|

시장보고서

상품코드

1689761

디지털 서보 프레스 시장 : 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)Digital Servo Press - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

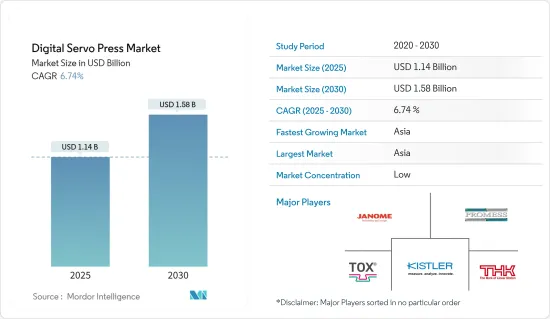

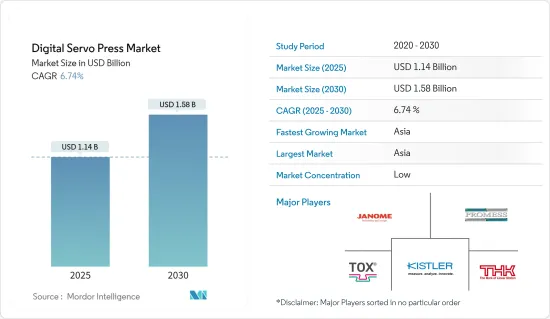

세계의 디지털 서보프레스 시장 규모는 2025년 11억 4,000만 달러로 추정되며, 예측 기간 중(2025-2030년) CAGR 6.74%로 확대되어, 2030년에는 15억 8,000만 달러에 달할 것으로 예측되고 있습니다.

디지털 서보 프레스 시장은 제조 자동화의 진전과 조립 공정에서의 정밀도의 필요성에 의해 급속히 진화하고 있습니다. 디지털 서보 프레스는 정밀한 프레스력 제어를 제공하고 생산 효율을 높이기 위해 자동차, 항공우주, 일렉트로닉스 산업에 필수적입니다. 이러한 시스템 시장은 서보 프레스 기술의 혁신을 특징으로 하며, 제조업체가 보다 높은 정밀도와 유연한 작동을 실현할 수 있도록 합니다.

디지털 서보 프레스는 전동 서보 모터를 이용하여 프레스 램의 움직임을 고정밀도로 제어합니다. 이 기능은 자동차 및 전자 장비와 같은 정밀 조립이 가장 중요한 분야에서 특히 유용합니다. 다양한 산업에서 서보 프레스 시스템의 채용이 확대되고 있는 것은 현대의 제조 공정에서 서보 프레스의 중요성을 뒷받침하고 있습니다.

서보 프레스 기술 혁신

고급 제어 시스템: 최신 디지털 서보 프레스는 프레스 공정 중에 실시간 조정을 가능하게 하는 고급 제어 시스템을 갖추고 있습니다. 이러한 시스템은 힘을 가하는 방법의 정밀도를 향상시키고 부품 조립에 높은 정밀도가 요구되는 산업에서 매우 중요합니다. 이러한 제어 시스템을 서보 프레스기에 통합함으로써 효율성과 범용성이 향상되어 생산 라인의 최적화를 목표로 하는 제조업체로 선택되고 있습니다.

에너지 효율 개선: 디지털 서보 프레스에서 전동 서보 모터로의 이동은 기존의 유압 프레스 및 공압 프레스에 비해 에너지 소비를 크게 줄였습니다. 이러한 전동 시스템은 에너지 효율을 향상시킬 뿐만 아니라 제조 공정에서 환경에 미치는 영향을 감소시킵니다. 제조의 지속가능성과 비용 절감에 대한 지속적인 관심은 에너지 효율적인 서보 프레스 기계의 채택을 촉진하고 있습니다.

자동차 산업 수요: 자동차 산업은 디지털 서보 프레스의 주요 최종 사용자이며 에어백, 변속기 및 기타 안전 관련 시스템과 같은 중요한 구성 요소를 조립하는 데 활용됩니다. 이러한 용도로는 정밀도가 요구되기 때문에 일관되고 신뢰성이 높은 결과를 제공할 수 있는 고성능 서보 프레스 수요가 높아지고 있습니다. 자동차 제조업체가 기술 혁신을 계속하고 자동차 안전 기준을 향상시키고 있기 때문에 선진적인 서보 프레스 시스템에 대한 수요는 계속 견조하게 추이할 것으로 예상됩니다.

