|

시장보고서

상품코드

1721554

광업용 펌프 시장 기회, 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Mining Pump Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

세계의 광업용 펌프 시장은 2024년에는 71억 달러로 평가되었고, CAGR 4.9%를 나타내 2034년에는 115억 달러에 이를 것으로 추정되고 있습니다. 제조업체가 운용 코스트를 최소한으로 억제하면서 생산성을 최적화하려고 하는 중, 기술적으로 고도의 광업용 펌프에 수요가 높아지고 있습니다. 이 수요는 확대하는 전기자동차(EV) 산업, 재생 가능 에너지 프로젝트, 인프라 개발 이니셔티브에 의해 더욱 증폭되고 있습니다. 우리는 광업용 펌프 제조업체에 큰 비즈니스 기회를 제공합니다. 채굴 프로세스의 자동화와 디지털화가 진행됨에 따라 실시간으로 모니터링하고 가동 중지 시간을 줄이는 지능형 펌프 솔루션이 필요합니다.

광업용 펌프 시장의 성장은 주로 채굴 작업 증가, 효율적인 워터 핸들링 시스템의 필요성, 배터리 재료의 세계 수요의 급증에 의해 초래되고 있습니다. 이 솔루션은 특히 수분, 슬러리 이동 및 폐기물 처리 작업에서 이러한 목표를 달성하는 데 있어 매우 중요한 역할을 하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 71억 달러 |

| 예측 금액 | 115억 달러 |

| CAGR | 4.9% |

광업용 펌프 시장은 원심 펌프, 탈수 펌프, 슬러리 펌프, 다단 펌프, 다이어프램 펌프 등, 펌프 유형별로 구분됩니다. 랠리의 이송, 장거리의 유체 이송 등의 작업에 광업에서 널리 사용되고 있습니다. 그 수요는 범용성과 비용 효율에 뒷받침되고 있습니다.

정격 출력에 관해서는 시장에는 100HP 미만, 100-500HP, 500HP 이상의 펌프가 포함됩니다. 적당한 가격, 적응성, 엄격한 현장 조건 하에서의 운전 능력으로 인해 소규모 사업에서 일반적으로 사용되고 있습니다.

미국의 광업용 펌프 시장은 2024년에 15억 달러를 창출했는데 펌프 기술의 진보, 채굴 활동의 확대, 광물 수요 증가가 그 원동력이 되었습니다. 중요한 광물에 대한 수요가 국내와 세계에서 증가하는 동안, 미국의 채굴 사업은 성장을 계속하고 현대의 지속가능성과 효율성의 목표에 따라 고성능 펌프의 필요성을 밀어 올리고 있습니다.

세계의 광업용 펌프 시장 주요 기업으로는 Sulzer, The Weir Group, Xylem, KSB, Schurco Slurry, Multotec Group, 에바라 제작소, The Gorman-Rupp Company, Flowserve Corporation, Grundfos Holding, 츠루미 제작소, NETZSCH Pumpen & Systeme Corporation 등이 있습니다. 이 회사는 경쟁력을 강화하기 위해 기술 혁신을 활용하고 에너지 효율적인 펌프에 주력하고 예지 보전과 실시간 성능 추적을 지원하는 IoT 대응 기술을 통합하고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 밸류체인에 영향을 주는 요인

- 이익률 분석

- 파괴적 혁신

- 향후 전망

- 제조업체

- 유통업체

- 소매업체

- 영향요인

- 성장 촉진요인

- 광물과 금속에 대한 세계 수요 증가

- 기술적 진보

- 폐수 관리에의 경향

- 채굴 사업 확대

- 업계의 잠재적 위험 및 과제

- 빈번한 유지보수와 교환

- 변동하는 가격

- 성장 촉진요인

- 기술 및 혁신 전망

- 소비자 구매 행동 분석

- 인구 동향

- 구매결정에 영향을 미치는 요인

- 소비자 제품의 채용

- 우선 유통 채널

- 성장 가능성 분석

- 규제 상황

- 가격 분석

- Porter's Five Forces 분석

- PESTEL 분석

제4장 경쟁 구도

- 서론

- 기업의 시장 점유율 분석

- 경쟁 포지셔닝 매트릭스

- 전략적 전망 매트릭스

제5장 시장 추계·예측 : 펌프 유형별(2021-2034년)

- 주요 동향

- 원심 펌프

- 탈수 펌프

- 슬러리 펌프

- 다단 펌프

- 다이어프램 펌프

- 기타(피스톤 펌프, 연동 펌프 등)

제6장 시장 추계·예측 : 전원별(2021-2034년)

- 주요 동향

- 전기 및 태양열 펌프

- 디젤 펌프

- 기타(가솔린 태양열 등)

