|

시장보고서

상품코드

1801801

캡핑 기계 시장 : 기회, 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Capping Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

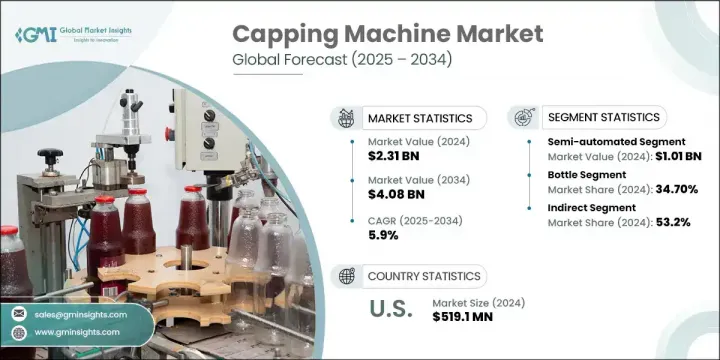

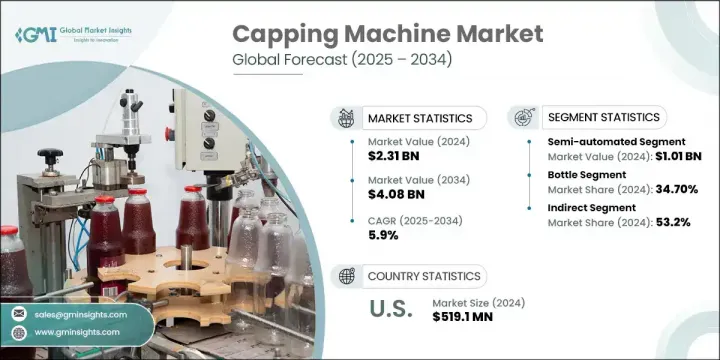

세계의 캡핑 기계 시장 규모는 2024년에 23억 1,000만 달러가 되고, CAGR 5.9%로 성장할 전망이며 2034년에는 40억 8,000만 달러에 이를 것으로 예측되고 있습니다.

다양한 산업 분야에서 포장 제품에 대한 전 세계 수요가 급증함에 따라 이 시장은 꾸준히 확대되고 있습니다. 소비자 선호도가 위생성, 사용 편의성, 제품 안전성으로 계속해서 변화함에 따라 병입 식품, 음료, 화장품, 의약품의 소비가 증가하고 있습니다. 이러한 수요를 충족시키기 위해 제조업체들은 실링 정확도를 제공하고, 유통 기한 안정성을 개선하며, 제품 변조를 방지하는 캡핑 시스템으로 점점 더 눈을 돌리고 있습니다. 특히 제품 무결성에 대한 규제 기준이 엄격한 경우, 이러한 기계들은 생산 공정에서 중요한 역할을 합니다.

자동화 통합 역시 산업을 변화시키고 있으며, 제조업체들은 원활한 운영 지원, 처리량 향상, 가동 중단 시간 감소를 위한 고급 캡핑 시스템을 전개하고 있습니다. IoT 통합, 실시간 모니터링, 예측 유지보수 같은 스마트 기능의 활용은 최근 제조 환경에서 표준이 되어가고 있습니다. 특히 FMCG(Fast-Moving Consumer Goods) 분야의 병 용도 작업에 대한 수요를 더욱 촉진하는 산업 4.0 기술의 도입이 지능형 고속 시스템에 대한 수요를 가속화하고 있습니다. 주요 제조 경제권의 투자 프로그램은 이러한 자동화 포장 솔루션의 도입을 더욱 경화 촉진제로 가속화하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 23억 1,000만 달러 |

| 예측 금액 | 40억 8,000만 달러 |

| CAGR | 5.9% |

2024년 반자동 캡핑 기계 분야는 10억 1,000만 달러를 창출해 2034년까지 연평균 성장률(CAGR) 6%를 보일 것으로 예측됩니다. 이러한 시스템은 경제성, 운영의 간편성, 다양한 용기 형태 및 크기에 대한 적응성 덕분에 여전히 가장 널리 사용되고 있습니다. 컴팩트한 디자인, 낮은 유지보수 비용, 쉬운 설치로 인해 제한된 바닥 공간이나 소규모 생산 라인을 운영하는 식품, 화장품, 의약품 분야의 소규모 생산자에게 특히 매력적입니다.

