|

시장보고서

상품코드

1808967

오일 상태 모니터링 시장 : 제공 제품별, 최종 용도별, 업계별, 지역별 예측(-2030년)Oil Condition Monitoring Market by Offering (Oil Analyzers, Oil Sensors, Spectrometers, Viscometers), Oil Sampling Type (On-Site, Off-Site), End Use (Turbines, Compressors, Engines, Hydraulic Systems, Gearboxes, Transformers) - Global Forecast to 2030 |

||||||

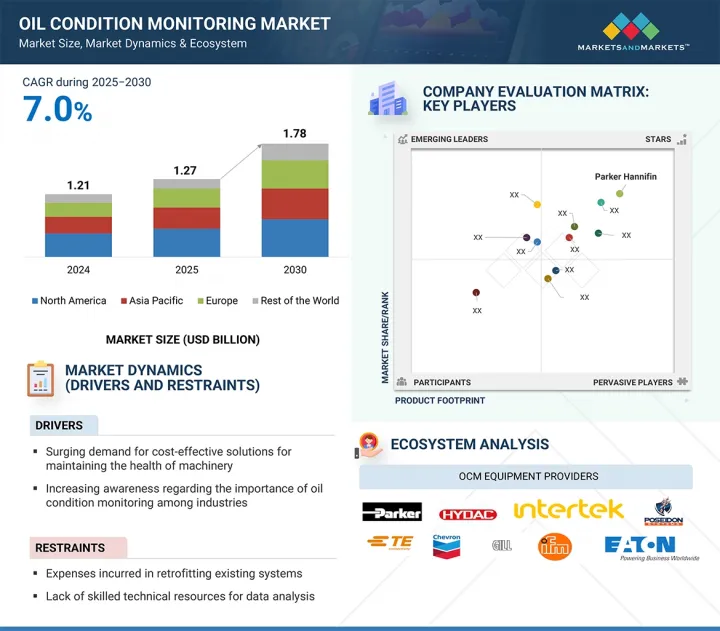

세계의 오일 상태 모니터링 시장 규모는 7.0%의 연평균 복합 성장률(CAGR)로 확대될 전망이며, 2025년 12억 7,000만 달러에서 2030년에는 17억 8,000만 달러로 성장할 것으로 예측됩니다.

자동차 및 운송 부문은 여전히 주요 촉진요인으로 엔진, 터빈, 컴프레서, 유압 시스템에서 OCM 솔루션을 채택하여 시기 적절한 유지 보수, 다운 타임 절감 및 장비 성능 최적화가 가능합니다. 가동성뿐만 아니라, 석유 및 가스, 공업 제조, 발전의 각 분야에서도 채용이 진행되고 있어 유품질의 지속적인 모니터링이 운전 효율, 비용 절감, 기기의 장수명화에 필수적입니다.

| 조사 범위 | |

|---|---|

| 조사 대상 연도 | 2021-2030년 |

| 기준 연도 | 2024년 |

| 예측 기간 | 2025-2030년 |

| 검토 단위 | 금액(10억 달러) |

| 부문별 | 제공 제품별, 최종 용도별, 업계별, 지역별 |

| 대상 지역 | 북미, 유럽, 아시아태평양 및 기타 지역 |

하드웨어, 소프트웨어 및 서비스를 포함한 오일 상태 모니터링 솔루션은 실시간 진단, 원격 모니터링, 데이터 구동 유지 보수 결정을 위해 도입되었습니다. 센서 기술, 분석 도구 및 예측 소프트웨어의 발전으로 측정 정확도가 향상되고 디지털 유지 보수 시스템과 원활하게 통합되어 유지 보수 팀에 실용적인 인사이트를 제공합니다. 산업이 자동화, 신뢰성 및 비용 효율적인 운영을 점점 더 우선시함에 따라 견고한 오일 상태 모니터링 솔루션에 대한 수요는 다양한 용도 및 산업에서 꾸준히 성장할 것으로 예측됩니다.

오일 상태 모니터링 시장의 소프트웨어 분야는 예측 기간 동안 가장 높은 CAGR로 성장할 것으로 설정되어 있으며, 업계 전체에서 데이터 구동형 유지보수 및 예측 분석의 채용이 증가하고 있는 것이 그 원동력이 되고 있습니다. 이러한 솔루션은 주요 오일 파라미터의 실시간 모니터링, 진단 및 보고를 가능하게 하고, 다운타임을 단축하며 장비 수명을 연장하는 적시 유지보수 작업을 가능하게 합니다. IoT 지원 센서, 클라우드 플랫폼 및 AI 기반 분석과의 통합은 측정 정확도를 높이고 원격 모니터링을 지원하며 유지보수 일정을 최적화합니다. 예측 소프트웨어의 지속적인 진보, 컨디션 기반 유지 보수에 대한 주목 증가, 디지털화의 진전이 보급을 뒷받침하고 있습니다. 산업계가 신뢰성, 효율성 및 비용 최적화를 우선시하는 동안 소프트웨어 분야는 석유 상태 모니터링 시장 생태계에서 주요 성장 촉진요인으로 부상하고 있습니다.