디지털 서보 프레스 시장 동향

전자기기 제조업체 지출 증가

전자 제조업의 성장 : 전자 산업은 디지털 서보 프레스의 또 다른 중요한 시장이며, 특히 힘의 변동을 최소화하는 것이 필수적인 섬세한 부품 조립에 중요합니다. 소비자 일렉트로닉스의 대두와 전자기기의 소형화에 의해 정밀한 조립 공정의 필요성이 높아지고, 서보 프레스 시스템 수요가 더욱 높아지고 있습니다. 전자 장치가 더욱 복잡해짐에 따라 고급 조립 프레스 시스템 시장은 아마도 확대될 것으로 보입니다.

디지털 서보 프레스 시장 경쟁 구도은 엄격하고 여러 주요 기업들이 연구 개발에 적극적으로 투자하고 제품을 충실히 하고 있습니다. Janome Industrial Equipment, Promess, Kistler와 같은 기업은 다양한 산업의 진화하는 요구에 부응하는 혁신의 도입을 담당하고 있습니다. 시장 경쟁은 서보 프레스 기술의 추가 발전을 촉진하고 시장 성장과 제조 공정의 지속적인 개선에 세계적으로 기여할 것으로 예상됩니다.

디지털 서보 프레스 기술에 대한 지출을 늘리는 전자 기기 제조업체:

전자기기 제조 부문은 대폭적인 성장을 이루고 있으며, 이는 디지털 서보 프레스 기술에 대한 투자 증가의 원동력이 되고 있습니다. 전자기기 조립에서는 정확성과 효율성이 가장 중요하며 디지털 서보 프레스가 필수적입니다. 이 기계는 프레스력을 비교할 수 없을 정도로 제어할 수 있으므로 가장 섬세한 부품도 고정밀도로 조립되어 불량품을 최소화할 수 있습니다. 전자기기의 소형화가 진행됨에 따라 복잡하고 작은 부품에 대응할 수 있는 고급 서보 프레스 수요가 급증하고 시장 확대에 크게 기여하고 있습니다. 디지털 프레스 자동화를 제조 공정에 통합하는 동향은 생산 효율성을 더욱 높이고, 폐기물을 줄이고, 다운타임을 최소화하고, 경쟁력을 유지하려는 전자기기 제조업체에 전략적 투자가 되고 있습니다.

전자 제조 시장을 선도하는 아시아태평양:

이 지역의 리더십의 원인은 제조공장에서의 로봇공학과 자동화의 급속한 도입으로 인해 효율과 생산성이 향상되고 있습니다. 전자기기의 복잡화에 따라 고정밀도의 프레스 시스템이 요구되고 있어, 이 지역에서 서보 프레스 수요를 견인하고 있습니다. 결과적으로 디지털 서보 프레스는 특히 인쇄 회로 기판에 커넥터를 설치하는 응용 분야에서 생산 기준을 유지하는 데 필수적입니다. 이 지역의 동향은 생산 능력을 강화하기 위해 첨단 제조 기술을 채택하려는 세계의 움직임을 반영합니다.

자동차 제조업체의 차량 경량화 중시가 디지털 서보 프레스 수요를 끌어올릴 전망

자동차 업계의 차량 경량화 중시가 서보 프레스 시장을 견인:

자동차 산업은 주로 연비를 향상시키고 엄격한 배기 가스 규제를 충족시키기 위해 차량의 경량화에 노력하고 있으며 디지털 서보 프레스 수요를 크게 밀어 올리고 있습니다. 경량 차량의 제조에 필수적인 알루미늄 및 고강도 강철과 같은 재료는 이러한 프레스가 제공하는 정밀한 성형 능력이 필요합니다. 서보 프레스 기술이 제공하는 일관되고 재현 가능한 결과는 약간의 변동으로도 자동차의 성능과 안전성에 영향을 미치는 바디 패널 및 구조 부품과 같은 부품 생산에 필수적입니다. 업계가 전기자동차(EV)로 이동함에 따라 경량 재료로 만들어지는 다양한 부품이 요구되고 있으며, 품질과 내구성을 확보하기 위한 디지털 서보 프레스의 역할이 더욱 중요해지고 있습니다.

