|

시장보고서

상품코드

1845348

GFRP 복합재료 시장 : 수지 유형별, 제조 공정별, 최종 이용 산업별, 지역별 - 예측(-2030년)GFRP Composites Market by Resin Type, Manufacturing Process (Compression & Injection Molding, Filament Winding, Layup, Pultrusion, Resin Transfer Molding, Other Manufacturing Processes), End-use Industry, Region - Global Forecast to 2030 |

||||||

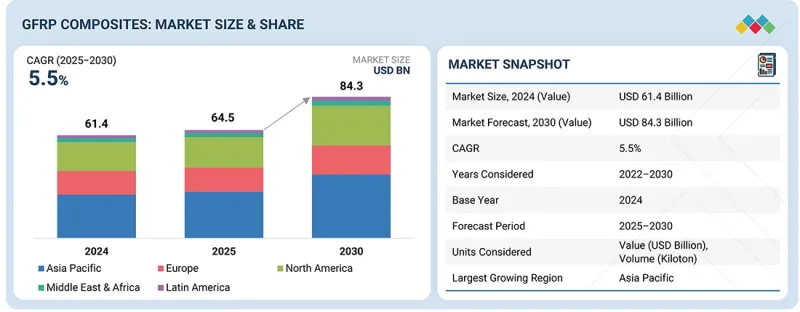

GFRP 복합재료 시장 규모는 2025년에 645억 달러에 이르고, 2025-2030년 연평균 복합 성장률(CAGR) 5.5%로 성장하여 2030년에는 843억 달러에 달할 것으로 예측됩니다.

섬유 강화 복합재료의 매트릭스 재료로서 열가소성 수지의 응용은 지난 몇 년 동안 크게 증가했습니다.

| 조사 범위 | |

|---|---|

| 조사 대상 연도 | 2022-2030년 |

| 기준 연도 | 2024년 |

| 예측 기간 | 2025-2030년 |

| 검토 단위 | 금액(100만 달러) 및 킬로톤 |

| 부문 | 수지 유형별, 제조 공정별, 최종 이용 산업별, 지역별 |

| 대상 지역 | 유럽, 북미, 아시아태평양, 중동 및 아프리카, 남미 |

열가소성 수지는 구조용 복합재 제품을 만들기 위해 연속 유리섬유와 함께 사용되어 왔습니다. 매트릭스 재료로서 열가소성 수지의 주요 장점은 열경화성 수지와 달리 형성된 GFRP 복합재료는 재형성 및 변형이 가능하다는 것입니다. 또한, 성형된 GFRP 복합재는 재활용이 용이합니다. 따라서 지난 10년간 그 사용량이 크게 증가했습니다. 그러나 열가소성 수지는 고체이기 때문에 강화섬유를 함침시키기가 어렵습니다. 따라서 열가소성 수지는 열경화성 수지에 비해 상당히 비쌉니다.

풍력 터빈 블레이드는 풍력 발전 시스템의 주요 부품입니다. 풍력 터빈 블레이드의 GFRP 복합재료는 대형 풍력 터빈 개발에 널리 사용되고 있습니다. 블레이드 제조업체의 연구 개발의 초점은 주로 풍력에너지의 비용 절감에 초점을 맞추었습니다. 이는 GFRP 복합재료가 다른 섬유보다 저렴한 비용으로 고성능 특성을 유지하면서 다른 섬유보다 저렴하기 때문에 GFRP 복합재료의 사용을 촉진하고 있습니다. GFRP 복합재료는 또한 높은 인장강도를 제공하여 블레이드의 대형화 및 고에너지 출력을 실현하는 데 기여하고 있습니다. GFRP 복합재는 내식성으로 인해 풍력 터빈이 가장 혹독한 환경에서도 작동할 수 있도록 합니다.

아시아태평양은 예측 기간 동안 GFRP 복합재료 시장에서 가장 높은 성장률을 나타낼 것으로 예측됩니다. 중국, 인도, 동남아시아 같은 국가들은 급속한 산업 성장과 도시 확장을 경험하고 있습니다. 인구 증가와 경제의 확장은 다양한 응용 분야에서 GFRP 복합재료의 사용 증가에 기여하고 있습니다. 지속 가능한 건축 관행을 장려하는 노력, 새로운 인프라 계획(예: 중국의 '신 인프라 계획'과 인도의 '스마트 시티 미션'), 국내 제조를 지원하는 정책은 이 지역 수요와 생산 능력을 높이고 있습니다.

