|

시장보고서

상품코드

1673894

다이캐스트 시장 : 주조 유형별, 재료별, 용도별, 지역별Die Casting Market, By Casting Type, By Material, By Application, By Geography |

||||||

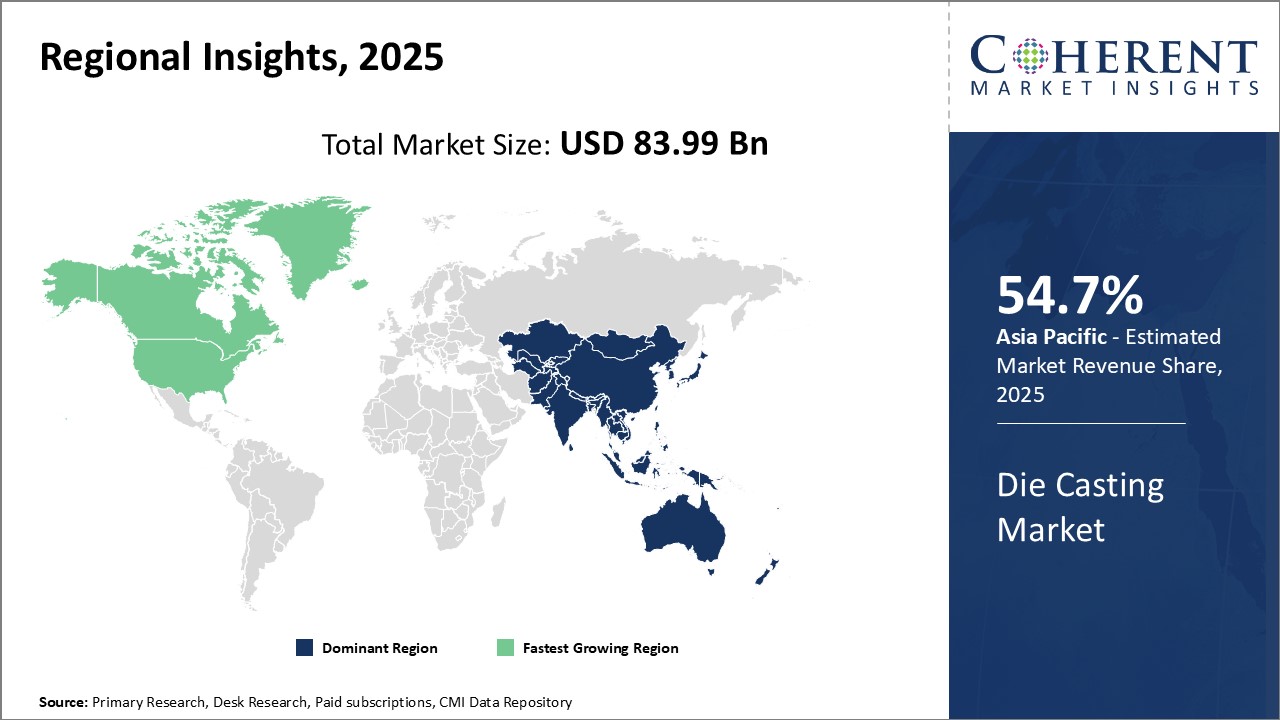

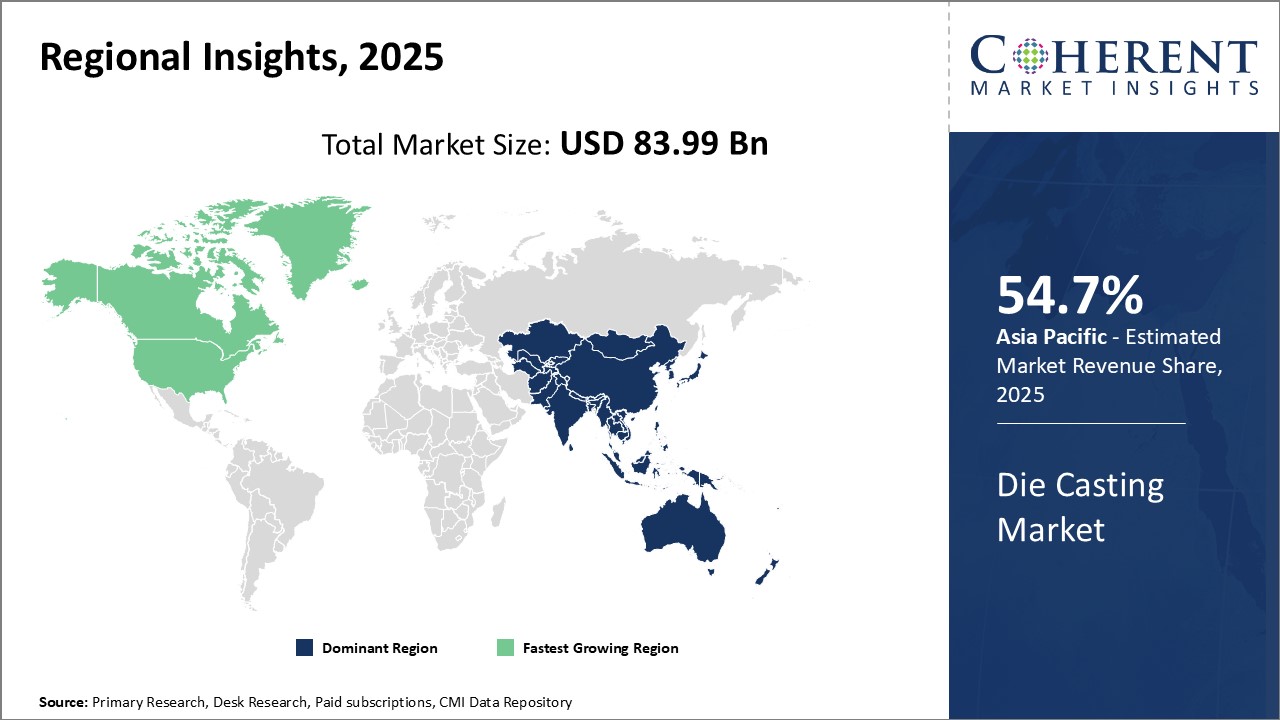

세계의 다이캐스트 시장은 2025년에 839억 9,000만 달러로 추정되며, 2032년에는 1,394억 3,000만 달러에 달할 것으로 예측되며, 2025-2032년 연간 평균 성장률(CAGR)은 7.5%로 성장할 전망입니다.

| 보고 범위 | 보고서 상세 내용 | ||

|---|---|---|---|

| 기준연도 | 2024년 | 2025년 시장 규모 | 839억 9,000만 달러 |

| 실적 데이터 | 2020-2024년 | 예측 기간 | 2025-2032년 |

| 예측 기간 : 2025-2032년 CAGR | 7.50% | 2032년 금액 예측 | 1,394억 3,000만 달러 |

소개

다이캐스팅 시장은 지난 수십년간 꾸준히 성장하며 왔습니다. 다이캐스팅은 용융 금속을 고압으로 금형 캐비티에 밀어 넣어 부품을 제조하는 제조 공정입니다. 다이캐스팅의 주요 장점으로는 높은 생산 속도, 순형상 생산, 치수 정확도 등이 있습니다. 다이캐스팅 부품은 자동차, 전자, 하드웨어 및 기타 산업에서 널리 사용됩니다. 자동차 산업은 경량화 및 순 형상 생산 요구로 인해 다이캐스팅 부품의 주요 수요처입니다. 다이캐스팅 부품에 대한 전반적인 수요는 최종 사용 산업의 성장과 함께 증가할 것으로 예상됩니다. 정밀성, 품질 및 복잡성에 대한 요구가 증가함에 따라 다이캐스팅 공정의 자동화 및 신기술 채택이 촉진될 것입니다.

