|

시장보고서

상품코드

1721477

생체 적합성 3D 프린팅 재료 시장 기회, 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Biocompatible 3D Printing Materials Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

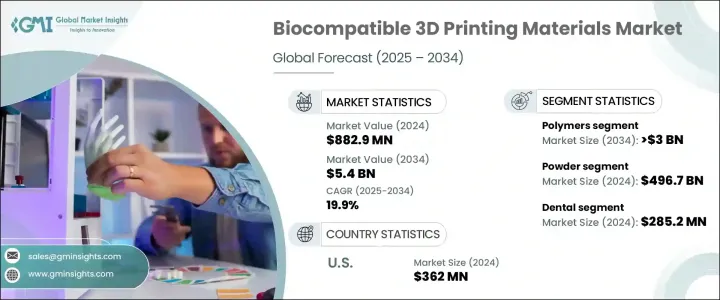

세계의 생체 적합성 3D 프린팅 재료 시장은 2024년에는 8억 8,290만 달러로 평가되었고 CAGR 19.9%를 나타내 2034년에는 54억 달러에 이를 것으로 추정되고 있습니다. 고령화 인구 증가는 다양한 건강 관리 응용 분야에서 3D 인쇄 재료를 채택하는 데 박차를 가하고 있습니다. 정형외과 및 의지 장비 외에도 이 재료는 치과 치료, 수술기구, 조직 비계 및 재생 의학에서 광범위하게 지지를 받고 있습니다. 시장은 선진국과 신흥 경제 국가들 모두에서 엄청난 추세를 보이고 있습니다.

시장의 성장은 선택적 레이저 소결(SLS), 스테레오 리소그래피(SLA), 직접 메탈 레이저 소결(DMLS) 등의 적층 조형 기술의 급속한 진보에도 크게 기인하고 있습니다. 성능 금속 합금, 폴리머, 바이오잉크의 개발에 의해 인쇄된 바이오메디컬 제품의 신뢰성, 내구성, 적합성이 향상해, 재료의 혁신이 시장 확대에 한층 더 기여하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 8억 8,290만 달러 |

| 예측 금액 | 54억 달러 |

| CAGR | 19.9% |

시장은 고분자, 금속 및 기타 재료 유형으로 구분되며 고분자 카테고리가 향후 성장을 이끌 것으로 예측됩니다. 이 부문은 2034년까지 19.9%의 연평균 성장률을 나타내 30억 달러에 달할 것으로 예상됩니다. 사용자 정의된 3D 프린팅 폴리머에 대한 수요 증가는 환자 고유의 임플란트, 치과 수복물, 보철 장치의 제조에 있어서 현저합니다.

치과 분야는 2024년 2억 8,520만 달러를 차지했으며, 치아 상실, 치주병, 우식과 같은 증상의 유병률 증가에 견인되어 꾸준히 확대되고 있습니다. SLA, 디지털 라이트 프로세싱(DLP), SLS 등의 기술은 치과 수복물의 정확성, 강도 및 적합성을 극적으로 개선하여 치과 전문가와 환자 수요를 밀어 올리고 있습니다.

미국의 생체 적합성 3D 프린팅 재료 시장은 2024년 3억 6,200만 달러로 평가되었으며, 고령화로 인한 치과 및 정형외과적 문제의 위험이 증가함에 따라 큰 성장을 이루고 있습니다. 맞춤형 보철물과 임플란트를 신속하게 제조할 수 있기 때문에 전국의 의료 시설에서 3D 프린팅의 도입이 가속화되고 있습니다.

