facilities support cutting-edge military rotorcraft and tiltrotor programs such as the Future Long-Range Assault Aircraft (FLRAA) and Future Attack Reconnaissance Aircraft (FARA). These programs demand high-speed endurance testing, dynamic load replication, and fault-tolerant diagnostics. Major defense contractors and research institutions collaborate closely with the Department of Defense to develop modular and digital testing frameworks that align with advanced aircraft timelines. In Europe, leading aerospace nations like France, Germany, and the UK conduct robust gearbox testing as part of next-generation combat air and naval platforms, including the Tempest and FCAS programs. European test centers often emphasize environmentally responsible lubricant performance, low-noise operation, and standardization for multinational fleet interoperability. Italy and Spain are strengthening their industrial testing capabilities to support increased involvement in NATO-aligned rotorcraft and shipborne systems.

In Asia-Pacific, China is rapidly building indigenous test facilities for high-load gear systems used in helicopters, UAVs, and heavy-lift aircraft. These facilities focus on long-term fatigue resistance and resilience to environmental extremes, particularly for gearboxes used in mountainous or maritime terrains. India, through HAL and DRDO, is expanding its test infrastructure for rotary components supporting aircraft such as the Light Combat Helicopter (LCH) and the Indian Multi Role Helicopter (IMRH). Meanwhile, South Korea and Japan are investing in advanced gearbox testing for stealth aircraft and naval propulsion systems, emphasizing automation, local production, and compact high-efficiency gear units. In the Middle East, countries like the UAE and Saudi Arabia are nurturing indigenous test capabilities as part of broader defense industrialization efforts. These countries often partner with Western OEMs to co-develop test protocols and support region-specific platforms. In South America, defense initiatives are largely focused on localized helicopter production and maintenance, leading to emerging demand for regional rotary test facilities, particularly in Brazil. Africa, while still developing its aerospace infrastructure, sees limited gearbox testing activities, often reliant on external validation through international defense collaborations. Across all regions, the trend is toward smarter, connected, and simulation-supported test environments that ensure the mechanical backbone of defense mobility platforms remains fail-safe and future-ready.

Key Gearbox and rotary testing Program:

Lockheed Martin Corporation's Sikorsky Aircraft division has been awarded an $84.3 million contract to deliver eight gearbox assemblies for the CH-53K helicopters. The work will be conducted in Stratford, Connecticut, with completion expected by December 2028. The contract supports both the U.S. Navy and the Israeli military and was issued by the Naval Supply Systems Command Weapon Systems Support in Philadelphia, Pennsylvania.

Table of Contents

Global Gearbox and rotary testing in defense- Table of Contents

Global Gearbox and rotary testing in defense Report Definition

Global Gearbox and rotary testing in defense Segmentation

By Region

By Type

By Application

By Component

Global Gearbox and rotary testing in defense Analysis for next 10 Years

The 10-year Global Gearbox and rotary testing in defense analysis would give a detailed overview of Global Gearbox and rotary testing in defense growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Global Gearbox and rotary testing in defense

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global Gearbox and rotary testing in defense Forecast

The 10-year Global Gearbox and rotary testing in defense forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Global Gearbox and rotary testing in defense Trends & Forecast

The regional counter drone market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Global Gearbox and rotary testing in defense

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Global Gearbox and rotary testing in defense

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Global Gearbox and rotary testing in defense

Hear from our experts their opinion of the possible analysis for this market.