|

시장보고서

상품코드

1811757

광업 자동화 시장(-2030년) : 제공별(자동 운반/채굴 트럭, 자동 시추 리그, 지하 LHD 로더, 터널 굴착기, 스마트 환기 시스템), 소프트웨어별(원격 모니터링, 자산 관리 시스템)Mining Automation Market by Offering (Autonomous Hauling/Mining Trucks, Autonomous Drilling Rigs, Underground LHD Loaders, Tunneling Equipment, Smart Ventilation Systems), Software (Remote Monitoring, Asset Management System) - Global Forecast to 2030 |

||||||

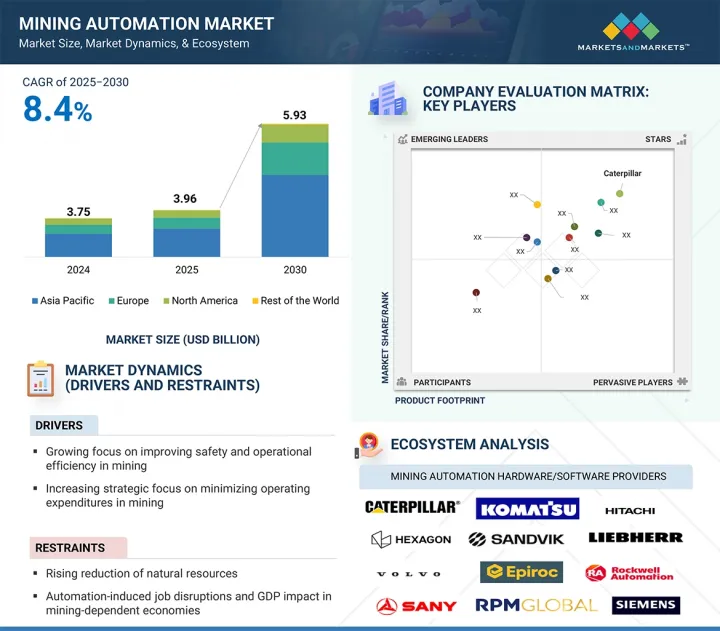

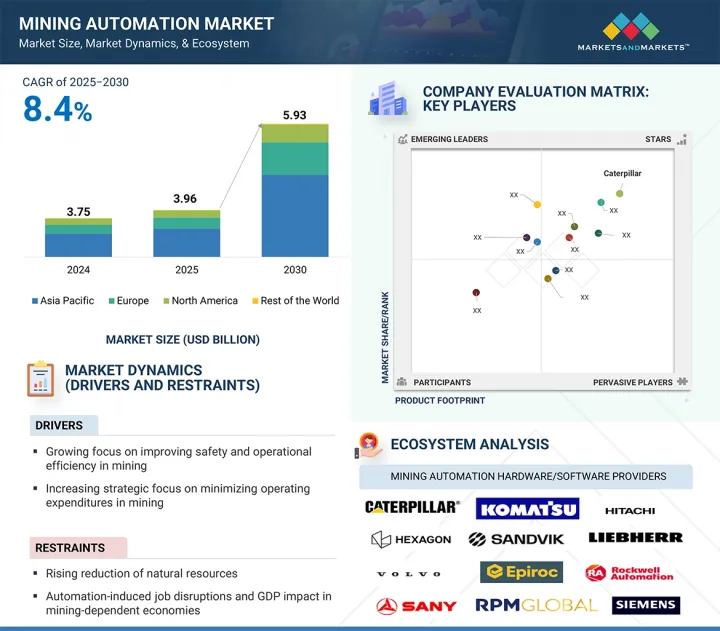

세계의 광업 자동화 시장 규모는 2025년 39억 6,000만 달러에서 8.4%의 CAGR로 증가하여 2030년에는 59억 3,000만 달러로 성장할 것으로 예측됩니다.

자동화는 광산 현장의 사고 등 안전에 대한 우려를 줄이고, 채굴 작업을 보다 효율적이고 안전하게 만드는 데 도움이 됩니다.

| 조사 범위 | |

|---|---|

| 조사 대상 연도 | 2021-2030년 |

| 기준 연도 | 2024년 |

| 예측 기간 | 2025-2030년 |

| 단위 | 금액(달러) |

| 부문 | 제공, 기술, 워크플로우, 용도, 지역 |

| 대상 지역 | 북미, 유럽, 아시아태평양, 기타 지역 |

채굴 프로세스를 자동화함으로써 광산 사업자는 효율성을 높이고, 시간과 자원 낭비를 줄이며, 비용을 절감할 수 있고, 궁극적으로 광산 산업에서 경쟁력을 강화할 수 있습니다. 생산성 향상의 필요성은 광석 등급 하락, 광물 비용 상승, 숙련된 노동력 부족, 엄격한 규제 준수 등의 요인에 의해 촉진되고 있습니다. 이러한 과제에 대응하기 위한 수단으로 자동화는 매력적인 솔루션이 되고 있습니다.

