|

시장보고서

상품코드

1626899

차량용 MEMS 센서 : 시장 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)Automotive MEMS Sensors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

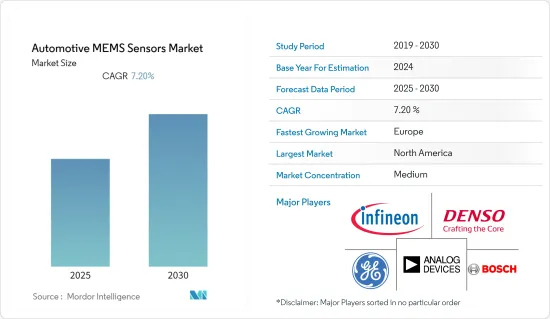

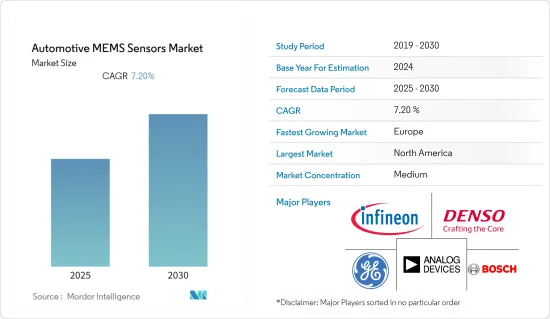

차량용 MEMS 센서 시장은 예측 기간 동안 CAGR 7.2%를 기록할 것으로 예상됩니다.

주요 하이라이트

- MEMS 센서는 자동차 분야의 수많은 발전에 기여하고 있습니다. 전 세계적으로 자동차 안전은 심각한 문제가 되고 있습니다. 차량용 내비게이션 시스템, 전복 감지, 충돌 감지 외에도 MEMS 센서는 다른 여러 응용 분야에도 적용될 수 있습니다. 차량용 MEMS 센서는 전자부품 제조업체, 자동차 부품 제조업체 및 최종사용자에게 영향을 미칠 것으로 예상됩니다. 차량용 MEMS 센서 시장의 표준 및 법규 개발은 각국 정부의 주요 관심사입니다.

- 차량용 MEMS 센서 시장은 고효율, 소형화, 저비용 등 다양한 이점을 제공합니다. 자동차 안전 및 보안에 대한 수요 증가는 조사 대상 시장의 성장에 중요한 역할을 하는 주요 요인 중 하나이며, MEMS 센서는 초소형 장치와 동일한 기술을 활용하기 때문에 마이크로 머신이라고도 합니다.

- 차량용 MEMS 센서에 대한 수요는 차량용 애플리케이션의 안전 및 보안에 대한 요구가 증가함에 따라 증가하고 있습니다. 차량용 MEMS 센서 시장은 IoT 기술에 대한 수요 증가와 커넥티드 디바이스의 보급으로 확대되고 있으며, MEMS 가속도계의 저렴한 비용과 엄격한 자체 테스트 기능으로 인해 에어백 제어를 위한 자동차 생산에서 G 스위치가 더 이상 사용되지 않고 있습니다. 이 시장의 성장에 영향을 미치는 촉진요인은 커넥티드카를 포함한 스마트 커넥티드 디바이스의 보급 증가입니다.

- 현재 자동차 산업의 두 가지 큰 트렌드는 전동화와 자동화입니다. 자동차 시스템에는 RADAR, LIDAR, 이미지 처리 등 고가의 센싱 모듈이 빠르게 통합되고 있습니다. 이에 따라 MEMS 센서의 판매량은 예측 기간 동안 크게 증가할 것으로 예상됩니다. 향후 몇 년 동안 프리미엄 자동차 제조업체들이 L5 자율주행에 접근함에 따라 가속도, LiDAR, 모션 감지 시스템과 관련된 IMU 탑재 MEMS 센서에 대한 시장 조사 결과, IMU 탑재 MEMS 센서에 큰 비즈니스 기회가 창출될 것으로 보입니다.