풍력에너지, 항공우주 및 방위, 자동차, 건설 및 인프라 분야의 성장은 터빈 블레이드 및 기타 부품에 사용되는 GFRP 복합재에 대한 수요를 촉진하고 있습니다. 제조 공정의 개선은 제품 품질 향상과 비용 절감을 실현하고 시장을 더욱 확대할 수 있습니다. 건설, 자동차 외에도 전기/전자, 해양, 파이프/탱크 등의 분야도 이 지역의 GFRP 복합재료 시장 성장에 기여하고 있습니다.

세계의 GFRP 복합재료 시장에 대해 조사했으며, 수지 유형별, 제조 공정별, 최종 이용 산업별, 지역별 동향, 시장 진출기업 프로파일 등의 정보를 정리하여 전해드립니다.

자주 묻는 질문

목차

제1장 서론

제2장 조사 방법

제3장 주요 요약

제4장 프리미엄 인사이트

제5장 시장 개요

- 서론

- 시장 역학

- Porter의 Five Forces 분석

- 주요 이해관계자와 구입 기준

- 밸류체인 분석

- 생태계 분석

- 가격 분석

- 무역 분석, 2021년-2024년

- 기술 분석

- AI/생성형 AI가 GFRP 복합재료 시장에 미치는 영향

- 거시경제 전망

- 특허 분석

- 규제 상황

- 2025년-2026년 주요 컨퍼런스 및 이벤트

- 사례 연구 분석

- 고객의 비즈니스에 영향을 미치는 동향/혼란

- 투자 및 자금조달 시나리오

- 2025년 미국 관세의 영향 - GFRP 복합재료 시장

제6장 GFRP 복합재료 시장(수지 유형별)

- 서론

- 폴리에스테르

- 비닐에스테르

- 에폭시

- 폴리우레탄

- 열가소성

- 기타

제7장 GFRP 복합재료 시장(제조 공정별)

- 서론

- 압축 성형 및 사출 성형 프로세스

- 필라멘트 와인딩

- 레이업

- 인발 성형

- 수지 트랜스퍼 성형(RTM)

- 기타

제8장 GFRP 복합재료 시장(최종 이용 산업별)

- 서론

- 운송

- 건설 및 인프라

- 전기 및 전자 공학

- 파이프 및 탱크

- 선박

- 항공우주 및 방위

- 풍력에너지

- 기타

제9장 GFRP 복합재료 시장(지역별)

- 서론

- 유럽

- 아시아태평양

- 북미

- 라틴아메리카

- 중동 및 아프리카

제10장 경쟁 구도

- 개요

- 주요 시장 진출기업의 전략/강점

- 매출 분석, 2020년-2024년

- 시장 점유율 분석, 2024년

- 브랜드 및 제품 비교

- 기업 평가 매트릭스 : 주요 시장 진출기업, 2024년

- 기업 평가 매트릭스 : 스타트업/중소기업, 2024년

- 기업 평가와 재무 지표

- 경쟁 시나리오

제11장 기업 개요

- 주요 시장 진출기업

- GURIT SERVICES AG

- STRONGWELL CORPORATION

- EXEL COMPOSITES

- MITSUBISHI CHEMICAL GROUP CORPORATION

- AGY

- ASAHI KASEI CORPORATION

- POLSER COMPOSITE MATERIALS CORPORATION

- LM WIND POWER

- TENCOM

- BASF

- SGL CARBON

- AVIENT CORPORATION

- LEHMANN&VOSS&CO.(LEHVOSS GROUP)

- LANXESS

- 기타 기업

- ADVANCED COMPOSITES INC.

- RELIANCE INDUSTRIES LIMITED(RELIANCE COMPOSITES SOLUTIONS)

- MRG COMPOSITES REBAR

- JPS COMPOSITE MATERIALS

- ASAHI YUKIZAI CORPORATION

- MATEENBAR COMPOSITE REINFORCEMENTS, LLC

- CELANESE CORPORATION

- DANTERR

- TOPOLO NEW MATERIALS

- CQDJ COMPOSITES

- BEETLE PLASTICS

제12장 부록

LSH 25.10.28The GFRP composites market is estimated at USD 64.5 billion in 2025 and is projected to reach USD 84.3 billion by 2030, at a CAGR of 5.5% from 2025 to 2030. The application of thermoplastic resin as a matrix material in fiber-reinforced composites has increased significantly over the last few years.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2022-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD million) and volume (kiloton) |

| Segments | Resin Type, Manufacturing Process, End-use Industry, and Region |

| Regions covered | Europe, North America, Asia Pacific, the Middle East & Africa, and South America |

Thermoplastic resin has been used with continuous glass fiber to create structural composite products. The main advantage of thermoplastic resin as a matrix material is that the GFRP composite formed can be reshaped and reformed, unlike a thermoset resin. The GFRP composite formed is also easily recyclable. Hence, its use has increased significantly over the last decade. However, thermoplastic resin is solid, which makes it difficult to impregnate with reinforcing fibers. Hence, thermoplastic resins are quite expensive in comparison to thermoset resins.

