|

시장보고서

상품코드

1773321

면 가공 기기 시장(2025-2034년) : 기회, 성장 촉진요인, 산업 동향 분석, 예측Cotton Processing Equipment Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

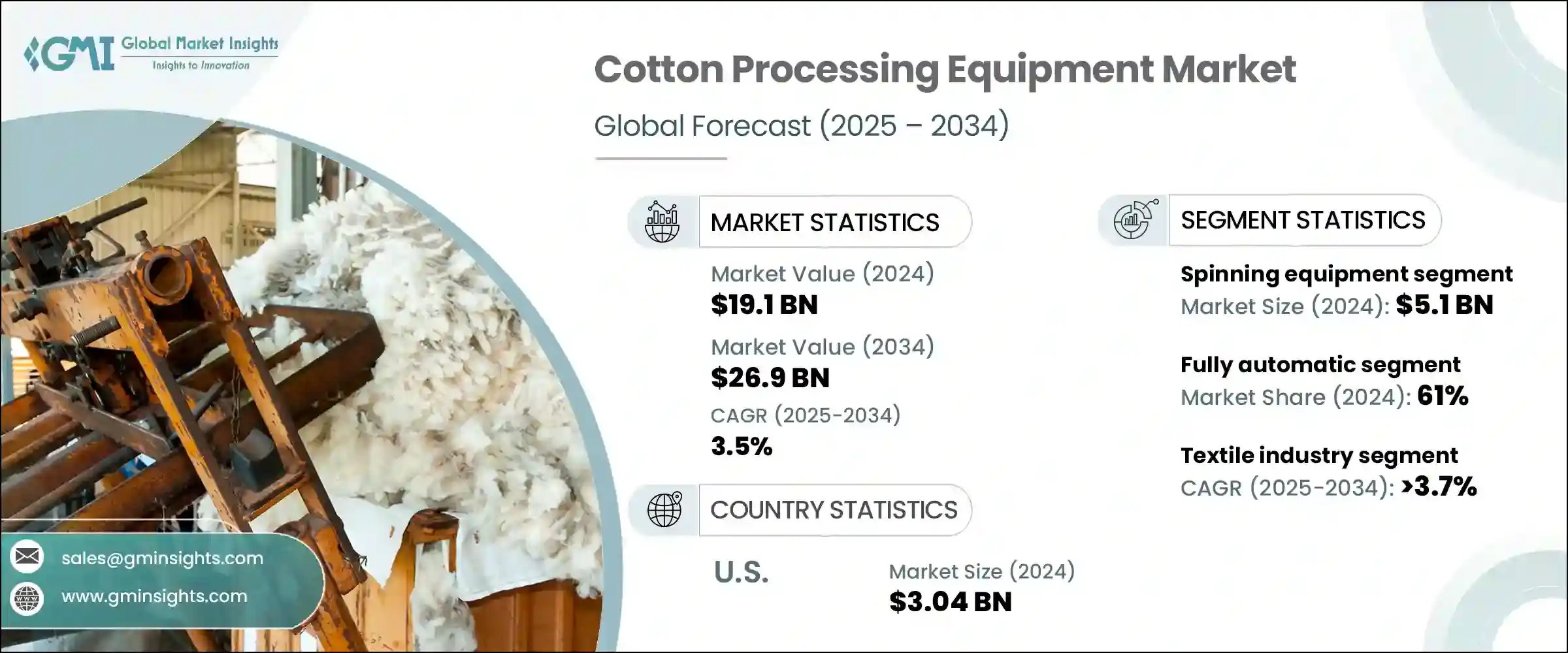

세계의 면 가공 기기 시장 규모는 2024년에 191억 달러를 달성하였고, CAGR 3.5%로 성장하여 2034년까지는 269억 달러에 이를 것으로 추정됩니다.

이 성장의 주요 요인은 최첨단 가공기술의 채용이 진행됨과 동시에 면 기반 의류와 섬유 수요가 증가하고 있다는 점입니다.