- 또한 업계의 전기자동차(EV)로의 전환은 압력 센서와 자기 센서의 유통 및 수요에 큰 영향을 미치고 있습니다. 이러한 추세는 장기적으로 지속될 것으로 예상됩니다. 전기자동차 판매량이 증가함에 따라 센서에 대한 수요도 급증 할 것입니다. 사용 된 배터리를 모니터링하고 자동차 이동 부품의 다양한 위치 및 감지용 센서가 증가하고 있습니다.

- 그러나 COVID-19 사태로 인해 연방, 주, 지방 정부가 시민들에게 가급적 집에 머물 것을 권고하기 시작하면서 전 세계 자동차 제조업체에 대한 공장 폐쇄 압력이 증가하고 있습니다. 그 결과 다양한 산업에서 공급망에 혼란이 발생하였습니다. 예를 들어, 포드와 제너럴모터스(GM)는 COVID-19 사태로 인해 북미 제조 시설의 생산을 중단했습니다.

- 차량용 MEMS 센서 시스템은 일반적으로 기계 부품과 전자부품이 함께 작동하도록 구성됩니다. 이러한 구성요소를 완벽하게 통합하는 것은 중요한 과제이며, 이는 차량용 MEMS 센서 시장의 성장에 도전이 될 수 있습니다.

차량용 MEMS 센서 시장 동향

자이로스코프 크게 성장

- 안전, 편안함, 성능, 안정성에 대한 관심이 높아짐에 따라 OEM은 첨단 차량 기능을 통합하려고 노력하고 있습니다. 이러한 발전으로 인해 자동차 산업에서 기계 부품의 편의성은 감소하는 반면, 전자부품의 성장은 가속화되고 있습니다. 자이로센서는 시간과 온도에 대한 안정성이 뛰어나 첨단 내비게이션 시스템에 필요한 높은 정확도와 모션 제어 기능의 신뢰성을 유지합니다.

- 차량용 자이로센서는 차량의 자세와 각속도를 측정하거나 유지할 수 있으며, ESP(Electronic Stability Control Program)에 탑재된 MEMS 기반 자이로스코프는 자동차 업계에서 널리 인정받고 있는 강력한 안전 시스템입니다. ESP 시스템은 각속도 센서를 통해 차량을 안정화시킵니다. 자이로 센서는 차량의 축 주위의 각속도를 감지하여 운전자가 차량을 궤도에 유지할 수 있도록 하는 시스템에 필수적인 입력을 생성합니다.

- 또한 차량 전복 감지에는 자이로스코프가 적용되어 롤 속도를 읽습니다. 그러나 차량의 롤 각도만으로는 차량의 전복 여부를 감지하기에 충분하지 않기 때문에 저G 가속도계를 사용하여 수직 가속도(Z축)를 판독합니다. 롤 오버 감지에 사용되는 자이로 센서는 VDC 시스템에 필요한 크기의 거의 절반에 불과하지만 외부 충격과 진동에 대한 우수한 제거 능력이 요구됩니다.

- 고정밀 데이터 처리 및 데이터 수집을 위해 최근 몇 년 동안 반도체, 수동 소자 및 상호연결이 지속적으로 개선되고 있습니다. 또한 175도 이상의 고온을 견딜 수 있는 센서가 필요하기 때문에 MEMS 센서가 널리 사용되고 있으며, MEMS 자이로스코프는 크기가 작고 고온에 강하며 유지보수 비용이 낮기 때문에 MEMS 자이로스코프가 널리 사용되고 있습니다.

눈에 띄는 성장세를 기록하는 북미 지역

- 미국은 세계 최대 규모의 자동차 제조 기지입니다. 이 지역의 경제 성장은 승용차 및 상용차 판매에 영향을 미쳤습니다. 미국 자동차 정책위원회에 따르면 지난 5년간 자동차 부문의 수출액은 6,920억 달러에 달했으며, 자동차 부문만 이 지역 GDP의 3%를 차지해 조사 대상 시장의 성장에 효과적으로 기여했습니다.

