|

시장보고서

상품코드

1699320

검사 로봇 시장 기회, 성장 촉진요인, 산업 동향 분석, 예측(2025-2034년)Inspection Robots Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025-2034 |

||||||

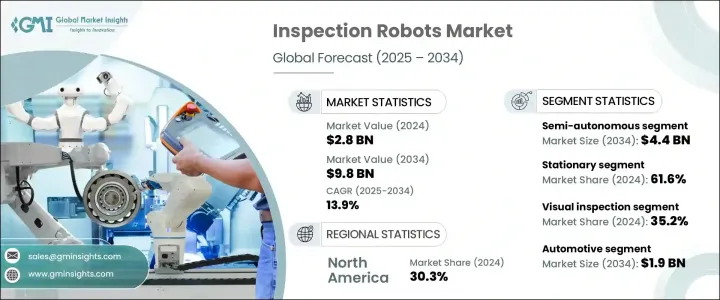

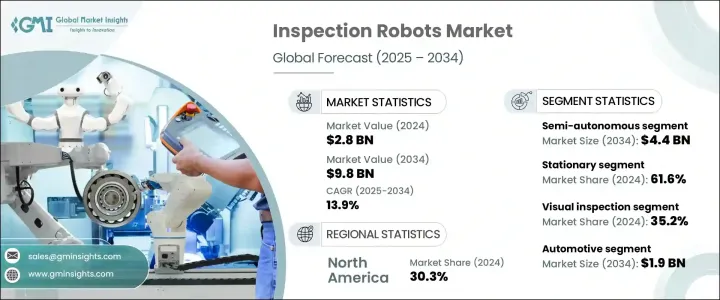

검사 로봇 세계 시장은 2024년 28억 달러로 평가되며, 2025년부터 2034년까지 연평균 13.9%의 성장률을 보일 것으로 예상됩니다.

효율성 향상, 운영 리스크 감소, 진화하는 안전 규정 준수를 위해 업계 전반에 걸쳐 채택이 증가하면서 성장의 원동력이 되고 있습니다. 제조, 에너지, 인프라 분야의 기업들은 워크플로우를 간소화하고, 다운타임을 최소화하며, 엄격한 산업 표준을 준수하기 위해 검사 로봇을 업무에 도입하고 있습니다.

자동화와 고정밀도가 우선시되는 가운데, 검사 로봇은 유지보수 및 품질 관리에서 중요한 역할을 하고 있습니다. 이러한 첨단 시스템은 정확성과 신뢰성을 높이고 수작업 검사에 따른 제약 사항을 제거합니다. 조직은 비파괴 검사, 실시간 분석, 예지보전에 대한 수요 증가에 대응하기 위해 로봇을 활용하고 있습니다. 인공지능(AI)과 머신러닝(ML) 기술에 대한 투자 증가는 로봇 검사 시스템의 기술 혁신을 더욱 촉진하여 자율적인 의사결정과 적응형 학습을 가능하게 하고 있습니다. 위험하고 접근하기 어려운 환경에서 지속적인 모니터링의 필요성은 기업이 업무 성과를 최적화하고 작업장 안전을 개선하는 동시에 작업장 안전을 향상시키려는 노력으로 인해 수요가 가속화되고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 28억 달러 |

| 예상 금액 | 98억 달러 |

| CAGR | 13.9% |

시장 세분화에는 비자율형 로봇, 반자율형 로봇, 완전 자율형 로봇, 완전 자율형 로봇이 포함됩니다. 반자율형 부문은 2034년까지 44억 달러에 달할 것으로 예상되며, 자동화와 인간 모니터링의 균형을 맞출 수 있는 능력으로 인해 상당한 도입이 예상됩니다. 이러한 시스템은 위험도가 높은 산업에서 특히 가치가 높으며, AI가 지원하는 의사결정을 통해 인간 운영자는 필요한 경우에만 개입할 수 있습니다. 복잡한 환경에서도 상시 모니터링 없이 작동할 수 있는 AI는 중요한 업무에 대한 통제력을 유지하면서 효율성을 높이고자 하는 기업에게 매력적인 선택이 될 수 있습니다.