"용도별로는 광물 채굴이 시장에서 주요 점유율을 차지"

광물 채굴에는 건설, 농업, 제조업에 필수적인 칼륨염, 인산염, 석회석, 석영, 실리카, 석고와 같은 산업용 광물 채굴이 포함됩니다. 이러한 광물 채굴은 대규모 채굴 작업에서 운영 효율을 높이고 인적 노동력을 줄이기 위해 자동화에 크게 의존하고 있습니다. 자동 운전 운반 트럭, 스마트 자재 취급 시스템 등 자동화 기술이 광범위하고 다양한 광상을 관리하기 위해 점점 더 많이 도입되고 있습니다. 여기서 초점은 생산성을 향상시키는 동시에 토지 이용과 토지 복구를 규제하는 환경 법규를 준수하는 데에 맞춰져 있습니다.

"워크플로우별로는 예측 기간 동안 채굴 프로세스 부문이 예측 기간 동안 2위 점유율을 유지"

광업 프로세스는 광산의 개발이 완료되어 사용 가능한 상태가 된 후 이루어지는 다양한 활동을 말합니다. 이 단계에서는 굴착, 발파, 광석을 투기장까지 운반하는 작업 등이 진행됩니다. 최근 몇 년간의 광업 자동화 기술 혁신으로 이러한 작업은 더욱 효율적이고 편리해졌습니다. 광산에서 광석을 채굴장에서 투기장까지 운반하는 작업은 광산 운영에서 가장 중요하고 자본 집약적인 활동입니다. 전반적인 생산성을 보장하기 위해서는 지속적이고 효율적인 운반 사이클이 필요합니다. 광산 내부의 운반 프로세스를 자동화함으로써 안전 및 생산성 향상, 유지보수 비용 절감, 연료 소비 효율화, 타이어 수명 연장, 가동 중단 시간 단축 등의 이점을 얻을 수 있습니다.

세계의 광업 자동화 시장을 조사했으며, 시장 개요, 시장 성장에 영향을 미치는 각종 영향요인 분석, 기술·특허 동향, 법·규제 환경, 사례 분석, 시장 규모 추정 및 예측, 각종 부문별·지역별·주요 국가별 상세 분석, 경쟁 구도, 주요 기업 개요 등의 정보를 정리하여 전해드립니다.

목차

제1장 소개

제2장 조사 방법

제3장 주요 요약

제4장 주요 인사이트

제5장 시장 개요

- 시장 역학

- 성장 촉진요인

- 성장 억제요인

- 기회

- 과제

- 고객의 사업에 영향을 미치는 동향/혼란

- 가격 분석

- 밸류체인 분석

- 생태계 분석

- 투자와 자금 조달 시나리오

- 기술 분석

- 특허 분석

- 무역 분석

- 2025-2026년의 주요 회의와 이벤트

- 사례 연구 분석

- 규제 상황

- Porter's Five Forces 분석

- 주요 이해관계자와 구입 기준

- AI/생성형 AI가 광업 자동화 시장에 미치는 영향

- 2025년 미국 관세의 영향 - 개요

제6장 광업 자동화 시장 : 제공 내용별

- 장비

- 자동 운반/채굴 트럭

- 자동 시추 리그

- 지하 LHD 로더

- 터널 굴착기

- 스마트 환기 시스템

- 펌프 스테이션

- 기타

- 소프트웨어

- 노동 안전 관리 소프트웨어

- 환경 모니터링 소프트웨어

- 차량·기기 관리 소프트웨어

- 원격 모니터링 소프트웨어

- 데이터 관리 소프트웨어

- 자산 관리 소프트웨어

- 통신 시스템

- 무선 메시 네트워크

- 내비게이션 시스템

- RFID 태그

제7장 광업 자동화 시장 : 기술별

- 지하 채굴

- 노천 채굴

제8장 광업 자동화 시장 : 워크플로우별

- 광산 개발

- 터널 굴착

- 액세스 도로 건설

- 부지 정비·벌채

- 채굴 프로세스

- 자동 운반

- 자동 굴착

- 광산 유지보수

- HVAC 설치·유지보수

- 광산 배수

제9장 광업 자동화 시장 : 용도별

- 광물 채굴

- 금속 채굴

- 석탄 채굴

제10장 광업 자동화 시장 : 지역별

- 북미

- 거시경제 전망

- 미국

- 캐나다

- 멕시코

- 유럽

- 거시경제 전망

- 튀르키예

- 스웨덴

- 독일

- 폴란드

- 기타

- 아시아태평양

- 거시경제 전망

- 중국

- 인도

- 호주

- 인도네시아

- 기타

- 기타 지역

- 거시경제 전망

- 남미

- 중동

- 아프리카

제11장 경쟁 구도

- 주요 진출 기업의 전략/강점

- 매출 분석

- 상위 5개사 시장 점유율 분석

- 제품 비교

- 기업 평가와 재무 지표

- 기업 평가 매트릭스 : 주요 기업

- 기업 평가 매트릭스 : 스타트업/중소기업

- 경쟁 시나리오

제12장 기업 개요

- 주요 기업

- CATERPILLAR

- KOMATSU

- SANDVIK AB

- EPIROC AB

- HITACHI CONSTRUCTION MACHINERY CO., LTD.