"In terms of value, the wind energy industry is projected to register the highest CAGR among all the end-use industries."

Wind turbine blades are the key components in the wind power generation system. GFRP composites in wind turbine blades are widely used in the development of large-scale wind turbines. The R&D focus of blade manufacturers has been mainly on reducing the cost of wind energy. This is driving the use of GFRP composites, as they are less costly than other fibers without compromising their high-performance properties. GFRP composites also provide high tensile strength, helping manufacturers achieve larger blades and higher energy output. GFRP composites allow wind turbines to work in the harshest environments due to their corrosion-resistant properties.

"The Asia Pacific region is projected to register the highest growth rate in the GFRP composites market during the forecast period."

Asia Pacific is projected to be the fastest-growing region in the GFRP composites market during the forecast period. Countries such as China, India, and Southeast Asia are experiencing swift industrial growth and urban expansion. Rising population and expanding economies contribute to increased use of GFRP composites in various applications. Initiatives promoting sustainable building practices, new infrastructure plans (e.g., China's "New Infrastructure Plan" and India's "Smart Cities Mission"), and policies supporting domestic manufacturing boost demand and production capacity in the region.

Growth in wind energy, aerospace & defense, automobile, and construction & infrastructure sectors fuels demand for GFRP composites used in turbine blades and other components. Improvements in manufacturing processes enhance product quality and reduce costs, further enabling market expansion. Beyond construction and automotive, sectors like electrical & electronics, marine, and pipes & tanks also contribute to the GFRP composites market growth in the region.

This study has been validated through primary interviews with industry experts globally. The primary sources have been divided into the following three categories:

- By Company Type: Tier 1 - 40%, Tier 2 - 33%, and Tier 3 - 27%

- By Designation: C-level - 50%, Director-level - 30%, and Managers - 20%

- By Region: North America - 15%, Europe - 50%, Asia Pacific - 20%, the Middle East & Africa - 10%, and Latin America - 5%

The report provides a comprehensive analysis of the following companies:

Prominent companies in this market include Gurit Services AG (Switzerland), Strongwell Corporation (US), Exel Composites (Finland), Mitsubishi Chemical Group of Companies (Japan), AGY (US), Asahi Kasei Corporation (Japan), POLSER Composite Materials Corporation (Turkey), LM Wind Power (Denmark), Tencom Limited (US), BASF (Germany), SGL Carbon (Germany), Avient Corporation (US), Lehmann&Voss&Co. (Germany), and LANXESS (Germany).

Research coverage

This research report categorizes the GFRP composites market, by resin type (polyester, vinyl ester, epoxy, polyurethane, thermoplastics, and other resins), by manufacturing process [compression & injection molding, filament winding, layup, pultrusion, resin transfer molding (RTM), other manufacturing processes], end-use industry (transportation, construction & infrastructure, electrical & electronics, pipes & tanks, marine, aerospace & defense, wind energy, and other end-use industries), and region. The scope of the report includes detailed information about the major factors influencing the growth of the GFRP composites market, such as drivers, restraints, challenges, and opportunities. A thorough examination of the key industry players has been conducted to provide insights into their business overview, solutions and services, key strategies, and recent developments in the GFRP composites market. This report includes a competitive analysis of upcoming startups in the GFRP composites market ecosystem.

Reasons to buy this report:

The report will help the market leaders/new entrants with information on the closest approximations of the revenue numbers for the overall GFRP composites market and the subsegments. This report will help stakeholders understand the competitive landscape and gain more insights to position their businesses better and plan suitable go-to-market strategies. The report also helps stakeholders understand the pulse of the market and provides them with information on key market drivers, restraints, challenges, and opportunities.

The report provides insights on the following points:

- Analysis of key drivers (increasing number of wind energy installations, increasing adoption of GFRP composites in the transportation industry, increasing use of GFRP composite pipes in sewage & water management and oil & gas industry), restraints (issues related to recycling, high processing and manufacturing costs, high processing and manufacturing costs), opportunities (high demand for GFRP composite pipes in the emerging economies, increasing demand for GFRP composites in the construction & infrastructure industry in Middle East & Africa), and challenges (developing low-cost technologies, standardization and regulation) influencing the growth of the GFRP composites market

- Product Development/Innovation: Detailed insights on upcoming technologies, research & development activities, and service launches in the GFRP composites market

- Market Development: Comprehensive information about lucrative markets-the report analyzes the GFRP composites market across varied regions

