|

시장보고서

상품코드

1685145

발포 폴리프로필렌(EPP) 폼 시장 기회, 성장 촉진요인, 산업 동향 분석, 예측(2025-2034년)Expanded Polypropylene (EPP) Foam Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

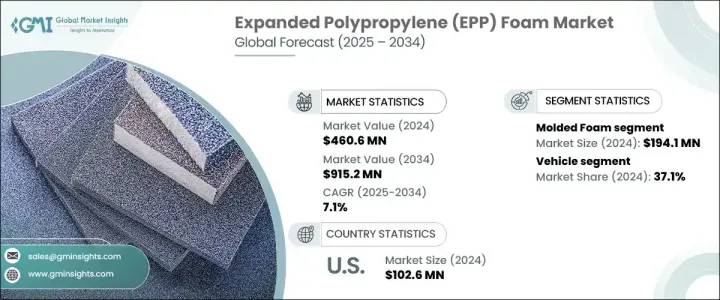

세계의 발포 폴리프로필렌(EPP) 폼 시장은 2024년에 4억 6,060만 달러에 이르렀으며, 2025년부터 2034년까지 연평균 복합 성장률(CAGR) 7.1%를 나타낼 것으로 예측됩니다.

이 성장은 자동차, 포장, 항공우주, 소비재 등 주요 산업 수요 증가가 주요 요인입니다. 기업이 경량으로 고성능 소재를 계속 요구하는 가운데, EPP 폼은 그 탁월한 쿠션성, 내충격성, 에너지 흡수 능력으로 두드러지고 있습니다. 이러한 특성으로 인해 특히 경량화와 내구성이 중요시되는 업계에서는 다양한 분야에서 필수적인 소재가 되고 있습니다.

EPP 폼의 인기가 높아지고 있는 것은 기존의 폼 소재에 비해 범용성이 높고, 성능이 뛰어난 것에 기인하고 있습니다. EPP 폼은 높은 강도 대 중량비, 단열성, 재활용성이 널리 인정되고 있으며 세계의 지속가능성 추진에 부합하고 있습니다. 친환경 소재를 장려하는 엄격한 규정에 따라 제조업체는 진화하는 업계 표준을 충족하기 위해 EPP 폼을 제품에 통합하고 있습니다. 또한 제조 기술의 발전으로 제품 품질, 맞춤형 옵션, 비용 효율성이 향상되고 EPP 폼 채택에 박차를 가하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 4억 6,060만 달러 |

| 예측 금액 | 9억 1,520만 달러 |

| CAGR | 7.1% |

시장 세분화에는 비즈 폼, 성형 폼, 제작 폼, 자동차 폼 등이 포함됩니다. 이 중 성형 폼이 2024년에는 1억 9,410만 달러를 차지해 우위를 차지했습니다. 비즈 폼은 자동차, 포장, 전자 기기에 널리 사용되며 충격 흡수성과 단열성이 평가됩니다. 제작 폼은 커스터마이징 능력으로 알려져 있으며 의료기기 및 보호 포장과 같은 맞춤형 솔루션이 필요한 산업에 기여합니다. EPP 폼의 유형은 다양하기 때문에 경량 고성능 소재로의 이행을 지원하면서 업계 특유 수요에 부응하여 시장의 꾸준한 확대를 확실히 하고 있습니다.

시장은 용도별로 구분되고 있으며, 차량, 포장, 소비재, 항공우주, 건축 및 건설, 스포츠 및 레저, 기타 등의 카테고리가 있습니다. 2024년 시장 점유율은 차량이 37.1%로 컸고, 자동차 제조업체가 계속해서 에너지 효율과 내충격성이 뛰어난 소재를 우선하고 있기 때문에 수요 증가가 전망되고 있습니다. 포장에서 EPP 폼은 전자 장비, 가전제품, 신선 제품과 같은 깨지기 쉬운 제품에 우수한 보호를 제공합니다. 전자상거래 산업의 급속한 확대는 보호 포장 솔루션에 대한 수요를 더욱 가속화하고 있습니다. 항공우주 제조업체는 내충격성과 단열성에서 EPP 폼에 대한 의존도를 높이고 있으며, 소비재에서 EPP 폼의 적응성의 높이는 다양한 산업에서 EPP 폼의 중요성을 돋보이게 하고 있습니다.

