|

시장보고서

상품코드

1773425

티타늄 알루미나이드(TiAl) 시장 기회와 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Titanium Aluminides (TiAl) Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

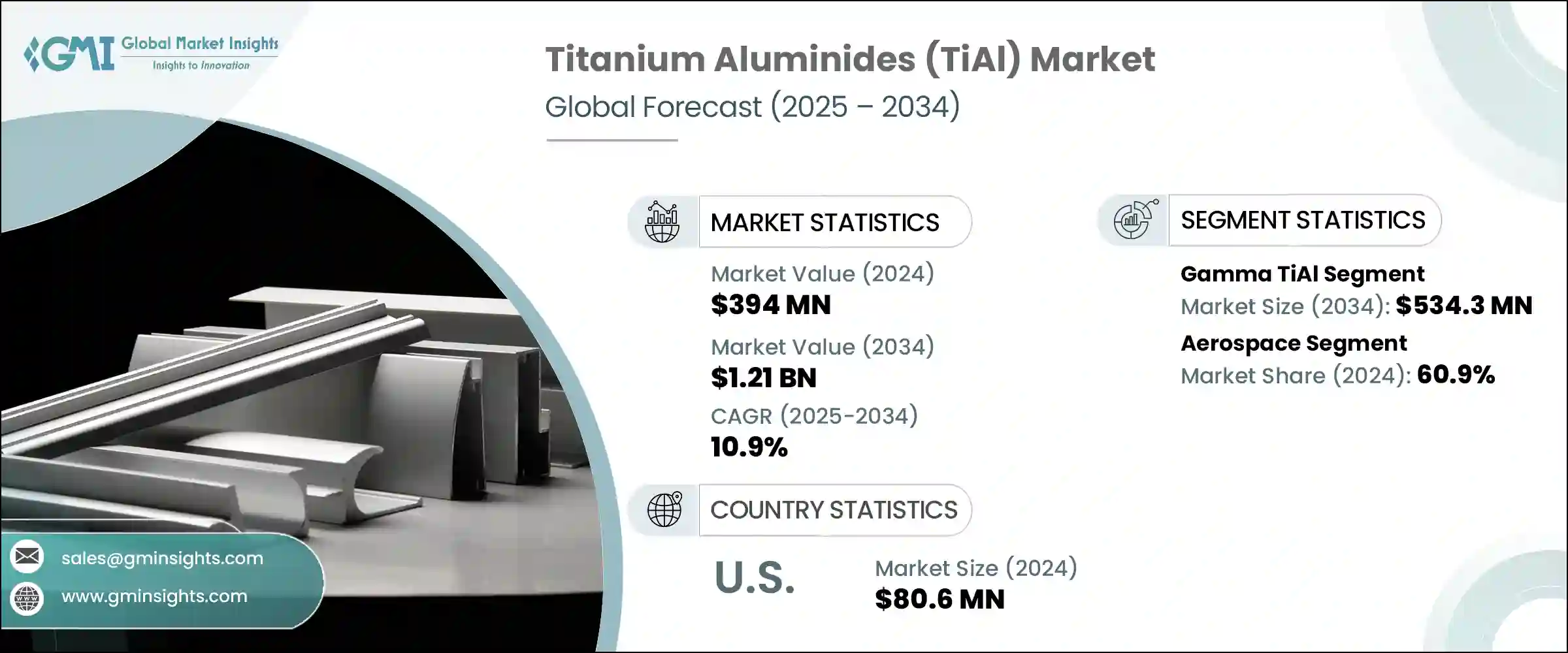

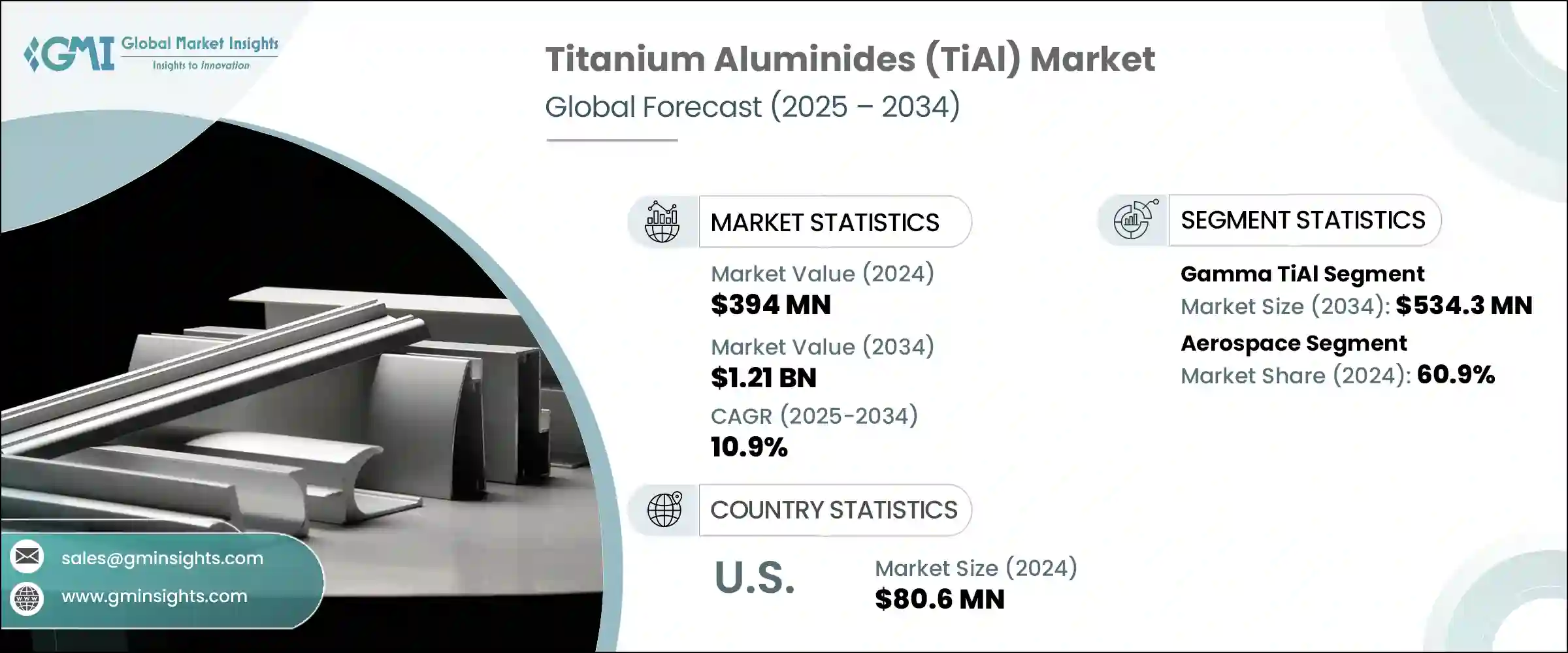

티타늄 알루미나이드(TiAl) 세계 시장은 2024년에 3억 9,400만 달러로 평가되었고, CAGR 10.9%로 성장하여 2034년에는 12억 1,000만 달러에 이를 것으로 추정되고 있습니다.

특히 무게, 내열성, 내구성이 중요한 산업에서 이 소재의 뛰어난 기계적 특성으로 인해 수요가 증가하고 있습니다. 티타늄 알루미나이드는 강철과 같은 기존 소재보다 훨씬 가벼워 전체 무게를 줄이고 에너지 효율을 향상시켜 항공우주 및 자동차 분야에서 큰 이점을 제공합니다. 티타늄 알루미나이드의 뛰어난 고온 성능은 극한의 열적 및 기계적 스트레스를 견딜 수 있어 항공기 엔진 부품 및 고성능 자동차 부품과 같은 응용 분야에 이상적입니다.

산화에 강하고, 응력 하에서 강성을 유지하며, 연료 소비를 줄이는 재료에 대한 요구는 첨단 엔지니어링 응용 분야에서 티타늄 알루미나이드의 입지를 강화시키고 있습니다. 전 세계 국방비 증가와 자동차 제조업체들이 첨단 복합재와 경량화 구조로 눈을 돌리면서 티타늄 알루미나이드는 큰 발판을 마련하고 있습니다. 미국과 인도를 포함한 여러 국가의 국방 부문은 성능 향상을 위한 기술 및 재료에 대한 투자를 늘리고 있으며, 티타늄 알루미나이드는 특히 제트 터빈과 차세대 추진 시스템에서 이러한 개발에서 요구되는 높은 기준을 충족하고 있습니다.