세계 자동차의 경량화 추진이 서보 프레스의 용도를 확대:

세계 자동차 시장은 연비 향상과 환경 부하 감소로 자동차 경량화에 점점 더 주력하고 있습니다. 이 동향은 디지털 서보 프레스, 특히 200KN 이상의 힘을 취급할 수 있는 서보 프레스의 순송 성형 용도에 대한 수요를 견인하고 있습니다. 자동차 제조에 있어서 고장력강이나 경량 알루미늄 합금의 사용이 증가할 것으로 예상되고, 그 결과, 세계적으로 서보 프레스의 판매가 가속되고 있습니다. 이 동향은 승용차 생산의 주요 시장이 되고 있는 아시아에서 특히 두드러지며, 자동차 제조업체가 경량화와 차량 성능 향상이라는 2개의 과제에 세계적으로 임하고 있기 때문에 앞으로도 계속될 것으로 예상됩니다.

EV 제조에 필수적인 서보 프레스 기술:

전기자동차(EV)의 대두도 디지털 서보 프레스 기술 수요를 높이는 큰 요인입니다. EV는 독특한 구성 요소와 어셈블리가 필요하며, 대부분은 정밀한 성형 공정이 필요한 경량 재료로 만들어집니다. 디지털 서보 프레스는 필요한 정확성과 제어를 제공하여 이러한 부품이 EV 제조에 필요한 엄격한 품질 기준을 충족하는지 확인합니다. 자동차산업이 전동 모빌리티로 옮겨가고 있는 가운데 서보프레스 기술의 채용은 가속화되어 시장 성장을 더욱 촉진할 것으로 보입니다.

각 업계의 서보 프레스 채용 증가:

디지털 서보 프레스 시스템의 채용은 자동차 산업이나 전자 산업에 국한되지 않습니다. 항공우주나 의료기기 제조 등 정밀도와 효율성을 우선하는 다른 분야에서도 이 기술에 대한 투자가 늘고 있습니다. 서보 프레스는 일관된 고품질 결과를 제공할 수 있으므로 정확도가 중요한 용도에 이상적입니다. 산업이 계속 발전하고 보다 복잡한 제조 공정을 채택함에 따라 고급 서보 프레스 기술에 대한 수요가 증가하고 있으며 이러한 시스템은 최신 생산 라인의 핵심 구성 요소로 자리매김할 것으로 예상됩니다.

디지털 서보 프레스 시장 전망 :

디지털 서보 프레스 시장은 기술의 진보와 다양한 산업에서의 채용 증가에 의해 지속적인 성장이 예상되고 있습니다. 서보 프레스 기술의 혁신은 이러한 기계의 효율성과 능력을 향상시키고 현대적인 제조 산업의 요구를 충족시키기 위해보다 범용적이고 효과적입니다. 산업계가 점점 지속가능성, 정확성, 효율성을 우선시함에 따라 디지털 서보 프레스는 생산 공정에서 더욱 중요한 역할을 할 것입니다. 이제 이 기술에 투자하는 기업은 경쟁 우위를 확보하고 제품 품질과 업무 효율성을 향상시키고 급속하게 진화하는 시장 환경에서 장기적인 성공을 거둘 수 있을 것으로 보입니다.

디지털 서보 프레스 산업 개요

세분화된 시장 구조: 디지털 서보 프레스 시장은 단편적인 시장 구조를 특징으로 하며, 세계 기업와 지역 기업이 혼재해 업계의 경쟁 역학에 공헌하고 있습니다. 소수의 주요 기업이 시장 점유율의 대부분을 차지하는 반면, 다수의 중소기업이 특수한 제품을 제공하고 다양한 경쟁 구도를 만들어 내고 있습니다. 이러한 세분화는 치열한 경쟁과 혁신을 가능하게 하며, 각 회사는 시장 포지션을 지속적으로 유지하기 위해 제공 제품을 개선할 것입니다. 그 결과, 시장은 다양한 산업용도에 대응하는 광범위한 제품 옵션을 볼 수 있습니다.