2024년 기준 병 용도 부문은 34.70%의 점유율을 차지했으며, 2025년부터 2034년까지 연평균 6.2%의 성장률을 보일 것으로 예상됩니다. 병은 경량 구조, 휴대성, 다양한 캡 유형과의 호환성 덕분에 수많은 산업에서 주요 포장 형태로 지배적 위치를 차지합니다. 음료 및 가정용 화학 제품부터 퍼스널 케어 및 의료용 액체에 이르기까지, 병 사용에는 제품 무결성을 유지하기 위한 정밀 캡핑 시스템이 필요합니다. 병의 유연성과 비용 효율성은 나사식, 스냅식, 프레스핏식 등 다양한 캡 디자인을 처리할 수 있는 병 전용 기계에 대한 수요를 지속적으로 촉진하고 있습니다.

미국의 캡핑 기계 시장은 2024년 75.1%의 점유율을 차지하며 5억 1,910만 달러를 창출합니다. 이 성장의 원동력은 패키지 식품 산업의 확대, 제조 라인 자동화의 진전, 생산 위생 및 안전에 관한 규제 요건 증가입니다. 이 나라의 제약 및 식품 가공 부문은 FDA 및 현행 적정 제조 기준(cGMP) 기준을 충족하는 고성능 캡핑 시스템에 투자하고 있습니다. AI, IoT, 원격 진단을 활용한 스마트 포장 기술도 기업이 예지보전과 효율중시 업그레이드를 추진하는 가운데 지지를 모으고 있습니다.

세계의 캡핑 기계 시장 주요 기업는 Zalkin, Tetra Pak, KHS, Arol Group, IMA Group, Krones, Accutek Packaging Equipment, Federal Manufacturing Co., A Pack, Closure Systems International, Syntegon, Filamatic, ProMach, Crown Holdings, E-Pak 세계의 캡핑 기계 시장에서 보다 견고한 발판을 확보하기 위해 기업은 기술 혁신과 기술 통합을 선호합니다. 많은 기업들이 다양한 캡 유형 및 용기 재질과의 호환성을 가능하게 하는 기계의 다용도성 향상을 위해 연구개발(R&D)에 투자하고 있습니다. 기업들은 증가하는 생산 수요를 충족시키기 위해 쉬운 업그레이드와 시스템 확장성을 허용하는 모듈식 설계에 집중하고 있습니다. 최종 사용 산업과의 전략적 파트너십은 특히 제약 및 식품 분야에서 부문별 요구 사항에 맞게 기계를 맞춤화하는 데 도움이 됩니다. 업체들은 또한 리드 타임을 단축하고 현지 시장을 효율적으로 지원하기 위해 지역별 제조 시설 및 애프터서비스 지원 센터를 통해 전 세계 입지가 확대되고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 공급자의 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 주는 요인

- 업계에 미치는 영향요인

- 성장 촉진요인

- 포장 제품 산업의 성장

- 자동화 전환

- 병 제품에 대한 수요 증가

- 업계의 잠재적 위험 및 과제

- 고액의 자본 투자

- 복잡한 유지보수 및 기술적 전문 지식

- 기회

- 복잡한 유지보수 및 기술적 전문 지식

- 스마트 포장 기술의 등장

- 성장 촉진요인

- 성장 가능성 분석

- 장래 시장 동향

- 기술과 혁신 미래

- 규제 환경

- 밸류체인 분석

- 원재료 공급업체 및 부품 제조업체

- 기기 제조업체 및 OEM

- 유통 채널과 판매 네트워크

- 최종 용도 부문 및 용도

- 애프터 서비스 제산업체

- 가격 동향

- 지역별

- 기계유형별

- 규제 상황

- 표준 및 규제 준수 요건

- 지역 규제 틀

- 인증기준 무역 통계(HS코드-5)

- 주요 수입국

- 주요 수출국

- Porter's Five Forces 분석

- PESTEL 분석

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 지역별

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 주요 발전

- 합병과 인수

- 파트너십 및 협업

- 신제품 발매

- 확장 계획

제5장 시장 추계 및 예측 : 기계 유형별(2021-2034년)

- 주요 동향

- 자동

- 반자동

- 수동

제6장 시장 추계 및 예측 : 캡 유형별(2021-2034년)

- 주요 동향

- 나사식 캡

- 스냅식 캡

- 프레스핏 캡

- ROPP(롤 온 도난 방지) 캡

- 어린이 안전 캡

- 코르크 캡

- 푸시온 캡

- 크림프 캡

제7장 시장 추계 및 예측 : 용기 유형별(2021-2034년)

- 주요 동향

- 병

- 항아리

- 튜브

- 바이알

- 기타(예 : 특수 용기 또는 산업용 용기)

제8장 시장 추계 및 예측 : 스피드 유형별(2021-2034년)

- 주요 동향

- 저속 : 60 cpm 미만

- 중속 : 60-300 cpm

- 고속 : 300-800 cpm

- 초고속 : 800 cpm 초과

제9장 시장 추계 및 예측 : 최종 이용 산업별(2021-2034년)

