|

시장보고서

상품코드

1822618

철 분말 시장 : 기회, 성장 촉진요인, 산업 동향 분석, 예측(2025-2034년)Iron Powder Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

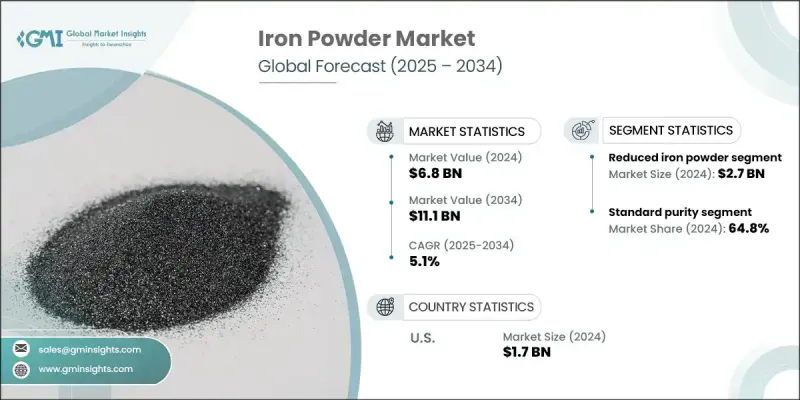

세계의 철 분말 세계 시장 규모는 68억 달러로 생산 공정의 기술적 진보를 배경으로 CAGR 5.1%로 성장해 2034년까지 111억 달러에 이를 것으로 추정되고 있습니다.

세련된 분말 제조 기술과 품질 관리 기준 강화 등의 기술 혁신이 철분의 특성을 향상시키고 있습니다. 이러한 개선으로 자동차에서 전자 제품에 이르기까지 광범위한 응용 분야에서 사용할 수 있습니다. 게다가, 분말 야금의 진보와 적층 조형의 상승에 의해 생산은 보다 정밀하고 효율적으로 되고 있습니다. 철분을 많이 사용하는 건설과 일렉트로닉스의 분야도 시장의 성장에 기여하고 있습니다. 세계 철강 협회의 보고서에 따르면 건설 분야의 철 분말 수요는 매년 4% 증가할 것으로 예측됩니다. 가공기술의 향상과 특수강종 등 생산방법의 혁신이 시장 역학을 더욱 촉진하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시장 매출 | 68억 달러 |

| 예측 금액 | 111억 달러 |

| CAGR | 5.1% |

또한, 엄격한 산업 표준 및 규정은 최적의 성능과 안전성을 달성하기 위해 필수적인 고순도 재료의 요구를 증가시키고 있습니다. 북미의 철 분말 시장은 산업활동의 활성화와 다양한 분야에서의 기술진보에 의해 2024년부터 2032년까지 강력한 CAGR을 나타낼 것으로 보입니다. 이 지역에서는 자동차 산업과 항공우주 산업이 확대되고 있으며 제조 공정에서 고품질 재료의 필요성이 커지고 있습니다. 게다가 인프라 개발과 재생에너지 프로젝트에 주력함으로써 이 지역 전체의 건설과 에너지 용도에 있어서의 철 분말 수요가 높아지고 있습니다. 부가제조에 있어서의 기술 혁신과 진보의 추진도 철 분말 수요 증가에 기여해, 북미 시장 성장을 가속하고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 업계 생태계 분석

- 공급자의 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 주는 요인

- 혁신

- 업계에 미치는 영향요인

- 성장 촉진요인

- 업계의 잠재적 리스크 및 과제

- 시장 기회

- 성장 가능성 분석

- 규제 상황

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- Porter's Five Forces 분석

- PESTEL 분석

- 기술과 혁신의 상황

- 현재의 기술 동향

- 신흥기술

- 가격 동향

- 지역별

- 유형별

- 미래 시장 동향

- 기술과 혁신의 상황

- 현재의 기술 동향

- 신흥기술

- 특허 상황

- 무역 통계(HS코드)(참고 : 무역 통계는 주요 국가에서만 제공됨)

- 주요 수입국

- 주요 수출국

- 지속가능성과 환경 측면

- 지속가능한 관행

- 폐기물 감축 전략

- 생산에서의 에너지 효율

- 환경 친화적인 노력

- 탄소발자국의 고려

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 지역별

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- 지역별

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 주요 발전

- 인수합병

- 파트너십 및 협업

- 신제품 발매

- 확장 계획

제5장 시장 추계 및 예측 : 유형별, 2021-2034년

- 주요 동향

- 환원 철 분말

- 아토마이즈 철 분멀

- 전해 철 분말

제6장 시장 추계 및 예측 : 순도별, 2021-2034년

- 주요 동향

- 고순도

- 표준 순도

제7장 시장 추계 및 예측 : 최종 이용 산업별, 2021-2034년

- 주요 동향

- 자동차

- 전자

- 일반산업

- 소비재 산업

- 건설

제8장 시장 추계 및 예측 : 지역별, 2021-2034년

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 스페인

- 이탈리아

- 기타 유럽

- 아시아태평양

- 중국

- 인도

- 일본

- 호주

- 한국

- 기타 아시아태평양

- 라틴아메리카

- 브라질

- 멕시코

- 아르헨티나

- 기타 라틴아메리카

- 중동 및 아프리카

- 사우디아라비아

- 남아프리카

- 아랍에미리트(UAE)