시장 역학

다이캐스팅 시장은 자동차 생산 증가와 전자 부품의 소형화 수요에 의해 주도되고 있습니다. 새로운 기능 및 신기술을 구현하기 위해 자동차 1대당 부품 수가 증가하고 있는 것이 다이캐스팅 부품의 사용을 촉진하고 있습니다. 그러나 원자재 가격의 변동은 시장 진출기업에게 여전히 중요한 과제입니다. 알루미늄은 널리 사용되는 원자재로 가격 변동은 비용에 큰 영향을 미칠 수 있으며, AI, IoT, 자동화 등 인더스트리 4.0 기술을 채택하여 복잡한 고부가가치 부품의 생산성, 품질 및 예비 능력을 향상시킬 수 있는 기회가 있습니다. 지속가능하고 재활용이 가능한 다이캐스팅 솔루션 또한 새로운 성장 전망을 제시합니다.

본 조사의 주요 특징

세계의 다이캐스팅(Die Casting) 시장을 상세하게 분석하여 2024년을 기준 연도로 하여 예측 기간(2025-2032년) 시장 규모와 연평균 성장률(CAGR%)을 조사 분석하여 전해드립니다.

또한 다양한 부문에 걸친 잠재적인 매출 성장 기회를 밝히고, 이 시장의 매력적인 투자 제안 매트릭스를 설명합니다.

또한 시장 성장 촉진요인, 억제요인, 기회, 신제품 출시 및 승인, 시장 동향, 지역별 전망, 주요 기업의 경쟁 전략 등에 대한 주요 인사이트를 제공합니다.

이 보고서는 기업 하이라이트, 제품 포트폴리오, 주요 하이라이트, 재무 성과, 전략 등의 매개 변수를 기반으로 세계 다이캐스팅 시장의 주요 기업을 프로파일링합니다.

본 조사의 대상이 되는 주요 기업에는 Alcoa Corporation, Bocar Group, Endurance Technologies Limited, Engtek Group, Form Technologies Inc., Georg Fischer Limited, Koch Enterprises, Linamar Corporation, Meridian Lightweight Technologies UK Ltd, Nemak, Rheinmetall AG, Rockman Industries, Ryobi Die Casting Ltd, Sandhar Group, Shiloh Industries, Sundaram Clayton Ltd 등이 있습니다.

이 보고서의 인사이트를 통해 마케팅 담당자와 기업 경영진은 향후 제품 출시, 유형화, 시장 확대, 마케팅 전술에 대한 정보에 입각한 의사결정을 내릴 수 있습니다.

이 보고서는 투자자, 공급업체, 제품 제조업체, 유통업체, 신규 시장 진출기업, 재무 분석가 등 이 산업의 다양한 이해관계자를 대상으로 합니다.

이해관계자들은 세계 다이캐스팅 시장 분석에 사용되는 다양한 전략 매트릭스를 통해 의사결정을 쉽게 내릴 수 있습니다.

목차

제1장 조사의 목적과 전제조건

- 조사 목적

- 전제조건

- 약어

제2장 시장 전망

- 리포트 설명

- 시장의 정의와 범위

- 개요

- COM(Coherent Opportunity Map)(COM)

제3장 시장 역학, 규제, 동향 분석

- 시장 역학

- 촉진요인

- 억제요인

- 시장 기회

- 규제 시나리오

- 산업 동향

- 합병과 인수

- 신시스템 출시/승인

- COVID-19 팬데믹의 영향

제4장 세계의 다이캐스트 시장, 주조 유형별, 2020-2032년

- 서론

- 압력 다이캐스트

- 진공 다이캐스트

- 스퀴즈 다이캐스트

- 기타

제5장 세계의 다이캐스트 시장, 재료별, 2020-2032년

- 서론

- 알루미늄

- 마그네슘

- 아연

제6장 세계의 다이캐스트 시장, 용도별, 2020-2032년

- 서론

- 상용

- 자동차

- 전기·전자

- 산업

- 기타

제7장 세계의 다이캐스트 시장, 지역별, 2020-2032년

- 서론

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

제8장 경쟁 구도

- 기업 개요

- Alcoa Corporation

- Bocar Group

- Endurance Technologies Limited

- Engtek Group

- Form Technologies Inc.