- AB VOLVO

- HEXAGON AB

- LIEBHERR-INTERNATIONAL DEUTSCHLAND GMBH

- ROCKWELL AUTOMATION

- RPMGLOBAL HOLDINGS LIMITED

- SANY GROUP

- SIEMENS

- TRIMBLE INC.

- ABB

- 기타 기업

- ATDI SA

- CIGEN

- COENCORP

- DATAMINE

- GROUNDHOG

- HAULTRAX

- MICROMINE

- SYMX.AI

- STI ENGINEERING

- ZITRON

- MINESENSE TECHNOLOGIES LTD.

제13장 부록

KSM 25.09.25At a CAGR of 8.4%, the global mining automation market is anticipated to grow from USD 3.96 billion in 2025 to USD 5.93 billion in 2030. Automation can help mitigate safety concerns, such as injuries at the mine site, and make mining operations more efficient and safer.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Billion) |

| Segments | By Offering, Technique, Workflow, Application, and Region |

| Regions covered | North America, Europe, APAC, RoW |

By automating mining processes, mine owners can improve efficiency, reduce waste of time and resources, and save costs, ultimately leading to a more competitive position in the mining industry. The need for increased productivity is also driven by declining ore grades, rising costs of minerals, a shortage of skilled labor, and stringent regulatory compliance, making automation an attractive solution to address these challenges.

"Mineral mining to capture prominent share of mining automation market"

The mineral mining encompasses the extraction of industrial minerals such as potash, phosphate, limestone, quartz, silica, and gypsum, which are vital for construction, agriculture, and manufacturing industries. This mineral mining relies heavily on automation to optimize bulk extraction processes, enhancing operational efficiency and reducing manual labor in large-scale operations. Automation technologies such as autonomous haul trucks and smart material handling systems are increasingly integrated to manage the diverse and widespread nature of these deposits. Here, the focus is improving productivity while adhering to environmental regulations governing land use and reclamation.

"Mining process segment to hold second-largest share of mining automation market, by workflow, throughout forecast period"

Mining processes involve various activities after the mine has been completely developed and is ready for use. During this phase, activities such as drilling, blasting, and ore hauling to the dumping points are performed. Recent technological advancements in mining automation have made these tasks more efficient and convenient. Hauling ore from the mining pit to the dumping point is the most important and capital-intensive activity in mining operations. A continuous and efficient hauling cycle is necessary for the overall productivity of mining companies. Advantages such as improved safety and productivity, reduced maintenance costs, efficient fuel consumption, increased tire life, and less downtime are achieved by automating the haulage processes inside a mine.

"Growing adoption of automation to position North America as the third largest market for mining automation"

The mining automation market in North America is witnessing growth as the region has large mining facilities. Canada has made remarkable strides in its mining sector in recent years, emphasizing innovation and adopting mining automation to enhance efficiency, safety, and productivity. As a global leader in mining automation, exemplified by Teck Resources Ltd.'s use of autonomous haulage systems at its Elkview coal mine in British Columbia, Canada, it is at the forefront of technological advancement in the industry. The increasing significance of adopting automation and advanced technologies is pivotal for improving safety, efficiency, and productivity in the Canadian mining sector. The industry's ongoing focus on innovation and automation underscores its critical role in shaping the country's mining future. In summary, Canada's dedication to innovation and automation, particularly in underground mining, signifies significant progress in the sector, with a growing emphasis on enhancing safety, efficiency, and productivity.

Breakdown of Primaries

Various executives from key organizations operating in the mining automation market, including CEOs, marketing directors, and innovation and technology directors, were interviewed in-depth.

- By Company Type: Tier 1 - 40%, Tier 2 - 35%, and Tier 3 - 25%

- By Designation: Directors - 30%, C-level Executives - 45%, and Others - 25%

- By Region: North America - 25%, Europe - 28%, Asia Pacific - 30%, and RoW - 17%

Note: Three tiers of companies have been defined based on their total revenue as of 2024: Tier 1: >USD 5 billion, Tier 2: USD 500 million-USD 5 billion, and Tier 3: <USD 500 million. Other designations include sales managers, marketing managers, and product managers.

Major players profiled in this report are Caterpillar (US), Komatsu (Japan), Sandvik AB (Sweden), Epiroc AB (Sweden), Hitachi Construction Machinery Co., Ltd. (Japan), AB Volvo (Sweden), Hexagon AB (Sweden), Liebherr-International Deutschland GmbH (Switzerland), Rockwell Automation (US), RPMGlobal Holdings Limited (Australia), SANY Group (China), Siemens (Germany), Trimble Inc. (US), ABB (Switzerland), ATDI SA (France), CiGen (Australia), Coencorp (Canada), Datamine (Australia), GroundHog (US), Haultrax (Australia), Micromine (Australia), SYMX.AI (Canada), STI Engineering (Australia), Zitron (Spain), and MineSense Technologies Ltd. (Canada). These leading companies possess a broad portfolio of products and establish a prominent presence in established and emerging markets.

