|

시장보고서

상품코드

1640347

중동 및 아프리카의 프로세스 자동화 : 시장 점유율 분석, 산업 동향, 성장 예측(2025-2030년)Middle East And Africa Process Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

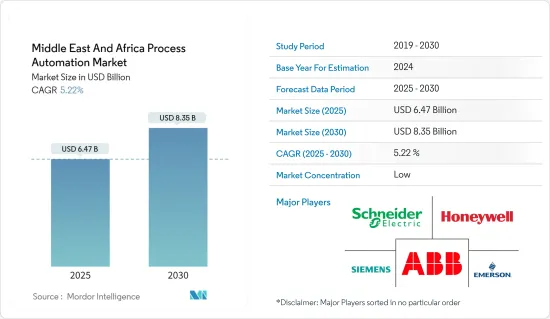

중동 및 아프리카의 프로세스 자동화 시장 규모는 2025년에 64억 7,000만 달러로 추정되며, 예측 기간(2025-2030년)의 CAGR은 5.22%로, 2030년에는 83억 5,000만 달러에 달할 것으로 예측됩니다.

자동화는 현대적인 제조 및 산업 프로세스에 필수적이며 기업이 우선 순위를 실현하는 데 도움이 됩니다. 이 지역의 기업들은 SCADA, DCS, MES, PLC 등 다양한 기술의 도움으로 업무를 자동화하고 있습니다. 이러한 기술에 대한 수요는 증가하고 있으며, 많은 벤더들이 기업이 제조 프로세스에서 더 높은 효율을 달성할 수 있도록 지원하는 솔루션을 제조하고 있습니다.

주요 하이라이트

- 제조 프로세스 자동화는 모니터링 용이성, 낭비 감소, 생산 속도 향상 등 다양한 이점을 제공합니다. 이 기술은 표준화를 통한 품질 향상과 고객에게 신뢰할 수 있는 제품을 짧은 시간과 저비용으로 제공합니다.

- SCADA, HMI, PLC 시스템 및 가시화를 제공하는 소프트웨어의 채용에 있어서 산업기계와 설비에 접속하고, 실시간 데이터를 취득하는 것이 중요한 역할을 하고, 그 결과, 제품의 결함을 줄이고, 다운타임을 줄이며, 유지보수를 스케줄링하고, 의사결정을 위해 반응적인 상태에서 예측적 및 처방적 단계의 전환이 가능해졌습니다.

- 인더스트리얼 사물 인터넷(IIoT)과 인더스트리 4.0은 스마트 공장 자동화으로 알려진 물류 체인 전체의 개발, 생산 및 관리를 위한 새로운 기술적 접근의 중심에 있습니다. 이들은 산업 부문의 동향을 지배하며 기계와 장치는 인터넷을 통해 연결됩니다.

- 또한 자동화를 통해 내부 프로세스를 현대화하고 운영 및 유지 보수 정보에 대한 액세스를 개선함으로써 이 지역의 산업은 생산과 유통을 간소화하고 높은 수율을 실현할 수 있습니다.

- 신기술에 대한 정부 지출 증가로 사우디아라비아는 공장 자동화 및 산업용 제어 시스템 산업에서 중동의 주요 국가 중 하나가 될 것으로 예상됩니다. 그 결과 국가의 자동화와 제조업의 미래에 인더스트리 4.0이 중요합니다.

- 사우디아라비아의 2030년 비전은 국가의 지위, 전략적 파트너십, 에너지 자원, 물류를 활용하여 산업과 자동화의 새로운 단계를 목표로 하고 있습니다. 또한 2030년까지 신재생에너지와 산업제조 부문을 자동화하여 국내 수요의 50%를 국내에서 제조하는 것을 목표로 하고 있습니다.

중동 및 아프리카 프로세스 자동화 시장 동향

석유 및 가스 최종 사용자 산업이 큰 시장 점유율을 차지할 전망

- 석유 및 가스 최종 사용자 업계에서는 자동화가 큰 원동력이며 동향입니다. 디지털화, 자동화, 첨단 기술을 통해 운영자와 기술자는 주요 성능, 자산 상황 및 기술 정보에 즉시 액세스할 수 있습니다. 이 지역의 석유 및 가스 기업은 의사 결정, 문제 해결 및 성능 효율성을 높이기 위해 프로세스 자동화 도구 채택을 늘리고 있습니다.