에너지 및 전력 산업 부문은 운영의 신뢰성과 효율성에 대한 관심 증가로 예측 기간 동안 높은 CAGR로 성장할 것으로 예측됩니다. 이 부문의 오일 상태 모니터링 솔루션을 통해 운영자는 장비 문제를 예측하고 유지보수 일정을 최적화하고 시스템 전체의 성능을 향상시키고 발전 중단을 보장할 수 있습니다. 디지털 모니터링 플랫폼 및 IoT 지원 센서와의 통합은 실시간 인사이트를 제공하고, 적극적인 의사 결정을 지원하며, 계획되지 않은 다운타임을 줄입니다. 전력 인프라 근대화, 스마트 그리드 구축, 신재생 에너지 통합을 위한 투자 확대는 채택을 더욱 가속화하고 있습니다. 산업계가 회복력, 효율, 비용 관리를 우선시하는 가운데 에너지 및 전력 분야는 보다 광범위한 오일 상태 모니터링 시장 중 주요 성장촉진요인으로 부상하고 있습니다.

북미는 이 지역의 첨단 산업 인프라, 예지보전 수법의 높은 채용률, 주요 시장 진출기업의 강력한 프레즌스에 힘입어 예측 기간 중에 오일 상태 모니터링(OCM) 시장을 독점할 것으로 예측됩니다. 석유 및 가스, 자동차, 항공우주, 제조업 등 업계에서는 자산 성능을 최적화하고, 가동 중지 시간을 줄이며, 운영 안전성을 높이기 위해 OCM 솔루션을 활용하고 있습니다. 이 지역에서는 IoT, AI, 클라우드 기반 애널리틱스 등의 첨단 기술을 유지 관리 업무에 통합하는 데 주력하고 있으며 시장 성장을 더욱 강화하고 있습니다. 또한 장비의 안전성과 환경 컴플라이언스에 대한 엄격한 규제가 산업계에 프로액티브 모니터링 시스템을 채택하도록 촉구하고 있습니다. 연구개발에 대한 지속적인 투자는 산업 프로세스의 급속한 디지털 변화와 함께 북미를 OCM 솔루션의 주요 시장으로 자리매김하고 있습니다.

본 보고서에서는 세계의 오일 상태 모니터링 시장에 대해 조사했으며, 제공 제품별, 최종 용도별, 업계별, 지역별 동향 및 시장 진출기업 프로파일 등을 정리했습니다.

목차

제1장 서론

제2장 조사 방법

제3장 주요 요약

제4장 중요 인사이트

제5장 시장 개요

- 서문

- 시장 역학

- 밸류체인 분석

- 가격 분석

- Porter's Five Forces 분석

- 고객의 비즈니스에 영향을 미치는 동향 및 혼란

- 생태계 분석

- 사례 연구 분석

- 기술 분석

- 무역 분석

- 특허 분석

- 규제 상황

- 오일 상태 모니터링 시장에서의 AI의 영향

- 미국의 2025년 관세

제6장 오일 컨디션을 측정하기 위한 파라미터

- 서문

- 온도

- 압력

- 밀도

- 점도

- 유전

- TAN 및 TBN

- 연료 희석

- 물 희석

- 그을음

- 마모 입자

제7장 오일 상태 모니터링에 사용되는 주요 센서

- 서문

- 유질 센서

- 마모 분말 센서 및 금속 입자 센서

- 점도 및 밀도 센서

- 유중수형 센서

제8장 오일 상태 모니터링에 사용되는 주요 기술

- 서문

- 페로그래피

- 오일 상태 모니터링에 있어서의 온라인 음향 점도 측정

- 유도 결합 플라즈마 발광 분광법(ICP-OES)

- 푸리에 변환 적외 분광법(FTIR)

- 절연 강도 시험

- 전위차 적정

제9장 오일 상태 모니터링에 사용되는 샘플링 유형

- 서문

- 현장

- 오프사이트

제10장 오일 상태 모니터링 시장 : 제공 제품별

- 서문

- 하드웨어

- 소프트웨어

- 서비스

제11장 오일 상태 모니터링 시장 : 최종 용도별

- 서문

- 터빈

- 컴프레서

- 엔진

- 유압 시스템

- 기타

제12장 오일 상태 모니터링 시장 : 업계별

- 서문

- 자동차 및 운송

- 석유 및 가스

- 에너지 및 전력

- 금속 및 광업

- 식품 및 음료

- 의약품

- 화학약품

- 기타

제13장 오일 상태 모니터링 시장 : 지역별

- 서문

- 북미

- 미국

- 캐나다

- 멕시코

- 유럽

- 독일

- 영국

- 프랑스

- 이탈리아

- 스페인

- 기타

- 아시아태평양

- 중국

- 일본

- 인도

- 한국

- 기타

- 기타 지역

- 남미

- 중동

- 아프리카

제14장 경쟁 구도

- 개요

- 주요 진입기업의 전략 및 강점

- 시장 점유율 분석(2024년)