- Market Diversification: Exhaustive information about services, untapped geographies, recent developments, and investments in the GFRP composites market

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players like are Gurit Services AG (Switzerland), Strongwell Corporation (US), Exel Composites (Finland), Mitsubishi Chemical Group of Companies (Japan), AGY (US), Asahi Kasei Corporation (Japan), POLSER Composite Materials Corporation (Turkey), LM Wind Power (Denmark), Tencom Limited (US), BASF (Germany), SGL Carbon (Germany), Avient Corporation (US), Lehmann&Voss&Co. (Germany), and LANXESS (Germany) in the GFRP composites market

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKETS COVERED AND REGIONAL SCOPE

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.3.4 CURRENCY CONSIDERED

- 1.3.5 UNITS CONSIDERED

- 1.4 STAKEHOLDERS

- 1.5 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Key secondary sources

- 2.1.1.2 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Key data from primary sources

- 2.1.2.2 Key primary participants

- 2.1.2.3 Breakdown of interviews with experts

- 2.1.2.4 Key industry insights

- 2.1.1 SECONDARY DATA

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 BOTTOM-UP APPROACH

- 2.2.2 TOP-DOWN APPROACH

- 2.3 BASE NUMBER CALCULATION

- 2.3.1 APPROACH 1: SUPPLY-SIDE ANALYSIS

- 2.3.2 APPROACH 2: DEMAND-SIDE ANALYSIS

- 2.4 MARKET FORECAST APPROACH

- 2.4.1 SUPPLY SIDE

- 2.4.2 DEMAND SIDE

- 2.5 DATA TRIANGULATION

- 2.6 FACTOR ANALYSIS

- 2.7 RESEARCH ASSUMPTIONS

- 2.8 RESEARCH LIMITATIONS AND RISK ASSESSMENT

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 SIGNIFICANT OPPORTUNITIES FOR PLAYERS IN GFRP COMPOSITES MARKET

- 4.2 GFRP COMPOSITES MARKET, BY RESIN TYPE AND REGION

- 4.3 GFRP COMPOSITES MARKET, BY END-USE INDUSTRY

- 4.4 GFRP COMPOSITES MARKET, BY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Increasing number of wind energy installations

- 5.2.1.2 Rising adoption of GFRP composites in transportation industry

- 5.2.1.3 Growing demand for GFRP composite pipes in sewage & water management and oil & gas industry

- 5.2.2 RESTRAINTS

- 5.2.2.1 Issues related to recycling

- 5.2.2.2 High processing and manufacturing costs

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Increasing demand for GFRP composites from construction & infrastructure industry in Middle East & Africa

- 5.2.3.2 High demand for GFRP composite pipes in emerging economies

- 5.2.4 CHALLENGES

- 5.2.4.1 Developing low-cost technologies

- 5.2.4.2 Standardization and regulation

- 5.2.1 DRIVERS

- 5.3 PORTER'S FIVE FORCES ANALYSIS

- 5.3.1 THREAT OF NEW ENTRANTS

- 5.3.2 THREAT OF SUBSTITUTES

- 5.3.3 BARGAINING POWER OF SUPPLIERS

- 5.3.4 BARGAINING POWER OF BUYERS

- 5.3.5 INTENSITY OF COMPETITIVE RIVALRY

- 5.4 KEY STAKEHOLDERS AND BUYING CRITERIA

- 5.4.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 5.4.2 BUYING CRITERIA

- 5.5 VALUE CHAIN ANALYSIS

- 5.6 ECOSYSTEM ANALYSIS

- 5.7 PRICING ANALYSIS

- 5.7.1 AVERAGE SELLING PRICE, BY KEY PLAYER, 2024

- 5.7.2 AVERAGE SELLING PRICE TREND, BY REGION (2023-2024)

- 5.8 TRADE ANALYSIS, 2021-2024

- 5.8.1 IMPORT SCENARIO (HS CODE 7019)

- 5.8.2 EXPORT SCENARIO (HS CODE 7019)

- 5.9 TECHNOLOGY ANALYSIS

- 5.9.1 KEY TECHNOLOGIES (GFRP COMPOSITES MANUFACTURING)

- 5.9.1.1 GRP Molding

- 5.9.1.2 GRP Pultrusion

- 5.9.1.3 GRP Hand/Spray Layup Molding

- 5.9.2 COMPLEMENTARY TECHNOLOGIES (GFRP COMPOSITE MANUFACTURING)

- 5.9.2.1 GRP Resin Transfer Molding

- 5.9.2.2 GRP Compression Molding

- 5.9.2.3 GRP Long Fiber Injection Molding

- 5.9.1 KEY TECHNOLOGIES (GFRP COMPOSITES MANUFACTURING)