- 석유 및 가스 최종 사용자 산업의 업스트림 부문에서는 엄격한 정부 규제를 충족해야 하며 운영 비용을 절감하기 위한 면밀한 계획을 필요로 하는 여러가지 굴착 활동이 이루어지고 있습니다. 대부분의 경우, 최종 사용자 업계는 방대한 공간 데이터 셋을 다루고 여러가지 의사 결정을 내립니다. 공간 데이터의 힘을 최대한 활용하기 위해 여러 프로세스 자동화 도구와 분석 엔진이 채택되었습니다.

- 중동의 석유 및 가스 회사는 더 많은 재생 가능 에너지로 전환 할 때 종종 문제에 직면합니다. 다양한 상황에서 수요에 대응하기 위해 에너지 기업은 비즈니스 모델 내에서 프로세스 자동화와 같은 혁신적인 기술에 초점을 맞추고 혁신을 도입하며 효율성을 높여야 합니다.

- 2024년 2월 현재, 이 지역에는 296기의 육상 리그가 있으며, 또한 중동의 해안에 53기, 이 지역에 95기의 육상 리그가 배치되어 있습니다. 아프리카 해상에는 16개의 리그가 배치되어 있습니다.

- 석유 및 가스산업의 프로세스에서는 안전성과 신뢰성에 대한 수요가 급증하고 있습니다. 공급망은 자동화, 업계 전문 지식, 광범위한 파트너 네트워크에 대한 큰 요구를 창출하고 있습니다. 프로세스 자동화는 석유 및 가스 생산자가 정보를 통합하고, 동력을 제어하며, 역동적인 세계 수요에 대응하기 위한 안전 솔루션을 제공하는 데 도움이 됩니다.

- 원유 가격의 변동에 따라 여러 석유 및 가스 회사는 유통 체인 전체에서 비용을 최소화하고 효율성을 극대화하는 데 주력하고 있습니다. 경쟁 환경의 격화와 소매 마진의 감소 속에서 비즈니스를 지속하기 위해서는 여러 부문에서 여러 프로세스를 최적화해야 합니다.

아랍에미리트(UAE)가 큰 시장 점유율을 차지할 전망

- 인더스트리 4.0에 힘입어 아랍에미리트(UAE)는 공장 자동화 및 산업용 제어 시스템 업계에서 혁신을 계속하고 그 지위를 강화하고 있습니다. 이 시장에서 스마트 기술의 채택은 국민 경제에 긍정적인 영향을 미칩니다.

- 아랍에미리트(UAE)에서는 건설 산업이 경제 향상과 개발에 필수적인 역할을 하고 있습니다. SCADA는 건설 업계에서 점점 더 많이 사용되고 있습니다. SCADA(Supervisory Control and Data Acquisition : 감시 제어 및 데이터 취득)를 통해 사용자는 현장 및 원격에서 산업 운영을 제어할 수 있습니다. 건설 업계의 SCADA의 장점은 실시간으로 데이터를 모니터링하고 수집하며 이를 산업용으로 처리할 수 있다는 점입니다.

- 세계 제조업의 통합이 진행됨에 따라 자동화 투자에 대한 압력이 높아지고 있습니다.

- 아랍에미리트(UAE)의 스마트 공장에서는 사이버 공격이 증가하고 있으며 산업용 제어 시스템 사용에 대한 우려가 커지고 있습니다. 정부도 이러한 범죄 증가를 억제할 대책을 가지고 있으며 이는 국내의 사이버 보안 침해 위험을 배제하는 스마트 공장 산업 제어 시스템 제조 증가 추세와 일치합니다.

- 프로세스 발견, 프로세스 최적화, 프로세스 인텔리전스, 프로세스 오케스트레이션 등의 기술은 로봇 프로세스 자동화(RPA)의 주요 부분을 차지하고 있습니다. 앞으로 비즈니스 프로세스 관리(BPM)와 RPA 간의 관계는 더욱 밀접해질 것으로 예상됩니다.