- 주요 기업의 수익 분석(2020-2024년)

- 기업 평가 매트릭스 : 주요 진입기업(2024년)

- 기업 평가 매트릭스 : 스타트업 및 중소기업(2024년)

- 경쟁 시나리오

제15장 기업 프로파일

- 주요 진출기업

- PARKER HANNIFIN CORP

- SCHAEFFLER AG

- IFM ELECTRONIC GMBH

- TE CONNECTIVITY

- EATON

- SHELL

- GE VERNOVA

- CHEVRON CORPORATION

- INTERTEK GROUP PLC

- BUREAU VERITAS

- TOTALENERGIES

- 기타 기업

- EVERLLENCE

- UNIMARINE

- HYDAC INTERNATIONAL GMBH

- TAN DELTA SYSTEMS PLC

- VERITAS PETROLEUM SERVICES

- SPECTRO ANALYTICAL INSTRUMENTS GMBH

- AVENISENSE

- MICROMEN TECHNOLOGIES INC.

- GILL SENSORS & CONTROLS LIMITED

- POSEIDON SYSTEMS, LLC

- CM TECHNOLOGIES GMBH

- ERALYTICS

- DES-CASE

- BUHLER TECHNOLOGIES GMBH

- MINIMAC SYSTEMS PVT LTD

제16장 부록

AJY 25.09.16With a CAGR of 7.0%, the global oil condition monitoring market is projected to grow from USD 1.27 billion in 2025 to USD 1.78 billion by 2030. The automotive and transportation sector remains a key growth driver, with OCM solutions increasingly adopted in engines, turbines, compressors, and hydraulic systems to enable timely maintenance, reduce downtime, and optimize equipment performance. Beyond mobility, adoption is rising across the oil and gas, industrial manufacturing, and power generation sectors, where continuous monitoring of oil quality is critical for operational efficiency, cost reduction, and equipment longevity.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Billion) |

| Segments | By Offering, End Use, Industry, and Region |

| Regions covered | North America, Europe, APAC, RoW |

Oil condition monitoring solutions, including hardware, software, and services, are being deployed for real-time diagnostics, remote monitoring, and data-driven maintenance decisions. Advances in sensor technology, analytical tools, and predictive software are enhancing measurement accuracy, integrating seamlessly with digital maintenance systems, and providing actionable insights for maintenance teams. As industries increasingly prioritize automation, reliability, and cost-efficient operations, the demand for robust oil condition monitoring solutions is expected to grow steadily across diverse applications and industries.

" Rise of Predictive Analytics to Drive Growth of Software in the Oil Condition Monitoring Market."

The software segment in the oil condition monitoring market is set to grow at the highest CAGR during the forecast period, driven by the rising adoption of data-driven maintenance and predictive analytics across industries. These solutions enable real-time monitoring, diagnostics, and reporting of key oil parameters, allowing timely maintenance actions that reduce downtime and extend equipment life. Integration with IoT-enabled sensors, cloud platforms, and AI-based analytics enhances measurement accuracy, supports remote monitoring, and optimizes maintenance schedules. Continuous advancements in predictive software, growing focus on condition-based maintenance, and increasing digitalization are fueling adoption. As industries prioritize reliability, efficiency, and cost optimization, the software segment is emerging as a key growth driver within the oil condition monitoring market ecosystem.

" Rising Focus on Reliability and Efficiency to Propel Energy & Power Industry Segment Growth."

The energy & power industry segment is expected to grow at a significant CAGR during the forecast period, driven by the increasing focus on operational reliability and efficiency. Oil condition monitoring solutions in this segment enable operators to anticipate equipment issues, optimize maintenance schedules, and improve overall system performance, ensuring uninterrupted power generation. Integration with digital monitoring platforms and IoT-enabled sensors provides real-time insights, supports proactive decision-making, and reduces unplanned downtime. Growing investments in power infrastructure modernization, smart grid deployment, and renewable energy integration are further accelerating adoption. As industries continue to prioritize resilience, efficiency, and cost management, the energy & power segment is emerging as a key growth driver within the broader oil condition monitoring market.