제7장 시장 추계·예측 : 유량별(2021-2034년)

- 주요 동향

- 100m³/h 이하

- 100-500 m³/h

- 500m³/h 이상

제8장 시장 추계·예측 : 마력별(2021-2034년)

- 주요 동향

- 100HP 이하

- 100-500마력

- 500HP 이상

제9장 시장 추계·예측 : 기술별(2021-2034년)

- 주요 동향

- 기존

- 스마트

제10장 시장 추계·예측 : 용도별(2021-2034년)

- 주요 동향

- 광산 탈수

- 광물 처리

- 물 및 폐수 처리

- 먼지 억제

- 기타(윤활 등)

제11장 시장 추계·예측 : 유통 채널별(2021-2034년)

- 주요 동향

- 직접

- 간접

제12장 시장 추계·예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 이탈리아

- 스페인

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 라틴아메리카

- 브라질

- 멕시코

- 중동 및 아프리카

- 사우디아라비아

- 아랍에미리트(UAE)

- 남아프리카

제13장 기업 프로파일

- Ebara Corporation

- Flowserve Corporation

- Grundfos Holding

- Gorman-Rupp

- JEE Pumps

- KSB

- Metso Outotec Corporation

- Multotec Group

- NETZSCH Pumps &Systems

- Schurco Slurry

- Sulzer

- The Gorman-Rupp Company

- The Weir Group

- Tsurumi Manufacturing

- Xylem

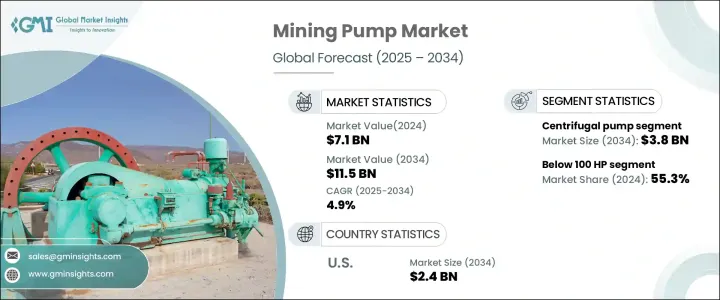

The Global Mining Pump Market was valued at USD 7.1 billion in 2024 and is estimated to grow at a CAGR of 4.9% to reach USD 11.5 billion by 2034. This steady growth trajectory reflects a broader industry shift toward sustainable and high-efficiency solutions that support modern mining needs. As governments across the globe push for greener infrastructure and manufacturers seek to optimize productivity while minimizing operational costs, the demand for technologically advanced mining pumps is rising. With growing industrialization, particularly in emerging economies, the global appetite for minerals and metals such as copper, lithium, nickel, and cobalt continues to surge. This demand is further amplified by the expanding electric vehicle (EV) industry, renewable energy projects, and infrastructure development initiatives. The mining industry, responding to this momentum, is ramping up activities to ensure consistent raw material supply, which in turn is creating substantial opportunities for mining pump manufacturers. As mining processes become increasingly automated and digitized, the need for intelligent pumping solutions that offer real-time monitoring and reduced downtime is more critical than ever.

The growth of the mining pump market is primarily driven by increasing mining operations, the need for efficient water handling systems, and the surging global demand for battery materials. Mining companies are investing heavily in advanced machinery to improve productivity, reduce energy consumption, and meet environmental regulations. Effective pumping solutions play a pivotal role in achieving these goals, especially in water extraction, slurry movement, and waste handling operations. The rising need for durable, high-performance, and energy-efficient pumps is compelling manufacturers to integrate cutting-edge technologies into their product lines.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $7.1 Billion |

| Forecast Value | $11.5 Billion |

| CAGR | 4.9% |

The mining pump market is segmented by pump type, including centrifugal, dewatering, slurry, multi-stage, and diaphragm pumps. Centrifugal pumps emerged as the top revenue-generating category in 2024, accounting for USD 2.2 billion in value. These pumps are widely used in mining for tasks such as dewatering, transporting abrasive slurries, and transferring fluids over long distances. Their demand is fueled by their versatility and cost-efficiency. With operational costs rising in the mining industry, there is a clear preference for energy-saving centrifugal pumps equipped with advanced control systems and better hydraulic designs.

In terms of power rating, the market includes pumps below 100 HP, between 100-500 HP, and above 500 HP. Pumps below 100 HP dominated the landscape in 2024, holding a 55.3% market share. These pumps are commonly used in small-scale operations due to their affordability, adaptability, and ability to operate under challenging site conditions. They serve various applications such as water transfer, dewatering, and slurry management where lower capacity is sufficient but consistent performance is essential.