- 주요 동향

- 식품 및 음료

- 의약품

- 화장품 및 퍼스널케어

- 화학 및 산업

- 기타(틈새 분야와 신흥 분야 포함)

제10장 시장 추계 및 예측 : 유통 채널별(2021-2034년)

- 주요 동향

- 직접 판매

- 간접 판매

제11장 시장 추계 및 예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 영국

- 독일

- 프랑스

- 이탈리아

- 스페인

- 러시아

- 아시아태평양

- 중국

- 인도

- 일본

- 호주

- 한국

- 라틴아메리카

- 브라질

- 멕시코

- 중동 및 아프리카

- 아랍에미리트(UAE)

- 남아프리카

- 사우디아라비아

제12장 기업 프로파일

- Accutek Packaging Equipment

- 어팩

- Arol Group

- Closure Systems International

- Crown Holdings

- E-Pak Machinery

- Federal Manufacturing Co.

- Filamatic

- IMA Group

- KHS

- Krones

- ProMach

- Syntegon

- Tetra Pak

- Zalkin

The Global Capping Machine Market was valued at USD 2.31 billion in 2024 and is estimated to grow at a CAGR of 5.9% to reach USD 4.08 billion by 2034. This market is expanding steadily as the global demand for packaged goods surges across multiple industries. Consumer preferences continue to shift toward hygiene, ease of use, and product safety, resulting in growing consumption of bottled food, beverages, cosmetics, and pharmaceuticals. To meet this demand, manufacturers are increasingly turning to capping systems that deliver sealing accuracy, improve shelf stability, and prevent product tampering. These machines play a vital role in the production process, especially when regulatory standards for product integrity are stringent.

The integration of automation is also transforming the industry, with manufacturers deploying advanced capping systems that support seamless operations, improve throughput, and reduce downtime. The use of smart features such as IoT integration, real-time monitoring, and predictive maintenance is becoming standard in modern manufacturing environments. Adoption of Industry 4.0 technologies is further pushing demand for intelligent and high-speed systems, particularly for bottling applications in fast-moving consumer goods. Investment programs in major manufacturing economies are further accelerating the adoption of these automated packaging solutions.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.31 Billion |

| Forecast Value | $4.08 Billion |

| CAGR | 5.9% |

In 2024, the semi-automatic capping machine segment generated USD 1.01 billion and is forecasted to grow at a CAGR of 6% through 2034. These systems remain the most widely used due to their affordability, operational simplicity, and ability to adapt to a variety of container shapes and sizes. Compact design, low maintenance, and ease of installation make them especially attractive to small-scale producers in the food, cosmetic, and pharmaceutical sectors operating with limited floor space or smaller production lines.

The bottle application segment held a 34.70% share in 2024 and is projected to grow at a CAGR of 6.2% between 2025 and 2034. Bottles dominate as the primary packaging format across numerous industries because of their lightweight construction, portability, and compatibility with various cap types. From beverages and household chemicals to personal care and medical liquids, the use of bottles requires precision capping systems to maintain product integrity. Their flexibility and cost-effectiveness continue to drive demand for bottle-focused machinery, which can handle diverse cap designs like screw, snap, or press-fit closures.

United States Capping Machine Market held 75.1% share in 2024, generating USD 519.1 million. This growth is driven by the expanding packaged foods industry, increased automation across manufacturing lines, and rising regulatory requirements for production hygiene and safety. The country's pharmaceutical and food processing sectors are investing in high-performance capping systems that meet FDA and current Good Manufacturing Practice (cGMP) standards. Smart packaging technologies powered by AI, IoT, and remote diagnostics are also gaining traction as companies push toward predictive maintenance and efficiency-focused upgrades.

Leading players in the Global Capping Machine Market include Zalkin, Tetra Pak, KHS, Arol Group, IMA Group, Krones, Accutek Packaging Equipment, Federal Manufacturing Co., A Pack, Closure Systems International, Syntegon, Filamatic, ProMach, Crown Holdings, and E-Pak Machinery. To secure a stronger foothold in the global capping machine market, companies are prioritizing innovation and technology integration. Many are investing in R&D to enhance machine versatility, enabling compatibility with various cap types and container materials. Businesses are focusing on modular designs that allow easy upgrades and system scalability to meet growing production needs. Strategic partnerships with End use industries help in tailoring machines to sector-specific requirements, especially in pharmaceuticals and food. Players are also expanding their global presence through regional manufacturing units and after-sales support centers to reduce lead times and serve local markets efficiently.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.3 Data collection methods