The study provides a detailed competitive analysis of these key market players, presenting their company profiles, most recent developments, and key market strategies.

Research Coverage

This report segments the mining automation market based on offering, technique, application, workflow, and region. The offering segment includes equipment, software, and communication systems. The technique segment includes underground and surface mining. The application segment comprises mineral mining, metal mining, and coal mining. The workflow segment includes mining process, mine maintenance, and mine development. The market has been segmented into four regions: North America, Asia Pacific, Europe, and Rest of the World (RoW).

Reasons to Buy the Report

The report will help the leaders/new entrants in this market with information on the closest approximations of the revenue numbers for the overall market and the subsegments. It will also help stakeholders understand the competitive landscape and gain more insights to position their businesses better and plan suitable go-to-market strategies. The report also helps stakeholders understand the mining automation market's pulse and provides information on key market drivers, restraints, challenges, and opportunities.

Key Benefits of Buying the Report

- Analysis of key drivers (growing focus on improving safety and operational efficiency in mining, rising strategic focus on minimizing operating expenditures in mining, Rising preference for fleet management systems by mining companies), restraints (rapid depletion of natural resources, automation-induced job disruptions and GDP impact in mining-dependent economies), opportunities (strategic integration of digital technologies to modernize global mining operations, Strategic shift toward smart connected mining for enhanced operational intelligence, accelerated lithium exploration driven by surging global battery demand), and challenges (strategic integration of digital technologies to modernize global mining operations, Strategic shift toward smart connected mining for enhanced operational intelligence, accelerated lithium exploration driven by surging global battery demand) influencing the growth of the mining automation market

- Product Development/Innovation: Detailed insights on upcoming technologies, research and development activities, and product launches in the mining automation market

- Market Development: Comprehensive information about lucrative markets, including the analysis of the mining automation market across varied regions

- Market Diversification: Exhaustive information about new products/services, untapped geographies, recent developments, and investments in mining automation solutions

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players, including Caterpillar (US), Komatsu (Japan), Sandvik AB (Sweden), Epiroc AB (Sweden), and Hitachi Construction Machinery Co., Ltd. (Japan).

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKETS COVERED AND REGIONAL SCOPE

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.3.4 CURRENCY CONSIDERED

- 1.4 LIMITATIONS

- 1.5 STAKEHOLDERS

- 1.6 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY AND PRIMARY RESEARCH

- 2.1.2 SECONDARY DATA

- 2.1.2.1 List of key secondary sources

- 2.1.2.2 Key data from secondary sources

- 2.1.3 PRIMARY DATA

- 2.1.3.1 List of primary interview participants

- 2.1.3.2 Key data from primary sources

- 2.1.3.3 Key industry insights

- 2.1.3.4 Breakdown of primaries

- 2.2 MARKET SIZE ESTIMATION METHODOLOGY

- 2.2.1 BOTTOM-UP APPROACH

- 2.2.1.1 Approach to derive market size using bottom-up analysis (demand side)

- 2.2.2 TOP-DOWN APPROACH

- 2.2.2.1 Approach to derive market size using top-down analysis (supply side)

- 2.2.1 BOTTOM-UP APPROACH

- 2.3 DATA TRIANGULATION

- 2.4 RESEARCH ASSUMPTIONS

- 2.5 RESEARCH LIMITATIONS

- 2.6 RISK ANALYSIS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN MINING AUTOMATION MARKET

- 4.2 MINING AUTOMATION MARKET, BY OFFERING

- 4.3 MINING AUTOMATION MARKET, BY APPLICATION

- 4.4 MINING AUTOMATION MARKET IN NORTH AMERICA, BY APPLICATION AND COUNTRY

- 4.5 MINING AUTOMATION MARKET, BY GEOGRAPHY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Growing focus on enhancing safety and operational efficiency at mining sites

- 5.2.1.2 Rising emphasis of mining firms on minimizing operating expenditure

- 5.2.1.3 Increasing preference for fleet management systems by mining companies

- 5.2.2 RESTRAINTS

- 5.2.2.1 Depletion of natural resources

- 5.2.2.2 Automation-induced job disruptions and GDP impact on mining-dependent economies

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Inclination of mine operators toward digital technologies

- 5.2.3.2 Growing trend of smart connected mining

- 5.2.3.3 Surging global demand for lithium-ion batteries

- 5.2.4 CHALLENGES

- 5.2.4.1 Interoperability issues associated with mining automation

- 5.2.4.2 Workforce shortage and skill gaps in operating automated mining systems

