|

시장보고서

상품코드

1708428

질화티타늄 코팅 시장 : 용도별, 기술별, 지역별Titanium Nitride Coating Market, By Application, By Technology, By Geography |

||||||

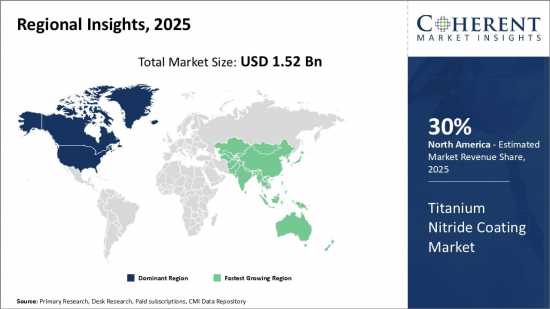

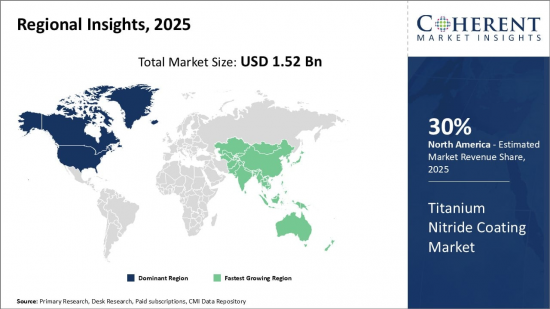

질화티타늄 코팅 세계 시장은 2025년에는 15억 2,000만 달러로 추정되며 2032년에는 25억 7,000만 달러에 달할 것으로 예상되며, 2025년부터 2032년까지 7.8%의 CAGR로 성장할 것으로 예상됩니다.

| 보고서 범위 | 보고서 상세 | ||

|---|---|---|---|

| 기준 연도 | 2024년 | 2025년 시장 규모 | 15억 2,000만 달러 |

| 실적 데이터 | 2020-2024년 | 예측 기간 | 2025-2032년 |

| 예측 기간 : 2025-2032년 CAGR: | 7.80% | 2032년 가치 예측 | 25억 7,000만 달러 |

TiN 코팅으로도 알려진 질화티타늄 코팅은 우수한 수준의 경도, 내마모성, 열 안정성을 제공하는 고성능 표면 처리입니다. 자동차, 항공우주, 의료, 산업 제조 등 다양한 산업에서 널리 사용되고 있습니다.

TiN 코팅은 금속, 세라믹, 플라스틱 등 다양한 기질에 얇은 질화티타늄 층을 입히는 코팅입니다. 일반적으로 진공 챔버에서 티타늄을 증발시킨 후 질소 가스와 반응시키는 물리적 증착(PVD) 기술로 표면에 증착됩니다.

TiN 코팅의 주요 목적은 경도, 내마모성, 내식성 향상 등 기판의 표면 특성을 향상시키는 것입니다. 따라서 기판이 고온, 연마 환경, 화학제품에 노출되는 등 가혹한 사용 조건에 노출되는 용도에 이상적인 선택이 될 수 있습니다.

시장 역학:

질화티타늄 코팅 시장은 다양한 최종 사용 산업의 수요 증가, 보호 코팅에 대한 수요 증가, 코팅 산업의 기술 발전 등의 요인으로 인해 향후 몇 년 동안 크게 성장할 것으로 예상됩니다.

시장의 주요 촉진요인 중 하나는 TiN 코팅의 주요 수요처인 자동차 산업입니다. 경량화 및 저연비 자동차에 대한 수요가 증가함에 따라 엔진 부품의 마찰과 마모 감소에 초점을 맞추는 제조업체가 증가하고 있으며, TiN 코팅은 우수한 마찰 특성으로 인해 피스톤 링, 밸브 리프터, 캠샤프트 등의 용도에 적합합니다.