- 팬데믹의 영향으로 UAE 경제를 부활시키기 위한 정부의 투자 시책으로 중소기업의 성장과 함께 인프라와 일렉트로닉스 산업이 주요 수혜자로 주목받았습니다. 인프라와 일렉트로닉스 산업은 산업용 제어 시스템의 하드웨어 제품과 소프트웨어 솔루션의 주요 사용 분야이므로 직접적인 플러스 효과가 기대됩니다.

중동 및 아프리카 프로세스 자동화 산업 개요

중동 및 아프리카의 프로세스 자동화 시장은 세계 기업과 중소기업 모두가 존재하기 때문에 매우 단편화되고 있습니다. 이 시장의 주요 기업으로는 ABB Ltd, Siemens AG, Schneider Electric, Emerson Electric Co., Honeywell International Inc. 등이 있습니다. 시장 기업은 제품 라인업을 강화하고 지속 가능한 경쟁 우위를 얻기 위해 제휴 및 인수와 같은 전략을 채택합니다.

- 2024년 2월 에너지 관리 및 자동화의 디지털 전환 선두 주자인 슈나이더 일렉트릭은 기술 기업 인텔 및 레드햇과 협력하여 분산 제어 노드(DCN) 소프트웨어 프레임워크 출시를 발표했습니다. 슈나이더 일렉트릭의 새로운 프레임워크는 EcoStruxure Automation의 확장이며 이를 통해 산업 기업은 소프트웨어 정의 플러그 앤 프로듀싱 솔루션으로 전환하여 운영 강화, 품질 확보, 복잡성 완화, 비용 최적화를 도모할 수 있습니다.

- 2023년 10월 에머슨은 현장, 엣지, 클라우드에서 데이터를 연결하는 소프트웨어 중심 산업용 오토메이션 플랫폼인 Boundless Automation 비전을 지원하는 신기술을 발표함으로써 보다 안전하고 유연하며 확장 가능한 솔루션을 소비자에게 제공하여 업무 최적화 및 자동화를 지원합니다. 에머슨의 혁신 제품에는 DeltaV Edge Environment, Ethernet APL, DeltaV PK Flex Controller 등이 있습니다.

기타 혜택

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트 서포트

목차

제1장 서론

- 조사의 전제조건과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 인사이트

- 시장 개요

- 업계의 매력도 - Porter's Five Forces 분석

- 공급기업의 협상력

- 소비자의 협상력

- 신규 진입업자의 위협

- 대체품의 위협

- 경쟁 기업간 경쟁 관계

- 중동 및 아프리카의 프로세스 자동화 시장에 미치는 거시적 동향

제5장 시장 역학

- 촉진요인

- 에너지 효율과 비용 절감 중시 분위기 고조

- 안전 자동화 시스템에 대한 수요

- IIoT의 출현

- 시장의 과제

- 비용과 구현 과제

제6장 시장 세분화

- 통신 프로토콜별

- 유선

- 무선

- 시스템 유형별

- 시스템 하드웨어별

- 감시 제어 및 데이터 취득 시스템(SCADA)

- 분산형 제어 시스템(DCS)

- 프로그래머블 로직 컨트롤러(PLC)

- 제조 실행 시스템(MES)

- 밸브 및 액추에이터

- 전동 모터

- 휴먼 머신 인터페이스(HMI)

- 프로세스 안전 시스템

- 센서 및 트랜스미터

- 시스템 소프트웨어

- APC(독립형 및 맞춤형 솔루션)

- 고급 규제 제어

- 다변수 모델

- 추론적 및 순차적

- 데이터 분석 및 보고서 기반 소프트웨어

- 기타 소프트웨어 및 서비스

- 시스템 하드웨어별

- 최종 사용자 산업별

- 석유 및 가스

- 화학제품 및 석유화학제품

- 전력 및 유틸리티

- 상하수도

- 음식

- 제지 및 펄프

- 제약

- 기타 최종 사용자 산업

- 국가별

- 아랍에미리트(UAE)

- 사우디아라비아

- 남아프리카

제7장 경쟁 구도

- 기업 프로파일

- ABB Ltd

- Siemens AG

- Schneider Electric

- Emerson Electric Co.

- Honeywell International Inc.

- General Electric

- Mitsubishi Electric

- Fuji Electric

- Eaton Corporation

- Delta Electronics Inc.