- 5.10 IMPACT OF AI/GEN AI ON GFRP COMPOSITES MARKET

- 5.10.1 TOP USE CASES AND MARKET POTENTIAL

- 5.10.2 CASE STUDIES OF AI IMPLEMENTATION IN GFRP COMPOSITES MARKET

- 5.11 MACROECONOMIC OUTLOOK

- 5.11.1 INTRODUCTION

- 5.11.2 GDP TRENDS AND FORECAST

- 5.11.3 TRENDS IN GLOBAL AEROSPACE INDUSTRY

- 5.11.4 TRENDS IN WIND ENERGY INDUSTRY

- 5.11.5 TRENDS IN AUTOMOTIVE INDUSTRY

- 5.11.6 TRENDS IN CONSTRUCTION INDUSTRY

- 5.12 PATENT ANALYSIS

- 5.12.1 INTRODUCTION

- 5.12.2 PATENT TYPES

- 5.12.3 INSIGHTS

- 5.12.4 LEGAL STATUS

- 5.12.5 JURISDICTION ANALYSIS

- 5.12.6 TOP APPLICANTS

- 5.13 REGULATORY LANDSCAPE

- 5.13.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 5.14 KEY CONFERENCES AND EVENTS, 2025-2026

- 5.15 CASE STUDY ANALYSIS

- 5.15.1 GURIT SERVICES AG ACQUIRED MAJORITY SHARE IN FIBERLINE COMPOSITES A/S

- 5.15.2 OWENS CORNING AND PULTRON COMPOSITES SIGNED AN AGREEMENT TO MANUFACTURE GFRP REBAR

- 5.15.3 EXEL COMPOSITES, OWENS CORNING, AND URBAN CANOPEE JOINED FORCES TO MAKE A COMPOSITE SOLUTION WHOLLY MADE FROM CIRCULAR AND BIOBASED INPUTS

- 5.16 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.17 INVESTMENT AND FUNDING SCENARIO

- 5.18 IMPACT OF 2025 US TARIFFS- GFRP COMPOSITES MARKET

- 5.18.1 INTRODUCTION

- 5.18.2 KEY TARIFF RATES

- 5.18.3 PRICE IMPACT ANALYSIS

- 5.18.4 IMPACT ON COUNTRIES/REGIONS

- 5.18.4.1 US

- 5.18.4.2 Europe

- 5.18.4.3 Asia Pacific

- 5.18.5 IMPACT ON END USERS

6 GFRP COMPOSITES MARKET, BY RESIN TYPE

- 6.1 INTRODUCTION

- 6.2 POLYESTER

- 6.2.1 MASS APPLICATIONS IN CONSTRUCTION PANELS, PIPES, TANKS, AUTOMOTIVE PARTS, AND CONSUMER GOODS TO DRIVE MARKET

- 6.3 VINYL ESTER

- 6.3.1 ENHANCED CORROSION RESISTANCE PROPERTIES TO BOOST DEMAND

- 6.4 EPOXY

- 6.4.1 HIGH PERFORMANCE AT ELEVATED TEMPERATURES TO DRIVE GROWTH IN ADVERSE APPLICATIONS

- 6.5 POLYURETHANE

- 6.5.1 FAST CURE TIME AND FLEXIBILITY TO PROPEL MARKET

- 6.6 THERMOPLASTIC

- 6.6.1 RECYCLABILITY TO BOOST DEMAND

- 6.7 OTHER RESIN TYPES

- 6.7.1 PHENOLIC

- 6.7.2 BENZOXAZINE

- 6.7.3 CYANATE ESTER

- 6.7.4 BISMALIMIDE (BMI)

7 GFRP COMPOSITES MARKET, BY MANUFACTURING PROCESS

- 7.1 INTRODUCTION

- 7.2 COMPRESSION & INJECTION MOLDING PROCESS

- 7.2.1 LOW MAINTENANCE AND INVESTMENT TO SUPPORT ADOPTION

- 7.3 FILAMENT WINDING

- 7.3.1 HIGH FIBER VOLUME FRACTION TO FOSTER GROWTH

- 7.4 LAYUP

- 7.4.1 INEXPENSIVE TOOLING AND SIMPLE MACHINERY TO DRIVE DEMAND

- 7.5 PULTRUSION

- 7.5.1 CONTINUOUS AND AUTOMATION PROPERTIES TO FUEL GROWTH

- 7.6 RESIN TRANSFER MOLDING (RTM)