또 다른 시장 촉진요인은 항공우주 산업으로, 터빈 블레이드, 랜딩 기어, 기체 등 주요 부품의 성능과 수명을 향상시키기 위해 TiN 코팅이 널리 사용되고 있습니다. 항공우주 산업은 항공 교통량의 증가와 연료 효율이 높은 항공기에 대한 수요에 힘입어 최근 몇 년 동안 괄목할 만한 성장세를 보이고 있습니다.

그러나 질화티타늄 코팅 시장의 성장을 억제하는 요인도 있습니다. 증착 장비와 관련된 높은 비용과 이러한 장비의 작동에 필요한 전문 교육이 특히 중소기업에서 TiN 코팅의 채택을 제한할 수 있습니다.

본 조사의 주요 특징

- 본 보고서는 2024년을 기준 연도로 하여 예측 기간(2025-2032년)의 시장 규모와 연평균 성장률(CAGR)을 포함한 질화티타늄 코팅 세계 시장을 상세히 분석하여 전해드립니다.

- 또한, 다양한 부문에 걸친 잠재적 수익 기회를 밝히고, 이 시장의 매력적인 투자 제안 매트릭스를 설명합니다.

- 또한 시장 촉진요인, 억제요인, 기회, 신제품 출시 및 승인, 시장 동향, 지역별 전망, 주요 기업의 경쟁 전략 등에 대한 중요한 인사이트를 제공합니다.

- 주요 기업으로는 PPG Industries, DuPont, Oerlikon Balzers, Ionbond, Crystallume Corporation, Kyocera Corporation, OC Oerlikon Corporation, Sulzer Ltd., Bodycote, Hoganas AB, Satisloh, DME Europe, Wallwork Heat Treatment, TST Engineered Coating Solutions, Tosoh Corporation, Acree Technologies, IHI Ionbond AG, Richter Precision, Aalberts, Techmetals 등이 있습니다.

- 이 보고서의 인사이트를 통해 마케팅 담당자와 경영진은 향후 제품 출시, 유형 업그레이드, 시장 확대, 마케팅 전술에 대한 정보에 입각한 의사결정을 내릴 수 있습니다.

- 이 보고서는 투자자, 공급업체, 제품 제조업체, 유통업체, 신규 진입자, 금융 분석가 등 업계의 다양한 이해관계자를 대상으로 합니다.

- 이해 관계자는 세계 티타늄 질화물 코팅 시장 분석에 사용되는 다양한 전략 매트릭스를 통해 이익을 얻고 의사결정을 용이하게 할 수 있습니다.

목차

제1장 조사 목적과 가정

- 조사 목적

- 가정

- 약어

제2장 시장 전망

- 보고서 설명

- 시장 정의와 범위

- 주요 요약

- Coherent Opportunity Map(COM)

제3장 시장 역학, 규제, 동향 분석

- 시장 역학

- 항공우주 산업으로부터의 수요 증가

- 높은 자본 투자 요건

- 의료기기 업계에서의 채용 증가

- 영향 분석

- 주요 하이라이트

- 규제 시나리오

- 제품 발매/승인

- PEST 분석

- PORTER의 분석

- 인수합병 시나리오

제4장 질화티타늄 코팅 시장 - 코로나바이러스(COVID-19) 팬데믹의 영향

- COVID-19 역학

- 공급측과 수요측 분석

- 경제에 대한 영향

제5장 질화티타늄 코팅 시장, 용도별, 2020-2032년

- 절삭 공구

- 항공우주 및 방위

- 자동차

- 헬스케어

- 석유 및 가스

- 발전

- 기타(건설, 플라스틱 등)

제6장 질화티타늄 코팅 시장, 기술별, 2020-2032년

- 물리 증착

- 화학 증착법

- 용사

- 기타(졸겔, 원자층 증착 등)

제7장 질화티타늄 코팅 시장, 지역별, 2020-2032년

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

제8장 경쟁 구도

- PPG Industries

- DuPont

- Oerlikon Balzers

- Ionbond

- Crystallume Corporation

- Kyocera Corporation

- OC Oerlikon Corporation

- Sulzer Ltd.