기술별로 보면 시장은 고정형 검사 로봇과 이동형 검사 로봇으로 구분되며, 2024년에는 고정형 로봇이 고정밀도와 자동화 제조 환경과의 원활한 통합으로 인해 시장 점유율의 61.6%를 차지했습니다. 이러한 로봇은 정밀한 품질 관리가 요구되는 산업에서 고정밀 결함 감지 및 실시간 성능 모니터링을 제공하여 필수적인 역할을 수행합니다. 비파괴 검사 및 고속 평가 기술에 대한 중요성이 부각되면서 도입에 박차를 가하고 있습니다. 제조업체들은 오류 감소와 작업 효율을 우선시하고 있으며, 고정형 검사 로봇은 최신 생산 라인에 필수적인 요소로 자리 잡고 있습니다.

미국 검사 로봇 시장은 2034년 28억 달러 규모에 달할 것으로 예상되는 등 큰 폭의 성장이 예상됩니다. 제조업의 자동화 의존도가 높아지고 결함 감지 및 품질 보증에 대한 관심이 높아지면서 로봇 검사 시스템의 도입이 가속화되고 있습니다. 기업들은 생산성 향상, 다운타임 최소화, 업무 효율성 최적화를 위해 첨단 로봇 기술에 투자하고 있습니다. 자동화가 산업 워크플로우를 지속적으로 변화시키고 있는 가운데, 로봇 검사 시스템은 일관된 품질과 탁월한 운영을 보장하는 필수적인 구성요소로 부상하고 있습니다.

목차

제1장 조사 방법과 조사 범위

제2장 주요 요약

제3장 업계 인사이트

- 업계 생태계 분석

- 업계에 대한 영향요인

- 성장 촉진요인

- 서비스 로봇 판매와 도입 증가

- 드론이나 모바일 로봇 원격 검사에 대한 이용 증가

- 스마트 매뉴팩처링과 인더스트리 4.0이니셔티브 성장

- 석유 및 가스, 에너지 분야 확대

- 각 업계의 엄격한 안전·품질 규제

- 업계의 잠재적 리스크·과제

- 중소기업 에서는 높은 도입 비용

- 복잡성과 통합 어려움

- 성장 촉진요인

- 성장 가능성 분석

- 규제 상황

- 기술 상황

- 향후 시장 동향

- 격차 분석

- Porters 분석

- PESTEL 분석

제4장 경쟁 구도

- 소개

- 기업 시장 점유율 분석

- 주요 시장 기업 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 전략 대시보드

제5장 시장 추정과 예측 : 유형별, 2021-2034년

- 주요 동향

- 비자율형

- 반자율형

- 완전 자율형

제6장 시장 추정과 예측 : 기술별, 2021-2034년

- 주요 동향

- 고정형

- 이동형

제7장 시장 추정과 예측 : 용도별, 2021-2034년

- 주요 동향

- 육안 검사

- 초음파 검사

- 레이저 스캔 검사

- 열검사

- 품질 검사

제8장 시장 추정과 예측 : 최종 이용 산업별, 2021-2034년

- 주요 동향

- 자동차

- 건설

- 식품 및 음료

- 제조업

- 석유 및 가스

- 전력

- 기타

제9장 시장 추정과 예측 : 지역별, 2021-2034년

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 스페인

- 이탈리아

- 네덜란드

- 아시아태평양

- 중국

- 인도

- 일본

- 호주

- 한국

- 라틴아메리카

- 브라질

- 멕시코

- 아르헨티나

- 중동 및 아프리카

- 사우디아라비아

- 남아프리카공화국

- 아랍에미리트

제10장 기업 개요

- ABB

- Cognex

- Denso Wave

- DSI Robotics

- Energy Robotics

- Fanuc

- Honeybee Robotics

- Innok Robotics

- JH Robotics

- Kuka

- Mitsubishi Heavy Industries

- Nexxis

- Robotnik Automation

- Staubli

- Superdroid Robotics

- Universal Robots

The Global Inspection Robots Market, valued at USD 2.8 billion in 2024, is set to expand at a CAGR of 13.9% from 2025 to 2034. The growth is driven by increasing adoption across industries seeking to enhance efficiency, reduce operational risks, and comply with evolving safety regulations. Businesses across manufacturing, energy, and infrastructure sectors are integrating inspection robots into their operations to streamline workflows, minimize downtime, and ensure compliance with stringent industry standards.