- 5.2.1 DRIVERS

- 5.3 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.4 PRICING ANALYSIS

- 5.4.1 PRICING RANGE OF MINING EQUIPMENT, 2024

- 5.4.2 INDICATIVE PRICING OF MINING AUTOMATION SOFTWARE, 2024

- 5.4.3 PRICING RANGE OF AUTONOMOUS MINING TRUCKS, BY KEY PLAYER, 2024

- 5.4.4 AVERAGE SELLING PRICE TREND OF AUTONOMOUS MINING TRUCKS, 2021-2024

- 5.4.5 AVERAGE SELLING PRICE TREND OF AUTONOMOUS MINING TRUCKS, BY REGION, 2021-2024

- 5.5 VALUE CHAIN ANALYSIS

- 5.6 ECOSYSTEM ANALYSIS

- 5.7 INVESTMENT AND FUNDING SCENARIO

- 5.8 TECHNOLOGY ANALYSIS

- 5.8.1 KEY TECHNOLOGIES

- 5.8.1.1 Artificial intelligence

- 5.8.1.2 Digital twin

- 5.8.1.3 Internet of Things

- 5.8.2 COMPLEMENTARY TECHNOLOGIES

- 5.8.2.1 Cloud computing

- 5.8.2.2 5G

- 5.8.3 ADJACENT TECHNOLOGIES

- 5.8.3.1 SATCOM

- 5.8.3.2 Advanced imaging

- 5.8.1 KEY TECHNOLOGIES

- 5.9 PATENT ANALYSIS

- 5.10 TRADE ANALYSIS

- 5.10.1 IMPORT SCENARIO (HS CODE 8429)

- 5.10.2 EXPORT SCENARIO (HS CODE 8429)

- 5.11 KEY CONFERENCES AND EVENTS, 2025-2026

- 5.12 CASE STUDY ANALYSIS

- 5.12.1 ROCKWELL AUTOMATION OFFERS CONTROL SYSTEMS AND VISUALIZATION SOLUTIONS TO MINIMIZE DOWNTIME AND OPERATIONAL COST IN MINING PLANT

- 5.12.2 KOMATSU PROVIDES AUTONOMOUS HAULAGE SYSTEM TO ENHANCE PRODUCTIVITY AND SAFETY IN COPPER MINE

- 5.12.3 ROCKWELL AUTOMATION DEPLOYS FACTORYTALK SUITE AT AMRUN BAUXITE MINE TO IMPROVE OPERATIONAL VISIBILITY

- 5.12.4 SANDVIK AB IMPLEMENTS MINING EQUIPMENT IN VELADERO GOLD MINE TO INCREASE PRODUCTIVITY

- 5.12.5 CATERPILLAR OFFERS AUTONOMOUS DRILLS AND TRUCKS TO CREATE CONNECTED VALUE CHAIN IN GUDAI-DARRI MINE

- 5.12.6 HEXAGON OFFERS OPERATIONS MANAGEMENT SOLUTIONS TO STREAMLINE OPERATIONS AT MINING SITES OF ANGLO AMERICAN PLATINUM

- 5.12.7 KOMATSU DEPLOYS LHD AT EI SANTO MINE SITE TO MEET CUSTOMIZED FINANCING AND TECHNICAL REQUIREMENTS

- 5.13 REGULATORY LANDSCAPE

- 5.13.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 5.13.2 STANDARDS

- 5.14 PORTER'S FIVE FORCES ANALYSIS

- 5.14.1 THREAT OF NEW ENTRANTS

- 5.14.2 THREAT OF SUBSTITUTES

- 5.14.3 BARGAINING POWER OF SUPPLIERS

- 5.14.4 BARGAINING POWER OF BUYERS

- 5.14.5 INTENSITY OF COMPETITIVE RIVALRY

- 5.15 KEY STAKEHOLDERS AND BUYING CRITERIA

- 5.15.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 5.15.2 BUYING CRITERIA

- 5.16 IMPACT OF AI/GEN AI ON MINING AUTOMATION MARKET

- 5.16.1 INTRODUCTION

- 5.16.2 AI USE CASES

- 5.16.3 FUTURE OF AI/GEN AI IN MINING AUTOMATION ECOSYSTEM

- 5.17 IMPACT OF 2025 US TARIFF - OVERVIEW

- 5.17.1 INTRODUCTION

- 5.17.2 KEY TARIFF RATES

- 5.17.3 PRICE IMPACT ANALYSIS

- 5.17.4 IMPACT ON COUNTRIES/REGIONS

- 5.17.4.1 US

- 5.17.4.2 Europe

- 5.17.4.3 Asia Pacific

- 5.17.5 IMPACT ON MINING INDUSTRY

6 MINING AUTOMATION MARKET, BY OFFERING

- 6.1 INTRODUCTION

- 6.2 EQUIPMENT

- 6.2.1 AUTONOMOUS HAULING/MINING TRUCKS

- 6.2.1.1 Strategic focus on maximizing asset utilization and mitigating workforce-related risks to boost demand

- 6.2.2 AUTONOMOUS DRILLING RIGS

- 6.2.2.1 Strong emphasis on enhancing ore recovery and reducing downtime to accelerate adoption

- 6.2.3 UNDERGROUND LHD LOADERS

- 6.2.3.1 Need to overcome depth, space, and safety constraints in underground mining to propel segmental growth