주요 기업 및 이점 디지털 서보 인쇄기 시장의 주요 기업은 Janome Industrial Equipment, Promess, Kistler, Tox Pressotechnik, THK 등입니다. 이러한 기업들은 기술의 진보, 견고한 제품 포트폴리오, 세계의 존재감으로 인정받고 있습니다. 지속적인 기술 혁신과 전략적 파트너십을 통해 리더로서의 지위를 확립하고 고객의 다양한 요구에 부응하는 종합적인 솔루션을 제공합니다. 이 회사의 이점은 광범위한 R&D 노력과 품질에 대한 헌신에 의해 더욱 뒷받침되며 시장에서 경쟁력을 유지하는 데 도움이 됩니다.

전략적 초점과 시장 동향 : 디지털 서보 프레스 시장은 IoT와 Industry 4.0 기술의 통합과 같은 동향을 목격하고 있으며, 이들은 제조와 자동화의 미래를 형성하고 있습니다. 기업은 정확성, 효율성 및 연결성을 강화한 고급 서보 프레스 개발에 점점 더 집중하고 있습니다. 이 시장에서의 성공은 기술 혁신, 맞춤형 솔루션 제공 능력, 전략적 제휴 및 인수를 통한 세계적인 발자국 확대 등의 요인에 달려 있습니다. 이러한 분야에 뛰어난 기업은 이 경쟁 시장에서 보다 견고한 지위를 확보할 가능성이 높습니다.

기타 혜택:

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트·지원

목차

제1장 서론

- 조사의 성과

- 조사의 전제

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 역학

- 시장 개요

- 시장 성장 촉진요인

- 전자기기 제조업체의 지출 증가

- 자동차 제조업체의 차체 경량화가 디지털 서보 프레스 수요를 끌어올릴 전망

- 시장 성장 억제요인

- 높은 초기 비용

- 시장 기회

- 지속가능성을 중시함으로써 제조업체는 보다 에너지 효율적이고 환경친화적인 기술을 채택하게 되었습니다.

- Porter's Five Forces 분석

- 신규 참가업체의 위협

- 구매자/소비자의 협상력

- 공급기업의 협상력

- 대체품의 위협

- 경쟁 기업간 경쟁 관계의 강도

제5장 시장 세분화

- 강도 범위

- 100KN 미만

- 100-200KN

- 200KN 이상

- 용도

- 자동차

- 항공우주

- 일렉트로닉스

- 지역

- 북미

- 미국

- 캐나다

- 멕시코

- 기타 북미

- 유럽

- 독일

- 영국

- 프랑스

- 러시아

- 스페인

- 기타 유럽

- 아시아태평양

- 인도

- 중국

- 일본

- 기타 아시아태평양

- 남미

- 브라질

- 아르헨티나

- 중동

- 아랍에미리트(UAE)

- 사우디아라비아

- 기타 중동

- 북미

제6장 경쟁 구도

- 벤더의 시장 점유율

- 합병과 인수

- 기업 프로파일

- Janome Industrial Equipment

- Promess

- Kistler

- Tox Pressotechnik

- THK

- Soress

- Intelligent Actuator

- FEC

- Sintokogio

- C and M Robotics

제7장 향후의 동향

JHS 25.04.07The Digital Servo Press Market size is estimated at USD 1.14 billion in 2025, and is expected to reach USD 1.58 billion by 2030, at a CAGR of 6.74% during the forecast period (2025-2030).

The digital servo press market has been evolving rapidly, driven by advancements in manufacturing automation and the need for precision in assembly processes. Digital servo presses are integral to the automotive, aerospace, and electronics industries because they provide precise press force control and enhance production efficiency. The market for these systems is characterized by innovations in servo press technology, enabling manufacturers to achieve higher accuracy and flexibility in their operations.

Digital servo presses utilize electric servo motors to control the movement of the press ram with high precision, which is critical in applications where exact force control is required. This capability is particularly beneficial in sectors such as automotive and electronics, where precision assembly is paramount. The growing adoption of servo press systems across various industries underscores their importance in modern manufacturing processes.

Innovations in Servo Press Technology:

Advanced Control Systems: Modern digital servo presses are equipped with sophisticated control systems that allow for real-time adjustments during the pressing process. These systems enhance the precision of force application, which is crucial in industries where component assembly requires high accuracy. The integration of these control systems into servo press machines has improved their efficiency and versatility, making them a preferred choice for manufacturers seeking to optimize production lines.