" North America Leads the Oil Condition Monitoring Market with Strong Technological Adoption"

North America is expected to dominate the oil condition monitoring (OCM) market during the forecast period, supported by the region's advanced industrial infrastructure, high adoption of predictive maintenance practices, and strong presence of key market players. Industries such as oil and gas, automotive, aerospace, and manufacturing are increasingly leveraging OCM solutions to optimize asset performance, reduce downtime, and enhance operational safety. The region's strong focus on integrating advanced technologies such as IoT, AI, and cloud-based analytics into maintenance operations further drives market growth. Additionally, stringent regulations on equipment safety and environmental compliance encourage industries to adopt proactive monitoring systems. Continuous investments in R&D, coupled with the rapid digital transformation of industrial processes, position North America as a leading market for OCM solutions.

Breakdown of primaries

A variety of executives from key organizations operating in the oil condition monitoring market, including CEOs, marketing directors, and innovation and technology directors, were interviewed in depth.

- By Company Type: Tier 1 - 45%, Tier 2 - 35%, and Tier 3 - 20%

- By Designation: Directors - 45%, C-level - 30%, and Others - 25%

- By Region: Asia Pacific - 45%, North America - 25%, Europe - 20%, and RoW - 10%

Note: Other designations include sales and product managers. The three tiers of the companies are defined based on their total revenue in 2024: Tier 1 - revenue greater than or equal to USD 1 billion; Tier 2 - revenue between USD 500 million and USD 1 billion; and Tier 3 revenue less than or equal to USD 500 million.

Major players profiled in this report are as follows: Parker Hannifin Corp (US), Eaton (Ireland), GE Vernova (US), ifm electronic gmbh (Germany), TE Connectivity (Ireland), Schaeffler AG (Germany), Shell (UK), TotalEnergies (France), Chevron Corporation (US), Intertek Group plc (UK), Bureau Veritas (France), Everllence (Germany), Unimarine (Singapore), HYDAC International GmbH (Germany), Tan Delta Systems PLC (UK), SPECTRO Analytical Instruments GmbH (Germany), Avenisense (France), Micromen Technologies Inc. (Canada), Gill Sensors & Controls Limited (UK), Poseidon Systems, LLC (US), CM Technologies GmbH (Germany), Des-Case (US), Minimac Systems Pvt Ltd (India), eralytics GmbH (Austria), and Buhler Technologies GmbH (Germany). These leading companies possess a wide portfolio of products, establishing a prominent presence in established as well as emerging markets.

The study provides a detailed competitive analysis of these key players in the oil condition monitoring market, presenting their company profiles, most recent developments, and key market strategies.

Research Coverage

In this report, the oil condition monitoring market has been segmented based on offering, end use, industry, and region. The offering segment includes hardware, software, and services. The end use segment is categorized into turbines, compressors, engines, hydraulic systems, and other systems (gear systems, industrial tooling systems, transformers). Based on industry, the market is segmented into automotive & transportation, energy & power, oil & gas, metal & mining, food & beverages, pharmaceutical, chemical, and others (pulp, paper & cement). The regional analysis covers North America, Europe, Asia Pacific, and the Rest of the World (RoW).

Reasons to buy the report

The report will help the leaders/new entrants in this market with information on the closest approximations of the revenue numbers for the overall market and the subsegments. It will also help stakeholders understand the competitive landscape and gain more insights to better position their businesses and plan suitable go-to-market strategies. The report also helps stakeholders understand the oil condition monitoring market's pulse and provides information on key market drivers, restraints, challenges, and opportunities.

Key Benefits of Buying the Report

- Analysis of key drivers (surging demand for cost-effective solutions for maintaining health of machinery, Increasing awareness regarding importance of oil condition monitoring among industries, growing focus on reducing maintenance costs, increasing use of synthetic and specialized lubricants), restraints (expenses incurred in retrofitting existing systems, lack of skilled technical resources for data analysis, data security concerns in connected monitoring systems), opportunities (growing demand for energy, increasing adoption of big data analytics and IIoT, integration of AI-powered diagnostics for real-time insights), and challenges (adaptation to harsh operating environments, offline oil sampling limitations) influencing the growth of the oil condition monitoring market.

- Product Development/Innovation: Detailed insights on upcoming technologies, research and development activities, and new product launches in the oil condition monitoring market.

- Market Development: Comprehensive information about lucrative markets - the report analyzes the oil condition monitoring market across varied regions.

- Market Diversification: Exhaustive information about new products/services, untapped geographies, recent developments, and investments in the oil condition monitoring market.