- 1.4 Data mining sources

- 1.4.1 Global

- 1.4.2 Regional/Country

- 1.5 Base estimates and calculations

- 1.5.1 Base year calculation

- 1.5.2 Key trends for market estimation

- 1.6 Primary research and validation

- 1.6.1 Primary sources

- 1.7 Forecast model

- 1.8 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Machine type

- 2.2.3 Cap type

- 2.2.4 Container type

- 2.2.5 Speed

- 2.2.6 End use industry

- 2.2.7 Distribution channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factors affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Growth in packaged goods industries

- 3.2.1.2 Shift toward automation

- 3.2.1.3 Rising demand for bottled products

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High capital investment

- 3.2.2.2 Complex maintenance & technical expertise

- 3.2.3 Opportunities

- 3.2.3.1 Complex maintenance & technical expertise

- 3.2.3.2 Emergence of smart packaging technologies

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.6 Regulatory environment

- 3.7 Value Chain Analysis

- 3.7.1 Raw material suppliers and component manufacturers

- 3.7.2 Equipment manufacturers and OEMs

- 3.7.3 Distribution channels and sales networks

- 3.7.4 End use segments and applications

- 3.7.5 After-sales service providers

- 3.8 Price trends

- 3.8.1 By region

- 3.8.2 By machine type

- 3.9 Regulatory landscape

- 3.9.1 standards and compliance requirements

- 3.9.2 Regional regulatory frameworks

- 3.10 Certification standards Trade statistics (HS code - 5)

- 3.10.1 Major importing countries

- 3.10.2 Major exporting countries

- 3.11 Porter’s analysis

- 3.12 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Machine Type, 2021 - 2034 ($Mn, Units)

- 5.1 Key trends

- 5.2 Automatic

- 5.3 Semi-automatic

- 5.4 Manual

Chapter 6 Market Estimates & Forecast, By Cap Type, 2021 - 2034 ($Mn, Units)

- 6.1 Key trends

- 6.2 Screw caps

- 6.3 Snap-on caps

- 6.4 Press-on caps

- 6.5 ROPP (Roll-On Pilfer Proof) caps

- 6.6 Child-resistant caps

- 6.7 Cork caps

- 6.8 Push-on caps

- 6.9 Crimp caps

Chapter 7 Market Estimates & Forecast, By Container Type, 2021 - 2034 ($Mn, Units)

- 7.1 Key trends

- 7.2 Bottles

- 7.3 Jars

- 7.4 Tubes

- 7.5 Vials

- 7.6 Others (e.g., specialty or industrial containers)

Chapter 8 Market Estimates & Forecast, By Speed Type, 2021 - 2034 ($Mn, Units)

- 8.1 Key trends

- 8.2 Low speed: ~60 caps per minute (cpm)

- 8.3 Medium-speed: 60-300 cpm

- 8.4 High-speed: 300-800 cpm

- 8.5 Ultra-high speed: >800 cpm

Chapter 9 Market Estimates & Forecast, By End Use Industry, 2021 - 2034 ($Mn, Units)

- 9.1 Key trends

- 9.2 Food & Beverage

- 9.3 Pharmaceuticals

- 9.4 Cosmetics / Personal Care

- 9.5 Chemicals & Industrial

- 9.6 Others (including niche or emerging sectors)

Chapter 10 Market Estimates & Forecast, By Distribution Channel 2021 - 2034 ($Mn, Units)

- 10.1 Key trends

- 10.2 Direct sales

- 10.3 Indirect sales

Chapter 11 Market Estimates & Forecast, By Region, 2021 - 2034 ($Mn, Units)

- 11.1 Key trends

- 11.2 North America

- 11.2.1 U.S.

- 11.2.2 Canada

- 11.3 Europe

- 11.3.1 UK

- 11.3.2 Germany

- 11.3.3 France

- 11.3.4 Italy

- 11.3.5 Spain

- 11.3.6 Russia

- 11.4 Asia Pacific

- 11.4.1 China

- 11.4.2 India

- 11.4.3 Japan

- 11.4.4 Australia

- 11.4.5 South Korea

- 11.5 Latin America

- 11.5.1 Brazil

- 11.5.2 Mexico

- 11.6 MEA

- 11.6.1 UAE

- 11.6.2 South Africa

- 11.6.3 Saudi Arabia

Chapter 12 Company Profiles

- 12.1 Accutek Packaging Equipment

- 12.2 Apacks

- 12.3 Arol Group

- 12.4 Closure Systems International

- 12.5 Crown Holdings

- 12.6 E-Pak Machinery

- 12.7 Federal Manufacturing Co.

- 12.8 Filamatic

- 12.9 IMA Group

- 12.10 KHS

- 12.11 Krones

- 12.12 ProMach

- 12.13 Syntegon

- 12.14 Tetra Pak

- 12.15 Zalkin