| 시장 범위 | |

|---|---|

| 개시 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 개시 금액 | 3억 9,400만 달러 |

| 예측 금액 | 12억 1,000만 달러 |

| CAGR | 10.9% |

티타늄 알루미나이드(TiAl)의 저밀도, 우수한 내크리프성, 뛰어난 고온 강도와 같은 특성으로 인해 티타늄 알루미나이드는 까다로운 다양한 분야에서 최고의 성능을 발휘하는 재료가 되었습니다. 높은 내식성 및 내 산화성과 함께 높은 사용 조건을 견딜 수 있는 티타늄 알루미나이드는 특히 항공우주 구조물, 터빈 부품 및 기존 합금으로 충분하지 않은 기타 응용 분야에 적합합니다. 기존 소재와 달리 티타늄 알루미나이드는 무게 때문에 강도를 포기하지 않으며, 이러한 균형으로 인해 재료의 한계에 도전하는 환경에서 매우 바람직한 소재가 되었습니다. 운송 및 방위 분야에서 지속가능성, 경량화 및 효율성이 전 세계적으로 강조되고 있는 가운데, 이러한 금속간 화합물의 성능과 신뢰성은 제조업체에게 경쟁 우위를 제공합니다.

2024년 감마 TiAl 부문은 1억 7,710만 달러의 가치를 창출하고 2034년에는 5억 3,430만 달러에 달할 것으로 예측됩니다. 이 특정 형태의 티타늄 알루미나이드는 기계적 무결성을 유지하고 600°C 이상의 온도에서 산화를 견딜 수 있는 능력으로 인해 매우 인기가 있습니다. 감마 TiAl 합금은 특히 강도와 경량화가 모두 필수적인 응용 분야에서 니켈 기반 초합금에 대한 고성능 대안을 제공합니다. 이러한 합금은 열 응력 하에서 우수한 안정성으로 인해 중요한 터빈 엔진 부품에서 기존 금속을 대체하는 경우가 증가하고 있습니다. 보다 에너지 효율적이고 가벼운 항공기 플랫폼의 개발로 인해 고응력 환경에서 감마 TiAl의 사용이 증가하고 있으며, 여러 주요 제조업체들이 감마 TiAl을 터빈 블레이드 부품에 통합하고 있습니다.

2024년 항공우주 분야의 점유율은 60.9%를 보일 것으로 예측됩니다. 항공기 엔진 및 관련 부품에서 가볍고 내열성이 강한 소재가 계속 선호되고 있는 것이 널리 채택되는 원동력이 되고 있습니다. 티타늄 알루미나이드는 현재 터빈 블레이드 및 고온에 지속적으로 노출되는 기타 부품에 사용되어 항공기의 총 중량을 줄이고 연료 효율을 향상시키고 있습니다. 티타늄 알루미나이드의 높은 탄성률, 열에 의한 강도 유지, 낮은 열팽창 특성은 항공우주 응용 분야에 이상적입니다. 방위 및 민간 항공 부문이 더 높은 엔진 성능과 낮은 배기가스 배출량을 요구함에 따라 티타늄 알루미나이드는 재료 혁신에 중요한 역할을 하고 있습니다. 티타늄 알루미나이드는 성능 저하 없이 가혹한 환경에 견딜 수 있어, 특히 재료의 결함이 허용되지 않는 항공 부품의 설계 및 제조에 필수적인 요소로 자리 잡고 있습니다.

미국 티타늄 알루미나이드(TiAl) 시장은 2024년 8,060만 달러 규모에 달할 것으로 예측됩니다. 국방 및 항공우주 장비의 주요 세계 수출국 중 하나로서 미국은 항공기의 효율성을 향상시키는 첨단 소재의 채택을 계속 주도하고 있습니다. 국내 티타늄 생산은 수요를 따라잡아 새로운 기체 및 엔진 생산의 급증에 필요한 원자재를 공급하고 있습니다. 더 가볍고 연비가 좋은 항공기 모델에 대한 대량 주문이 재료 선택에 영향을 미치고 있으며, 티타늄 알루미나이드는 차세대 항공기에 점점 더 많이 사용되는 탄소섬유 강화 구조와 우수한 호환성을 제공합니다. 이러한 호환성은 강도 대 중량 비율의 최적화와 연료 사용량 감소에 중점을 둔 설계가 이루어지는 새로 설계된 플랫폼에 재료의 통합을 지원합니다.

티타늄 알루미나이드(TiAl) 시장의 주요 기업으로는 Howmet Aerospace Inc., Precision Castparts Corp., KBM Affilips B.V., VSMPO-AVISMA Corporation, ATI 등이 있습니다. 이들 기업은 여러 최종 사용 분야에 걸쳐 특정 성능 요구 사항에 맞는 고급 합금 개발을 주도하고 있습니다. 티타늄 알루미나이드(TiAl) 시장의 기업들은 열 안정성과 제조 가능성을 높이기 위해 합금 조성을 개선하기 위한 연구 개발 노력을 강화하고 있습니다.

