|

시장보고서

상품코드

1640450

고무 시험기 시장 : 점유율 분석, 산업 동향, 성장 예측(2025-2030년)Rubber Testing Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

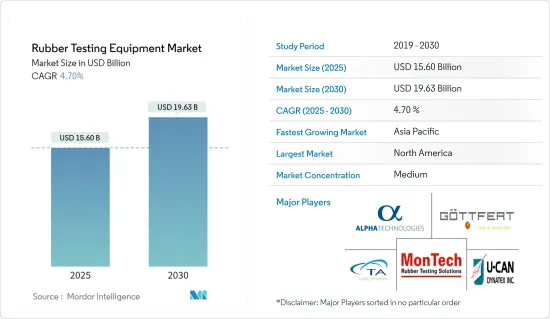

고무시험기 시장 규모는 2025년 156억 달러, 2030년 196억 3,000만 달러로 추계되며 예측기간(2025-2030년)의 CAGR은 4.7%에 달할 것으로 예측됩니다.

고무 수요는 세계 경제 강화에 대한 끊임없는 노력, 산업화 및 급속한 도시화로 인해 긍정적 영향을 받고 있습니다. 고무 시험기의 성장은 주로 자동차, 항공우주, 건강 관리, 건설과 같은 산업에서 고품질 고무 제품에 대한 수요 증가로 이어집니다.

또한, 엄격한 품질 기준과 규정은 제품의 내구성, 안전성 및 성능을 보장하기 위해 정밀한 테스트 및 분석의 필요성을 높입니다. 자동화 및 디지털화와 같은 기술의 진보는 테스트의 효율성과 정확성을 크게 향상시켜 시장 성장을 더욱 강화하고 있습니다.

고무 테스트에는 유량계, 큐어미터, 점도계를 사용하여 생산 및 최종 용도의 특성을 최적화하는 것이 포함됩니다. 고무용 유량게는 최소 점도, 최대 점도, 스코치 타임, 전환 시간 등의 중요한 특성을 측정합니다. 큐어 미터는 등온 및 비등온 시험 조건 하에서 사용자가 정의한 일정한 변형 및 주파수로 고무 화합물의 경화 프로파일을 측정합니다.

산업화와 도시화에 따른 건설활동의 격화는 자동차 생산의 꾸준한 증가와 함께 고무시험기 시장의 성장에 주로 기여할 것으로 예상됩니다.

오래 지속되는 상품에 대한 소비자 수요가 눈덩이처럼 증가하고 있기 때문에 호스나 벨트와 같은 제품은 수요가 꾸준히 증가할 것으로 예상됩니다. 건설 부문이 탄탄한 성장을 보였기 때문에 고무 지붕재에 대한 수요가 크게 증가할 수 있습니다. 제조업도 효과적인 성장을 계속 기록하고 있기 때문에 수요 증가에 기여할 것으로 예상됩니다.

시장 전망은 양호하고 지역별 분석에 따르면 성장은 주로 세계 최대의 고무 생산국인 아시아태평양에 집중하고 있습니다. 시장에서는 자동화 기술부터 소프트웨어 관리 도구 및 지능형 시험 기술 등장에 이르기까지 여러 가지 기술 개척이 진행되고 있습니다. 설계나 생산시에 시험을 필요로 하는 내구소비재 수요 증가에 더해, 이러한 기술 진보가 시장 성장의 주된 원동력이 될 것으로 예상됩니다.

고무 시험기 시장 동향

타이어 수요 증가가 시장을 견인

타이어용 고무 시험기는 고무 및 기타 재료의 인장 강도와 신장을 측정하는 데 널리 사용됩니다. 이 장치는 타이어의 동적 및 정적 테스트를 위해 특별히 설계되었습니다. 타이어의 성능과 속성을 파악하고 설계가 차량의 역학에 미치는 영향을 정의합니다.

