|

시장보고서

상품코드

1740970

튜브 충전기 시장 : 기회, 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Tube Filling Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

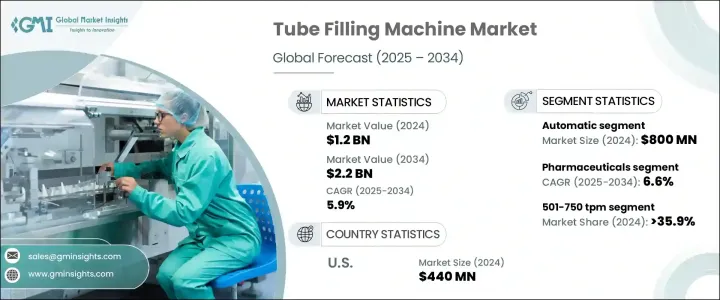

세계의 튜브 충전기 시장은 2024년에는 12억 달러로 평가되었고, 2034년에는 22억 달러에 이를 것으로 추정되며, CAGR 5.9%로 성장할 전망입니다.

이러한 성장은 산업 전반에 걸친 자동화 수요 증가와 포장 기술의 발전에 힘입은 바가 큽니다. 특히 소비재 부문은 기업들이 보다 정확하고 효율적이며 확장 가능한 제조 공정을 도입하고자 하면서 이러한 변화를 주도하고 있습니다. 튜브 충전기는 개인 위생용품, 제약, 식품을 비롯한 다양한 제품을 유연하게 포장할 수 있어 이러한 요구를 충족하는 데 매우 중요합니다. 이러한 기계는 생산 효율성을 향상시킬 뿐만 아니라 정밀한 충전을 보장하여 낭비를 최소화하고 궁극적으로 시간이 지남에 따라 운영 비용을 절감합니다. 또한 위생적인 일회용 및 휴대용 포장 솔루션에 대한 소비자 선호도가 높아지면서 튜브 충전 시스템에 대한 수요도 증가하고 있습니다. 이러한 추세는 용량 조절이 가능한 드레싱과 일회용 치약이 점점 더 인기를 얻고 있는 식음료 등 다양한 분야에서 뚜렷하게 나타나고 있습니다. 튜브 포장 제품에 대한 수요가 증가함에 따라 튜브 충전기 시장도 이에 대응하여 확대되고 있습니다.

2024년 자동 튜브 충전기 부문은 8억 달러의 매출을 올렸으며 2034년까지 6.2%의 연평균 성장률을 기록할 것으로 예상됩니다. 특히 식품, 제약, 화장품과 같이 고속 대량 생산이 필수적인 산업에서 자동화를 향한 전환이 가속화되고 있습니다. 자동 튜브 충전기는 충전, 밀봉, 라벨링과 같은 공정에서 사람의 개입을 최소화하여 생산 효율성을 높이는 데 핵심적인 역할을 합니다. 이를 통해 생산 속도가 빨라질 뿐만 아니라 일관성을 개선하고 오류를 줄일 수 있습니다. 이러한 기계에는 자동 튜브 공급 및 정밀한 충전 제어와 같은 고급 기능이 탑재되어 있어 제조업체가 생산성을 높이고 인건비를 절감하는 데 도움이 됩니다. 자동화 시스템의 채택이 증가하는 것은 또한 이러한 기계가 다양한 튜브 크기와 재료를 처리할 수 있는 혁신에 힘입어 다양한 부문에서 그 매력을 더욱 높이고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 12억 달러 |

| 예측 금액 | 22억 달러 |

| CAGR | 5.9% |

제약 부문에서만 2024년에 튜브 충전기로 5억 달러의 매출을 올렸으며, 2034년까지 6.6%의 연평균 성장률(CAGR)을 기록할 것으로 예상됩니다. 튜브 충전기에 대한 수요는 정밀하고 멸균된 포장의 필요성이 중요한 제약 산업에서 특히 강합니다. 튜브 충전기는 크림, 연고, 젤과 같은 제품을 무균 환경에서 정확하게 충전하여 제품의 품질과 안전성을 유지하는 데 매우 중요합니다. 제약 제조에 완전 자동화 시스템을 도입하면 운영이 간소화되고 오염 위험이 줄어들며 전반적인 생산 효율성이 향상됩니다. 업계가 계속해서 안전과 품질을 우선시함에 따라 튜브 충전기는 더욱 엄격한 규제 기준과 소비자의 기대치를 충족하기 위해 진화하고 있습니다.