- 기타 중동 및 아프리카

제9장 기업 프로파일

- American Element

- BASF SE

- Belmont Metals

- CNPC Powder

- Hoganas

- Industrial Metal Powders(India) Pvt. Ltd.

- JFE Steel Corporation

- Pometon

- Reade

- Rio Tinto Metal Powder

- SAGWELL USA INC.

- Serena Nutrition

The Global Iron Powder Market was valued at USD 6.8 billion and is estimated to grow at a CAGR of 5.1% to reach USD 11.1 billion by 2034, backed by the technological advancements in production processes. Innovations, including refined powder production techniques and enhanced quality control standards, are advancing the properties of iron powder. These improvements enable its use in a wider array of applications, from automotive to electronics. Additionally, advancements in powder metallurgy and the rise of additive manufacturing are making production more precise and efficient. The construction and electronics sectors, which heavily utilize iron powder, are also contributing to market growth. According to a report by the World Steel Association, the demand for iron powder in construction is expected to rise by 4% annually. Innovations in production methods, such as improved processing techniques and specialized grades, are further driving market dynamics.

The overall iron powder market is sorted based on type, purity, End Use industry, and region. The atomized iron powder segment will register decent CAGR through 2032, driven by its superior properties compared to other types. Atomized iron powder offers excellent uniformity in particle size and shape, which enhances performance in precision applications. Its consistent quality is crucial for industries requiring high levels of accuracy and reliability, such as aerospace and high-tech manufacturing. Additionally, advancements in atomization technology have made the production process more efficient, further boosting the segment revenues. By 2032, the high-purity segment will clutch a noticeable market share, because of its role in advanced manufacturing processes that require minimal contamination. High-purity iron powder is essential for producing components with precise characteristics and superior performance, particularly in high-tech industries such as electronics and pharmaceuticals.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $6.8 Billion |

| Forecast Value | $11.1 Billion |

| CAGR | 5.1% |

Additionally, stringent industry standards and regulations are catapulting the need for high-purity materials, as they are crucial for achieving optimal performance and safety. North America iron powder market will showcase a strong CAGR from 2024 to 2032, owing to increased industrial activity and technological advancements across various sectors. The region's expanding automotive and aerospace industries are driving the need for high-quality materials in manufacturing processes. Additionally, the focus on infrastructure development and renewable energy projects is creating a higher demand for iron powder in construction and energy applications across the region. The push for innovation and advancements in additive manufacturing also contributes to the rising demand for iron powder, bolstering the market growth in North America.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Type trends

- 2.2.2 Purity trends

- 2.2.3 End use industry trends

- 2.2.4 Regional trends

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and Innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Price trends

- 3.8.1 By region

- 3.8.2 By type

- 3.9 Future market trends

- 3.10 Technology and Innovation landscape

- 3.10.1 Current technological trends

- 3.10.2 Emerging technologies

- 3.11 Patent Landscape

- 3.12 Trade statistics (HS code)( Note: the trade statistics will be provided for key countries only)

- 3.12.1 Major importing countries

- 3.12.2 Major exporting countries

- 3.13 Sustainability and environmental aspects

- 3.13.1 Sustainable practices

- 3.13.2 Waste reduction strategies

- 3.13.3 Energy efficiency in production

- 3.13.4 Eco-friendly initiatives

- 3.14 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Type, 2021-2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Reduced iron powder

- 5.3 Atomised iron powder

- 5.4 Electrolytic iron powder

Chapter 6 Market Estimates and Forecast, By Purity, 2021-2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 High purity

- 6.3 Standard purity

Chapter 7 Market Estimates and Forecast, By End Use Industry, 2021-2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Automotive

- 7.3 Electronic

- 7.4 General industries

- 7.5 Consumer industries

- 7.6 Construction

Chapter 8 Market Estimates and Forecast, By Region, 2021-2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 American Element

- 9.2 BASF SE

- 9.3 Belmont Metals

- 9.4 CNPC Powder

- 9.5 Hoganas

- 9.6 Industrial Metal Powders (India) Pvt. Ltd.

- 9.7 JFE Steel Corporation

- 9.8 Pometon

- 9.9 Reade

- 9.10 Rio Tinto Metal Powder

- 9.11 SAGWELL USA INC.

- 9.12 Serena Nutrition