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players like Parker Hannifin Corp (US), Eaton (Ireland), ifm electronic gmbh (Germany), TE Connectivity (Ireland), Schaeffler AG (Germany), and others.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKET SEGMENTATION

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.4 YEARS CONSIDERED

- 1.5 CURRENCY CONSIDERED

- 1.6 LIMITATIONS

- 1.7 STAKEHOLDERS

- 1.8 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 RESEARCH APPROACH

- 2.1.2 SECONDARY DATA

- 2.1.2.1 Major secondary sources

- 2.1.2.2 Key data from secondary sources

- 2.1.3 PRIMARY DATA

- 2.1.3.1 Primary interviews with experts

- 2.1.3.2 Key data from primary sources

- 2.1.3.3 Key industry insights

- 2.1.3.4 Breakdown of primaries

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 BOTTOM-UP APPROACH

- 2.2.1.1 Steps for estimating market size by bottom-up approach (demand side)

- 2.2.2 TOP-DOWN APPROACH

- 2.2.2.1 Steps for estimating market size by top-down approach (supply side)

- 2.2.1 BOTTOM-UP APPROACH

- 2.3 MARKET BREAKDOWN AND DATA TRIANGULATION

- 2.4 RESEARCH ASSUMPTIONS

- 2.5 RISK ASSESSMENT

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ASIA PACIFIC TO CREATE LUCRATIVE OPPORTUNITIES FOR PLAYERS IN OIL CONDITION MONITORING MARKET

- 4.2 OIL CONDITION MONITORING MARKET, BY OFFERING

- 4.3 OIL CONDITION MONITORING MARKET, BY END USE

- 4.4 OIL CONDITION MONITORING MARKET, BY INDUSTRY

- 4.5 OIL CONDITION MONITORING MARKET, BY REGION

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Increasing requirement for cost-efficient strategies to maintain equipment health

- 5.2.1.2 Growing awareness regarding value of oil condition monitoring

- 5.2.1.3 Increasing attention toward lowering maintenance costs

- 5.2.1.4 Increasing use of synthetic and specialized lubricants

- 5.2.2 RESTRAINTS

- 5.2.2.1 Rising expenses for modernizing current systems

- 5.2.2.2 Deficit of expertise in managing data analysis and software systems

- 5.2.2.3 Data security concerns in connected monitoring systems

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Rising demand for energy with predictive maintenance solutions

- 5.2.3.2 Adoption of big data analytics and IIoT

- 5.2.3.3 Integration of AI-powered diagnostics for real-time insights

- 5.2.4 CHALLENGES

- 5.2.4.1 Adaptation to harsh operating environments

- 5.2.4.2 Offline oil sampling limitations

- 5.2.1 DRIVERS

- 5.3 VALUE CHAIN ANALYSIS

- 5.4 PRICING ANALYSIS

- 5.4.1 INDICATIVE PRICING OF OIL QUALITY SENSORS AND TESTING KITS, BY KEY PLAYER

- 5.4.2 AVERAGE SELLING PRICE OF OIL QUALITY SENSORS

- 5.4.3 AVERAGE SELLING PRICE OF OIL QUALITY SENSORS, BY REGION

- 5.5 PORTER'S FIVE FORCES ANALYSIS

- 5.6 TRENDS AND DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.7 ECOSYSTEM ANALYSIS

- 5.8 CASE STUDY ANALYSIS

- 5.8.1 AUSTRIAN PAPER MILL ADOPTED ERALYTICS' OIL CONDITION MONITORING SYSTEM TO REDUCE DOWNTIME AND IMPROVE LUBRICATION

- 5.8.2 EUROPEAN FARM OPERATOR ADOPTED INTERTEK'S SEM/EDS TO IDENTIFY FAILURE INDICATORS AND PREVENT FUTURE BREAKDOWNS

- 5.8.3 INTERTEK CALEB BRETT ENHANCED PARTICLE CHARACTERISATION WITH SEM/EDS FOR VARIOUS INDUSTRIAL CLIENTS

- 5.9 TECHNOLOGY ANALYSIS

- 5.9.1 KEY TECHNOLOGIES

- 5.9.1.1 Wear debris analysis

- 5.9.1.2 Spectroscopic oil analysis

- 5.9.1.3 Moisture and particle counters

- 5.9.2 COMPLEMENTARY TECHNOLOGIES

- 5.9.2.1 IoT-enabled sensors

- 5.9.2.2 Cloud computing

- 5.9.3 ADJACENT TECHNOLOGIES

- 5.9.3.1 Vibration monitoring systems

- 5.9.3.2 Infrared thermography

- 5.9.1 KEY TECHNOLOGIES

- 5.10 TRADE ANALYSIS

- 5.10.1 IMPORT SCENARIO (HS CODE 903190)

- 5.10.2 EXPORT SCENARIO (HS CODE 903190)