타이어 시험에는 내구성과 인내성, 하중, 모멘트, 실내 트레드 마모, 가속 노화, 정부 규제 시험, 고장 분석 등 여러 특성에 대한 상세한 분석이 포함됩니다.

iOR, 대형 트럭용 타이어, 소형 트럭용 타이어, 승용차용 타이어 등, OTR 타이어를 장착하는 차량이 증가하고 있는 것이, 고무 시험기 시장을 세계적으로 견인하고 있습니다. 내구 시험이나 라디칼 런아웃 시험 등 타이어 시험 기술의 진화가 시장의 성장을 더욱 뒷받침하고 있습니다.

미국은 중국과 함께 판매 및 생산 측면에서 세계에서 가장 중요한 자동차 시장 중 하나입니다. OICA에 따르면 2023년 미국 자동차 산업은 약 1,060만 대의 자동차를 생산했습니다. 이러한 요인이 시장을 크게 밀어 올 것으로 예상됩니다.

북미가 가장 큰 시장 점유율을 차지

북미의 산업용 고무 제품 수요는 약간의 침체가 있지만, 자동차 생산의 대폭적인 호전과 제조업의 회복에 의해 서서히 회복되고 있습니다.

미국은 세계 최대급의 자동차 제조업체로 연간 평균 1,400만대 이상의 자동차를 생산하고 있습니다. Honda가 미국에 최초의 제조 공장을 개설한 이래 일본, 한국, 유럽의 자동차 제조업체의 대부분이 미국에 하나 이상의 제조 공장을 설립하고 있습니다.

연방 정부의 새로운 법률과 전기자동차 수요 증가로 미국 자동차 산업은 새로운 공장 건설에 수십억 달러의 자금을 투입하고 있습니다. 예를 들어 Hyundai는 미국 최초의 전기자동차 공장을 빠르게 건설 중이며 2025년 생산을 목표로 하고 있습니다.

캐나다 자동차 산업은 경쟁력이 있으며 캐나다 GDP에 크게 기여하고 있습니다. 캐나다는 점차 제조 거점을 잃고 있지만, 여전히 연간 120만 대 이상의 자동차를 생산하고 있으며, 고무 시험기 시장을 견인하고 있습니다.

5개 이상의 대형 조립 공장, 540개 이상의 OEM 부품 제조업체, 400개 이상의 딜러 및 기타 많은 자동차 관련 산업을 보유한 캐나다는 북미 2위의 자동차 생산국입니다. 이 부문은 이 나라의 제조업에 가장 큰 공헌을 하고 있기 때문에 고무 시험기 수요를 견인하고 있습니다.

고무 시험기 산업 개요

고무 시험기 시장은 여러 회사의 대기업으로 구성되어 있습니다. 시장 점유율 측면에서 현재 여러 회사의 대기업이 시장을 독점하고 있습니다. 돌출된 시장 점유율을 가진 이러한 선도 기업들은 해외에서 고객 기반의 확대에 주력하고 있습니다. 이러한 기업들은 시장 점유율과 수익성을 높이기 위해 전략적 공동 이니셔티브를 활용합니다.

2024년 4월 - Alpha Technologies는 차세대 인장 솔루션 AlphaFlex10 인장 시험기의 발매를 발표했습니다. AlphaFlex10 인장 시험기는 고무 및 엘라스토머 재료의 테스트 요구를 충족시키는 알파 기술의 종합적인 솔루션에 필수적인 레올로지 장비 제품의 신뢰할 수 있는 소프트웨어 및 서비스 지원과 원활하게 통합됩니다.

2023년 11월 - Metso는 밀 라이닝 고무를 출시했습니다. 이 고무는 현재의 프리미엄 고무보다 마모 수명이 최대 25% 긴 혁신적인 SkegaTM Life 고무입니다. 이 새로운 고무는 Metso 연구소에서 개발되었으며 현장 연구에서 검증되었습니다. Skega Life는 Metso가 제공하는 Planet Positive의 일부로 내마모성 향상과 유지 보수 감소로 지속가능성과 안전성 향상, 처리 능력 최적화, 가동률 향상을 실현합니다.