분당 501-750tpm 부문은 2024년 튜브 충전기 시장의 35.9% 이상을 차지했으며 2034년까지 6.1%의 비율로 성장할 것으로 예상됩니다. 이 부문은 다양한 제품, 튜브 크기 및 점도를 수용할 수 있기 때문에 다양한 제품을 생산하거나 새로운 품목을 시장에 출시할 계획이 있는 회사에 이상적입니다. 501-750tpm 기계는 생산 능력과 비용 효율성 사이의 균형을 유지하여 튜브 충진 작업을 최적화하려는 중견 기업에게 매력적인 옵션을 제공합니다. 대용량 기계는 더 빠른 처리량을 제공하지만, 일부 기업에서는 감당하기 어려운 상당한 가격표를 달고 있습니다. 반면 501-750tpm 기계는 경제성이 뛰어나며 과도한 리소스 없이도 생산성을 향상시킬 수 있습니다.

북미, 특히 미국은 2024년 4억 4,000만 달러의 가치로 시장을 주도하고 있으며 2025년부터 2034년까지 7%의 연평균 성장률을 보일 것으로 예상됩니다. 미국은 고도로 자동화된 대규모 소비재 산업을 보유하고 있으며, 세면용품, 화장품, 제약과 같은 제품을 포장하기 위해 튜브 충전기에 크게 의존하고 있습니다. 제조 자동화는 이 지역의 핵심 촉진요인으로, 기업들이 튜브의 자동 로딩, 충전, 밀봉 및 코딩을 제공하는 로봇 튜브 충전 시스템에 점점 더 많은 투자를 하고 있습니다. 이러한 자동화 시스템은 생산 효율성을 높이고 인건비를 절감하는 데 필수적인 요소입니다.

몇몇 주요 업체가 튜브 충전기 산업을 지배하며 시장 점유율의 15-20%를 차지하고 있습니다. 이러한 기업들은 경쟁 우위를 유지하기 위해 연구 개발과 제품 혁신에 집중하고 있습니다. 또한 일부 제조업체는 환경에 미치는 영향을 줄이기 위해 친환경적인 기계 설계를 우선시하는 등 지속 가능성에 대한 관심이 높아지고 있습니다. 자동화와 지속 가능성의 지속적인 발전으로 튜브 충전기 시장은 계속 확장될 것이며, 다양한 분야에서 고품질의 효율적인 포장 제품에 대한 수요 증가를 충족하는 데 필요한 도구를 기업에 제공할 것입니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 트럼프 정권의 관세 분석

- 무역에 미치는 영향

- 무역량의 혼란

- 보복 조치

- 업계에 미치는 영향

- 공급측의 영향(원자재)

- 주요 원자재의 가격 변동

- 공급망 재구성

- 생산 비용에 미치는 영향

- 수요측의 영향(판매가격)

- 최종 시장에의 가격 전달

- 시장 점유율 동향

- 소비자의 반응 패턴

- 영향을 받는 주요 기업

- 전략적인 업계 대응

- 공급망 재구성

- 가격 설정 및 제품 전략

- 정책관여

- 전망과 향후 검토 사항

- 무역에 미치는 영향

- 공급자의 상황

- 가격 분석

- 기술과 혁신의 상황

- 주요 뉴스와 대처

- 규제 상황

- 제조업자

- 리셀러

- 소매업체

- 영향요인

- 성장 촉진요인

- 산업 전반의 자동화

- 포장 산업의 기술 발전

- 제약 및 화장품 산업의 확장

- 인더스트리 4.0 기술의 통합

- 업계의 잠재적 위험 및 과제

- 고비용 투자

- 정기 유지보수

- 성장 촉진요인

- 기술과 혁신의 상황

- 성장 가능성 분석

- 규제 상황

- 가격 분석

- Porter's Five Forces 분석

- PESTEL 분석

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 경쟁 포지셔닝 매트릭스

- 전략적 전망 매트릭스

제5장 시장 추계 및 예측 : 유형별(2021-2034년)