- 5.11 PATENT ANALYSIS

- 5.12 REGULATORY LANDSCAPE

- 5.12.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS RELATED TO OIL CONDITION MONITORING MARKET

- 5.12.2 MAJOR STANDARDS RELATED TO OIL CONDITION MONITORING MARKET

- 5.13 IMPACT OF AI ON OIL CONDITION MONITORING MARKET

- 5.13.1 INTRODUCTION

- 5.13.2 IMPACT OF AI ON KEY INDUSTRIES IN OIL CONDITION MONITORING MARKET

- 5.13.2.1 Automotive & transportation

- 5.13.2.2 Energy & power

- 5.13.3 FUTURE OF AI IN OIL CONDITION MONITORING ECOSYSTEM

- 5.14 US 2025 TARIFF

- 5.14.1 INTRODUCTION

- 5.14.2 KEY TARIFF RATES

- 5.14.3 PRICE IMPACT ANALYSIS

- 5.14.4 IMPACT ON COUNTRY

- 5.14.4.1 US

- 5.14.4.2 Europe

- 5.14.4.3 Asia Pacific

- 5.14.5 IMPACT ON KEY END-USE INDUSTRIES

6 PARAMETERS FOR MEASURING OIL CONDITION

- 6.1 INTRODUCTION

- 6.2 TEMPERATURE

- 6.3 PRESSURE

- 6.4 DENSITY

- 6.5 VISCOSITY

- 6.6 DIELECTRIC

- 6.7 TAN/TBN

- 6.8 FUEL DILUTION

- 6.9 WATER DILUTION

- 6.10 SOOT

- 6.11 WEAR PARTICLES

7 KEY SENSORS USED FOR OIL CONDITION MONITORING

- 7.1 INTRODUCTION

- 7.2 OIL QUALITY SENSORS

- 7.3 WEAR DEBRIS SENSORS/METALLIC PARTICLE SENSORS

- 7.4 VISCOSITY/DENSITY SENSORS

- 7.5 WATER-IN-OIL SENSORS

8 MAJOR TECHNIQUES USED FOR OIL CONDITION MONITORING

- 8.1 INTRODUCTION

- 8.2 FERROGRAPHY

- 8.3 ON-LINE ACOUSTIC VISCOMETRY IN OIL CONDITION MONITORING

- 8.4 INDUCTIVELY COUPLED PLASMA - OPTICAL EMISSION SPECTROSCOPY (ICP-OES)

- 8.5 FOURIER TRANSFORM INFRARED (FTIR) SPECTROSCOPY

- 8.6 DIELECTRIC STRENGTH TEST

- 8.7 POTENTIOMETRIC TITRATION

9 SAMPLING TYPES IMPLEMENTED FOR OIL CONDITION MONITORING

- 9.1 INTRODUCTION

- 9.2 ON-SITE

- 9.2.1 PORTABLE KITS

- 9.2.1.1 Expanding use of portable test kits to enable flexibility and rapid troubleshooting in critical operations

- 9.2.2 FIXED CONTINUOUS MONITORING

- 9.2.2.1 Rising adoption of fixed continuous monitoring to support digital transformation and proactive asset management

- 9.2.1 PORTABLE KITS

- 9.3 OFF-SITE

- 9.3.1 RELIANCE ON LABORATORY ACCURACY AND COMPREHENSIVE ANALYSIS TO SUSTAIN DEMAND FOR OFF-SITE SAMPLING

10 OIL CONDITION MONITORING MARKET, BY OFFERING

- 10.1 INTRODUCTION

- 10.2 HARDWARE

- 10.2.1 ACCELERATED DEPLOYMENT OF SMART SENSORS AND PORTABLE ANALYZERS TO DRIVE MARKET

- 10.3 SOFTWARE

- 10.3.1 RISING INTEGRATION OF AI AND CLOUD-BASED ANALYTICS TO REDEFINE OIL CONDITION MONITORING SOFTWARE LANDSCAPE

- 10.4 SERVICES

- 10.4.1 DEMAND FOR COMPREHENSIVE TESTING AND MAINTENANCE SERVICES TO STRENGTHEN GROWTH

11 OIL CONDITION MONITORING MARKET, BY END USE

- 11.1 INTRODUCTION

- 11.2 TURBINES

- 11.2.1 NEED FOR PREDICTIVE MAINTENANCE AND ASSET RELIABILITY TO DRIVE ADOPTION OF OIL CONDITION MONITORING IN TURBINES

- 11.3 COMPRESSORS

- 11.3.1 FOCUS ON OPERATIONAL EFFICIENCY AND ENERGY OPTIMIZATION TO ACCELERATE ADOPTION OF COMPRESSOR OIL CONDITION MONITORING SOLUTIONS

- 11.4 ENGINES

- 11.4.1 EMPHASIS ON ENHANCED PERFORMANCE AND REDUCED MAINTENANCE COSTS TO DRIVE NEED FOR OIL CONDITION MONITORING FOR ENGINES

- 11.5 HYDRAULIC SYSTEMS

- 11.5.1 FOCUS ON SYSTEM RELIABILITY AND MAINTENANCE EFFICIENCY TO DRIVE NEED FOR OIL CONDITION MONITORING IN HYDRAULIC SYSTEMS