- 자동차 산업의 역학이 변화하는 가운데, 자동차 제조업체들은 차세대 소비자의 요구에 부응하기 위해 전기자동차와 자율주행차로 전환하고 있습니다. 미국에서는 전기자동차 보급이 빠르게 진행되고 있으며, 미국 시장 내 자동차 판매량의 1.0%가 전기자동차로 추정되고 있습니다. 뉴섬 주지사에 따르면, 캘리포니아주는 전기자동차(EV) 판매에서 미국 시장을 독점하고 있습니다. 캘리포니아주의 무공해 자동차(ZEV) 프로그램은 캘리포니아주 내 자동차 제조업체들이 일정 비율의 전기자동차를 판매하도록 의무화함으로써 전기자동차 수요를 촉진하고 있습니다.

- 2022년 2월, 캘리포니아의 무공해 자동차(ZEV) 시장이 호황을 누리며 미국 전역을 선도하고 있습니다. 개빈 뉴섬 주지사는 캘리포니아주의 플러그인 전기자동차, 오토바이, 픽업 트럭, SUV 판매량이 다른 10개 주의 판매량을 합친 것보다 더 많다고 칭찬했습니다. 이러한 요인으로 인해 전기자동차의 MEMS 센서에 대한 수요가 증가하고 있습니다.

- 북미에서는 전기자동차에 대한 선호도가 꾸준히 기존 자동차를 대체하고 있습니다. 센서와 MEMS 기반 부품은 자동차 전자 제어 시스템의 핵심 구성요소입니다. 하이브리드 전기자동차와 플러그인 하이브리드 자동차(PHEV)를 포함한 현대 자동차의 온보드 컴퓨터 시스템은 수많은 센서의 데이터를 사용하여 수천 개의 의사결정을 내립니다. 센서는 극한의 온도, 진동, 환경 오염 물질에 노출되는 등 혹독한 환경에서도 작동하기 때문에 자동차의 보안 목적으로도 사용됩니다.

- 또한, 이 지역은 ADAS 지원 차량과 자율주행 교통 솔루션 도입의 선구자 중 하나가 될 것으로 예상됩니다. 또한, 턴바이턴 내비게이션에 대한 위치 정보 서비스 사용이 증가함에 따라 터널, 주차장, 도시 협곡과 같은 환경으로 인한 GPS 또는 GNSS 신호 손실을 방지하는 것이 점점 더 중요해지고 있습니다. 이에 많은 센서 솔루션 업체들이 이 문제에 대응하기 위해 노력하고 있습니다. 따라서 이 지역에서는 차량용 MEMS 센서에 대한 수요가 확대될 것으로 예상됩니다.

차량용 MEMS 센서 산업 개요

차량용 MEMS 센서 시장은 경쟁이 치열하고 여러 대기업이 진출해 있습니다. 시장 점유율은 현재 몇몇 대기업이 시장을 독점하고 있습니다. 압도적인 시장 점유율을 자랑하는 이들 대기업들은 해외 고객 기반 확대에 주력하고 있습니다. ST마이크로일렉트로닉스는 2022년 10월, 도로 소음을 제거하는 첨단 진동 센서를 통해 전기자동차 시대의 조용한 실내를 구현할 수 있는 첨단 진동 센서로 시장 점유율을 확대하고 수익성을 높이기 위해 전략적 협력 이니셔티브를 활용하고 있습니다. ST마이크로일렉트로닉스는 차량 내 음향 환경을 정밀하게 제어하고 정숙화하기 위한 동급 최고의 차량용 MEMS 가속도계인 AIS25BA를 발표했습니다. 2022년 9월, 정밀 타이밍의 선두주자인 SiTime Corporation은 SiTime의 최첨단 MEMS 기술을 기반으로 한 새로운 차량용 발진기 제품군을 발표했습니다. 새로운 차동 발진기 제품군을 발표했습니다. AEC-Q100 SiT9396/7 차량용 오실레이터의 출시로 SiTime의 공급 가능 시장(SAM) 규모는 5,000만 달러가 증가할 것으로 예상되며, AEC-Q100 SiT9396/7 차량용 오실레이터의 출시와 함께 10배 향상된 내구성을 통해 모든 날씨와 도로 조건에서 신뢰할 수 있는 ADAS 작동을 보장합니다.