향상된 기계적 성능을 가진 복잡한 부품을 제조하기 위해 첨단 주조, 단조 및 적층 가공 기술에 대한 전략적 투자가 이루어지고 있습니다. 또한, 항공우주 OEM 및 방위산업체와의 파트너십을 통해 장기 공급 계약을 확보하고 기술 혁신 주기를 간소화하기 위해 노력하고 있습니다. 또한, 세계 시장 리더들은 생산 능력을 확장하고, 원자재 공급을 확보하며, 품질 관리를 보장하기 위해 수직적 통합을 추진하고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 공급업체 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 미치는 요인

- 파괴적 변화

- 업계에 대한 영향요인

- 성장 촉진요인

- 업계의 잠재적 리스크&과제

- 시장 기회

- 성장 가능성 분석

- 규제 상황

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- Porter's Five Forces 분석

- PESTEL 분석

- 가격 동향

- 지역별

- 유형별

- 향후 시장 동향

- 기술 및 혁신 상황

- 현재 기술 동향

- 신기술

- 특허 상황

- 무역 통계(HS코드)(주 : 무역 통계는 주요 국가에 한해 제공됩니다)

- 주요 수입국

- 주요 수출국

- 지속가능성과 환경 측면

- 지속가능한 관행

- 폐기물 감축 전략

- 생산 에너지 효율

- 친환경 대처

- 탄소발자국 고려

제4장 경쟁 구도

- 서론

- 기업의 시장 점유율 분석

- 지역별

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- 지역별

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 주요 발전

- 인수합병(M&A)

- 파트너십 및 협업

- 신제품 발매

- 확장 계획

제5장 시장 규모와 예측 : 유형별, 2021년-2034년

- 주요 동향

- 감마 TiAl(γ-TiAl)

- 알파 2-Ti3Al(α2-Ti3Al)

- 사방정계 Ti2AlNb(O-Ti2AlNb)

- 베타형(β-TiAl)

- 기타

제6장 시장 규모와 예측 : 제조 공정별, 2021년-2034년

- 주요 동향

- 잉곳 야금

- Vacuum arc remelting (VAR)

- Electron beam melting (EBM)

- Plasma arc melting (PAM)

- Vacuum induction melting (VIM)

- 분말야금

- Gas atomization

- Plasma rotating electrode process (PREP)

- Mechanical alloying

- 적층 가공

- Powder bed fusion (PBF)

- Direct energy deposition (DED)

- 기타

- 기타

제7장 시장 규모와 예측 : 용도별, 2021년-2034년

- 주요 동향

- 항공우주

- 저전압 터빈 블레이드

- 고압 압축기 블레이드

- 구조 부품

- 기타

- 자동차

- 터보차저 휠

- 밸브

- 배기 시스템

- 기타

- 산업

- 가스 터빈

- 화학 처리 장비

- 기타

- 의료

- 임플란트

- 수술 기구

- 기타

- 기타

제8장 시장 규모와 예측 : 최종 이용 산업별, 2021년-2034년

- 주요 동향

- 항공우주 및 방위

- 상용 항공

- 군용 항공

- 우주 용도

- 자동차

- 승용차

- 상용차

- 레이싱카 및 고성능차

- 산업

- 발전

- 화학 처리

- 석유 및 가스

- 기타

- 헬스케어

- 정형외과용 임플란트

- 치과 용도

- 기타

- 기타

제9장 시장 규모와 예측 : 지역별, 2021년-2034년

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 영국

- 독일

- 프랑스

- 이탈리아

- 스페인

- 기타 유럽

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주

- 기타 아시아태평양

- 라틴아메리카

- 브라질

- 멕시코

- 아르헨티나

- 기타 라틴아메리카

- 중동 및 아프리카

- 남아프리카공화국

- 사우디아라비아

- 아랍에미리트(UAE)