기타 혜택:

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트 서포트

목차

제1장 서론

- 조사의 전제조건과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 인사이트

- 시장 개요

- 업계의 매력도 - Porter's Five Forces 분석

- 신규 진입업자의 위협

- 구매자/소비자의 협상력

- 공급기업의 협상력

- 대체품의 위협

- 경쟁 기업간 경쟁 관계의 강도

- COVID-19의 영향과 기타 거시 경제 요인이 시장에 미치는 영향

제5장 시장 역학

- 시장 성장 촉진요인

- 내구 소비재 수요 증가

- 고무 시험에 있어서의 기술 진보

- 시장 성장 억제요인

- 높은 소유 비용

제6장 시장 세분화

- 시험 유형별

- 밀도 시험

- 점도시험

- 경도 시험

- 굽힘 시험

- 기타 시험

- 최종 사용자용도별

- 타이어

- 일반 고무 제품

- 공업용 고무 제품

- 일반 폴리머

- 컴파운드

- 지역별

- 북미

- 유럽

- 아시아

- 호주 및 뉴질랜드

- 라틴아메리카

- 중동 및 아프리카

제7장 경쟁 구도

- 기업 프로파일

- Alpha Technologies

- TA Instruments Inc.

- U-Can Dynatex Inc.

- Montech Rubber Testing Instruments

- Goettfert Inc.

- Prescott Instruments Ltd

- Ektron Tek Co. Ltd

- Gotech Testing Machines

- Norka Instruments, Sanghai Ltd.

- Gibitre Instruments Srl

제8장 투자 분석

제9장 시장 기회와 앞으로의 동향

JHS 25.02.18The Rubber Testing Equipment Market size is estimated at USD 15.60 billion in 2025, and is expected to reach USD 19.63 billion by 2030, at a CAGR of 4.7% during the forecast period (2025-2030).

The demand for rubber is positively influenced by the constant efforts to strengthen global economies, industrialization, and rapid urbanization. The growth of rubber testing equipment is primarily driven by the increasing demand for high-quality rubber products across industries like automotive, aerospace, healthcare, and construction.

Additionally, stringent quality standards and regulations contribute to the need for precise testing and analysis to ensure product durability, safety, and performance. Technological advancements, such as automation and digitalization, also significantly enhance testing efficiency and accuracy, further fueling market growth.

Rubber testing includes using rheometers, curemeters, and viscometers to optimize production and end-use properties. Rubber rheometers measure important characteristics such as minimum and maximum viscosity, scorch time, and conversion time. Curemeters measure curing profiles of rubber compounds under isothermal and non-isothermal test conditions at constant user-defined strain and frequency.

The intensifying construction activities, on account of industrialization and urbanization, combined with the steady rise in the production of automobiles, are expected to primarily contribute to the growth of the rubber testing equipment market.

Owing to the snowballing consumer demand for long-lasting goods, products like hoses and belts are expected to witness a steady rise in demand. There can be a substantial requirement for rubber roofing, as the construction sector saw robust growth. The manufacturing industry is also expected to contribute to the growing demand as it continues to record growth effectively.

The market outlook is positive, and the region-wise analysis reveals that growth is mainly concentrated in Asia-Pacific, the largest global rubber producer. There have been several technological developments in the market, ranging from automated techniques to the advent of software management tools and intelligent testing techniques. In addition to the growing demand for durable goods, which require testing during design and production, these technological advancements are expected to majorly drive the market's growth.

Rubber Testing Equipment Market Trends

The Rising Demand for Tires to Drive the Market

Rubber testing equipment for tires is widely used to determine rubber and other materials' tensile strength and elongation. The equipment is specially designed for dynamic and static testing of tires. It identifies the tire's performance and attributes and defines its design's effect on the vehicle's dynamics.