- 7.6.1 PRODUCTION OF COMPLEX, DURABLE PARTS AT COMPETITIVE COSTS TO FUEL MARKET

- 7.7 OTHER MANUFACTURING PROCESSES

- 7.7.1 3D PRINTING

- 7.7.2 COLD PRESS MOLDING

- 7.7.3 VACUUM BAGGING

8 GFRP COMPOSITES MARKET, BY END-USE INDUSTRY

- 8.1 INTRODUCTION

- 8.2 TRANSPORTATION

- 8.2.1 HIGH STRENGTH-TO-WEIGHT RATIO TO DRIVE DEMAND

- 8.2.2 RAIL

- 8.2.3 AUTOMOTIVE

- 8.3 CONSTRUCTION & INFRASTRUCTURE

- 8.3.1 SUSTAINABILITY AND REGULATORY SUPPORT TO PROPEL MARKET GROWTH

- 8.3.2 DECKING AND RAILING

- 8.3.3 REBARS

- 8.3.4 OTHER CONSTRUCTION & INFRASTRUCTURE END-USE INDUSTRIES

- 8.4 ELECTRICAL & ELECTRONICS

- 8.4.1 EXCELLENT ELECTRICAL CONDUCTIVITY AND THERMAL RESISTANCE PROPERTIES TO BOOST GROWTH

- 8.5 PIPES & TANKS

- 8.5.1 LONG SERVICE LIFE AND DURABILITY TO DRIVE ADOPTION

- 8.5.2 OIL & GAS

- 8.5.3 WATER & WASTEWATER TREATMENT PLANTS

- 8.5.4 PULP & PAPER

- 8.6 OTHER PIPE & TANK END-USE INDUSTRIES

- 8.7 MARINE

- 8.7.1 EXCEPTIONAL CORROSION RESISTANCE TO FUEL GROWTH

- 8.8 AEROSPACE & DEFENSE

- 8.8.1 DESIGN AND MANUFACTURING FLEXIBILITY TO BOOST MARKET

- 8.8.2 INTERIOR

- 8.8.3 EXTERIOR

- 8.9 WIND ENERGY

- 8.9.1 HIGH STRENGTH-TO-WEIGHT RATIO TO PROPEL DEMAND

- 8.10 OTHER END-USE INDUSTRIES

- 8.10.1 HEALTHCARE

- 8.10.2 CONSUMER GOODS

- 8.10.3 SPORTING GOODS

9 GFRP COMPOSITES MARKET, BY REGION

- 9.1 INTRODUCTION

- 9.1.1 GFRP COMPOSITES MARKET, BY REGION

- 9.2 EUROPE

- 9.2.1 EUROPE: GFRP COMPOSITES MARKET, BY RESIN TYPE

- 9.2.2 EUROPE: GFRP COMPOSITES MARKET, BY MANUFACTURING PROCESS

- 9.2.3 EUROPE: GFRP COMPOSITES MARKET, BY END-USE INDUSTRY

- 9.2.4 EUROPE: GFRP COMPOSITES MARKET, BY COUNTRY

- 9.2.4.1 Germany

- 9.2.4.1.1 Growth of automotive and aerospace sectors to drive demand

- 9.2.4.2 France

- 9.2.4.2.1 Presence of aerospace manufacturers to boost market

- 9.2.4.3 Italy

- 9.2.4.3.1 Shift toward sustainability to propel demand

- 9.2.4.4 UK

- 9.2.4.4.1 Increase in demand for lightweight and high-performance materials for automobiles to fuel market

- 9.2.4.5 Spain

- 9.2.4.5.1 Demand from wind energy sector to propel market

- 9.2.4.6 Russia

- 9.2.4.6.1 Innovation in fiber-reinforced technologies to boost growth

- 9.2.4.7 Rest of Europe

- 9.2.4.1 Germany

- 9.3 ASIA PACIFIC

- 9.3.1 ASIA PACIFIC: GFRP COMPOSITES MARKET, BY RESIN

- 9.3.2 ASIA PACIFIC: GFRP COMPOSITES MARKET, BY MANUFACTURING PROCESS

- 9.3.3 ASIA PACIFIC: GFRP COMPOSITES MARKET, BY END-USE INDUSTRY

- 9.3.4 ASIA PACIFIC: GFRP COMPOSITES MARKET, BY COUNTRY

- 9.3.4.1 China

- 9.3.4.1.1 Presence of major fiberglass and GFRP composites manufacturing companies to fuel market

- 9.3.4.2 Japan

- 9.3.4.2.1 Demand for lightweight composites from automotive industry to drive market