기타 혜택:

- 엑셀 형식의 시장 예측(ME) 시트

- 3개월간 애널리스트 지원

목차

제1장 소개

- 조사 가정과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 역학

- 시장 개요

- 업계의 매력 - Porter’s Five Forces

- 공급 기업의 교섭력

- 소비자의 협상력

- 신규 참여업체의 위협

- 경쟁 기업 간의 경쟁 관계

- 대체품의 위협

- 기술 현황

- 시장 성장 촉진요인

- 여객 안전·보안 규제와 컴플라이언스 중시 상승

- 고객에게 선호되는 자동화 기능 증가와 성능 향상

- 시장 성장 억제요인

- 인터페이스 설계 고려에 의한 MEMS 센서 구현 비용 증가

제5장 시장 세분화

- 유형별

- 타이어 공기압 센서

- 엔진 오일 센서

- 연소 센서

- 연료 분사·연료 펌프 센서

- 에어백 전개 센서

- 자이로스코프

- 연료 레일 압력 센서

- 기타 유형(에어 플로우 컨트롤, 크랭크 샤프트 위치 센서, 횡전 감지 센서, 오토매틱 도어락 센서)

- 지역별

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 기타 유럽

- 아시아태평양

- 중국

- 일본

- 인도

- 기타 아시아태평양

- 세계 기타 지역

- 북미

제6장 경쟁 구도

- 기업 개요

- Analog Devices Inc.

- Delphi Automotive PLC

- Denso Corporation

- General Electric Co.

- Freescale Semiconductors Ltd

- Infineon Technologies AG

- Sensata Technologies Inc.

- STMicroelectronics NV

- Panasonic Corporation

- Robert Bosch GmbH

제7장 투자 분석

제8장 시장 전망

ksm 25.01.16The Automotive MEMS Sensors Market is expected to register a CAGR of 7.2% during the forecast period.

Key Highlights

- MEMS sensors contribute to numerous advancements in the automotive sector. The world over, vehicle safety has grown to be a serious problem. In addition to in-vehicle navigation systems, rollover detection, and crash detection, MEMS sensors could be incorporated into several other applications. Automotive MEMS sensors are anticipated to have an impact on manufacturers of electronic components, producers of auto parts, and end users. The development of standards and laws for the market for automotive MEMS sensors is of great interest to the governments of various countries.

- The MEMS sensor market for automotive provides various advantages of high efficiency, small size, and low cost. The growing demand for safety and security in automobiles is one of the main factors that has played a vital role in the growth of the market studied. MEMS sensors are also known as micromachines because they make use of the same technology as tiny devices.

- The demand for automotive MEMS sensors has increased due to the growing need for safety and security in automotive applications. The market for automotive MEMS sensors is expanding as a result of rising IoT technology demand and the widespread adoption of connected devices. As a result of MEMS accelerometers' low cost and rigorous self-testing capabilities, g-switches are no longer used in the production of automobiles for airbag control. The drivers influencing the growth of this market are the rise in smart connected device adoption, including connected cars.

- Currently, the two significant trends in the automotive industry are electrification and automation. There has been a rapid integration of high-value sensing modules, like RADAR, LIDAR, and imaging, in automotive systems. As a result, the MEMS sensor's sales volume growth is expected to be significant during the forecast period. The market investigated would create a substantial opportunity for IMU-powered MEMS sensors related to acceleration, LiDAR, and motion detection systems as the premium automakers would approach L5 autonomous driving in the following few years.