- 6.2.4 TUNNELLING EQUIPMENT

- 6.2.4.1 Ability to reduce tunnel lining costs to promote deployment

- 6.2.5 SMART VENTILATION SYSTEMS

- 6.2.5.1 Necessity to eliminate risk of gas leaks or explosions to fuel segmental growth

- 6.2.6 PUMPING STATIONS

- 6.2.6.1 Urgency to address water accumulation challenges in mines to foster segmental growth

- 6.2.7 OTHER EQUIPMENT

- 6.2.7.1 Hybrid shovels

- 6.2.7.2 Mining dozers

- 6.2.7.3 Wheeled loaders

- 6.2.7.4 Mining excavators

- 6.2.1 AUTONOMOUS HAULING/MINING TRUCKS

- 6.3 SOFTWARE

- 6.3.1 WORKFORCE SAFETY & MANAGEMENT SOFTWARE

- 6.3.1.1 High priority need to safeguard personnel and optimize resource allocation to drive demand

- 6.3.2 ENVIRONMENT MONITORING SOFTWARE

- 6.3.2.1 Stringent safety regulations focused on sustainable mining practices to support market growth

- 6.3.3 FLEET & EQUIPMENT MANAGEMENT SOFTWARE

- 6.3.3.1 Greater emphasis on seamless mining operations to contribute to segmental growth

- 6.3.4 REMOTE MONITORING SOFTWARE

- 6.3.4.1 Proficiency in protecting miners from hazardous conditions to boost demand

- 6.3.5 DATA MANAGEMENT SOFTWARE

- 6.3.5.1 Shift from conventional management to fact-based, decision-driven management to create opportunities

- 6.3.6 ASSET MANAGEMENT SOFTWARE

- 6.3.6.1 Critical necessity to ensure equipment reliability in extreme mining conditions to stimulate adoption

- 6.3.1 WORKFORCE SAFETY & MANAGEMENT SOFTWARE

- 6.4 COMMUNICATION SYSTEMS

- 6.4.1 WIRELESS MESH NETWORKS

- 6.4.1.1 Easy installation and low maintenance costs to contribute to segmental growth

- 6.4.2 NAVIGATION SYSTEMS

- 6.4.2.1 Potential to help operators navigate safely through mines to fuel demand

- 6.4.3 RFID TAGS

- 6.4.3.1 Need for real-time tracking of mining equipment and personnel to drive adoption

- 6.4.1 WIRELESS MESH NETWORKS

7 MINING AUTOMATION MARKET, BY TECHNIQUE

- 7.1 INTRODUCTION

- 7.2 UNDERGROUND MINING

- 7.2.1 PARAMOUNT NEED TO ENSURE SECURE AND CONTROLLED ENVIRONMENT FOR UNDERGROUND OPERATORS TO DRIVE MARKET

- 7.3 SURFACE MINING

- 7.3.1 STRATEGIC ADOPTION OF AUTOMATION TO REDUCE COSTS AND BOOST PRODUCTIVITY TO FUEL MARKET GROWTH

8 MINING AUTOMATION MARKET, BY WORKFLOW

- 8.1 INTRODUCTION

- 8.2 MINE DEVELOPMENT

- 8.2.1 TUNNEL BORING

- 8.2.1.1 Exploration of rich mineral reserves to spur demand

- 8.2.2 ACCESS ROAD CONSTRUCTION

- 8.2.2.1 Necessity for safe and efficient means of transport to and from tunnel sites to propel market

- 8.2.3 SITE PREPARATION & CLEARING

- 8.2.3.1 Growing trend of modular infrastructure deployment to accelerate market growth

- 8.2.1 TUNNEL BORING

- 8.3 MINING PROCESS

- 8.3.1 AUTONOMOUS HAULAGE

- 8.3.1.1 Strong focus on productivity gains and cost savings to spur demand

- 8.3.2 AUTOMATED DRILLING

- 8.3.2.1 Potential to address drilling-related challenges to spike demand

- 8.3.1 AUTONOMOUS HAULAGE

- 8.4 MINE MAINTENANCE

- 8.4.1 HVAC INSTALLATION & MAINTENANCE

- 8.4.1.1 Need to improve ventilation and ensure operational continuity in mining sites to fuel market growth

- 8.4.2 MINE DEWATERING

- 8.4.2.1 Rising use of dewatering systems to reduce risk of flooding to contribute to segmental growth

- 8.4.1 HVAC INSTALLATION & MAINTENANCE

9 MINING AUTOMATION MARKET, BY APPLICATION

- 9.1 INTRODUCTION

- 9.2 MINERAL MINING

- 9.2.1 ELEVATING DEMAND FOR MINERALS FROM CONSTRUCTION, AGRICULTURE, AND MANUFACTURING INDUSTRIES TO DRIVE MARKET

- 9.3 METAL MINING

- 9.3.1 RISING DEMAND FOR METALS TO MANUFACTURE ELECTRONICS AND EV PARTS TO PROMOTE MARKET GROWTH

- 9.4 COAL MINING

- 9.4.1 SURGING USE OF REMOTE-OPERATED MACHINERY TO MINIMIZE HUMAN EXPOSURE TO SUPPORT MARKET GROWTH

10 MINING AUTOMATION MARKET, BY REGION

- 10.1 INTRODUCTION

- 10.2 NORTH AMERICA

- 10.2.1 MACROECONOMIC OUTLOOK FOR NORTH AMERICA

- 10.2.2 US

- 10.2.2.1 Rising adoption of digital technologies in mining operations to accelerate market growth