미국의 발포 폴리프로필렌(EPP) 폼 시장은 2024년에 1억 260만 달러를 창출했고 향후 수년간 크게 성장할 전망입니다. 경량으로 에너지 흡수성이 높은 소재를 우선하는 호조 자동차 산업이 이 성장의 주요 원동력이 되고 있습니다. 게다가 급성장하는 전자상거래 부서는 소비자의 구매 행동 변화에 맞추어 고급 보호 포장의 필요성을 부추기고 있습니다. 미국에는 선진적인 제조 시설이 있어 기술 혁신에 중점을 두고 있기 때문에 세계의 발포 폴리프로필렌(EPP) 폼 시장에서 주도적인 지위를 더욱 견고하게 하고 있습니다. 고성능, 지속가능한 소재에 대한 수요가 계속 증가하고 있는 가운데, EPP 폼은 여러 산업에서 더욱 큰 역할을 하고 장기적인 시장 확대를 촉진할 것으로 예상됩니다.

목차

제1장 조사 방법과 조사 범위

- 시장 범위와 정의

- 기본 추정과 계산

- 예측 계산

- 데이터 소스

- 1차 데이터

- 2차 자료

- 유료 소스

- 공적 소스

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 밸류체인에 영향을 주는 요인

- 이익률 분석

- 파괴적 혁신

- 향후 전망

- 제조업체

- 유통업체

- 공급업체 상황

- 이익률 분석

- 주요 뉴스

- 규제 상황

- 영향요인

- 성장 촉진요인

- 업계의 잠재적 위험 및 과제

- 잠재성장력 분석

- Porter's Five Forces 분석

- PESTEL 분석

제4장 경쟁 구도

- 서론

- 기업 점유율 분석

- 경쟁 포지셔닝 매트릭스

- 전략 전망 매트릭스

제5장 시장 추계·예측 : 유형별(2021-2034년)

- 주요 동향

- 비즈 폼

- 성형 폼

- 제작 폼

- 자동차 폼

- 기타

제6장 시장 추계·예측 : 용도별(2021-2034년)

- 주요 동향

- 자동차

- 포장

- 소비재

- 항공우주

- 건축 및 건설

- 스포츠 및 레저

- 기타

제7장 시장 추계·예측 : 최종 용도별(2021-2034년)

- 주요 동향

- 자동차

- 전자기기

- 의료

- 포장

- 항공우주

- 건설

- 기타

제8장 시장 추계·예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 영국

- 독일

- 프랑스

- 이탈리아

- 스페인

- 러시아

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주

- 라틴아메리카

- 브라질

- 멕시코

- 중동 및 아프리카

- 남아프리카

- 사우디아라비아

- 아랍에미리트(UAE)

제9장 기업 프로파일

- JSP Corporation

- BASF SE

- Kaneka Corporation

- Furukawa Electric Co.

- DS Smith PLC

- Hanwha Corporation

- Sonoco Products Company

- The Woodbridge Group

- Knauf Industries GmbH

- Greiner Holding AG

- Recticel NV

- Armacell International GmbH

- Zotefoams plc

- Swedfoam AB

- FoamPartner AG

The Global Expanded Polypropylene Foam Market reached USD 460.6 million in 2024 and is projected to expand at a CAGR of 7.1% between 2025 and 2034. This growth is largely driven by increasing demand from key industries such as automotive, packaging, aerospace, and consumer goods. As businesses continue to seek lightweight and high-performance materials, EPP foam stands out for its exceptional cushioning, impact resistance, and energy absorption capabilities. These properties make it an indispensable material across multiple sectors, especially in industries where weight reduction and durability are critical.