시장 주요 기업으로는 Stratasys, 3D Systems, GE Additive, Formlabs, Materialises, Renishaw, Royal DSM, Arkema, Solvay, Cellink, Concept Laser, EOS, Evonik Industries, EnvisionTEC, Hoganas 등이 있습니다. 이러한 기업들은 생체 적합성과 응용 정밀도를 향상시키기 위해 첨단 고성능 소재에 적극적으로 투자하고 있습니다. 의료 제공업체 및 연구 기관과의 전략적 제휴는 3D 프린팅의 임상적 유용성을 확대하는 데 도움이 됩니다. 게다가 혁신적이고 병태에 특화된 솔루션에 초점을 맞춘 지속적인 제품 개발로 시장 리더기업은 세계적인 사업 전개와 경쟁력 강화를 도모하고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 업계에 미치는 영향요인

- 성장 촉진요인

- 헬스케어 업계에 있어서 생체 적합성 3D 프린팅 수요 증가

- 3D 프린팅 재료의 기술적 진보

- 맞춤형 의료 도입 확대

- 업계의 잠재적 위험 및 과제

- 생체 적합성 3D 프린팅 재료의 높은 비용

- 엄격한 규제 요건

- 성장 촉진요인

- 성장 가능성 분석

- 규제 상황

- 기술 환경

- 향후 시장 동향

- 갭 분석

- Porter's Five Forces 분석

- PESTEL 분석

제4장 경쟁 구도

- 서론

- 기업 시장 점유율 분석

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 전략 대시보드

제5장 시장 추계·예측 : 재료 유형별(2021-2034년)

- 주요 동향

- 폴리머

- 금속

- 기타 재료 유형

제6장 시장 추계·예측 : 형태별(2021-2034년)

- 주요 동향

- 분말

- 액체

- 기타 형식

제7장 시장 추계·예측 : 용도별(2021-2034년)

- 주요 동향

- 치과

- 약물전달 시스템

- 수술기구 및 임플란트

- 조직공학

- 심혈관

- 정형외과

- 기타 용도

제8장 시장 추계·예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 스페인

- 이탈리아

- 네덜란드

- 아시아태평양

- 중국

- 일본

- 인도

- 호주

- 한국

- 라틴아메리카

- 브라질

- 멕시코

- 아르헨티나

- 중동 및 아프리카

- 남아프리카

- 사우디아라비아

- 아랍에미리트(UAE)

제9장 기업 프로파일

- Arkema

- BIO INX

- Cellink

- EnvisionTEC

- EOS

- Evonik Industries

- Formlabs

- GE Additive

- Hoganas

- Materialise

- Renishaw

- Royal DSM

- Solvay

- Stratasys

- 3D Systems

The Global Biocompatible 3D Printing Materials Market was valued at USD 882.9 million in 2024 and is estimated to grow at a CAGR of 19.9% to reach USD 5.4 billion by 2034. This growth trajectory reflects the rising demand for next-generation medical materials that offer high levels of precision, performance, and patient compatibility. The increasing need for advanced medical interventions, particularly among the aging population, is fueling the adoption of 3D-printed materials across a variety of healthcare applications. As global healthcare systems pivot toward more patient-centric approaches, the use of biocompatible 3D printing materials is becoming critical in delivering customized, efficient, and minimally invasive medical solutions. In addition to orthopedics and prosthetics, the materials are gaining widespread traction in dental care, surgical tools, tissue scaffolds, and regenerative medicine. The ability of these materials to support complex geometries, enhance surgical outcomes, and reduce recovery times positions them as essential components in modern medical manufacturing. With favorable regulatory policies, growing R&D investments, and expanding awareness about personalized healthcare, the market continues to experience substantial momentum across both developed and emerging economies.