Tire testing encompasses a detailed analysis of several properties, such as durability and endurance, force, moment, indoor tread wear, accelerated aging, government regulatory testing, and failure analysis.

The increasing number of vehicles with off-the-road tires, i.e., OTR, heavy truck tires, and light truck and passenger car tires, has driven the rubber testing equipment market globally. The evolution of tire testing techniques, such as endurance and radical run-out testing, has further boosted the market's growth.

Along with China, the United States is among the most significant automobile markets worldwide in terms of sales and production. As per OICA, in 2023, the auto industry in the United States produced approximately 10.6 million motor vehicles. Such factors are expected to boost the market significantly.

North America Holds Largest Market Share

Although there is a slight slump, North America's demand for industrial rubber products is gradually recovering, owing to a drastic turnaround in motor vehicle production and the recovering manufacturing sector.

The United States is one of the largest automotive manufacturers in the world, manufacturing an average of over 14 million vehicles annually. Since Honda opened its first manufacturing plant in the United States, almost every Japanese, Korean, and European automaker has established one or more manufacturing plants in the United States.

Due to new federal legislation and increased demand for electric vehicles, the US automotive industry is pouring billions of dollars into building new factories. For instance, Hyundai is rapidly building its first US electric vehicle plant, with production on track for 2025.

Canada's automotive industry is competitive and significantly contributes to the Canadian GDP. Although Canada is gradually losing its manufacturing base, it still produces more than 1.2 million cars annually, driving the rubber testing equipment market.

With over five heavy-duty assembly plants, over 540 OEM parts manufacturers, 400 dealerships, and many other automotive-related industries, Canada is the 2nd largest vehicle producer in North America. This sector is the most significant contributor to the country's manufacturing industry, thus driving the demand for rubber testing equipment.

Rubber Testing Equipment Industry Overview

The rubber testing equipment market consists of a few major players. In terms of market share, few of the major players currently dominate the market. These major players, with a prominent market share, focus on expanding their customer base across foreign countries. These companies leverage strategic collaborative initiatives to increase their market share and profitability.

April 2024 - Alpha Technologies announced the launch of its next-generation tensile solution, the AlphaFlex10 Tensile Tester. The AlphaFlex10 tensile tester seamlessly integrates with the trusted software and service support of rheology equipment products that are an integral part of Alpha's comprehensive solutions for rubber and elastomer material testing needs.

November 2023 - Metso launched a mill lining rubber that introduced its mill lining portfolio, an innovative SkegaTM Life rubber with up to 25% longer wear life than the current premium rubber. The new rubber type is developed in Metso's laboratory and validated by field studies. Skega Life is a part of Metso's Planet Positive offering, enabling increased sustainability and safety, optimized throughput, and uptime due to improved wear resistance and lower maintenance.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers/Consumers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 Aftereffects and Other Macroeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Demand for Durable Goods

- 5.1.2 Technological Advancements in Rubber Testing

- 5.2 Market Restraints

- 5.2.1 High Cost of Ownership

6 MARKET SEGMENTATION

- 6.1 By Type of Testing

- 6.1.1 Density Testing

- 6.1.2 Viscocity Testing

- 6.1.3 Hardness Testing

- 6.1.4 Flex Testing

- 6.1.5 Other Types of Testing

- 6.2 By End-user Application

- 6.2.1 Tire

- 6.2.2 General Rubber Goods

- 6.2.3 Industrial Rubber Products

- 6.2.4 General Polymer

- 6.2.5 Compound

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Alpha Technologies

- 7.1.2 TA Instruments Inc.

- 7.1.3 U-Can Dynatex Inc.

- 7.1.4 Montech Rubber Testing Instruments

- 7.1.5 Goettfert Inc.

- 7.1.6 Prescott Instruments Ltd

- 7.1.7 Ektron Tek Co. Ltd

- 7.1.8 Gotech Testing Machines

- 7.1.9 Norka Instruments, Sanghai Ltd.

- 7.1.10 Gibitre Instruments Srl