|

시장보고서

상품코드

1630252

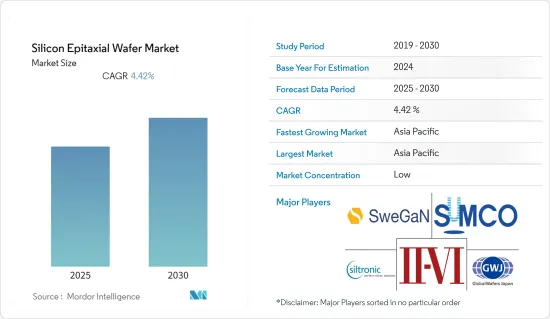

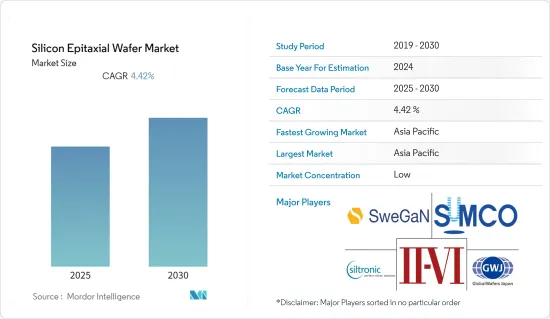

실리콘 에피택셜 웨이퍼 : 시장 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)Silicon Epitaxial Wafer - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

실리콘 에피택셜 웨이퍼 시장은 예측 기간 동안 4.42%의 CAGR을 기록할 것으로 예상됩니다.

주요 하이라이트

- 반도체 실리콘 웨이퍼는 많은 마이크로 전자 장치의 핵심 부품으로 전자 산업의 초석을 형성하고 있습니다. 디지털화와 전자 이동성이 현재 기술 트렌드로서, 이 제품들은 많은 장치에 적용되고 있습니다.

- 현재 시장에서는 실리콘 웨이퍼의 수요가 산업 공급을 초과하고 있습니다. 각 업체들은 이러한 추세를 이용해 생산량을 늘리고 시장 점유율을 확대하고 있습니다.

- 또한, 소형 가젯에 대한 수요로 인해 하나의 장치에 더 많은 기능이 요구되고 있습니다. 즉, IC 칩은 더 많은 기능을 지원하기 위해 더 많은 트랜지스터를 탑재해야 합니다. 이처럼 스마트폰, 태블릿과 같은 무선 컴퓨팅 장치의 발전은 반도체 설계자들의 설계 활동을 더욱 활발하게 하고 있습니다. 또한, 전자제품의 소형화 수요 증가(저전력 소비를 위한 박형 웨이퍼에 대한 수요 증가)는 예측 기간 동안 실리콘 에피택셜 웨이퍼 시장의 발전을 촉진할 것으로 예상됩니다.

- 산업의 평균 가격이 상승하고 있습니다. 예를 들어, 일본의 신에츠화학(Shin-Etsu Chemical Co., Ltd.)은 실리콘 에피택셜 웨이퍼 시장 점유율의 대부분을 차지하고 있습니다. 예를 들어, 시장 점유율의 대부분을 차지하는 일본 신에츠화학은 2021년 4월부터 모든 실리콘 웨이퍼 제품의 가격을 10%에서 20%로 인상할 것이라고 발표했습니다. 세계 2위의 웨이퍼 공급업체인 GlobalWafer Co., Ltd는 실리콘 웨이퍼 생산라인이 가득 찼고, 가격 인상과 함께 3월 수익이 증가하여 전년 동월 대비 12.99% 증가했다고 밝혔습니다. 증가했다고 밝혔습니다.

- 소비자 전자제품과 같은 소비자 중심의 최종사용자 산업은 실리콘 웨이퍼에 대한 수요가 강하고, 이 산업의 공급업체들은 생산 설비를 확장하는 동시에 기술 혁신을 위한 연구 투자에 박차를 가하고 있습니다.