- Additionally, the industry's transition to electric vehicles (EVs) has significantly impacted the distribution and demand for pressure and magnetic sensors. It is anticipated that this trend will continue in the long run. As the number of electric vehicle sales rises, the demand for sensors also escalates. There is an increase in sensors for used battery monitoring and various positioning and detection of moving automotive parts.

- However, the COVID-19 pandemic has increased pressure on automakers across the globe to close down their factories after the federal, state, and local governments began advising citizens to spend as much time as possible at home. Various industries have experienced supply chain disruptions as a result of this. For instance, Ford and General Motors halted production at their respective North American manufacturing facilities due to the coronavirus outbreak.

- An automotive MEMS sensor system is typically made up of mechanical and electronic components that work in tandem. Perfect integration of these components is a significant challenge, which can create a challenge for the growth of the automotive MEMS sensor market.

Automotive MEMS Sensors Market Trends

Gyroscope to Witness Significant Growth

- Due to growing concerns about safety, comfort, performance, and stability, OEMs have been attempting to incorporate advanced vehicle features. As a result of this development, the convenience of mechanical components has decreased across the automotive industry while the growth of electronics has accelerated. The gyroscope maintains a higher level of accuracy needed for sophisticated navigation systems embedded in it and the dependability of motion-controlled functionalities because it offers superior stability over time and temperature.

- A gyroscope in automotive has been allowed to measure or maintain the vehicle's orientation and angular velocity. The MEMS-based gyroscope in the ESP (Electronic Stability Control Program) is a widely accepted and powerful safety system in the automotive industry. The ESP system depends on the angular rate sensors to stabilize the car. It detects the vehicle's angular rate around its axis and creates the essential input to the systems that enable the driver to keep the vehicle on track.

- Further, in the rollover detection of the vehicle, a gyroscope is applied to read the roll rate. But as only the roll angle of the vehicle is not sufficient to detect whether the vehicle is going to roll over, a low-g accelerometer is used to read vertical acceleration (Z-axis). The gyroscope used for roll overdetection is almost half the magnitude required in the VDC system but requires excellent rejection of external shock and vibration.

- To enable high-precision data processing and acquisition, semiconductors, passives, and interconnects have all undergone continuous improvement in recent years. Due to the demand for sensors that can withstand temperatures higher than 175 degrees, MEMS sensors are widely accepted. MEMS gyroscopes are used because of their small size, high-temperature tolerance, and low maintenance costs.

North America to Register Significant Growth

- The United States is one of the largest automotive manufacturing hubs in the world. The region's economic growth posed an impact on the sale of passenger and commercial vehicles. According to the American Automotive Policy Council, over the past five years, the exports from the automotive sector were valued at USD 692.0 billion, and the automotive sector alone contributes to 3% of the region's GDP, effectively contributing to the growth of the market studied.

- With changing dynamics in the industry, automotive manufacturers are moving toward electric vehicles and autonomous vehicles to meet the needs of next-generation consumers. Electric vehicle use in the United States has risen rapidly, with an estimated 1.0% of automotive sales in the United States market coming from electric vehicles. According to Governor Newsom, California dominates the United States market regarding electric vehicle (EVs) sales. Its zero-emission vehicle (ZEV) program is driving the demand for EVs by requiring automakers in the state to sell a certain percentage of electric cars.

- In February 2022, California's booming zero-emission vehicle (ZEV) market continued to lead the country. Governor Gavin Newsom praised the state for selling more plug-in electric cars, motorcycles, pickup trucks, SUVs, and SUVs than the combined sales of the following ten states. Such factors will boost the demand for MEMS sensors in Electric Vehicles.