EPP foam's growing popularity stems from its versatility and superior performance compared to conventional foam materials. It is widely recognized for its high strength-to-weight ratio, thermal insulation, and recyclability, aligning with the global push toward sustainability. With stringent regulations encouraging eco-friendly materials, manufacturers are integrating EPP foam into their products to meet evolving industry standards. Additionally, advancements in manufacturing techniques are enhancing product quality, customization options, and cost-efficiency, further fueling its adoption.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $460.6 Million |

| Forecast Value | $915.2 Million |

| CAGR | 7.1% |

Market segmentation by type includes bead foam, molded foam, fabricated foam, automotive foam, and others. Among these, molded foam dominated in 2024, accounting for USD 194.1 million. Bead foam, widely used in automotive, packaging, and electronics, is valued for its shock-absorbing and insulating properties. Fabricated foam, known for its customization capabilities, serves industries requiring tailored solutions, such as medical devices and protective packaging. The diverse range of EPP foam types ensures a steady market expansion, catering to industry-specific demands while supporting the transition toward lightweight, high-performance materials.

The market is also segmented by application, with categories including vehicles, packaging, consumer goods, aerospace, building and construction, sports and leisure, and others. Vehicles accounted for a substantial 37.1% market share in 2024, with demand expected to rise as automakers continue prioritizing energy-efficient and impact-resistant materials. In packaging, EPP foam provides superior protection for fragile goods such as electronics, appliances, and perishables. The rapid expansion of the e-commerce industry has further accelerated its demand for protective packaging solutions. Aerospace manufacturers increasingly rely on EPP foam for impact resistance and thermal insulation, while its adaptability in consumer goods highlights its importance across various industries.

The U.S. expanded polypropylene foam market generated USD 102.6 million in 2024 and is poised for significant growth in the coming years. A strong automotive industry, prioritizing lightweight and energy-absorbing materials, remains a primary driver of this growth. Additionally, the booming e-commerce sector has fueled the need for advanced protective packaging, aligning with shifting consumer purchasing behaviors. The presence of advanced manufacturing facilities and a focus on innovation in the U.S. further solidify the country's leading position in the global EPP foam market. As demand for high-performance and sustainable materials continues to rise, EPP foam is expected to play an even greater role across multiple industries, driving long-term market expansion.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Supplier landscape

- 3.3 Profit margin analysis

- 3.4 Key news & initiatives

- 3.5 Regulatory landscape

- 3.6 Impact forces

- 3.6.1 Growth drivers

- 3.6.2 Industry pitfalls & challenges

- 3.7 Growth potential analysis

- 3.8 Porter’s analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Type, 2021-2034 (USD Million) (Kilo Tons)

- 5.1 Key trends

- 5.2 Bead foam

- 5.3 Molded foam

- 5.4 Fabricated foam

- 5.5 Automotive foam

- 5.6 Others

Chapter 6 Market Estimates & Forecast, By Application, 2021-2034 (USD Million) (Kilo Tons)

- 6.1 Key trends

- 6.2 Vehicle

- 6.3 Packaging

- 6.4 Consumer goods

- 6.5 Aerospace

- 6.6 Building & construction

- 6.7 Sports & leisure

- 6.8 Others

Chapter 7 Market Estimates & Forecast, By End Use, 2021-2034 (USD Million) (Kilo Tons)

- 7.1 Key trends

- 7.2 Automotive

- 7.3 Electronics

- 7.4 Medical

- 7.5 Packaging

- 7.6 Aerospace

- 7.7 Construction

- 7.8 Others

Chapter 8 Market Estimates & Forecast, By Region, 2021-2034 (USD Million) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 UK

- 8.3.2 Germany

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Russia

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 South Korea

- 8.4.5 Australia

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.6 MEA

- 8.6.1 South Africa

- 8.6.2 Saudi Arabia

- 8.6.3 UAE

Chapter 9 Company Profiles

- 9.1 JSP Corporation

- 9.2 BASF SE

- 9.3 Kaneka Corporation

- 9.4 Furukawa Electric Co.

- 9.5 DS Smith PLC

- 9.6 Hanwha Corporation

- 9.7 Sonoco Products Company

- 9.8 The Woodbridge Group

- 9.9 Knauf Industries GmbH

- 9.10 Greiner Holding AG

- 9.11 Recticel NV

- 9.12 Armacell International GmbH

- 9.13 Zotefoams plc

- 9.14 Swedfoam AB

- 9.15 FoamPartner AG