- 11.6 OTHER SYSTEMS

12 OIL CONDITION MONITORING MARKET, BY INDUSTRY

- 12.1 INTRODUCTION

- 12.2 AUTOMOTIVE & TRANSPORTATION

- 12.2.1 RISING DEMAND FOR PREDICTIVE MAINTENANCE IN VEHICLES AND FLEETS TO BOOST DEMAND

- 12.3 OIL & GAS

- 12.3.1 OIL CONDITION MONITORING TO ENHANCE EQUIPMENT RELIABILITY IN EXPLORATION AND REFINING

- 12.4 ENERGY & POWER

- 12.4.1 RISING DEMAND FOR PREDICTIVE MAINTENANCE IN POWER INFRASTRUCTURE TO DRIVE ADOPTION OF OIL CONDITION MONITORING SOLUTIONS

- 12.5 METAL & MINING

- 12.5.1 INCREASING ADOPTION OF OIL CONDITION MONITORING SYSTEMS TO ENHANCE HEAVY MACHINERY RELIABILITY

- 12.6 FOOD & BEVERAGES

- 12.6.1 GROWING ADOPTION OF OIL CONDITION MONITORING SOLUTIONS TO SAFEGUARD HYGIENE AND EQUIPMENT RELIABILITY

- 12.7 PHARMACEUTICALS

- 12.7.1 FOCUS ON MAINTAINING PRODUCTION CONSISTENCY AND STERILITY WITH OIL CONDITION MONITORING TO DRIVE MARKET

- 12.8 CHEMICALS

- 12.8.1 NEED FOR IMPROVING SAFETY AND PROCESS RELIABILITY TO BOOST GROWTH

- 12.9 OTHER INDUSTRIES

13 OIL CONDITION MONITORING MARKET, BY REGION

- 13.1 INTRODUCTION

- 13.2 NORTH AMERICA

- 13.2.1 US

- 13.2.1.1 Industrial digitalization and government support to propel growth

- 13.2.2 CANADA

- 13.2.2.1 Need for modernization of energy sector to boost market

- 13.2.3 MEXICO

- 13.2.3.1 Rapid industrial growth and infrastructure development to drive market

- 13.2.1 US

- 13.3 EUROPE

- 13.3.1 GERMANY

- 13.3.1.1 Advancements in manufacturing and automotive sectors to drive market

- 13.3.2 UK

- 13.3.2.1 Focus on energy transition and offshore industries to spur demand

- 13.3.3 FRANCE

- 13.3.3.1 Strong growth in aerospace and automotive sectors to boost growth

- 13.3.4 ITALY

- 13.3.4.1 Expanding industrial manufacturing and marine sectors to spur market growth

- 13.3.5 SPAIN

- 13.3.5.1 Wind energy expansion and industrial diversification to propel market

- 13.3.6 REST OF EUROPE

- 13.3.1 GERMANY

- 13.4 ASIA PACIFIC

- 13.4.1 CHINA

- 13.4.1.1 Expanding industrial base and manufacturing leadership to strengthen adoption of oil condition monitoring solutions

- 13.4.2 JAPAN

- 13.4.2.1 Focus on maintaining robust automotive base to drive market growth

- 13.4.3 INDIA

- 13.4.3.1 Industrial expansion, energy transformation, and growth of oil & gas to accelerate market

- 13.4.4 SOUTH KOREA

- 13.4.4.1 Growth in automotive fleets, heavy industries, and marine operations to boost demand

- 13.4.5 REST OF ASIA PACIFIC

- 13.4.1 CHINA

- 13.5 ROW

- 13.5.1 SOUTH AMERICA

- 13.5.1.1 Rapid industrial expansion and energy sector modernization to propel market

- 13.5.2 MIDDLE EAST

- 13.5.2.1 Emphasis on predictive maintenance to accelerate need for oil condition monitoring

- 13.5.2.2 GCC countries

- 13.5.2.2.1 Dominance of oil & gas sector and rapid industrial modernization to fuel market

- 13.5.2.3 Rest of Middle East

- 13.5.3 AFRICA

- 13.5.3.1 Increase in mining, energy, and infrastructure projects to propel growth

- 13.5.1 SOUTH AMERICA

14 COMPETITIVE LANDSCAPE

- 14.1 OVERVIEW

- 14.2 KEY PLAYER STRATEGIES/RIGHT TO WIN

- 14.3 MARKET SHARE ANALYSIS, 2024

- 14.4 REVENUE ANALYSIS OF KEY COMPANIES, 2020-2024

- 14.5 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 14.5.1 STARS

- 14.5.2 EMERGING LEADERS

- 14.5.3 PERVASIVE PLAYERS

- 14.5.4 PARTICIPANTS

- 14.5.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 14.5.5.1 Company footprint