- 주요 동향

- 반자동

- 자동

제6장 시장 추계 및 예측 : 용량별(2021-2034년)

- 주요 동향

- 250tpm 미만

- 251-500tpm

- 501-750tpm

- 750tpm 이상

제7장 시장 추계 및 예측 : 용도별(2021-2034년)

- 주요 동향

- 제약

- 화장품

- 식음료

- 화학

제8장 시장 추계 및 예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 이탈리아

- 스페인

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주

- 라틴아메리카

- 브라질

- 멕시코

- 중동 및 아프리카

- 사우디아라비아

- 아랍에미리트(UAE)

- 남아프리카

제9장 기업 프로파일

- Accutek Packaging Equipment Company

- Advanced Dynamics

- Aligned Machinery

- APACKS Packaging

- Axomatic

- BellatRx

- Bischoff &Munneke

- Blenzor India

- Busch Machinery

- Caelsons Industries

- GGM Group

- Gustav Obermeyer

- Harish Pharma Engineering

- Makwell Machinery

- ProSys Servo Filling Systems

The Global Tube Filling Machine Market was valued at USD 1.2 billion in 2024 and is estimated to grow at a CAGR of 5.9% to reach USD 2.2 billion by 2034. This growth is fueled by the increasing demand for automation across industries, as well as advancements in packaging technology. The consumer goods sector, in particular, is driving this shift as businesses seek to adopt more precise, efficient, and scalable manufacturing processes. Tube filling machines are critical in meeting these demands, offering flexibility in packaging a wide range of products, including personal care items, pharmaceuticals, and food products. These machines not only improve production efficiency but also minimize waste by ensuring precise filling, ultimately reducing operational costs over time. Additionally, the rising consumer preference for hygienic, single-dose, and portable packaging solutions is contributing to the growing demand for tube-filling systems. This trend is evident across various sectors, including food and beverages, where portion-controlled dressings and single-serve toothpaste are becoming increasingly popular. As the demand for tube-packaged products grows, the market for tube filling machines is expanding in response.

In 2024, the automatic tube filling machine segment generated a revenue of USD 800 million and is expected to experience a CAGR of 6.2% through 2034. The shift toward automation is gaining momentum, particularly in industries like food, pharmaceuticals, and cosmetics, where high-speed, high-volume production is essential. Automatic tube filling machines play a key role in enhancing production efficiency by minimizing human interaction during processes like filling, sealing, and labeling. This not only ensures a faster production pace but also improves consistency and reduces errors. These machines are equipped with advanced features, such as automatic tube feeding and precise filling control, which help manufacturers achieve higher productivity and lower labor costs. The growing adoption of automated systems is also fueled by innovations that allow these machines to handle a wide range of tube sizes and materials, further boosting their appeal in various sectors.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.2 Billion |

| Forecast Value | $2.2 Billion |

| CAGR | 5.9% |

The pharmaceutical sector alone generated USD 500 million in revenue from tube filling machines in 2024, with an expected CAGR of 6.6% through 2034. The demand for tube filling machines is particularly strong in the pharmaceutical industry, where the need for precise and sterile packaging is critical. Tube filling machines ensure that products such as creams, ointments, and gels are filled accurately in sterile environments, which is crucial for maintaining product quality and safety. The adoption of fully automated systems in pharmaceutical manufacturing has streamlined operations, reduced the risk of contamination, and improved overall production efficiency. As the industry continues to prioritize safety and quality, tube filling machines are evolving to meet stricter regulatory standards and consumer expectations.