- COVID-19로 인해 중국은 국내 공급망과 생산에 혼란을 겪었습니다. 지난 20-30년 동안 중국이 세계 생산의 중심지가 되면서 주요 반도체 제조 산업이 큰 영향을 받고 있습니다.

실리콘 에피택셜 웨이퍼 시장 동향

파워 일렉트로닉스가 큰 비중을 차지할 전망

- 전력 효율이 높은 제품에 대한 수요 증가는 모든 최종사용자 산업에서 파워 일렉트로닉스 제품용 에피택셜 웨이퍼의 수요를 견인하는 주요 요인 중 하나입니다. 따라서 시장 공급업체들은 리스크를 줄이고 고객 기반을 확대하기 위해 다양한 산업을 대상으로 하고 있습니다.

- IGBT와 MOSFET 시장은 계속 증가할 것으로 예상되지만, 특히 EV/HEV용 모듈의 경우, 시장의 일부가 SiC로 전환될 것으로 예상됩니다. 또한, 파워 MOSFET의 수요는 절연 게이트형, 바이폴라 트랜지스터, 사이리스터를 대체할 수 있는 용도의 확대에 의해 뒷받침되고 있습니다. 또한, 전력 MOSFET을 사용하면 저전압에서 장치의 전력 효율을 향상시킬 수 있다는 큰 이점이 세계 전력 MOSFET 시장의 수요를 더욱 촉진하고 있습니다.

- 민생 기기에서 파워 일렉트로닉스의 사용 증가도 수요를 견인하고 있습니다. 스마트폰과 스마트 기기의 보급 확대, 사물인터넷(IoT) 기기의 채택 확대, 산업용 애플리케이션의 증가도 파워 일렉트로닉스의 신흥국 시장 개척에 기여하고 있습니다. 파워 일렉트로닉스에 대한 높은 수요로 인해 2018년과 2019년에는 200mm 웨이퍼 부족 현상이 발생하기도 했습니다. 대형 고객들은 여전히 막대한 장비 재고를 보유하고 있어 고객 수요가 감소하고 있습니다. 파워 일렉트로닉스 시장의 장기적인 성장도 300mm 웨이퍼 기반 생산에 힘을 실어주고 있습니다. 7곳 이상의 세계 파워 일렉트로닉스 업체들이 2021년부터 생산을 개시하기 위해 새로운 생산능력에 대한 투자를 발표했습니다.

- Imec과 Qromis는 Aixtron의 G5 C 200mm MOVCD 플랫폼에서 에피택시 층을 성장시키고 200mm QST 기판에서 강화 모드, p-GaN 디스크리트 및 IC 전력 소자를 개발하기 위해 협력하고 있습니다. 양사는 첨단 CMOS 실리콘 파일럿 라인에서 GaN 전력 소자, 이산형 및 모놀리식 집적 IC 형태, 200mm QST 기판에서 GaN 전력 소자를 개발하기 위해 장치 제조에 전념하고 있습니다. 독일에 본사를 둔 GaN MOCVD 장비 제조업체인 Aixtron과 협력하고 있습니다. 많은 업계 전문가들은 전 세계 300mm 웨이퍼를 처리하는 집적회로(IC) 반도체 제조 공장의 수가 2002년 15개에서 2023년까지 138개로 증가할 것으로 예측하고 있습니다.

아시아태평양이 주요 점유율을 차지할 것으로 예상

- 반도체 웨이퍼 시장은 2021-2022년 동안 200mm 웨이퍼 생산이 활성화될 것으로 예상되며, 300mm 웨이퍼에 대한 수요는 2025년까지 증가할 것으로 예상되며, 조사된 시장은 진보와 혁신을 확인할 수 있을 것으로 예상됩니다. 반도체 제조의 우위로 인해 아시아태평양은 SiC 기판의 높은 시장 가격과 LED 수요 증가로 인해 많은 아시아 제조업체들이 GaN 웨이퍼로 전환해야 했습니다. 그러나 2019-2020년 많은 중국 LED 제조업체들이 GaN 웨이퍼를 과잉 생산했습니다. 유기 금속 화학 기상 증착(MOCVD) 시장에서도 GaN LED 생산량이 생산량에 비해 크게 초과되었습니다.