The U.S. mining pump market generated USD 1.5 billion in 2024, driven by advancements in pump technologies, expanded mining activities, and rising mineral demand. The country's mining sector remains a crucial component of its economy, supplying raw materials to industries such as construction, automotive, and electronics. As demand for critical minerals increases domestically and globally, U.S. mining operations continue to grow, pushing the need for high-performance pumps that align with modern sustainability and efficiency goals.

Key players in the global mining pump market include Sulzer, The Weir Group, Xylem, KSB, Schurco Slurry, Multotec Group, Ebara Corporation, The Gorman-Rupp Company, Flowserve Corporation, Grundfos Holding, Tsurumi Manufacturing, NETZSCH Pumpen & Systeme, JEE Pumps, and Metso Outotec Corporation. These companies are leveraging innovation to strengthen their competitive edge, focusing on energy-efficient pumps and integrating IoT-enabled technologies that support predictive maintenance and real-time performance tracking.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definition

- 1.2 Base estimates & calculations

- 1.3 Forecast parameters

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factors affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.1.7 Retailers

- 3.2 Impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Increased global demand for minerals and metals

- 3.2.1.2 Technological advancements

- 3.2.1.3 Inclination towards wastewater management

- 3.2.1.4 Expanded mining operations

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 Frequent maintenance and replacement

- 3.2.2.2 Fluctuating prices

- 3.2.1 Growth drivers

- 3.3 Technology & innovation landscape

- 3.4 Consumer buying behavior analysis

- 3.4.1 Demographic trends

- 3.4.2 Factors affecting buying decision

- 3.4.3 Consumer product adoption

- 3.4.4 Preferred distribution channel

- 3.5 Growth potential analysis

- 3.6 Regulatory landscape

- 3.7 Pricing analysis

- 3.8 Porter’s analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Pump Type, 2021 - 2034, (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Centrifugal pump

- 5.3 Dewatering pump

- 5.4 Slurry pump

- 5.5 Multi-Stage pump

- 5.6 Diaphragm pump

- 5.7 Others (Piston Pumps, Peristaltic Pumps, etc.)

Chapter 6 Market Estimates & Forecast, By Power Source, 2021 - 2034, (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Electric & Solar Pumps

- 6.3 Diesel pump

- 6.4 Others (Gasoline Solar, etc.)

Chapter 7 Market Estimates & Forecast, By Flow Rate, 2021 - 2034, (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Below 100 m³/h

- 7.3 100 - 500 m³/h

- 7.4 Above 500 m³/h

Chapter 8 Market Estimates & Forecast, By Horsepower, 2021 - 2034, (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Below 100 HP

- 8.3 100 - 500 HP

- 8.4 Above 500 HP

Chapter 9 Market Estimates & Forecast, By Technology, 2021 - 2034, (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Conventional

- 9.3 Smart

Chapter 10 Market Estimates & Forecast, By Application, 2021 - 2034, (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 Mine dewatering

- 10.3 Mineral processing

- 10.4 Water & Wastewater Treatment

- 10.5 Dust suppression

- 10.6 Others (Lubrication, etc.)

Chapter 11 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034, (USD Billion) (Thousand Units)

- 11.1 Key trends

- 11.2 Direct

- 11.3 Indirect

Chapter 12 Market Estimates & Forecast, By Region, 2021 - 2034, (USD Billion) (Million Units)

- 12.1 Key trends

- 12.2 North America

- 12.2.1 U.S.

- 12.2.2 Canada

- 12.3 Europe

- 12.3.1 Germany

- 12.3.2 UK

- 12.3.3 France

- 12.3.4 Italy

- 12.3.5 Spain

- 12.4 Asia Pacific

- 12.4.1 China

- 12.4.2 India

- 12.4.3 Japan

- 12.4.4 South Korea

- 12.5 Latin America

- 12.5.1 Brazil

- 12.5.2 Mexico

- 12.6 MEA

- 12.6.1 Saudi Arabia

- 12.6.2 UAE

- 12.6.3 South Africa

Chapter 13 Company Profiles (Business Overview, Financial Data, Product Landscape, Strategic Outlook, SWOT Analysis)

- 13.1 Ebara Corporation

- 13.2 Flowserve Corporation

- 13.3 Grundfos Holding

- 13.4 Gorman-Rupp

- 13.5 JEE Pumps

- 13.6 KSB

- 13.7 Metso Outotec Corporation

- 13.8 Multotec Group

- 13.9 NETZSCH Pumps & Systems

- 13.10 Schurco Slurry

- 13.11 Sulzer

- 13.12 The Gorman-Rupp Company

- 13.13 The Weir Group

- 13.14 Tsurumi Manufacturing

- 13.15 Xylem