- Bodycote

- Hoganas AB

- Satisloh

- DME Europe

- Wallwork Heat Treatment

- TST Engineered Coating Solutions

- Tosoh Corporation

- Acree Technologies

- IHI Ionbond AG

- Richter Precision

- Aalberts

- Techmetals

제9장 섹션

- 조사 방법

- 출판사 소개

Global Titanium Nitride Coating Market is estimated to be valued at USD 1.52 Bn in 2025 and is expected to reach USD 2.57 Bn by 2032, growing at a compound annual growth rate (CAGR) of 7.8% from 2025 to 2032.

| Report Coverage | Report Details | ||

|---|---|---|---|

| Base Year: | 2024 | Market Size in 2025: | USD 1.52 Bn |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 7.80% | 2032 Value Projection: | USD 2.57 Bn |

Titanium Nitride Coating, also known as TiN coating, is a high-performance surface treatment that offers excellent levels of hardness, wear resistance, and thermal stability. It is widely used in various industries such as automotive, aerospace, medical, and industrial manufacturing.

TiN coating is a thin layer of titanium nitride that is applied to a variety of substrates including metals, ceramics, and plastics. It is typically deposited onto the surface through physical vapor deposition (PVD) techniques, which involve the evaporation of titanium in a vacuum chamber and the subsequent reaction with nitrogen gas.

The primary objective of TiN coating is to enhance the surface properties of the substrate material, including improved hardness, wear resistance, and corrosion resistance. This makes it an ideal choice for applications where the substrate is exposed to harsh operating conditions, such as high temperatures, abrasive environments, and chemical exposure.

Market Dynamics:

The Titanium Nitride Coating market is poised for significant growth in the coming years, driven by factors such as increasing demand from various end-use industries, the growing need for protective coatings, and technological advancements in the coating industry.

One of the key drivers for the market is the automotive industry, which is a major consumer of TiN coatings. With the rising demand for lightweight and fuel-efficient vehicles, manufacturers are increasingly focusing on reducing friction and wear in engine components. TiN coatings offer excellent tribological properties, making them an ideal choice for applications such as piston rings, valve lifters, and camshafts.

Another driver for the market is the aerospace industry, where TiN coatings are used extensively for improving the performance and longevity of critical components such as turbine blades, landing gears, and airframes. The aerospace sector has witnessed significant growth in recent years, driven by increasing air traffic and the demand for fuel-efficient aircraft.

However, there are certain factors that may restrain the growth of the Titanium Nitride Coating market. The high cost associated with the deposition equipment and the specialized training required for operating these systems can limit the adoption of TiN coatings, especially among small and medium-sized enterprises.

Key features of the study:

- This report provides in-depth analysis of the global Titanium Nitride Coating market, including market size (US$ Billion) and compound annual growth rate (CAGR%) for the forecast period (2025-2032), with 2024 as the base year.

- It elucidates potential revenue opportunities across different segments and explains attractive investment proposition matrices for this market.

- This study also provides key insights about market drivers, restraints, opportunities, new product launches or approvals, market trends, regional outlook, and competitive strategies adopted by key players.

- Key companies covered in this study include PPG Industries, DuPont, Oerlikon Balzers, Ionbond, Crystallume Corporation, Kyocera Corporation, OC Oerlikon Corporation, Sulzer Ltd., Bodycote, Hoganas AB, Satisloh, DME Europe, Wallwork Heat Treatment, TST Engineered Coating Solutions, Tosoh Corporation, Acree Technologies, IHI Ionbond AG, Richter Precision, Aalberts, and Techmetals.

- Insights from this report would enable marketers and management authorities to make informed decisions regarding future product launches, type upgrades, market expansion, and marketing tactics.

- The global Titanium Nitride Coating market report caters to various stakeholders in the industry, including investors, suppliers, product manufacturers, distributors, new entrants, and financial analysts.

- Stakeholders will benefit from various strategy matrices used in analyzing the global Titanium Nitride Coating market, facilitating ease in decision-making.