- 중국 반도체 산업은 지난 10년간 증가 추세를 보이고 있습니다. 중국 공업정보화부에 따르면 2018년 중국 제조업체의 반도체 매출은 973억 달러로 같은 해 세계 반도체 매출의 약 20%에 해당합니다. 중국은 2020년까지 전체 사용 반도체의 40%, 2025년까지 70%를 생산하는 것을 목표로 하고 있습니다.

- 중국 정부의 국가 전략 계획인 '메이드 인 차이나 2025'도 이 간행물이 부상하는 데 큰 영향을 미쳤습니다. 이 계획의 핵심 목표는 반도체 산업의 성장입니다. 또한, 중국 국가지식재산권국(CNIP)의 2021년 예산은 2023년까지 연간 200만 건의 출원을 예상하고 있으며, 이는 연구 시장의 성장을 촉진할 것으로 예상됩니다.

- 또한 TSMC는 애리조나에 첨단 5나노 웨이퍼 공장 건설 계획에 관심을 표명하고 최종 결정을 내렸습니다. 이 회사의 이사회는 또한 애리조나에 위치한 전액 출자 주조 공장에 35억 달러를 투자하는 것을 승인했습니다. 또한 2021년부터 2029년까지 총 120억 달러를 투자해 12인치 웨이퍼 공장을 건설하고 첨단 5나노 공정으로 칩을 생산할 계획입니다.

실리콘 에피택셜 웨이퍼 산업 개요

실리콘 에피택셜 웨이퍼 시장의 경쟁은 중간 정도이며, SweGaN, GlobalWafers Japan, Siltronic AG, II-VI Incorporated, Sumco Corporation 등 많은 주요 업체들이 진입했습니다. 현재 시장 점유율로 시장을 독점하고 있는 주요 기업은 없습니다. 각 업체들은 제품 혁신에 집중하고 있으며, 경쟁 우위를 유지하기 위해 M&A를 진행하고 있습니다.

- 2022년 8월 - II-VI Incorporated는 Tianyu의 장기 고객과의 공급 요구 사항을 충족시키기 위해 Tianyu에 전력 전자용 탄화규소 기판을 공급하기 위해 1억 달러 규모의 계약을 체결했습니다.

- 2022년 6월 - SK Siltron Corporation.Ltd는 2024년 상반기까지 국내 생산능력 확대에 8억 1,000만 달러를 투자할 계획을 발표했으며, 이를 통해 생산량을 늘릴 계획입니다.

기타 혜택

- 엑셀 형식의 시장 예측(ME) 시트

- 3개월간 애널리스트 지원

목차

제1장 소개

- 조사 가정과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 인사이트

- 시장 개요

- 산업의 매력 - Porter's Five Forces 분석

- 공급 기업의 교섭력

- 공급 기업의 교섭력

- 신규 참여업체의 위협

- 경쟁 기업 간의 경쟁 관계

- 대체품의 위협

- 산업 밸류체인 분석

- COVID-19의 시장에 대한 영향

제5장 시장 역학

- 시장 성장 촉진요인

- 기술 소형화

- 고성능 조명 수요 증가

- 시장 성장 억제요인

- 설계의 복잡성

제6장 시장 세분화

- 용도별

- 파워 일렉트로닉스

- MEMS

- RF 일렉트로닉스

- 포토닉스

- 지역별

- 중국

- 대만

- 한국

- 북미

- 유럽

- 기타

제7장 에피택셜 웨이퍼 유형과 우선 용도 상세 매핑

제8장 에피택셜 성장 응용과 기회

제9장 에피택셜 웨이퍼의 주요 속성

제10장 다른 종류의 상세 분석

웨이퍼(GaAS, GaN/기판, InP 등) 상세 분석

제11장 경쟁 구도

- 기업 개요

- SweGaN AB

- Sumco Corporation

- GlobalWafers Japan CO. Ltd

- Siltronic AG

- MOSPEC Semiconductor Corporation

- IQE PLC

- II-VI Incorporated

- SHOWA DENKO K.K.

