|

시장보고서

상품코드

1740803

워터리스 염색 기술 시장 : 기회, 성장 촉진요인, 산업 동향 분석, 예측(2025-2034년)Waterless Dyeing Technology Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

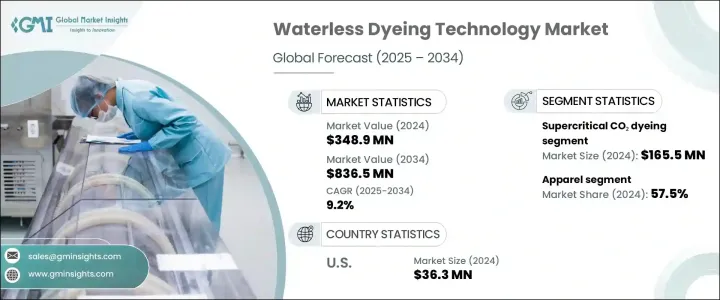

세계의 워터리스 염색 기술 시장은 2024년 3억 4,890만 달러에 달했고, CAGR 9.2%로 성장하여 2034년까지 8억 3,650만 달러에 이를 것으로 예측되고 있습니다.

이 기술을 둘러싼 관심의 높아짐은 특히 과도한 물의 소비와 오염으로 악명 높은 업계에 있어서 환경에 배려한 특성과 강하게 연결되어 있습니다. 물 부족과 오염, 기후 변화에 대한 세계의 우려가 강해지는 가운데, 섬유 산업은 보다 지속 가능한 대체 수단에의 전환을 강요되고 있습니다. 소비자와 규제 당국 모두 수요 증가에 부응하는 미래를 향한 솔루션을 제공합니다. 세계의 의식의 고조와 규제의 압력에 대응하기 위해, 제조업체는 배출량의 삭감, 효율의 향상, 워터 풋 프린트의 삭감을 약속하는 보다 지속 가능한 수법을 채용하고 있습니다.

워터리스 염색 기술 시장은 기술 유형별로 초임계 CO2 염색, 공기 염색, 기타로 구분됩니다. 예측기간 중 CAGR은 약 9.9%를 보일 것으로 예측되고 있습니다. 때문에 섬유에 깊이 침투하고 효율적으로 색상을 흡수할 수 있습니다. 이 과정은 폐수 배출을 크게 줄이고 염색 작업을 간소화합니다. 이 기술은 브랜드가 지속가능성 기준을 충족하고 환경 발 인쇄를 줄이기 위해 점점 더 많은 채택이 진행되고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 3억 4,890만 달러 |

| 예측 금액 | 8억 3,650만 달러 |

| CAGR | 9.2% |

용도별로 시장은 의류, 홈 텍스타일, 산업용 텍스타일, 테크니컬 텍스타일로 나뉘어져 있습니다. 2034년까지 CAGR 9.5%로 예측됩니다. 패션 분야에서의 환경에 배려한 생산의 필요성이, 이 성장에 중요한 역할을 하고 있습니다. 오염 감소의 긴급성을 감안할 때, 무수 염색은 실행 가능하고 영향을 미치는 솔루션을 제시합니다. 유해 물질의 존재를 줄이는 기술을 적극적으로 모색하고 있습니다. 특히 의류 제조에서는 물을 대체 용매로 대체하거나 비액체 접근에 의존하거나 하는 염색 기술이 선호되고 있습니다.

섬유유형별로 분류하면 시장에는 면, 폴리에스테르, 나일론, 비스코스, 린넨 등이 포함됩니다. 기존의 폴리에스테르 염색에는 고온, 대량의 물, 다양한 유해물질이 필요했습니다.

지역별로는 미국이 2024년 3,630만 달러의 평가액으로 북미 시장을 선도하고 예측기간 동안 CAGR 9.8%를 보일 것으로 예측됩니다. 이 성장의 주요 요인은 환경 규제 강화와 기존의 섬유 염색 관행의 개혁에 대한 노력입니다. 더 엄격한 기준을 준수하는 솔루션을 채택하기 위해 점점 더 강력해지고 있습니다. 이 때문에 섬유 분야는보다 깨끗한 기술과 순환 경제에 대한 접근 방식으로 전국적인 변화를 촉구합니다.

물없는 염색 기술 업계는 물 사용량과 독성 폐기물을 줄이는 초 임계 CO2 염색 및 플라즈마 치료와 같은 혁신을 통해 진보하고 있습니다. 동향에는 에너지 효율이 높은 모듈식 염색, 재활용 가능한 소재, 탄소 중립 등이 포함됩니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 밸류체인에 영향을 주는 요인

- 이익률 분석

- 혁신

- 미래의 전망

- 제조업자

- 리셀러

- 트럼프 정권의 관세 분석

- 무역에 미치는 영향

- 무역량의 혼란

- 보복 조치

- 업계에 미치는 영향

- 공급측의 영향(원재료)

- 주요 원재료의 가격 변동

- 공급망 재구성

- 생산 비용에 미치는 영향

- 수요측의 영향(판매가격)