제8장 투자 분석

제9장 시장의 미래

CSM 25.02.17The Middle East And Africa Process Automation Market size is estimated at USD 6.47 billion in 2025, and is expected to reach USD 8.35 billion by 2030, at a CAGR of 5.22% during the forecast period (2025-2030).

Automation has become an essential part of modern manufacturing and industrial processes. It helps enterprises to realize priorities. Companies in the region are automating their operations with the help of different technologies like SCADA, DCS, MES, and PLC. The demand for these technologies is escalating, and many vendors are manufacturing solutions to help enterprises achieve higher efficiency in their manufacturing processes.

Key Highlights

- Automation of manufacturing processes offers various benefits, such as effortless monitoring, reduction of waste, and production speed. This technology provides customers with improved quality with standardization and dependable products within time and at a much lower cost.

- Connecting the industrial machinery and equipment and obtaining real-time data have played a vital role in the adoption of SCADA, HMI, PLC systems, and software that offer visualization, thus enabling reducing the faults in the product, reducing downtime, scheduling maintenance, and switching from being in the reactive state to predictive and prescriptive stages for decision-making.

- The Industrial Internet of Things (IIoT) and Industrial 4.0 are at the center of new technological approaches for the development, production, and management of the entire logistics chain, otherwise known as smart factory automation. They dominate industrial sector trends, with machinery and devices being connected via the internet.

- Further, modernizing internal processes with automation and better access to information about operations and maintenance will help the industry streamline production and distribution and allow for a higher yield in the region.

- Increased government spending on new technologies is expected to make Saudi Arabia one of the major countries in the Middle East in the factory automation and industrial control system industry. As a result, Industry 4.0 is important for the future of national automation and manufacturing.

- Saudi Arabia's 2030 vision aims for a new phase of industry and automation by exploiting the country's position, strategic partnerships, energy resources, and logistics. It also seeks to automate the country's renewable energy and industrial manufacturing sectors by 2030 and manufacture 50% of its needs within the country.

Middle East And Africa Process Automation Market Trends

The Oil and Gas End-user Industry is Expected to Hold a Significant Market Share

- Automation is a significant driver and trend in the oil and gas end-user industry. Digitization, automation, and advanced technologies give operators and technicians immediate access to critical performance, asset conditions, and technical information. Oil and Gas companies in the region are increasingly adopting process automation tools to enhance decision-making, troubleshooting, and performance efficiency.

- The upstream sector of the oil and gas end-user industry involves several drilling activities that must meet stringent government regulations and require intense planning to cut operational costs. Often, the end-user industry deals with vast sets of spatial data to make several decisions. Several process automation tools and analytical engines are employed to harness the full power of spatial data.

- Middle Eastern oil and gas companies often face challenges when transitioning to more renewable sources. To meet the demand in diverse situations, energy companies must focus on innovative technologies like process automation within their business models to embrace innovation and increase efficiency.

- As of February 2024, there were 296 land rigs in the region, with a further 53 rigs located offshore in the Middle East and 95 land rigs in that region; 16 rigs were located offshore in Africa.

- There is a surging demand for safety and reliability in the oil and gas industry processes. The supply chain creates a significant need for automation, industry expertise, and an extensive partner network. Process automation helps oil and gas producers integrate information, control power, and provide safety solutions to respond to the dynamic global demand.

- With the fluctuation in crude oil prices, several oil and gas companies focus on minimizing costs and maximizing efficiency throughout the distribution chain. To sustain itself in the rising competitive environment and decrease retail margins, the company needs to optimize several processes in multiple sectors.

The United Arab Emirates is Expected to Account For a Significant Market Share

- Fueled by Industry 4.0, the UAE continues to innovate and consolidate its position in the factory automation and industrial control systems industry. The adoption of smart technologies in the market has positively impacted the national economy.

- In the United Arab Emirates, the construction industry plays an essential role in economic upliftment and development. SCADA is being increasingly used in the construction industry. Supervisory Control and Data Acquisition (SCADA) allows users to control industrial operations on-site and remotely. The advantage of SCADA in the construction industry lies in the ability to monitor and gather data in real-time and then process it for industrial usage.

- Increasing global manufacturing integration is raising the pressure for automation investment, as cost minimization with quality maximization looms ever more significantly as an operating paradigm for Arab manufacturers.