Energy Efficiency Improvements: The shift towards electric servo motors in digital servo presses has significantly reduced energy consumption compared to traditional hydraulic and pneumatic presses. These electric systems not only offer better energy efficiency but also reduce the environmental impact of manufacturing processes. The ongoing focus on sustainability and cost reduction in manufacturing is driving the adoption of energy-efficient servo press machines.

Automotive Sector Demand: The automotive industry is a major end-user of digital servo presses, utilizing them in the assembly of critical components such as airbags, transmissions, and other safety-related systems. The need for precision in these applications drives the demand for high-performance servo presses that can deliver consistent and reliable results. As automotive manufacturers continue to innovate and improve vehicle safety standards, the demand for advanced servo press systems is expected to remain strong.

Digital Servo Press Market Trends

Increase in Expenditure of Electronics Manufacturers

Electronics Manufacturing Growth: The electronics industry is another significant market for digital servo presses, particularly in the assembly of delicate components where minimal force variation is essential. The rise of consumer electronics and the miniaturization of electronic devices has increased the need for precise assembly processes, further boosting the demand for servo press systems. As electronic devices become more complex, the market for advanced assembly press systems will likely expand.

The digital servo press market's landscape is competitive, with several key players actively investing in research and development to enhance their offerings. Companies like Janome Industrial Equipment, Promess, and Kistler are in charge of introducing innovations that cater to the evolving needs of various industries. The market's competitive nature is expected to foster further advancements in servo press technology, contributing to the market's growth and the continuous improvement of manufacturing processes globally.

Electronics Manufacturers Increasing Expenditure on Digital Servo Press Technology:

The electronics manufacturing sector has seen substantial growth, which is driving an increased investment in digital servo press technology. Precision and efficiency are paramount in electronics assembly, making digital servo presses indispensable. These machines offer unparalleled control over press force, ensuring that even the most delicate components are assembled with high accuracy, thus minimizing defects. As electronic devices continue to miniaturize, the demand for advanced servo presses capable of handling intricate and tiny components has surged, contributing significantly to the market's expansion. The trend towards integrating digital press automation into manufacturing processes has further enhanced production efficiency, reduced waste, and minimized downtime, making it a strategic investment for electronics manufacturers aiming to remain competitive.

Asia-Pacific Leading in Electronics Manufacturing Market:

The region's leadership is partly due to the rapid adoption of robotics and automation in manufacturing plants, which boosts efficiency and productivity. The growing complexity of electronic devices requires high-precision press systems, which is driving the demand for servo presses in the region. As a result, digital servo presses are becoming essential in maintaining production standards, especially in applications like installing connectors on printed circuit boards. This regional trend reflects the broader global move towards adopting advanced manufacturing technologies to enhance production capabilities.

Focus of Automobile Manufacturers on Reducing Vehicle Weight Expected to Boost the Demand for Digital Servo Press:

Automotive Industry's Focus on Vehicle Weight Reduction Driving Servo Press Market:

The automotive industry's ongoing efforts to reduce vehicle weight, primarily to improve fuel efficiency and meet stringent emissions regulations, are significantly boosting the demand for digital servo presses. Materials like aluminum and high-strength steel, which are critical for lightweight vehicle manufacturing, require the precise forming capabilities provided by these presses. The consistent, repeatable results offered by servo press technology are vital in producing components such as body panels and structural parts, where even minor variations can impact vehicle performance and safety. As the industry shifts towards electric vehicles (EVs), which demand different components often made from lightweight materials, the role of digital servo presses in ensuring quality and durability is becoming even more crucial.

Global Push for Lightweight Vehicles Expanding Servo Press Applications:

The global automotive market increasingly focuses on producing lighter vehicles to enhance fuel efficiency and reduce environmental impact. This trend is driving the demand for digital servo presses, particularly those capable of handling more than 200KN force, for progressive forming applications. The use of high tensile strength steel and lightweight aluminum alloys in vehicle manufacturing is expected to grow, which in turn is accelerating the sales of servo presses worldwide. This trend is particularly strong in Asia, now a leading market for passenger vehicle production, and is expected to continue as automakers globally strive to meet the dual challenges of improving vehicle performance while reducing weight.

Servo Press Technology Critical for EV Manufacturing:

The rise of electric vehicles (EVs) is another significant factor driving the demand for digital servo press technology. EVs require unique components and assemblies, many of which are crafted from lightweight materials that need precise forming processes. Digital servo presses provide the necessary accuracy and control, ensuring these components meet the stringent quality standards required in EV manufacturing. As the automotive industry continues to shift towards electric mobility, the adoption of servo press technology is likely to accelerate, further driving market growth.