이 수요가 높아짐에 따라 제조업체는 선진적인 면 가공 기기 도입으로 생산능력과 효율 강화를 촉진하고 있습니다. 이를 위해 연구개발 이니셔티브에 자원을 투입하고 있습니다. 또한, 자동화와 지속 가능한 제조로의 전환이 일반화되면서 면 가공사업의 전망을 형성하여 환경목표에 따른 스마트기술에 대한 투자를 촉진하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작연도 | 2024년 |

| 예측연도 | 2025-2034년 |

| 시작금액 | 191억 달러 |

| 예측금액 | 269억 달러 |

| CAGR | 3.5% |

다양한 유형의 기기 중에서도 방사기기 분야는 2024년 시장 규모가 51억 달러를 넘어서면서 두드러지고 있습니다. 특히 방적시스템에 대한 주목이 높아짐에 따라 강한 기세를 보이고 있습니다. 각 제조업체는 생산을 최적화하기 위해 고속 로터, 고급 링 스핀들, 디지털 툴 등의 기능을 통합하고 있습니다.

이러한 기술을 통해 실시간 모니터링, 예측 유지보수, 실 출력의 향상이 가능하게 되어 고장의 감소와 조업 효율의 향상으로 이어지며 대규모 생산시설 전체에서 방적시스템의 진화에 대한 요구가 증가하고 있습니다.

작동 모드별로는 전자동기계가 2024년 시장 점유율의 약 61%를 차지하였고 2025년부터 2034년에 걸쳐 CAGR 3.7%를 보일 것으로 예측됩니다. 전자동기계는 조작 실수를 대폭 줄이면서 고정밀도의 출력을 실현할 수 있습니다.

IoT, 머신러닝 및 실시간 데이터 분석과 같은 지능형 기술의 도입으로 이러한 시스템의 기능과 출력 품질이 향상되었습니다. 따라서 자동화 시스템의 선호가 강해질 것으로 예측됩니다. 이와는 대조적으로, 수동 기계는 특히 비용 제약과 고급 인프라에 대한 액세스가 제한되는 지역과 같은 소규모 국지 시장에서 계속 시장성을 유지합니다.

용도별로는 섬유산업이 여전히 면 가공 기기의 압도적인 소비자이며 예측기간 중 CAGR은 3.7%를 넘을 것으로 예측됩니다.

의류 외에도 의료 분야는 거즈, 붕대, 수술용품 등 고품질의 면제품을 지속적으로 소비하는 부문으로 대두하고 있습니다. 내구성 있는 소재의 생산을 서포트하는 고도의 면 가공 시스템의 필요성이 높아지고 있으며 이 동향은 의료 분야의 요구에 맞춘 정밀 가공 기계의 채용을 제조업체에 촉구하고 있습니다.

지역별로는 미국이 계속 북미 시장을 독점하고 있으며 지역별 점유율의 83%를 차지하였고, 2024년에는 30억 4,000만 달러에 이르렀습니다. 최신 기술을 적용한 기계의 도입이 증가함에 따라 미국의 면 가공 기기 시장은 일관된 성장을 이루고 있습니다.

이 분야에서 사업을 전개하는 주요 기업은 고객에게 효과적이고 적응성이 높은 솔루션을 도입하기 때문에 기술적인 업그레이드와 협력적인 파트너십에 일관적으로 투자하고 있습니다. 각사는 세계 밸류체인 전반에서 제조업체의 경쟁력을 높이고 있습니다. 진화하는 고객의 기대와 스마트하고 환경친화적인 솔루션에 대한 꾸준한 뒷받침으로 면 가공 기기 시장은 앞으로 몇 년 동안 강력한 성장 궤도를 유지할 것입니다.

목차

제1장 조사방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 업계 생태계 분석

- 공급자의 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 주는 요인

- 업계에 미치는 영향요인

- 성장 촉진요인

- 업계의 잠재적 리스크 및 과제

- 기회

- 성장 가능성 분석

- 장래 시장 동향

- 기술과 혁신의 상황

- 현재의 기술 동향

- 신흥기술

- 가격 동향

- 지역별

- 기기 유형별

- 규제 상황

- 표준 및 컴플라이언스 요건

- 지역 규제 프레임워크

- 인증기준

- Porter's Five Forces 분석

- PESTEL 분석

제4장 경쟁구도

- 소개

- 기업의 시장 점유율 분석

- 지역별

- 기업 매트릭스 분석

- 주요 시장기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 주요 발전

- 합병과 인수

- 파트너십 및 협업

- 신제품 발매

- 확장 계획

제5장 시장 추계 및 예측 : 기기 유형별(2021-2034년)