- With cyber-attacks increasing in smart factories in the UAE, there is growing concern about using Industrial Control Systems. The government also has plans to curb the rise of such crimes. This aligns with the growing trend of industrial control systems manufactured in the country for smart factories to avoid the risk of cybersecurity breaches.

- Technologies such as process discovery, process optimization, process intelligence, and process orchestration are becoming a more significant part of Robotic Process Automation (RPA). There is an ongoing trend of increasing a closer relationship between business process management (BPM) and RPA in the future.

- With investment roll-outs by the government to revive the UAE economy from the effects of the pandemic, the infrastructure and electronics industry were marked as the primary beneficiaries, alongside the growth of small and medium-sized enterprises. The infrastructure and electronics industry are heavy users of industrial control systems' hardware products and software solutions and are expected to have a direct positive effect.

Middle East And Africa Process Automation Industry Overview

The Middle East and African process automation market is highly fragmented due to the presence of both global players and small and medium-sized enterprises. Some of the major players in the market are ABB Ltd, Siemens AG, Schneider Electric, Emerson Electric Co., and Honeywell International Inc. Players in the market are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

- February 2024: Schneider Electric, one of the leaders in the digital transformation of energy management and automation, collaborated with the technology companies Intel and Red Hat and announced the release of a Distributed Control Node (DCN) software framework. An extension of Schneider Electric's EcoStruxure Automation, this new framework enables industrial companies to move to a software-defined, plug-and-produce solution to enhance their operations, ensure quality, reduce complexity, and optimize costs.

- October 2023: Emerson introduced new technologies to support its Boundless Automation vision, a software-centric industrial automation platform that connects data from the field, the edge, and the cloud. More secure, flexible and scalable solutions are provided to consumers to help optimize and automate their operations. Emerson's innovations include DeltaV Edge Environment, Ethernet APL and DeltaV PK Flex Controller.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of Macro Trends on the Middle East and Africa Process Automation Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Emphasis on Energy Efficiency & Cost Reduction

- 5.1.2 Demand for Safety Automation Systems

- 5.1.3 Emergence of IIoT

- 5.2 Market Challenges

- 5.2.1 Cost and Implementation Challenges

6 MARKET SEGMENTATION

- 6.1 By Communication Protocol

- 6.1.1 Wired

- 6.1.2 Wireless

- 6.2 By System Type

- 6.2.1 By System Hardware

- 6.2.1.1 Supervisory Control and Data Acquisition System (SCADA)

- 6.2.1.2 Distributed Control System (DCS)

- 6.2.1.3 Programmable Logic Controller (PLC)

- 6.2.1.4 Manufacturing Execution System (MES)

- 6.2.1.5 Valves and Actuators

- 6.2.1.6 Electric Motors

- 6.2.1.7 Human Machine Interface (HMI)

- 6.2.1.8 Process Safety Systems

- 6.2.1.9 Sensors and Transmitters

- 6.2.2 By System Software

- 6.2.2.1 APC (Standalone and Customized Solutions)

- 6.2.2.1.1 Advanced Regulatory Control

- 6.2.2.1.2 Multivariable Model

- 6.2.2.1.3 Inferential and Sequential

- 6.2.2.2 Data Analytics and Reporting-based Software

- 6.2.2.3 Other Software and Services

- 6.2.1 By System Hardware

- 6.3 By End-user Industry

- 6.3.1 Oil and Gas

- 6.3.2 Chemical and Petrochemical

- 6.3.3 Power and Utilities

- 6.3.4 Water and Wastewater

- 6.3.5 Food and Beverage

- 6.3.6 Paper and Pulp

- 6.3.7 Pharmaceutical

- 6.3.8 Other End-user Industries

- 6.4 By Country

- 6.4.1 United Arab Emirates

- 6.4.2 Saudi Arabia

- 6.4.3 South Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd

- 7.1.2 Siemens AG

- 7.1.3 Schneider Electric

- 7.1.4 Emerson Electric Co.

- 7.1.5 Honeywell International Inc.

- 7.1.6 General Electric

- 7.1.7 Mitsubishi Electric

- 7.1.8 Fuji Electric

- 7.1.9 Eaton Corporation

- 7.1.10 Delta Electronics Inc.