- The preference for electric vehicles is steadily replacing conventional vehicles in North America. Sensors and MEMS-based components are crucial components of the electronic control system in cars. The on-board computer system of contemporary cars, including hybrid electric vehicles and plug-in hybrid vehicles (PHEV), uses data from numerous sensors to inform thousands of decisions. Since the sensors can function under challenging circumstances like extreme temperatures, vibrations, and exposure to environmental contaminants, they are used for security purposes in automobiles.

- Additionally, the region is also expected to be one of the pioneers in adopting ADAS-enabled vehicles and self-driven transportation solutions. In addition, with the increased usage of location services for turn-by-turn navigation, the importance of not losing GPS or GNSS signal due to environments like tunnels, parking garages, and urban canyons has gained more prominence. Thus, many sensor solution companies have been working toward addressing this issue. This is anticipated to augment the demand for automotive MEMS sensors in the region.

Automotive MEMS Sensors Industry Overview

The automotive MEMS sensors market is highly competitive and consists of several major players. In terms of market share, a few of the major players currently dominate the market. These major players, with a prominent market share, are focusing on expanding their customer base across foreign countries. These companies are leveraging strategic collaborative initiatives to increase their market share and increase their profitability. In October 2022, STMicroelectronics will enable quieter cabins for the electric-vehicle age with an advanced vibration sensor to eliminate road noise. The company announced its AIS25BA, a best-in-class automotive MEMS accelerometer for accurately controlling and quieting the in-cabin acoustic environment. The sensor has the lowest electrical noise in the market, which helps vehicle engineers achieve the calmest possible in-car environment. In September 2022, SiTime Corporation, a leader in precision timing, released a new family of automotive oscillators based on SiTime's cutting-edge MEMS technology. The new differential oscillators are 10 times more durable and guarantee dependable ADAS operation in all weather and road conditions. The AEC-Q100 SiT9396/7 automotive oscillator's introduction increases the SiTime served available market's (SAM) size by USD 50 million.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Attractiveness- Porter Five Forces

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Intensity of Competitive Rivalry

- 4.2.5 Threat of Substitutes

- 4.3 Technology Snapshot

- 4.4 Market Drivers

- 4.4.1 Passenger Safety and Security Regulations, and Increased Focus on Compliance

- 4.4.2 Increased Automation Features and Performance Improvements Preferred by Customers

- 4.5 Market Restraints

- 4.5.1 Increase in Overall Cost of MEMS Sensors Implementation due to Interface Design Considerations

5 MARKET SEGMENTATION

- 5.1 By Type

- 5.1.1 Tire Pressure Sensors

- 5.1.2 Engine Oil Sensors

- 5.1.3 Combustion Sensors

- 5.1.4 Fuel Injection and Fuel Pump Sensors

- 5.1.5 Air Bag Deployment Sensors

- 5.1.6 Gyroscopes

- 5.1.7 Fuel Rail Pressure Sensors

- 5.1.8 Other Types (Airflow Control, Crank Shaft Position Sensors, Roll-over Detection Sensors, and Automatic Door Lock Sensors)

- 5.2 Geography

- 5.2.1 North America

- 5.2.1.1 United States

- 5.2.1.2 Canada

- 5.2.2 Europe

- 5.2.2.1 Germany

- 5.2.2.2 UK

- 5.2.2.3 France

- 5.2.2.4 Rest of Europe

- 5.2.3 Asia-Pacific

- 5.2.3.1 China

- 5.2.3.2 Japan

- 5.2.3.3 India

- 5.2.3.4 Rest of Asia-Pacific

- 5.2.4 Rest of World

- 5.2.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Analog Devices Inc.

- 6.1.2 Delphi Automotive PLC

- 6.1.3 Denso Corporation

- 6.1.4 General Electric Co.

- 6.1.5 Freescale Semiconductors Ltd

- 6.1.6 Infineon Technologies AG

- 6.1.7 Sensata Technologies Inc.

- 6.1.8 STMicroelectronics NV

- 6.1.9 Panasonic Corporation

- 6.1.10 Robert Bosch GmbH