- 주요 동향

- 면 조면기기

- 나이프 롤러 조면기

- 맥카티 조면기

- 톱 조면기

- 청소기기

- 원면 청소기

- 면 먼지 청소기

- 카딩기기

- 플랫 카딩기기

- 롤러 카딩기기

- 고생산 카딩기기

- 방적기기

- 링 스피닝

- 로터 회전

- 컴팩트 스피닝

- 에어젯 스피닝

- 직물기

- 마무리 기계

- 기타(분할 등)

제6장 시장 추계 및 예측 : 동작모드별(2021-2034년)

- 주요 동향

- 수동

- 반자동

- 전자동

제7장 시장 추계 및 예측 : 용량별(2021-2034년)

- 주요 동향

- 소용량

- 중용량

- 대용량

제8장 시장 추계 및 예측 : 용도별(2021-2034년)

- 주요 동향

- 섬유산업

- 의료 및 외과

- 기타

제9장 시장 추계 및 예측 : 유통 채널별(2021-2034년)

- 주요 동향

- 직접판매

- 간접판매

제10장 시장 추계 및 예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 스페인

- 이탈리아

- 네덜란드

- 아시아태평양

- 중국

- 일본

- 인도

- 호주

- 한국

- 라틴아메리카

- 브라질

- 멕시코

- 아르헨티나

- 중동 및 아프리카

- 남아프리카

- 사우디아라비아

- 아랍에미리트(UAE)

제11장 기업 프로파일

- Abel

- Continental Eagle

- Giannitsa Ginning Mills

- Kimbell Gin Machinery

- Lummus

- Mitsun

- Multipro Machines

- Muratec

- Rieter

- Sando Tech

- Saurer

- Savio

- Suntech Textile Machinery

- Tongda Group

- Trutzschler

The Global Cotton Processing Equipment Market was valued at USD 19.1 billion in 2024 and is estimated to grow at a CAGR of 3.5% to reach USD 26.9 billion by 2034. This growth is primarily fueled by increasing demand for cotton-based apparel and textiles, along with the growing adoption of cutting-edge processing technologies. Cotton continues to be a vital raw material in the textile sector, and the growing global population, coupled with higher disposable incomes, has significantly increased the need for quality textiles.

This heightened demand is prompting manufacturers to enhance production capacity and efficiency through the deployment of advanced cotton processing equipment. Companies are channeling resources into R&D initiatives to bring to market solutions that reduce material waste, improve productivity, and ensure the consistent quality of processed cotton. Additionally, the rising shift toward automation and sustainable manufacturing is shaping the landscape of cotton processing operations, driving investments in smart technologies that align with environmental goals.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $19.1 Billion |

| Forecast Value | $26.9 Billion |

| CAGR | 3.5% |

Among the various equipment types, the spinning equipment segment stood out with a market value exceeding USD 5.1 billion in 2024. It is anticipated to grow at a CAGR of 4.1% through the forecast period. This segment is experiencing strong momentum due to the rising focus on automated, efficient, and high-speed spinning systems. Manufacturers are increasingly integrating features like high-speed rotors, advanced ring spindles, and digital tools to optimize production.

These technologies are enabling real-time monitoring, predictive maintenance, and enhanced yarn output, leading to fewer breakdowns and better operational efficiency. The emphasis on digital transformation, coupled with the need for sustainability, is driving the evolution of spinning systems across large-scale production facilities. This transformation is also reshaping labor patterns, reducing the dependency on manual labor while simultaneously creating new roles in technical support and equipment maintenance.

In terms of operation mode, fully automatic machinery accounted for approximately 61% of the market share in 2024 and is forecast to grow at a CAGR of 3.7% between 2025 and 2034. The appeal of fully automatic cotton processing systems lies in their ability to deliver high-precision output while significantly lowering operational errors. These machines are proving essential for large-scale manufacturers aiming to enhance productivity while reducing labor costs.

The incorporation of intelligent technologies such as IoT, machine learning, and real-time data analytics is enhancing the functionality and output quality of these systems. As businesses seek to implement smart manufacturing strategies, the preference for fully automated systems is expected to intensify across key manufacturing hubs. In contrast, manual machinery continues to hold relevance in smaller, localized markets, particularly in regions where cost constraints or limited access to advanced infrastructure prevail.