- Georg Fischer Limited

- Koch Enterprises

- Linamar Corporation

- Meridian Lightweight Technologies UK Ltd

- Nemak

- Rheinmetall AG

- Rockman Industries

- Ryobi Die Casting Ltd

- Sandhar Group

- Shiloh Industries

- Sundaram Clayton Ltd

제9장 운명의 수레바퀴

- 운명의 수레바퀴

- COM(Coherent Opportunity Map)

제10장 섹션

- 참고 문헌

- 조사 방법

Global Die Casting Market is estimated to be valued at USD 83.99 Bn in 2025 and is expected to reach USD 139.43 Bn by 2032, growing at a compound annual growth rate (CAGR) of 7.5% from 2025 to 2032.

| Report Coverage | Report Details | ||

|---|---|---|---|

| Base Year: | 2024 | Market Size in 2025: | USD 83.99 Bn |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 7.50% | 2032 Value Projection: | USD 139.43 Bn |

Introduction:

The die casting market has been growing steadily over the past few decades. Die casting is a manufacturing process used to produce parts by forcing molten metal under high pressure into a mold cavity. Some key advantages of die casting include high production rates, net shape production, and dimensional accuracy. Die cast parts are widely used in the automotive, electronics, hardware, and other industries. The automotive industry is a major consumer of die cast components due to requirements for lightweighting and net shape production. Overall demand for die cast parts is expected to rise in line with growth in the end-use industries. Precision, quality, and complexity requirements are increasing which will drive automation and new technology adoption in the die casting process.

Market Dynamics:

The die casting market is driven by growing automotive production and demand for the miniaturization of electronic components. Increasing vehicle content per vehicle to enable new features and technologies is boosting the usage of die cast parts. However, volatility in raw material prices remains a key challenge for market participants. Aluminum is a widely used raw material and its price fluctuations can significantly impact costs. Opportunities lie in adopting Industry 4.0 technologies like AI, IoT, and automation to improve productivity, quality, and spare capacity for complex high-value components. Sustainable and recycling-friendly die casting solutions also present new growth prospects.

Key Features of the Study:

This report provides an in-depth analysis of the global die casting market, and provides market size (US$ Billion) and compound annual growth rate (CAGR %) for the forecast period (2025-2032), considering 2024 as the base year

It elucidates potential revenue growth opportunities across different segments and explains attractive investment proposition matrices for this market

This study also provides key insights about market drivers, restraints, opportunities, new product launches or approval, market trends, regional outlook, and competitive strategies adopted by key players

It profiles key players in the global die casting market based on the following parameters - company highlights, products portfolio, key highlights, financial performance, and strategies

Key companies covered as a part of this study include Alcoa Corporation, Bocar Group, Endurance Technologies Limited, Engtek Group, Form Technologies Inc., Georg Fischer Limited, Koch Enterprises, Linamar Corporation, Meridian Lightweight Technologies UK Ltd, Nemak, Rheinmetall AG, Rockman Industries, Ryobi Die Casting Ltd, Sandhar Group, Shiloh Industries, and Sundaram Clayton Ltd are the major players.

Insights from this report would allow marketers and the management authorities of the companies to make informed decisions regarding their future product launches, type up-gradation, market expansion, and marketing tactics

The global die casting market report caters to various stakeholders in this industry including investors, suppliers, product manufacturers, distributors, new entrants, and financial analysts

Stakeholders would have ease in decision-making through various strategy matrices used in analyzing the global die casting market

Detailed Segmentation-

- By Casting Type

- Pressure Die Casting

- Vacuum Die Casting

- Squeeze Die Casting,

- Other

- By Material

- Aluminum

- Magnesium

- Zinc

- By Application

- Automotive

- Electrical and Electronics

- Industrial

- Other

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

- Key Players Insights

- Alcoa Corporation

- Bocar Group

- Endurance Technologies Limited

- Engtek Group

- Form Technologies Inc.