제12장 벤더 시장 점유율 분석 웨이퍼 시장

제13장 투자 분석

제14장 투자 분석 시장 전망

ksm 25.01.23The Silicon Epitaxial Wafer Market is expected to register a CAGR of 4.42% during the forecast period.

Key Highlights

- Semiconductor silicon wafer remains the core component of many microelectronic devices and forms the cornerstone of the electronics industry. With digitization and electronic mobility being the current trends in technology, these products are finding applications in many devices.

- Currently, the demand for silicon wafers in the market exceeds the supply in the industry. This factor creates considerable scope for expansion, as the companies utilize this trend to expand their market shares by ramping up production.

- In addition, the demand for small-sized gadgets has increased the requirement for more functionalities from a single device. This means that an IC chip should now house more transistors to support more functionalities. Thus, the advancements in wireless computing devices, such as smartphones and tablets, have helped increase semiconductor designers' design activities. Further, the growing need for miniaturization in electronics (due to the demand for thinner wafers that consume low power) is expected to drive some advancements in the silicon epitaxial wafer market over the forecast period.

- The average prices in the industry are increasing. For instance, the Japanese company, Shin -Etsu Chemical Co . , which holds most of the market share, announced a price hike on all silicon wafer products to rise from 10 % -20 % from April 2021 onwards. The companies are taking advantage of the growing demand, further impacting the revenue accrued. GlobalWafer Co . , the second largest silicon wafer supplier, said that their silicon wafer production lines are fully loaded, coupled with the price hike, which led to an increase in revenue in March, which reached a 12 .99 % yearly increase.

- Consumer-centric end-user industries, such as consumer electronics, have robust demand for silicon wafers, forcing vendors in the industry to expand production facilities while investing in research to innovate.

- Due to COVID-19, China disrupted the country's supply chain and production. Major semiconductor manufacturing industries have been significantly affected due to China becoming a world production center over the past two to three decades.

Silicon Epitaxial Wafer Market Trends

Power Electronics is Expected to Significant Share

- The growing need for power-efficient products is one of the major factors driving the demand for the epitaxial wafer for power electronics products across all the end-user industries. Therefore, the market vendors are targeting a wide range of industries to mitigate risk and expand their customer base.

- The IGBT and MOSFET markets may continue to increase, but a part of the market is expected to go to SiC, especially when discussing modules for EV/ HEV. Moreover, the demand for power MOSFET is supported by its growing use in replacing insulated-gate, bipolar transistors, and thyristors. Additionally, the significant advantage of using power MOSFET in reinforcing the power efficiency of devices at low voltages further drives the demand for the global power MOSFET market.

- The increasing usage of power electronics in consumer devices also fuels the demand. The growing penetration of smartphones and smart devices, increasing the adoption of IoT devices, and increasing industrial usage are also developing markets for power electronics. The high demand for power electronics devices has also resulted in a shortage of 200 mm wafers in 2018 and 2019. The customer demand is falling because major customers still have vast equipment inventory. The long-term growth in the power electronics market is also driving 300 mm wafer-based production. More than seven global power electronics vendors have announced an investment in new fabrication capabilities to be in production from 2021.

- Imec and Qromis have collaborated for the developed enhancement-mode, p-GaN discrete, and IC power devices on 200 mm QST substrates, with epitaxy layers grown in Aixtron's G5+ C 200 mm MOVCD platform. Both companies have been working on device fabrication, developing GaN power devices, indiscreet and monolithically-integrated ICs forms, and 200 mm QST substrates in an advanced CMOS silicon pilot line. Imec and Qromis have collaborated with Germany-based GaN MOCVD equipment manufacturer, Aixtron on GaN-on-QST epitaxy development. Many industrial experts claim that the number of integrated circuits (IC) semiconductor fabrication plants processing 300 mm wafers worldwide are expected to grow from 15 in 2002 to 138 by 2023.