Increasing Servo Press Adoption Across Industries:

The adoption of digital servo press systems is not limited to the automotive and electronics industries. Other sectors that prioritize precision and efficiency, such as aerospace and medical device manufacturing, are also increasingly investing in this technology. The ability of servo presses to deliver consistent, high-quality results makes them ideal for applications where accuracy is critical. As industries continue to evolve and adopt more complex manufacturing processes, the demand for advanced servo press technology is expected to grow, positioning these systems as a key component in modern production lines.

Future Prospects for the Digital Servo Press Market:

The digital servo press market is poised for continued growth, driven by technological advancements and increasing adoption across various industries. Innovations in servo press technology are enhancing the efficiency and capabilities of these machines, making them more versatile and effective in meeting the demands of modern manufacturing. As industries increasingly prioritize sustainability, precision, and efficiency, digital servo presses are set to play an even more critical role in production processes. Companies that invest in this technology now are likely to gain a competitive edge, improving product quality and operational efficiency, and positioning themselves for long-term success in a rapidly evolving market environment.

Digital Servo Press Industry Overview

Fragmented Market Structure: The digital servo press market is characterized by a fragmented market structure, with a mix of global and regional players contributing to the industry's competitive dynamics. While a few key players hold a significant portion of the market share, numerous smaller companies offer specialized products, creating a diverse competitive landscape. This fragmentation allows for intense competition and innovation, driving companies to improve their offerings to maintain their market positions continuously. As a result, the market sees a wide range of product options catering to various industrial applications.

Key Players and Their Dominance: Major players in the digital servo press market include Janome Industrial Equipment, Promess, Kistler, Tox Pressotechnik, and THK. These companies are recognized for their technological advancements, robust product portfolios, and strong global presence. They have established themselves as leaders through continuous innovation and strategic partnerships, providing comprehensive solutions that cater to the diverse needs of their customers. Their dominance is further supported by extensive R&D efforts and a commitment to quality, which helps them maintain a competitive edge in the market.

Strategic Focus and Market Trends: The digital servo press market is witnessing trends such as the integration of IoT and Industry 4.0 technologies, which are shaping the future of manufacturing and automation. Companies are increasingly focusing on developing advanced servo presses that offer enhanced precision, efficiency, and connectivity. Success in this market will depend on factors like technological innovation, the ability to offer customized solutions, and expanding global footprints through strategic alliances and acquisitions. Companies that excel in these areas are likely to secure a stronger position in this competitive market.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increase in Expenditure of Electronics Manufacturers

- 4.2.2 Automobile Manufacturers on Reducing Vehicle Weight Expected to Boost the Demand for Digital Servo Press

- 4.3 Market Restraints

- 4.3.1 High Initial Cost

- 4.4 Market Opportunities

- 4.4.1 Emphasis on sustainability is pushing manufacturers to adopt more energy-efficient and eco-friendly technologies

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers/Consumers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 Force Range

- 5.1.1 Less than 100KN

- 5.1.2 100KN - 200KN

- 5.1.3 More than 200KN

- 5.2 Application

- 5.2.1 Automotive

- 5.2.2 Aerospace

- 5.2.3 Electronics

- 5.3 Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Mexico

- 5.3.1.4 Rest of North America

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 United Kingdom

- 5.3.2.3 France

- 5.3.2.4 Russia

- 5.3.2.5 Spain

- 5.3.2.6 Rest of Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 India

- 5.3.3.2 China

- 5.3.3.3 Japan

- 5.3.3.4 Rest of Asia-Pacific

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.5 Middle East

- 5.3.5.1 United Arab Emirates

- 5.3.5.2 Saudi Arabia

- 5.3.5.3 Rest of Middle East

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Mergers and Acquisitions

- 6.3 Company Profiles

- 6.3.1 Janome Industrial Equipment

- 6.3.2 Promess

- 6.3.3 Kistler

- 6.3.4 Tox Pressotechnik

- 6.3.5 THK

- 6.3.6 Soress

- 6.3.7 Intelligent Actuator

- 6.3.8 FEC

- 6.3.9 Sintokogio

- 6.3.10 C and M Robotics