- 기타 중동 및 아프리카

제10장 기업 개요

- ATI

- VSMPO-AVISMA Corporation

- Precision Castparts

- Howmet Aerospace

- KBM Affilips

- GfE Metalle und Materialien

- AMG Advanced Metallurgical Group

- Alcoa Corporation

- Western Superconducting Technologies

- Carpenter Technology Corporation

- American Elements

- Toho Titanium

- Titanium Metals Corporation

- Stanford Advanced Materials

- Aerospace Alloys

- 6K

- Arconic Corporation

- Daido Steel

- Kobe Steel

The Global Titanium Aluminides (TiAl) Market was valued at USD 394 million in 2024 and is estimated to grow at a CAGR of 10.9% to reach USD 1.21 billion by 2034. Rising demand is driven by the material's exceptional mechanical properties, especially in industries where weight, heat resistance, and durability are critical. Titanium aluminides are far lighter than conventional materials like steel, offering significant advantages in the aerospace and automotive sectors by reducing overall weight and improving energy efficiency. Their superior high-temperature performance enables them to withstand extreme thermal and mechanical stress, making them ideal for applications like aircraft engine parts and high-performance automotive components.

The need for materials that resist oxidation, maintain stiffness under stress, and lower fuel consumption is reinforcing their position in advanced engineering applications. With global defense spending on the rise and automotive manufacturers turning to advanced composites and lighter structures, titanium aluminides are gaining significant ground. The defense sectors in countries including the U.S. and India are experiencing increased investment in technology and materials to enhance performance, and titanium aluminides meet the high standards demanded by these developments, especially in jet turbines and next-gen propulsion systems.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $394 Million |

| Forecast Value | $1.21 Billion |

| CAGR | 10.9% |

The properties of titanium aluminides such as low density, excellent creep resistance, and outstanding high-temperature strength, are turning them into top-performing materials in multiple demanding fields. Their ability to endure elevated operating conditions, coupled with high corrosion and oxidation resistance, makes them especially suited for aerospace structures, turbine components, and other applications where conventional alloys fall short. Unlike traditional materials, titanium aluminides do not compromise strength for weight, and that balance makes them highly desirable in environments that push material limits. With a rising global emphasis on sustainability, lightweight, and efficiency in both transportation and defense, the performance and reliability of these intermetallic compounds offer manufacturers a competitive advantage.

In 2024, the Gamma TiAl segment generated USD 177.1 million and is forecasted to reach USD 534.3 million by 2034. This specific form of titanium aluminide is highly sought after for its ability to retain mechanical integrity and resist oxidation at temperatures exceeding 600°C. Gamma TiAl alloys offer a high-performance alternative to nickel-based superalloys, particularly in applications where both strength and weight-saving are essential. These alloys are increasingly replacing traditional metals in critical turbine engine parts due to their impressive stability under thermal stress. The push to develop more energy-efficient and lightweight aircraft platforms has elevated the use of gamma TiAl in high-stress environments, with several major manufacturers incorporating it into turbine blade components.

The aerospace segment held a 60.9% share in 2024. The continued preference for lightweight yet heat-resistant materials in aircraft engines and related components has driven widespread adoption. Titanium aluminides are now being used in turbine blades and other parts that face constant exposure to high temperatures, reducing total aircraft weight and improving fuel efficiency. Their high modulus, strength retention under heat, and lower thermal expansion properties make them ideal for aerospace applications. As the defense and commercial aviation sectors demand higher engine performance and lower emissions, titanium aluminides play a critical role in material innovation. Their capacity to withstand harsh environments without compromising performance makes them indispensable in aviation component design and manufacturing, especially where material failure is not an option.

United States Titanium Aluminides (TiAl) Market generated USD 80.6 million in 2024. As one of the major global exporters of defense and aerospace equipment, the country continues to lead in adopting advanced materials that boost aircraft efficiency. Domestic titanium production has kept pace with demand, supplying the raw materials required for the surge in new airframe and engine production. High-volume orders for lighter, fuel-efficient aircraft models are influencing material choices, and titanium aluminides offer superior compatibility with carbon-fiber-reinforced structures increasingly used in next-gen airframes. This compatibility has supported the material's integration into newly engineered platforms, where design emphasis is placed on strength-to-weight optimization and reduced fuel usage.

The top-performing companies in the Titanium Aluminides (TiAl) Market include Howmet Aerospace Inc., Precision Castparts Corp, KBM Affilips B.V., VSMPO-AVISMA Corporation, and ATI. These players lead in developing advanced alloys tailored to specific performance requirements across multiple end-use sectors. Companies in the titanium aluminides market are intensifying R&D efforts to improve alloy compositions for higher thermal stability and manufacturability.