On the basis of application, the textile industry remains the dominant consumer of cotton processing equipment and is expected to expand at a CAGR of over 3.7% during the forecast period. The continued growth of the global apparel and home furnishing sectors is generating strong demand for cotton-based products. A noticeable rise in consumer preference for eco-friendly and natural fibers is also propelling the consumption of cotton across both fashion and interior decor markets.

Beyond apparel, the medical sector is emerging as a consistent consumer of high-quality cotton products, including gauze, bandages, and surgical items. Increasing emphasis on hygiene and infection control in healthcare facilities has reinforced the need for advanced cotton processing systems that support the production of sterile and durable materials. This trend is encouraging manufacturers to adopt precision-based processing machinery tailored to the needs of the medical segment.

Regionally, the United States continues to dominate the North American market, holding 83% of the regional share and expected to reach USD 3.04 billion in 2024. The country benefits from being a major hub for both the import and export of cotton and cotton-related products. With growing demand for modern textile solutions and rising adoption of technologically upgraded machinery, the market for cotton processing equipment in the U.S. is experiencing consistent growth. Businesses in the country are focusing on investing in advanced systems that increase efficiency and align with shifting industry standards. Efforts to modernize infrastructure and boost output with minimal environmental impact are pushing demand for intelligent machinery.

Key players operating in this space are consistently investing in technological upgrades and collaborative partnerships to introduce more effective and adaptive solutions for customers. These strategies are not only improving product offerings but also enhancing the competitiveness of manufacturers across the global value chain. With evolving customer expectations and the steady push for smart, eco-conscious solutions, the cotton processing equipment market is poised to maintain a strong growth trajectory in the coming years.

Table of Contents

Chapter 1 Methodology and scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 By regional

- 2.2.2 By equipment type

- 2.2.3 By mode of operation

- 2.2.4 By capacity

- 2.2.5 By application

- 2.2.6 By distribution channel

- 2.3 CXO perspectives: strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls & challenges

- 3.2.3 Opportunities

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By equipment type

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Equipment Type, 2021 - 2034 ($Billion, Thousand Units)

- 5.1 Key trends

- 5.2 Ginning equipment

- 5.2.1 Knife roller gin

- 5.2.2 Macarty gin

- 5.2.3 Saw gin

- 5.3 Cleaning equipment

- 5.3.1 Raw cotton cleaning machine

- 5.3.2 Cotton lint cleaner machines

- 5.4 Carding equipment

- 5.4.1 Flat carding machines

- 5.4.2 Roller carding machines

- 5.4.3 High-production carding machines

- 5.5 Spinning equipment

- 5.5.1 Ring spinning

- 5.5.2 Rotor spinning

- 5.5.3 Compact spinning

- 5.5.4 Air jet spinning

- 5.6 Weaving equipment

- 5.7 Finishing machines

- 5.8 Others (sorting etc.)

Chapter 6 Market Estimates & Forecast, By Mode of Operation, 2021 - 2034 ($Billion, Thousand Units)

- 6.1 Key trends

- 6.2 Manual

- 6.3 Semi-automatic

- 6.4 Fully automatic

Chapter 7 Market Estimates & Forecast, By Capacity, 2021 - 2034 ($Billion, Thousand Units)

- 7.1 Key trends

- 7.2 Low capacity

- 7.3 Medium capacity

- 7.4 High capacity

Chapter 8 Market Estimates & Forecast, By Application, 2021 - 2034 ($Billion, Thousand Units)

- 8.1 Key trends

- 8.2 Textile industry

- 8.3 Medical & surgical

- 8.4 Others

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034 ($Billion, Thousand Units)

- 9.1 Key trends

- 9.2 Direct sales

- 9.3 Indirect sales

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 ($Billion, Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Spain

- 10.3.5 Italy

- 10.3.6 Netherlands

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 Japan

- 10.4.3 India

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 MEA

- 10.6.1 South Africa

- 10.6.2 Saudi Arabia

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Abel

- 11.2 Continental Eagle

- 11.3 Giannitsa Ginning Mills

- 11.4 Kimbell Gin Machinery

- 11.5 Lummus

- 11.6 Mitsun

- 11.7 Multipro Machines

- 11.8 Muratec

- 11.9 Rieter

- 11.10 Sando Tech

- 11.11 Saurer

- 11.12 Savio

- 11.13 Suntech Textile Machinery

- 11.14 Tongda Group

- 11.15 Trutzschler