Asia Pacific is Expected to Hold Major Share

- The semiconductor wafer market is expected to ramp up 200 mm manufacturing between 2021-2022. The demand for 300 mm wafers is expected to grow by 2025; the market studied may also witness advancement and innovation. Due to their dominance in semiconductor manufacturing, Asia-Pacific is also dominating the market looked. The high market price of the SiC substrate and the growing LED demand forced many Asian manufacturers to GaN wafers. However, in 2019-2020, many Chinese LED manufacturers overproduced GaN wafers. The Metalorganic Chemical Vapour Deposition (MOCVD) market is also witnessing a significant overcapacity for GaN LED production compared to what is produced.

- The semiconductor industry of China has been showing an upward trend for the past ten years. According to China's Ministry of Industry and Information Technology, semiconductor sales by Chinese manufacturers reached USD 97.3 billion in 2018, which is around 20% of the global semiconductor revenue for the year. The country aims to produce 40% of the semiconductors it uses by 2020 and 70% by 2025.

- The Chinese government's Made in China 2025 national strategic plan has also been a significant factor in the publications' rise. The central aim of the plan is the growth of the semiconductor industry. Further, China's National Intellectual Property Administration (CNIP) 2021 budget anticipates 2 million filings per year till 2023, which is expected to drive the growth of the studied market.

- Moreover, TSMC cited its interest and finalized its plan to build an advanced 5-nanometer wafer plant in Arizona. The company's board of directors had also approved investing USD 3.5 billion in a wholly-owned foundry in Arizona. It also stated to spend a total of USD 12 billion from 2021 to 2029 to build a 12-inch wafer plant to produce chips using the advanced 5nm process.

Silicon Epitaxial Wafer Industry Overview

The Silicon Epitaxial Wafer Market is moderately competitive and consists of many significant players SweGaN, GlobalWafers Japan CO. Ltd, Siltronic AG, II-VI Incorporated, and Sumco Corporation. None of the major players currently dominate the market in terms of market share. Along with an increased focus on product innovation, the companies also engage in mergers and acquisitions to stay competitive.

- August 2022 - II-VI Incorporated has invested in a USD 100 Million Contract to Supply Tianyu with Silicon Carbide Substrates for Power Electronics to meet the requirements of Tianyu's supply with long-term customers.

- June 2022 - SK Siltron Corporation. Ltd. announced a plan to spend USD 810 million on expanding its domestic capacity by the first half of 2024, from which it plans to ramp up output.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Suppliers

- 4.2.3 Threat of New Entrants

- 4.2.4 Intensity of Competitive Rivalry

- 4.2.5 Threat of Substitutes

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Miniaturization of Technology

- 5.1.2 Rise in Demand of High Performance Lighting

- 5.2 Market Restraints

- 5.2.1 Complexities Associated with the Design

6 MARKET SEGMENTATION

- 6.1 By Applications

- 6.1.1 Power Electronics

- 6.1.2 MEMS

- 6.1.3 RF Electronics

- 6.1.4 Photonics

- 6.2 By Geography

- 6.2.1 China

- 6.2.2 Taiwan

- 6.2.3 Korea

- 6.2.4 North America

- 6.2.5 Europe

- 6.2.6 Rest of the World

7 DETAILED MAPPING OF EPITAXIAL WAFER TYPE WITH PREFERRED APPLICATION

8 EPITAXIAL GROWTH APPLICATIONS AND OPPORTUNITIES

9 KEY ATTRIBUTES OF AN EPITAXIAL WAFER

10 DETAILED ANALYSIS ON OTHER TYPES

OF WAFERS (GaAS ,GaN/Substrate, InP, etc.)

11 COMPETITIVE LANDSCAPE

- 11.1 Company Profiles

- 11.1.1 SweGaN AB

- 11.1.2 Sumco Corporation

- 11.1.3 GlobalWafers Japan CO. Ltd

- 11.1.4 Siltronic AG

- 11.1.5 MOSPEC Semiconductor Corporation

- 11.1.6 IQE PLC

- 11.1.7 II-VI Incorporated

- 11.1.8 SHOWA DENKO K.K.