- 14.5.5.2 Offering footprint

- 14.5.5.3 Industry footprint

- 14.5.5.4 Region footprint

- 14.6 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 14.6.1 PROGRESSIVE COMPANIES

- 14.6.2 RESPONSIVE COMPANIES

- 14.6.3 DYNAMIC COMPANIES

- 14.6.4 STARTING BLOCKS

- 14.7 COMPETITIVE SCENARIO

- 14.7.1 PRODUCT LAUNCHES

- 14.7.2 DEALS

15 COMPANY PROFILES

- 15.1 KEY PLAYERS

- 15.1.1 PARKER HANNIFIN CORP

- 15.1.1.1 Business overview

- 15.1.1.2 Products/Solutions/Services offered

- 15.1.1.3 Recent developments

- 15.1.1.3.1 Product launches

- 15.1.1.3.2 Deals

- 15.1.1.4 MnM view

- 15.1.1.4.1 Key strengths/Right to win

- 15.1.1.4.2 Strategic choices

- 15.1.1.4.3 Weaknesses and competitive threats

- 15.1.2 SCHAEFFLER AG

- 15.1.2.1 Business overview

- 15.1.2.2 Products/Solutions/Services offered

- 15.1.2.3 MnM view

- 15.1.2.3.1 Key strengths/Right to win

- 15.1.2.3.2 Strategic choices

- 15.1.2.3.3 Weaknesses and competitive threats

- 15.1.3 IFM ELECTRONIC GMBH

- 15.1.3.1 Business overview

- 15.1.3.2 Products/Solutions/Services offered

- 15.1.3.3 MnM view

- 15.1.3.3.1 Key strengths/Right to win

- 15.1.3.3.2 Strategic choices

- 15.1.3.3.3 Weaknesses and competitive threats

- 15.1.4 TE CONNECTIVITY

- 15.1.4.1 Business overview

- 15.1.4.2 Products/Solutions/Services offered

- 15.1.4.3 MnM view

- 15.1.4.3.1 Key strengths/Right to win

- 15.1.4.3.2 Strategic choices

- 15.1.4.3.3 Weaknesses and competitive threats

- 15.1.5 EATON

- 15.1.5.1 Business overview

- 15.1.5.2 Products/Solutions/Services offered

- 15.1.5.3 Recent developments

- 15.1.5.3.1 Product launches

- 15.1.5.4 MnM view

- 15.1.5.4.1 Key strengths/Right to win

- 15.1.5.4.2 Strategic choices

- 15.1.5.4.3 Weaknesses and competitive threats

- 15.1.6 SHELL

- 15.1.6.1 Business overview

- 15.1.6.2 Products/Solutions/Services offered

- 15.1.6.3 Recent developments

- 15.1.6.3.1 Deals

- 15.1.7 GE VERNOVA

- 15.1.7.1 Business overview

- 15.1.7.2 Products/Solutions/Services offered

- 15.1.8 CHEVRON CORPORATION

- 15.1.8.1 Business overview

- 15.1.8.2 Products/Solutions/Services offered

- 15.1.9 INTERTEK GROUP PLC

- 15.1.9.1 Business overview

- 15.1.9.2 Products/Solutions/Services offered

- 15.1.9.3 Recent developments

- 15.1.9.3.1 Deals

- 15.1.10 BUREAU VERITAS

- 15.1.10.1 Business overview

- 15.1.10.2 Products/Solutions/Services offered

- 15.1.11 TOTALENERGIES

- 15.1.11.1 Business overview

- 15.1.11.2 Products/Solutions/Services offered

- 15.1.11.3 Recent developments

- 15.1.11.3.1 Deals

- 15.1.1 PARKER HANNIFIN CORP

- 15.2 OTHER KEY PLAYERS

- 15.2.1 EVERLLENCE

- 15.2.2 UNIMARINE

- 15.2.3 HYDAC INTERNATIONAL GMBH

- 15.2.4 TAN DELTA SYSTEMS PLC

- 15.2.5 VERITAS PETROLEUM SERVICES

- 15.2.6 SPECTRO ANALYTICAL INSTRUMENTS GMBH

- 15.2.7 AVENISENSE

- 15.2.8 MICROMEN TECHNOLOGIES INC.

- 15.2.9 GILL SENSORS & CONTROLS LIMITED

- 15.2.10 POSEIDON SYSTEMS, LLC

- 15.2.11 CM TECHNOLOGIES GMBH

- 15.2.12 ERALYTICS

- 15.2.13 DES-CASE

- 15.2.14 BUHLER TECHNOLOGIES GMBH

- 15.2.15 MINIMAC SYSTEMS PVT LTD

16 APPENDIX

- 16.1 DISCUSSION GUIDE

- 16.2 KNOWLEDGE STORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 16.3 CUSTOMIZATION OPTIONS

- 16.4 RELATED REPORTS

- 16.5 AUTHOR DETAILS