With industries prioritizing automation and precision, inspection robots are playing a critical role in maintenance and quality control. These advanced systems offer enhanced accuracy and reliability, eliminating the limitations associated with manual inspections. Organizations are leveraging robotics to meet growing demands for non-destructive testing, real-time analytics, and predictive maintenance. Increasing investments in artificial intelligence (AI) and machine learning (ML) technologies are further driving innovation in robotic inspection systems, enabling autonomous decision-making and adaptive learning. The need for continuous monitoring in hazardous and hard-to-reach environments is accelerating demand as companies aim to improve workplace safety while optimizing operational performance.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.8 Billion |

| Forecast Value | $9.8 Billion |

| CAGR | 13.9% |

Market segmentation by type includes non-autonomous, semi-autonomous, and fully autonomous robots. The semi-autonomous segment is expected to reach USD 4.4 billion by 2034, witnessing significant adoption due to its ability to strike a balance between automation and human oversight. These systems are particularly valuable in high-risk industries, where AI-assisted decision-making allows human operators to intervene only when necessary. Their ability to function in complex environments without constant supervision makes them an attractive choice for businesses seeking to enhance efficiency while maintaining control over critical operations.

Based on technology, the market is segmented into stationary and mobile inspection robots. In 2024, stationary systems accounted for 61.6% of the market share, gaining traction due to their high precision and seamless integration into automated manufacturing environments. These robots play an essential role in industries that demand meticulous quality control, offering high-accuracy defect detection and real-time performance monitoring. The growing emphasis on non-destructive testing and high-speed evaluation techniques is further fueling adoption. Manufacturers are prioritizing error reduction and operational efficiency, making stationary inspection robots indispensable across modern production lines.

The US inspection robots market is poised for substantial growth, projected to reach USD 2.8 billion by 2034. Increasing reliance on automation in manufacturing, coupled with a strong focus on defect detection and quality assurance, is accelerating the deployment of robotic inspection systems. Companies are investing in advanced robotic technologies to enhance productivity, minimize downtime, and optimize operational efficiency. As automation continues to transform industrial workflows, robotic inspection systems are emerging as an essential component in ensuring consistent quality and operational excellence.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Base estimates and calculations

- 1.3.1 Base year calculation

- 1.3.2 Key trends for market estimation

- 1.4 Forecast model

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Increased sales and adoption of service robots

- 3.2.1.2 Increasing use of drones and mobile robots for remote inspections

- 3.2.1.3 Growth in smart manufacturing and industry 4.0 initiatives

- 3.2.1.4 Expansion of the oil & gas and energy sectors

- 3.2.1.5 Stringent safety and quality regulations across industries

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High deployment cost for SME

- 3.2.2.2 Complexity & integration difficulties

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.5 Technology landscape

- 3.6 Future market trends

- 3.7 Gap analysis

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategy dashboard

Chapter 5 Market Estimates and Forecast, By Type, 2021 – 2034 (USD Bn)

- 5.1 Key trends

- 5.2 Non-autonomous

- 5.3 Semi-autonomous

- 5.4 Fully autonomous

Chapter 6 Market Estimates and Forecast, By Technology , 2021 – 2034 (USD Bn)

- 6.1 Key trends

- 6.2 Stationary

- 6.3 Mobile

Chapter 7 Market Estimates and Forecast, By Application, 2021 – 2034 (USD Bn)

- 7.1 Key trends

- 7.2 Visual inspection

- 7.3 Ultrasonic inspection

- 7.4 Laser scanning inspection

- 7.5 Thermal inspection

- 7.6 Quality inspection

Chapter 8 Market Estimates and Forecast, By End Use Industry, 2021 – 2034 (USD Bn)

- 8.1 Key trends

- 8.2 Automotive

- 8.3 Construction

- 8.4 Food & beverages

- 8.5 Manufacturing

- 8.6 Oil & gas

- 8.7 Power

- 8.8 Others

Chapter 9 Market Estimates and Forecast, By Region, 2021 – 2034 (USD Bn)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Spain

- 9.3.5 Italy

- 9.3.6 Netherlands

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 Middle East and Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

Chapter 10 Company Profiles

- 10.1 ABB

- 10.2 Cognex

- 10.3 Denso Wave

- 10.4 DSI Robotics

- 10.5 Energy Robotics

- 10.6 Fanuc

- 10.7 Honeybee Robotics

- 10.8 Innok Robotics

- 10.9 JH Robotics

- 10.10 Kuka

- 10.11 Mitsubishi Heavy Industries

- 10.12 Nexxis

- 10.13 Robotnik Automation

- 10.14 Staubli

- 10.15 Superdroid Robotics

- 10.16 Universal Robots