The 501-750 tubes per minute (tpm) segment accounted for more than 35.9% of the tube filling machine market in 2024 and is expected to grow at a rate of 6.1% until 2034. This segment is favored due to its ability to accommodate a broad range of products, tube sizes, and viscosities, making it ideal for companies that produce various products or are planning to introduce new items to the market. The 501-750 tpm machines strike a balance between production capacity and cost efficiency, offering an attractive option for mid-sized businesses looking to optimize their tube-filling operations. While high-capacity machines offer faster throughput, they come with a significant price tag, which can be prohibitive for some companies. In contrast, the 501-750 tpm machines are economically viable and offer improved production without requiring excessive resources.

North America, particularly the United States, leads the market with a valuation of USD 440 million in 2024 and is expected to grow at a CAGR of 7% from 2025 to 2034. The U.S. has a large and highly automated consumer packaged goods industry, which is heavily reliant on tube filling machines for packaging products like toiletries, cosmetics, and medicines. Automation in manufacturing is a key driver in the region, with companies increasingly investing in robotic tube filling systems that offer automatic loading, filling, sealing, and coding of tubes. These automated systems are integral to increasing production efficiency and reducing labor costs.

Several key players dominate the tube filling machine industry, holding 15-20% of the market share. To maintain a competitive edge, these companies are focusing on research and development and product innovation. There is also a growing trend toward sustainability, with some manufacturers prioritizing eco-friendly machine designs to reduce environmental impact. With the ongoing advancements in automation and sustainability, the tube filling machine market is set to continue expanding, offering businesses the tools they need to meet the growing demand for high-quality, efficiently packaged products across various sectors.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates and calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimates

- 1.3 Forecast model

- 1.4 Primary research & validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.2 Price volatility in key materials

- 3.2.2.3 Supply chain restructuring

- 3.2.2.4 Production cost implications

- 3.2.2.5 Demand-side impact (selling price)

- 3.2.2.6 Price transmission to end markets

- 3.2.2.7 Market share dynamics

- 3.2.2.8 Consumer response patterns

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Supplier landscape

- 3.4 Pricing analysis

- 3.5 Technology & innovation landscape

- 3.6 Key news & initiatives

- 3.7 Regulatory landscape

- 3.8 Manufacturers

- 3.9 Distributors

- 3.10 Retailers

- 3.11 Impact forces

- 3.11.1 Growth drivers

- 3.11.1.1 Automation across industries

- 3.11.1.2 Technological advancement in packaging industry

- 3.11.1.3 The expanding pharmaceutical and cosmetics industries

- 3.11.1.4 Integration of Industry 4.0 technologies

- 3.11.2 Industry pitfalls & challenges

- 3.11.2.1 High-cost investment

- 3.11.2.2 Regular maintenance

- 3.11.1 Growth drivers

- 3.12 Technology & innovation landscape

- 3.13 Growth potential analysis

- 3.14 Regulatory landscape

- 3.15 Pricing analysis

- 3.16 Porter's analysis

- 3.17 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Type, 2021 – 2034, (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 Semi-automatic

- 5.3 Automatic

Chapter 6 Market Estimates & Forecast, By Capacity, 2021 – 2034, (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Less than 250 tpm

- 6.3 251-500 tpm

- 6.4 501-750 tpm

- 6.5 Above 750 tpm

Chapter 7 Market Estimates & Forecast, By Application, 2021 – 2034, (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 Pharmaceutical

- 7.3 Cosmetics

- 7.4 Food & beverages

- 7.5 Chemicals

Chapter 8 Market Estimates & Forecast, By Region, 2021 – 2034, (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 South Korea

- 8.4.5 Australia

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.6 MEA

- 8.6.1 Saudi Arabia

- 8.6.2 UAE

- 8.6.3 South Africa

Chapter 9 Company Profiles

- 9.1 Accutek Packaging Equipment Company

- 9.2 Advanced Dynamics

- 9.3 Aligned Machinery

- 9.4 APACKS Packaging

- 9.5 Axomatic

- 9.6 BellatRx

- 9.7 Bischoff & Munneke

- 9.8 Blenzor India

- 9.9 Busch Machinery

- 9.10 Caelsons Industries

- 9.11 GGM Group

- 9.12 Gustav Obermeyer

- 9.13 Harish Pharma Engineering

- 9.14 Makwell Machinery

- 9.15 ProSys Servo Filling Systems