- Georg Fischer Limited

- Koch Enterprises

- Linamar Corporation

- Meridian Lightweight Technologies UK Ltd

- Nemak

- Rheinmetall AG

- Rockman Industries

- Ryobi Die Casting Ltd

- Sandhar Group

- Shiloh Industries

- Sundaram Clayton Ltd

Table of Contents

1. Research Objectives and Assumptions

- Research Objectives

- Assumptions

- Abbreviations

2. Market Purview

- Report Description

- Market Definition and Scope

- Executive Summary

- Market Snippet, By Casting Type

- Market Snippet, By Material Type

- Market Snippet, By Application Type

- Market Snippet, By Region

- Coherent Opportunity Map (COM)

3. Market Dynamics, Regulations, and Trends Analysis

- Market Dynamics

- Drivers

- Restraints

- Market Opportunities

- Regulatory Scenario

- Industry Trend

- Merger and Acquisitions

- New System Launches/Approvals

- Impact of COVID-19 Pandemic

4. Global Die Casting Market, By Casting Type, 2020-2032 (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021-2032

- Segment Trends

- Pressure Die Casting

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Vacuum Die Casting

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Squeeze Die Casting

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Other

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

5. Global Die Casting Market, By Material Type, 2020-2032 (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021-2032

- Segment Trends

- Aluminum

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Magnesium

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Zinc

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

6. Global Die Casting Market, By Application Type, 2020-2032 (US$ Billion)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021-2032

- Segment Trends

- Commercial

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Automotive

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Electrical and Electronics

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Industrial

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

- Other

- Introduction

- Market Size and Forecast, 2020-2032, (US$ Billion)

7. Global Die Casting Market, By Region, 2020-2032 (US$ Billion)

- Introduction

- Market Share Analysis, By Region, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021-2032

- North America

- Regional Trends

- Market Size and Forecast, By Casting Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Material Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Application Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2025 and 2032 (%)

- U.S.

- Canada

- Europe

- Regional Trends

- Market Size and Forecast, By Casting Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Material Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Application Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2025 and 2032 (%)

- U.K.

- Germany

- France

- Russia

- Rest of Europe

- Asia Pacific

- Regional Trends

- Market Size and Forecast, By Casting Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Material Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Application Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2025 and 2032 (%)

- China

- India

- Japan

- ASEAN

- Australia

- South Korea

- Rest of Asia Pacific

- Latin America

- Regional Trends

- Market Size and Forecast, By Casting Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Material Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Application Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2025 and 2032 (%)

- Brazil

- Argentina

- Mexico

- Rest of Latin America

- Middle East and Africa

- Regional Trends

- Market Size and Forecast, By Casting Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Material Type, 2020-2032 (US$ Billion)

- Market Size and Forecast, By Application Type, 2020-2032 (US$ Billion)

- Market Share Analysis, By Country, 2025 and 2032 (%)

- South Africa

- GCC Countries

- Rest of the Middle East and Africa

8. Competitive Landscape

- Company Profiles

- Alcoa Corporation

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Bocar Group

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Endurance Technologies Limited

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Engtek Group

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Form Technologies Inc.

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Georg Fischer Limited

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Koch Enterprises

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Linamar Corporation

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Meridian Lightweight Technologies UK Ltd

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Nemak

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Rheinmetall AG

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Rockman Industries

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Ryobi Die Casting Ltd

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Sandhar Group

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Shiloh Industries

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Sundaram Clayton Ltd

- Company Overview

- Product Portfolio

- Financial Performance

- Key Strategies

- Recent Developments/Updates

- Alcoa Corporation

9. Wheel of Fortune

- Wheel of Fortune

- Analyst View

- Coherent Opportunity Map

10. Section

- References

- Research Methodology

- About us and Sales Contact