- 9.3.4.3 India

- 9.3.4.3.1 Growing construction industry to fuel demand

- 9.3.4.4 South Korea

- 9.3.4.4.1 Presence of key electronics companies to drive demand

- 9.3.4.5 Australia

- 9.3.4.5.1 Expansion of renewable energy infrastructure to propel demand

- 9.3.4.6 Rest of Asia Pacific

- 9.3.4.1 China

- 9.4 NORTH AMERICA

- 9.4.1 NORTH AMERICA: GFRP COMPOSITES MARKET, BY RESIN TYPE

- 9.4.2 NORTH AMERICA: GFRP COMPOSITES MARKET, BY MANUFACTURING PROCESS

- 9.4.3 NORTH AMERICA: GFRP COMPOSITES MARKET, BY END-USE INDUSTRY

- 9.4.4 NORTH AMERICA: GFRP COMPOSITES MARKET, BY COUNTRY

- 9.4.4.1 US

- 9.4.4.1.1 Increasing reliance on lightweight, corrosion-resistant, and durable materials for key end-use industries to drive market

- 9.4.4.2 Canada

- 9.4.4.2.1 Growing aerospace industry to support market growth

- 9.4.4.1 US

- 9.5 LATIN AMERICA

- 9.5.1 LATIN AMERICA: GFRP COMPOSITES MARKET, BY RESIN TYPE

- 9.5.2 LATIN AMERICA: GFRP COMPOSITES MARKET, BY MANUFACTURING PROCESS

- 9.5.3 LATIN AMERICA: GFRP COMPOSITES MARKET, BY END-USE INDUSTRY

- 9.5.4 LATIN AMERICA: GFRP COMPOSITES MARKET, BY COUNTRY

- 9.5.4.1 Brazil

- 9.5.4.1.1 Growth of automotive industry to fuel demand

- 9.5.4.2 Mexico

- 9.5.4.2.1 Increase in demand from automotive industry to drive growth

- 9.5.4.3 Rest of Latin America

- 9.5.4.1 Brazil

- 9.6 MIDDLE EAST & AFRICA

- 9.6.1 MIDDLE EAST & AFRICA: GFRP COMPOSITES MARKET, BY RESIN TYPE

- 9.6.2 MIDDLE EAST & AFRICA: GFRP COMPOSITES MARKET, BY MANUFACTURING PROCESS

- 9.6.3 MIDDLE EAST & AFRICA: GFRP COMPOSITES MARKET, BY END-USE INDUSTRY

- 9.6.4 MIDDLE EAST & AFRICA: GFRP COMPOSITES MARKET, BY COUNTRY

- 9.6.5 GCC COUNTRIES

- 9.6.5.1 UAE

- 9.6.5.1.1 Stringent energy efficiency regulations to boost market

- 9.6.5.2 Saudi Arabia

- 9.6.5.2.1 Increased investments in infrastructural development to drive market

- 9.6.5.1 UAE

- 9.6.6 REST OF GCC COUNTRIES

- 9.6.7 SOUTH AFRICA

- 9.6.7.1 Increased spending on infrastructure projects to boost growth

- 9.6.8 REST OF MIDDLE EAST & AFRICA

10 COMPETITIVE LANDSCAPE

- 10.1 OVERVIEW

- 10.2 KEY PLAYER STRATEGIES/RIGHT TO WIN

- 10.2.1 KEY STRATEGIES ADOPTED BY PLAYERS IN GFRP COMPOSITES MARKET

- 10.3 REVENUE ANALYSIS, 2020-2024

- 10.4 MARKET SHARE ANALYSIS, 2024

- 10.5 BRAND/PRODUCT COMPARISON

- 10.5.1 SPRINT (GURIT SERVICES AG)

- 10.5.2 EXTREN (STRONGWELL COMPOSITES)

- 10.5.3 GMT (MITSUBISHI CHEMICAL GROUP CORPORATION)

- 10.5.4 LENCEN (ASAHI KASEI CORPORATION)

- 10.6 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 10.6.1 STARS

- 10.6.2 EMERGING LEADERS

- 10.6.3 PERVASIVE PLAYERS

- 10.6.4 PARTICIPANTS

- 10.6.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 10.6.5.1 Company footprint

- 10.6.5.2 Region footprint

- 10.6.5.3 Resin type footprint

- 10.6.5.4 Manufacturing process footprint

- 10.6.5.5 End-use industry footprint

- 10.7 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 10.7.1 PROGRESSIVE COMPANIES

- 10.7.2 RESPONSIVE COMPANIES

- 10.7.3 DYNAMIC COMPANIES

- 10.7.4 STARTING BLOCKS

- 10.7.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 10.7.5.1 Detailed list of key startups/SMEs