- 10.2.3 CANADA

- 10.2.3.1 Presence of rich mineral and metal reserves to fuel demand

- 10.2.4 MEXICO

- 10.2.4.1 Mineral wealth and favorable regulatory policies to foster market growth

- 10.3 EUROPE

- 10.3.1 MACROECONOMIC OUTLOOK FOR EUROPE

- 10.3.2 TURKEY

- 10.3.2.1 Mineral deposits of coal, iron ore, copper, manganese, gold, silver, lead, and zinc to create opportunities

- 10.3.3 SWEDEN

- 10.3.3.1 Strategic integration of autonomous haulage and AI-driven systems to propel market

- 10.3.4 GERMANY

- 10.3.4.1 Elevating adoption of electric vehicles and renewable energy systems to promote market growth

- 10.3.5 POLAND

- 10.3.5.1 Rising demand for metals and rare-earth materials to drive market

- 10.3.6 REST OF EUROPE

- 10.4 ASIA PACIFIC

- 10.4.1 MACROECONOMIC OUTLOOK FOR ASIA PACIFIC

- 10.4.2 CHINA

- 10.4.2.1 Mining modernization and automation efforts to accelerate market growth

- 10.4.3 INDIA

- 10.4.3.1 Increasing efforts to digitize mines to drive market

- 10.4.4 AUSTRALIA

- 10.4.4.1 Presence of abundant and diverse mineral reserves to facilitate market growth

- 10.4.5 INDONESIA

- 10.4.5.1 Launch of 5G smart mining technology to contribute to market growth

- 10.4.6 REST OF ASIA PACIFIC

- 10.5 ROW

- 10.5.1 MACROECONOMIC OUTLOOK FOR ROW

- 10.5.2 SOUTH AMERICA

- 10.5.2.1 Brazil

- 10.5.2.1.1 Presence of gold mines to boost adoption

- 10.5.2.2 Peru

- 10.5.2.2.1 Strategic investments and growing importance of mining automation to drive market

- 10.5.2.3 Chile

- 10.5.2.3.1 Presence of high-quality iron ore beds to fuel market growth

- 10.5.2.4 Rest of South America

- 10.5.2.1 Brazil

- 10.5.3 MIDDLE EAST

- 10.5.3.1 GCC

- 10.5.3.1.1 Increasing adoption of Industry 4.0 and digital technologies to create opportunities

- 10.5.3.2 Rest of Middle East

- 10.5.3.1 GCC

- 10.5.4 AFRICA

- 10.5.4.1 South Africa

- 10.5.4.1.1 Government initiatives promoting safe mining practices to support market growth

- 10.5.4.2 Rest of Africa

- 10.5.4.1 South Africa

11 COMPETITIVE LANDSCAPE

- 11.1 INTRODUCTION

- 11.2 KEY PLAYER STRATEGIES/RIGHT TO WIN, 2021-2025

- 11.3 REVENUE ANALYSIS, 2020-2024

- 11.4 MARKET SHARE ANALYSIS OF TOP 5 PLAYERS, 2024

- 11.5 PRODUCT COMPARISON

- 11.6 COMPANY VALUATION AND FINANCIAL METRICS

- 11.7 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 11.7.1 STARS

- 11.7.2 EMERGING LEADERS

- 11.7.3 PERVASIVE PLAYERS

- 11.7.4 PARTICIPANTS

- 11.7.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 11.7.5.1 Company footprint

- 11.7.5.2 Region footprint

- 11.7.5.3 Technique footprint

- 11.7.5.4 Equipment footprint

- 11.7.5.5 Software footprint

- 11.8 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 11.8.1 PROGRESSIVE COMPANIES

- 11.8.2 RESPONSIVE COMPANIES

- 11.8.3 DYNAMIC COMPANIES

- 11.8.4 STARTING BLOCKS

- 11.8.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 11.8.5.1 Detailed list of key startups/SMEs