- 최종 시장에의 가격 전달

- 시장 점유율 동향

- 소비자의 반응 패턴

- 영향을 받는 주요 기업

- 전략적인 업계 대응

- 공급망 재구성

- 가격 설정 및 제품 전략

- 정책관여

- 전망과 향후 검토 사항

- 무역에 미치는 영향

- 공급자의 상황

- 무역 분석

- 이익률 분석

- 기술 개요

- 주요 뉴스와 대처

- 규제 상황

- 영향요인

- 성장 촉진요인

- 환경의 지속가능성에 대한 우려

- 규제 압력과 컴플라이언스

- 지속가능한 제품에 대한 소비자 수요

- 세계 파트너십과 업계 제휴

- 업계의 잠재적 위험 및 과제

- 높은 초기 자본 투자액

- 직물의 호환성이 한정되어 있음

- 성장 촉진요인

- 성장 가능성 분석

- Porter's Five Forces 분석

- PESTEL 분석

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 경쟁 포지셔닝 매트릭스

- 전략적 전망 매트릭스

제5장 시장 추계 및 예측 : 기술종별, 2021-2034년

- 주요 동향

- 초임계 CO2 염색

- 공기 염색

- 기타

제6장 시장 추계 및 예측 : 섬유 유형별, 2021-2034년

- 주요 동향

- 코튼

- 폴리에스테르

- 나일론

- 비스코스

- 린넨

- 기타

제7장 시장 추계 및 예측 : 용도별, 2021-2034년

- 주요 동향

- 옷

- 홈 섬유

- 산업용 섬유

- 테크니컬 텍스타일

제8장 시장 추계 및 예측 : 최종 용도별, 2021-2034년

- 주요 동향

- 섬유 제조업체

- 패션 브랜드

- 화학약품 및 염료 제조업체

제9장 시장 추계 및 예측 : 유통 채널별, 2021-2034년

- 주요 동향

- 직접

- 간접

제10장 시장 추계 및 예측 : 지역별, 2021-2034년

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 영국

- 독일

- 프랑스

- 이탈리아

- 스페인

- 러시아

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주

- 라틴아메리카

- 브라질

- 멕시코

- 중동 및 아프리카

- 남아프리카

- 사우디아라비아

- 아랍에미리트(UAE)

제11장 기업 프로파일

- AirDye

- Alchemie Technology

- Archroma

- Deven Supercriticals Pvt. Ltd

- DMS Dilmenler Makina ve Tekstil San. Tic. AS.

- DyeCoo

- eCO2Dye

- Guangdong Exponent Envirotech Ltd.

- HISAKA WORKS, LTD

- Kingfull Machinery CO2 Ltd

- Kornit Digital

- NTX

- Shanghai Singularity Imp&exp Company Limited

- Twine Solutions

- Xefco Pty Ltd

The Global Waterless Dyeing Technology Market was valued at USD 348.9 million in 2024 and is estimated to grow at a CAGR of 9.2% to reach USD 836.5 million by 2034. The surge in interest surrounding this technology is strongly linked to its environmentally conscious attributes, especially in an industry notorious for its excessive water consumption and pollution. Conventional textile dyeing methods continue to be among the most resource-intensive and environmentally damaging due to the heavy use of freshwater and the toxic wastewater they produce. As global concerns over water scarcity, pollution, and the broader implications of climate change intensify, the textile industry is being pushed to shift toward more sustainable alternatives. Waterless dyeing technology offers a forward-looking solution that not only helps reduce environmental impact but also meets the growing demand from both consumers and regulators for cleaner production methods. The development of cleaner technologies in textile manufacturing is becoming a strategic imperative. Innovations that eliminate or drastically reduce the need for water during dyeing are gaining significant traction. In response to increasing global awareness and regulatory pressure, manufacturers are embracing more sustainable practices that promise lower emissions, higher efficiency, and reduced water footprints.

The waterless dyeing technology market is segmented by technology type into supercritical CO2 dyeing, air dyeing, and others. Among these, supercritical CO2 dyeing dominated the segment with a market value of USD 165.5 million in 2024 and is expected to grow at a CAGR of approximately 9.9% during the forecast period. This method stands out for its ability to carry dyes into fibers without using water or harsh chemicals. It employs carbon dioxide in its supercritical state, which allows for deep fiber penetration and efficient color absorption. The appeal lies in its eco-friendly nature, high dye uptake, lower energy use, and recyclability of CO2 ,This process significantly cuts down on wastewater discharge and streamlines dyeing operations. The technology is increasingly being adopted as brands aim to meet sustainability benchmarks and reduce their environmental footprints. As companies aim for more efficient manufacturing processes that align with green initiatives, the demand for advanced dyeing systems continues to grow.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $348.9 Million |

| Forecast Value | $836.5 Million |

| CAGR | 9.2% |

In terms of application, the market is divided into apparel, home textiles, industrial textiles, and technical textiles. The apparel segment led the market with a 57.5% share and is projected to grow at a CAGR of 9.5% from 2025 to 2034. The need for eco-conscious production in the fashion sector is playing a key role in this growth. Given the massive volume of textiles produced for clothing and the urgency to reduce pollution, waterless dyeing presents a viable and impactful solution. The fashion industry, often criticized for its environmental impact, is now actively seeking technologies that eliminate the use of water and reduce the presence of hazardous substances in its processes. Dyeing techniques that replace water with alternative solvents or rely on non-liquid approaches are gaining preference, particularly in apparel manufacturing.