Titanium Nitride Coating Market Segmentation

- By Application

- Cutting Tools

- Aerospace & Defence

- Automotive

- Healthcare

- Oil & Gas

- Power Generation

- Others (Construction, Plastics etc)

- By Technology

- Physical Vapor Deposition

- Chemical Vapor Deposition

- Thermal Spraying

- Others (sol-gel, atomic layer deposition etc)

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

- Company Profiles

- PPG Industries

- DuPont

- Oerlikon Balzers

- Ionbond

- Crystallume Corporation

- Kyocera Corporation

- OC Oerlikon Corporation

- Sulzer Ltd.

- Bodycote

- Hoganas AB

- Satisloh

- DME Europe

- Wallwork Heat Treatment

- TST Engineered Coating Solutions

- Tosoh Corporation

- Acree Technologies

- IHI Ionbond AG

- Richter Precision

- Aalberts

- Techmetals

Table of Contents

1. Research Objectives and Assumptions

- Research Objectives

- Assumptions

- Abbreviations

2. Market Purview

- Report Description

- Market Definition and Scope

- Executive Summary

- Titanium Nitride Coating Market, By Application

- Titanium Nitride Coating Market, By Technology

- Titanium Nitride Coating Market, By Region

- Coherent Opportunity Map (COM)

3. Market Dynamics, Regulations, and Trends Analysis

- Market Dynamics

- Drivers

- Increasing demand from aerospace industry

- Restraints

- High capital investment requirements

- Opportunities

- Rising adoption in the medical device industry

- Impact Analysis

- Key Highlights

- Regulatory Scenario

- Product launch/Approvals

- PEST Analysis

- PORTER's Analysis

- Merger and Acquisition Scenario

4. Titanium Nitride Coating Market - Impact of Coronavirus (COVID-19) Pandemic

- COVID-19 Epidemiology

- Supply Side and Demand Side Analysis

- Economic Impact

5. Titanium Nitride Coating Market , By Application, 2020-2032, (US$ Bn)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021 - 2032

- Segment Trends

- Cutting Tools

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- Aerospace & Defence

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- Automotive

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- Healthcare

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- Oil & Gas

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- Power Generation

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- Others (Construction, Plastics etc)

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

6. Titanium Nitride Coating Market , By Technology, 2020-2032, (US$ Bn)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021- 2032

- Segment Trends

- Physical Vapor Deposition

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Billion)

- Chemical Vapor Deposition

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Billion)

- Thermal Spraying

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Billion)

- Others (sol-gel, atomic layer deposition etc)

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Billion)

7. Titanium Nitride Coating Market , By Region, 2020-2032, (US$ Bn)

- Introduction

- Market Share Analysis, By Country, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, For Country 2021-2032

- Country Trends

- North America

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Technology, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- U.S.

- Canada

- Europe

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Technology, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- Germany

- U.K.

- Spain

- France

- Italy

- Russia

- Rest of Europe

- Asia Pacific

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Technology, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- China

- India

- Japan

- Australia

- South Korea

- ASEAN

- Rest of Asia Pacific

- Latin America

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Technology, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- Brazil

- Argentina

- Mexico

- Rest of Latin America

- Middle East & Africa

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Application, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Technology, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- GCC Countries

- Israel

- Rest of Middle East & Africa

8. Competitive Landscape

- PPG Industries

- Company Highlights

- Product Portfolio

- Key Developments

- Financial Performance

- Strategies

- DuPont

- Oerlikon Balzers

- Ionbond

- Crystallume Corporation

- Kyocera Corporation

- OC Oerlikon Corporation

- Sulzer Ltd.

- Bodycote

- Hoganas AB

- Satisloh

- DME Europe

- Wallwork Heat Treatment

- TST Engineered Coating Solutions

- Tosoh Corporation

- Acree Technologies

- IHI Ionbond AG

- Richter Precision

- Aalberts

- Techmetals

- Analyst Views

9. Section

- Research Methodology

- About us