- 11.8.5.2 Competitive benchmarking of key startups/SMEs

- 11.9 COMPETITIVE SCENARIO

- 11.9.1 PRODUCT LAUNCHES

- 11.9.2 DEALS

- 11.9.3 EXPANSIONS

- 11.9.4 OTHER DEVELOPMENTS

12 COMPANY PROFILES

- 12.1 KEY PLAYERS

- 12.1.1 CATERPILLAR

- 12.1.1.1 Business overview

- 12.1.1.2 Products/Solutions/Services offered

- 12.1.1.3 Recent developments

- 12.1.1.3.1 Product launches

- 12.1.1.4 MnM view

- 12.1.1.4.1 Key strengths

- 12.1.1.4.2 Strategic choices

- 12.1.1.4.3 Weaknesses and competitive threats

- 12.1.2 KOMATSU

- 12.1.2.1 Business overview

- 12.1.2.2 Products/Solutions/Services offered

- 12.1.2.3 Recent developments

- 12.1.2.3.1 Deals

- 12.1.2.3.2 Expansions

- 12.1.2.4 MnM view

- 12.1.2.4.1 Key strengths

- 12.1.2.4.2 Strategic choices

- 12.1.2.4.3 Weaknesses and competitive threats

- 12.1.3 SANDVIK AB

- 12.1.3.1 Business overview

- 12.1.3.2 Products/Solutions/Services offered

- 12.1.3.3 Recent developments

- 12.1.3.3.1 Deals

- 12.1.3.3.2 Other developments

- 12.1.3.4 MnM view

- 12.1.3.4.1 Key strengths

- 12.1.3.4.2 Strategic choices

- 12.1.3.4.3 Weaknesses and competitive threats

- 12.1.4 EPIROC AB

- 12.1.4.1 Business overview

- 12.1.4.2 Products/Solutions/Services offered

- 12.1.4.3 Recent developments

- 12.1.4.3.1 Deals

- 12.1.4.3.2 Expansions

- 12.1.4.3.3 Other developments

- 12.1.4.4 MnM view

- 12.1.4.4.1 Key strengths

- 12.1.4.4.2 Strategic choices

- 12.1.4.4.3 Weaknesses and competitive threats

- 12.1.5 HITACHI CONSTRUCTION MACHINERY CO., LTD.

- 12.1.5.1 Business overview

- 12.1.5.2 Products/Solutions/Services offered

- 12.1.5.3 Recent developments

- 12.1.5.3.1 Product launches

- 12.1.5.3.2 Deals

- 12.1.5.4 MnM view

- 12.1.5.4.1 Key strengths

- 12.1.5.4.2 Strategic choices

- 12.1.5.4.3 Weaknesses and competitive threats

- 12.1.6 AB VOLVO

- 12.1.6.1 Business overview

- 12.1.6.2 Products/Solutions/Services offered

- 12.1.6.3 Recent developments

- 12.1.6.3.1 Deals

- 12.1.7 HEXAGON AB

- 12.1.7.1 Business overview

- 12.1.7.2 Products/Solutions/Services offered

- 12.1.7.3 Recent developments

- 12.1.7.3.1 Product launches

- 12.1.7.3.2 Deals

- 12.1.7.3.3 Expansions

- 12.1.8 LIEBHERR-INTERNATIONAL DEUTSCHLAND GMBH

- 12.1.8.1 Business overview

- 12.1.8.2 Products/Solutions/Services offered

- 12.1.8.3 Recent developments

- 12.1.8.3.1 Product launches

- 12.1.8.3.2 Deals

- 12.1.8.3.3 Expansions

- 12.1.9 ROCKWELL AUTOMATION

- 12.1.9.1 Business overview

- 12.1.9.2 Products/Solutions/Services offered

- 12.1.10 RPMGLOBAL HOLDINGS LIMITED

- 12.1.10.1 Business overview

- 12.1.10.2 Products/Solutions/Services offered

- 12.1.10.3 Recent developments

- 12.1.10.3.1 Product launches

- 12.1.10.3.2 Deals

- 12.1.11 SANY GROUP

- 12.1.11.1 Business overview

- 12.1.11.2 Products/Solutions/Services offered

- 12.1.11.3 Recent developments

- 12.1.11.3.1 Product launches

- 12.1.11.3.2 Expansions

- 12.1.11.3.3 Other developments

- 12.1.12 SIEMENS

- 12.1.12.1 Business overview

- 12.1.12.2 Products/Solutions/Services offered

- 12.1.12.3 Recent developments

- 12.1.12.3.1 Deals

- 12.1.13 TRIMBLE INC.

- 12.1.13.1 Business overview

- 12.1.13.2 Products/Solutions/Services offered

- 12.1.13.3 Recent developments

- 12.1.13.3.1 Product launches

- 12.1.14 ABB

- 12.1.14.1 Business overview

- 12.1.14.2 Products/Solutions/Services offered

- 12.1.1 CATERPILLAR

- 12.2 OTHER PLAYERS

- 12.2.1 ATDI SA

- 12.2.2 CIGEN

- 12.2.3 COENCORP

- 12.2.4 DATAMINE

- 12.2.5 GROUNDHOG

- 12.2.6 HAULTRAX

- 12.2.7 MICROMINE

- 12.2.8 SYMX.AI

- 12.2.9 STI ENGINEERING

- 12.2.10 ZITRON

- 12.2.11 MINESENSE TECHNOLOGIES LTD.

13 APPENDIX

- 13.1 INSIGHTS FROM INDUSTRY EXPERTS

- 13.2 DISCUSSION GUIDE

- 13.3 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 13.4 CUSTOMIZATION OPTIONS

- 13.5 RELATED REPORTS

- 13.6 AUTHOR DETAILS