When segmented by fiber type, the market includes cotton, polyester, nylon, viscose, linen, and others. Polyester emerged as the dominant fiber type in 2024 and is expected to maintain its leading position throughout the forecast period. Known for its affordability, resilience, and widespread usage, polyester benefits immensely from waterless dyeing methods. Traditional polyester dyeing requires high temperatures, large volumes of water, and various harmful substances. In contrast, waterless dyeing-especially using supercritical CO2-allows for efficient penetration of dye molecules, better color fastness, and minimal chemical usage. These advantages make it particularly well-suited for modern textile manufacturing processes.

Regionally, the United States led the North American market with a valuation of USD 36.3 million in 2024 and is anticipated to grow at a CAGR of 9.8% during the forecast period. This growth is largely driven by mounting environmental regulations and efforts to reform conventional textile dyeing practices. As sustainability becomes a core aspect of textile policies, manufacturers are under increasing pressure to adopt solutions that reduce water usage, minimize emissions, and comply with stricter standards. This has encouraged a nationwide shift toward cleaner technologies and a circular economy approach within the textile sector.

The waterless dyeing technology industry is advancing through innovations like supercritical CO2 dyeing and plasma treatments, which reduce water usage and toxic waste. Leading companies such as DyeCO2 drive eco-friendly solutions that cut wastewater treatment costs. As the industry shifts toward circular economy practices, trends include energy-efficient modular dyeing, recyclable materials, and carbon neutrality. Growing ethical fashion demand, stricter regulations, and enhanced collaboration are accelerating sustainable practices and boosting adoption of waterless dyeing technologies across the textile supply chain.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-Side impact (Raw Materials)

- 3.2.2.2 Price volatility in key materials

- 3.2.2.3 Supply chain restructuring

- 3.2.2.4 Production cost implications

- 3.2.2.5 Demand-Side impact (Selling Price)

- 3.2.2.6 Price transmission to end markets

- 3.2.2.7 Market share dynamics

- 3.2.2.8 Consumer response patterns

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Supplier landscape

- 3.4 Trade analysis

- 3.5 Profit margin analysis

- 3.6 Technological overview

- 3.7 Key news & initiatives

- 3.8 Regulatory landscape

- 3.9 Impact forces

- 3.9.1 Growth drivers

- 3.9.1.1 Environmental sustainability concerns

- 3.9.1.2 Regulatory pressures and compliance

- 3.9.1.3 Consumer demand for sustainable products

- 3.9.1.4 Global partnerships & industry collaboration

- 3.9.2 Industry pitfalls & challenges

- 3.9.2.1 High initial capital investment

- 3.9.2.2 Limited fabric compatibility

- 3.9.1 Growth drivers

- 3.10 Growth potential analysis

- 3.11 Porter's analysis

- 3.12 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Technology Type, 2021 - 2034 (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 Supercritical CO2 dyeing

- 5.3 Air dyeing

- 5.4 Others

Chapter 6 Market Estimates & Forecast, By Fiber Type, 2021 - 2034 (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Cotton

- 6.3 Polyester

- 6.4 Nylon

- 6.5 Viscose

- 6.6 Linen

- 6.7 Others

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034 (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 Apparel

- 7.3 Home textiles

- 7.4 Industrial textiles

- 7.5 Technical textiles

Chapter 8 Market Estimates & Forecast, By End Use, 2021 - 2034 (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 Textile manufacturers

- 8.3 Fashion brands

- 8.4 Chemical & dye producers

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034 (USD Million) (Thousand Units)

- 9.1 Key trends

- 9.2 Direct

- 9.3 Indirect

Chapter 10 Market Estimates & Forecast, By Region, 2021-2034 (USD Million) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 South Africa

- 10.6.2 Saudi Arabia

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 AirDye

- 11.2 Alchemie Technology

- 11.3 Archroma

- 11.4 Deven Supercriticals Pvt. Ltd

- 11.5 DMS Dilmenler Makina ve Tekstil San. Tic. A.S..

- 11.6 DyeCoo

- 11.7 eCO2Dye

- 11.8 Guangdong Exponent Envirotech Ltd.

- 11.9 HISAKA WORKS, LTD

- 11.10 Kingfull Machinery CO2 Ltd

- 11.11 Kornit Digital

- 11.12 NTX

- 11.13 Shanghai Singularity Imp&exp Company Limited

- 11.14 Twine Solutions

- 11.15 Xefco Pty Ltd