The market's growth is also largely attributed to rapid advancements in additive manufacturing techniques, including Selective Laser Sintering (SLS), Stereolithography (SLA), and Direct Metal Laser Sintering (DMLS). These technologies enable the production of highly accurate and biocompatible medical components that align with individual anatomical requirements. Material innovations further contribute to market expansion, with the development of high-performance metal alloys, polymers, and bioinks improving the reliability, durability, and compatibility of printed biomedical products. These breakthroughs are particularly relevant in creating functional implants, prosthetics, and surgical tools that offer improved performance and reduced complication rates.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $882.9 Million |

| Forecast Value | $5.4 Billion |

| CAGR | 19.9% |

The market is segmented into polymers, metals, and other material types, with the polymers category expected to lead future growth. This segment is projected to reach USD 3 billion by 2034, growing at a CAGR of 19.9%. The rising demand for customized 3D-printed polymers is evident in the production of patient-specific implants, dental restorations, and prosthetic devices. Advanced materials such as Polyether Ether Ketone (PEEK), Polylactic Acid (PLA), and bioresorbable polymers are gaining ground due to their superior strength, biocompatibility, and adaptability to complex medical requirements.

The dental sector accounted for USD 285.2 million in 2024 and is expanding steadily, driven by the increasing prevalence of conditions like tooth loss, periodontal diseases, and dental caries. Technologies such as SLA, Digital Light Processing (DLP), and SLS have dramatically improved the precision, strength, and fit of dental restorations, boosting demand among dental professionals and patients alike.

The U.S. Biocompatible 3D Printing Materials Market was valued at USD 362 million in 2024 and is experiencing significant growth due to the aging population's heightened risk of dental and orthopedic issues. The ability to rapidly manufacture tailored prosthetics and implants has accelerated the adoption of 3D printing in medical facilities across the country.

Key players in the global market include Stratasys, 3D Systems, GE Additive, Formlabs, Materialise, Renishaw, Royal DSM, Arkema, Solvay, Cellink, Concept Laser, EOS, Evonik Industries, EnvisionTEC, and Hoganas. These companies are actively investing in advanced, high-performance materials to improve biocompatibility and application precision. Strategic collaborations with healthcare providers and research organizations are helping to expand the clinical utility of 3D printing. Moreover, ongoing product development focused on innovative, condition-specific solutions is allowing market leaders to enhance their global footprint and competitive positioning.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Base estimates and calculations

- 1.3.1 Base year calculation

- 1.3.2 Key trends for market estimation

- 1.4 Forecast model

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Increasing demand of biocompatible 3D printing in healthcare industry

- 3.2.1.2 Technological advancements in 3D printing materials

- 3.2.1.3 Growing adoption of personalized medicine

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High cost of biocompatible 3D printing materials

- 3.2.2.2 Stringent regulatory requirements

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.5 Technology landscape

- 3.6 Future market trends

- 3.7 Gap analysis

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Strategy dashboard

Chapter 5 Market Estimates and Forecast, By Material Type, 2021 - 2034 ($ Mn)

- 5.1 Key trends

- 5.2 Polymers

- 5.3 Metals

- 5.4 Other material types

Chapter 6 Market Estimates and Forecast, By Form, 2021 - 2034 ($ Mn)

- 6.1 Key trends

- 6.2 Powder

- 6.3 Liquid

- 6.4 Other forms

Chapter 7 Market Estimates and Forecast, By Application, 2021 - 2034 ($ Mn)

- 7.1 Key trends

- 7.2 Dental

- 7.3 Drug delivery systems

- 7.4 Surgical tools and implants

- 7.5 Tissue engineering

- 7.6 Cardiovascular

- 7.7 Orthopedic

- 7.8 Other applications

Chapter 8 Market Estimates and Forecast, By Region, 2021 - 2034 ($ Mn)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Netherlands

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 Japan

- 8.4.3 India

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.6 Middle East and Africa

- 8.6.1 South Africa

- 8.6.2 Saudi Arabia

- 8.6.3 UAE

Chapter 9 Company Profiles

- 9.1 Arkema

- 9.2 BIO INX

- 9.3 Cellink

- 9.4 EnvisionTEC

- 9.5 EOS

- 9.6 Evonik Industries

- 9.7 Formlabs

- 9.8 GE Additive

- 9.9 Hoganas

- 9.10 Materialise

- 9.11 Renishaw

- 9.12 Royal DSM

- 9.13 Solvay

- 9.14 Stratasys

- 9.15 3D Systems