- 10.7.5.2 Competitive benchmarking of key startups/SMEs

- 10.8 COMPANY VALUATION AND FINANCIAL METRICS

- 10.9 COMPETITIVE SCENARIO

- 10.9.1 PRODUCT LAUNCHES

- 10.9.2 DEALS

11 COMPANY PROFILES

- 11.1 KEY PLAYERS

- 11.1.1 GURIT SERVICES AG

- 11.1.1.1 Business overview

- 11.1.1.2 Products/Solutions/Services offered

- 11.1.1.3 Recent developments

- 11.1.1.3.1 Deals

- 11.1.1.4 MnM view

- 11.1.1.4.1 Right to win

- 11.1.1.4.2 Strategic choices

- 11.1.1.4.3 Weaknesses and competitive threats

- 11.1.2 STRONGWELL CORPORATION

- 11.1.2.1 Business overview

- 11.1.2.2 Products/Solutions/Services offered

- 11.1.2.3 Recent developments

- 11.1.2.3.1 Deals

- 11.1.2.4 MnM view

- 11.1.2.4.1 Right to win

- 11.1.2.4.2 Strategic choices

- 11.1.2.4.3 Weaknesses and competitive threats

- 11.1.3 EXEL COMPOSITES

- 11.1.3.1 Business overview

- 11.1.3.2 Products/Solutions/Services offered

- 11.1.3.3 Recent developments

- 11.1.3.3.1 Deals

- 11.1.3.4 MnM view

- 11.1.3.4.1 Right to win

- 11.1.3.4.2 Strategic choices

- 11.1.3.4.3 Weaknesses and competitive threats

- 11.1.4 MITSUBISHI CHEMICAL GROUP CORPORATION

- 11.1.4.1 Business overview

- 11.1.4.2 Products/Solutions/Services offered

- 11.1.4.3 Recent developments

- 11.1.4.3.1 Deals

- 11.1.4.4 MnM view

- 11.1.4.4.1 Right to win

- 11.1.4.4.2 Strategic choices

- 11.1.4.4.3 Weaknesses and competitive threats

- 11.1.5 AGY

- 11.1.5.1 Business overview

- 11.1.5.2 Products/Solutions/Services offered

- 11.1.5.3 Recent developments

- 11.1.5.3.1 Deals

- 11.1.6 ASAHI KASEI CORPORATION

- 11.1.6.1 Business overview

- 11.1.6.2 Products/Solutions/Services offered

- 11.1.7 POLSER COMPOSITE MATERIALS CORPORATION

- 11.1.7.1 Business overview

- 11.1.7.2 Products/Solutions/Services offered

- 11.1.7.3 Recent developments

- 11.1.7.3.1 Product launches

- 11.1.8 LM WIND POWER

- 11.1.8.1 Business overview

- 11.1.8.2 Products/Solutions/Services offered

- 11.1.8.3 Recent developments

- 11.1.8.3.1 Deals

- 11.1.9 TENCOM

- 11.1.9.1 Business overview

- 11.1.9.2 Products/Solutions/Services offered

- 11.1.10 BASF

- 11.1.10.1 Business overview

- 11.1.10.2 Products/Solutions/Services offered

- 11.1.11 SGL CARBON

- 11.1.11.1 Business overview

- 11.1.11.2 Products/Solutions/Services offered

- 11.1.12 AVIENT CORPORATION

- 11.1.12.1 Business overview

- 11.1.12.2 Products/Solutions/Services offered

- 11.1.13 LEHMANN&VOSS&CO. (LEHVOSS GROUP)

- 11.1.13.1 Business overview

- 11.1.13.2 Products/Solutions/Services offered

- 11.1.14 LANXESS

- 11.1.14.1 Business overview

- 11.1.14.2 Products/Solutions/Services offered

- 11.1.1 GURIT SERVICES AG

- 11.2 OTHER PLAYERS

- 11.2.1 ADVANCED COMPOSITES INC.

- 11.2.2 RELIANCE INDUSTRIES LIMITED (RELIANCE COMPOSITES SOLUTIONS)

- 11.2.3 MRG COMPOSITES REBAR

- 11.2.4 JPS COMPOSITE MATERIALS

- 11.2.5 ASAHI YUKIZAI CORPORATION

- 11.2.6 MATEENBAR COMPOSITE REINFORCEMENTS, LLC

- 11.2.7 CELANESE CORPORATION

- 11.2.8 DANTERR

- 11.2.9 TOPOLO NEW MATERIALS

- 11.2.10 CQDJ COMPOSITES

- 11.2.11 BEETLE PLASTICS

12 APPENDIX

- 12.1 DISCUSSION GUIDE

- 12.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 12.3 CUSTOMIZATION OPTIONS

- 12.4 RELATED REPORTS

- 12.5 AUTHOR DETAILS