Strategic investments are being made in advanced casting, forging, and additive manufacturing technologies to produce complex parts with enhanced mechanical performance. Firms are also forming alliances with aerospace OEMs and defense contractors to secure long-term supply contracts and streamline innovation cycles. Additionally, global market leaders are expanding production capacity and vertically integrating to secure raw material supply and ensure quality control.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Type

- 2.2.3 Manufacturing process

- 2.2.4 Application

- 2.2.5 End use industry

- 2.3 TAM analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.6.1 Technology and innovation landscape

- 3.6.2 Current technological trends

- 3.6.3 Emerging technologies

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By type

- 3.8 Future market trends

- 3.9 Technology and innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent landscape

- 3.11 Trade statistics (HS code) (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Size and Forecast, By Type, 2021-2034 (USD Million) (Tons)

- 5.1 Key trends

- 5.2 Gamma TiAl (γ-TiAl)

- 5.3 Alpha2-Ti3Al (α2-Ti3Al)

- 5.4 Orthorhombic Ti2AlNb (O-Ti2AlNb)

- 5.5 Beta Type (β-TiAl)

- 5.6 Others

Chapter 6 Market Size and Forecast, By Manufacturing Process, 2021-2034 (USD Million) (Tons)

- 6.1 Key trends

- 6.2 Ingot metallurgy

- 6.2.1 Vacuum arc remelting (VAR)

- 6.2.2 Electron beam melting (EBM)

- 6.2.3 Plasma arc melting (PAM)

- 6.2.4 Vacuum induction melting (VIM)

- 6.3 Powder metallurgy

- 6.3.1 Gas atomization

- 6.3.2 Plasma rotating electrode process (PREP)

- 6.3.3 Mechanical alloying

- 6.4 Additive manufacturing

- 6.4.1 Powder bed fusion (PBF)

- 6.4.2 Direct energy deposition (DED)

- 6.4.3 Others

- 6.5 Others

Chapter 7 Market Size and Forecast, By Application, 2021-2034 (USD Million) (Tons)

- 7.1 Key trends

- 7.2 Aerospace

- 7.2.1 Low pressure turbine blades

- 7.2.2 High pressure compressor blades

- 7.2.3 Structural components

- 7.2.4 Others

- 7.3 Automotive

- 7.3.1 Turbocharger wheels

- 7.3.2 Valves

- 7.3.3 Exhaust systems

- 7.3.4 Others

- 7.4 Industrial

- 7.4.1 Gas turbines

- 7.4.2 Chemical processing equipment

- 7.4.3 Others

- 7.5 Medical

- 7.5.1 Implants

- 7.5.2 Surgical instruments

- 7.5.3 Others

- 7.6 Others

Chapter 8 Market Size and Forecast, By End Use Industry, 2021-2034 (USD Million) (Tons)

- 8.1 Key trends

- 8.2 Aerospace & defense

- 8.2.1 Commercial aviation

- 8.2.2 Military aviation

- 8.2.3 Space applications

- 8.3 Automotive

- 8.3.1 Passenger vehicles

- 8.3.2 Commercial vehicles

- 8.3.3 Racing & high-performance vehicles

- 8.4 Industrial

- 8.4.1 Power generation

- 8.4.2 Chemical processing

- 8.4.3 Oil & gas

- 8.4.4 Others

- 8.5 Healthcare

- 8.5.1 Orthopedic implants

- 8.5.2 Dental applications

- 8.5.3 Others

- 8.6 Others

Chapter 9 Market Size and Forecast, By Region, 2021-2034 (USD Million) (Tons)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Rest of Europe

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 Australia

- 9.4.6 Rest of Asia Pacific

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.5.4 Rest of Latin America

- 9.6 MEA

- 9.6.1 South Africa

- 9.6.2 Saudi Arabia

- 9.6.3 UAE

- 9.6.4 Rest of Middle East & Africa

Chapter 10 Company Profiles

- 10.1 ATI

- 10.2 VSMPO-AVISMA Corporation

- 10.3 Precision Castparts

- 10.4 Howmet Aerospace

- 10.5 KBM Affilips

- 10.6 GfE Metalle und Materialien

- 10.7 AMG Advanced Metallurgical Group

- 10.8 Alcoa Corporation

- 10.9 Western Superconducting Technologies

- 10.10 Carpenter Technology Corporation

- 10.11 American Elements

- 10.12 Toho Titanium

- 10.13 Titanium Metals Corporation

- 10.14 Stanford Advanced Materials

- 10.15 Aerospace Alloys

- 10.16 6K

- 10.17 Arconic Corporation

- 10.18 Daido Steel

- 10.19 Kobe Steel