|

시장보고서

상품코드

1690081

인베스트먼트 주조 : 시장 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)Investment Casting - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

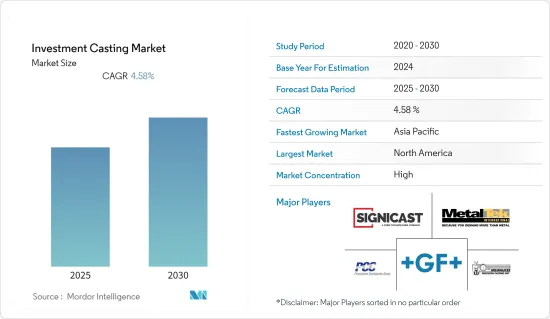

인베스트먼트 주조 시장은 예측 기간 동안 4.58%의 연평균 복합 성장률(CAGR)을 나타낼 것으로 전망됩니다.

COVID-19의 유행은 세계의 많은 산업에 빠르고 심각한 영향을 미쳤습니다. 유행은 세계 수요 하락을 동반하는 산업에 강한 압력이 되었습니다. 수요가 감소함에 따라 기업은 유행 후 전략과 사업 계획을 고려하고 있습니다. 경제가 완만하게 회복되기 때문에 인베스트먼트 주조 시장은 예측 기간 동안 플러스 성장이 예상됩니다.

인베스트먼트 주조 수요는 성장하는 항공우주·군사 산업이 주요한 원동력이 되고 있습니다. 인베스트먼트 주조에 의해 제조되는 항공기, 헬리콥터 및 제트기는 다양한 용도와 부품이 있기 때문입니다. 인베스트먼트 주조에 의해 제조되는 항공기, 헬리콥터 및 제트기 부품에는 비행에 필수적인 부품, 안전 부품, 착륙 부품, 브레이크 부품, 유압 유체 시스템 부품 등이 있습니다.

제조 비용과 높은 에너지 소비와 같은 인베스트먼트 주조 수요를 방해하는 요인도 몇 가지 있습니다. 그러나 주조공장은 시뮬레이션을 이용한 첨단 주조기술의 혁신에 협력함으로써 이러한 과제를 극복하려고 하고 있으며, 현장에서의 작업시간을 단축하고 주조수율을 향상시킬 가능성이 높습니다.

북미는 현재 인베스트먼트 주조 시장을 선도하고 있습니다. 이 지역의 성장 요인은 제조업, 의료, 항공우주 및 군사 분야의 확대입니다. 아시아태평양은 예측 기간 동안 가장 빠르게 성장하는 지역으로 예측됩니다. 중국은 인베스트먼트 주조 산업의 성장에 크게 기여하는 중요한 국가 중 하나이기 때문에이 지역을 선도할 가능성이 높습니다.

인베스트먼트 주조 시장 동향

규산나트륨 공정이 가장 높은 성장률을 보일 것으로 예상

실리카 솔 주조는 투자 주물의 치수 정밀도와 표면 마감을 향상시켜 결함을 최소화합니다. 따라서, 이 공정의 비용은 물 유리 주조보다 높습니다. 실리카 솔의 지르콘 샌드는 매우 비싸고 필요한 준비도 높고 이것이 비용이 많이 드는 주된 이유입니다.

비용이 높기 때문에 실리카 솔 공정은 주조소에서의 채용이 비교적 적습니다. 자동차 부품 및 산업 부품에 사용되는 실리카 솔 인베스트먼트 주조 비용은 평균 약 6.5 USD/kg입니다.

현재 일부 기업은 세라믹 주조보다 규산나트륨 주조가 더 경제적이라고 합니다. 그러나 최고의 주조 품질과 낮은 수리율이 최종 사용자의 주요 초점이라면이 과정을 선호합니다. 물유리 공정에 비해 실리카 솔 공정은 50-100kg의 초대형 부품을 제조할 수 있습니다. 따라서, 이 공정은 워터 펌프, 임펠러, 분수 쉘, 펌프 몸체, 볼 밸브 몸체, 밸브 플레이트와 같은 더 크고 무거운 부품의 제조에 사용됩니다. 동시에, 이 공정은 높은 치수 정밀도를 요구하는 초소형 부품(2-1,000g)의 제조에도 널리 사용됩니다.

규산 소다 제법은 아시아태평양에서 점차 보급되고 있으며, 일본이 최전선에서 생산 수요를 선도하고 있습니다. 생산되는 부품의 품질과 치수 정밀도를 향상시키기 위한 지속적인 노력의 결과입니다.

북미가 인베스트먼트 주조 시장을 선도

북미는 인베스트먼트 주조 시장을 선도하고 있으며 아시아태평양과 유럽에 이어 최고 자리를 유지할 가능성이 높습니다. 북미의 성장 요인은 주로 산업가스나 항공우주 및 방위용도의 제조업이 확대되고 있는 것과 록히드·마틴, 레이세온, 노스롭·그라만 등, 이 지역에 중요한 방위 항공기·부품 제조업체가 존재하는 것입니다.

항공우주 산업은 미국의 주요 산업 중 하나이며 보잉 737, 보잉 777, 보잉 787, 에어 버스 A220 등 주요 항공기 프로그램 생산 공장이이 지역에 있습니다. 이 나라에서는 F-35와 같은 군용기 프로그램의 제조가 인베스트먼트 주조 부품에 대한 수요를 창출할 것으로 예상됩니다.

미국은 세계 유수의 자동차 산업국이며 국내총생산(GDP) 전체의 적어도 3%에 공헌하고 있습니다. 또한 이 나라는 고급차 시장에서 가장 큰 제조업체 중 하나이며 2021년 순수입은 50억 달러였습니다. 고급차 제조업체인 BMW는 2021년 33만 6,600대가 넘는 기록적인 판매량을 기록했습니다.

그러나 미국의 자동차 산업은 COVID-19 팬데믹에 의해 타격을 받았고 대부분의 생산 거점이 폐쇄되거나 조업 능력이 저하되었습니다. 2022년 4월 미국의 신차 판매 대수는 125만 6,224대로 2021년 4월의 숫자와 비교해 18% 감소했습니다. 또한 4월 승용차 판매 대수는 27만 8,827대에서 23.3% 감소했으며 SUV와 트럭 판매 대수도 97만 7,397대에서 16.3% 감소했습니다. 2022년 1분기는 미국 자동차 부문에 불리한 상황이 되었습니다. 이러한 자동차 섹터의 확대는 자동차 부품 및 부품에 대한 인베스트먼트 주조 용도의 높은 이용률을 불러일으키며, 장기적인 기간 동안 인베스트먼트 주조 수요를 증가시킬 가능성이 높습니다.

또한 캐나다 항공우주 산업 협회에 따르면 에어버스, 보잉, 드 하빌랜드 캐나다, 봄바르디아는 캐나다의 주요 항공우주 제조업체이며 95%의 기업이 부분적인 생산 능력으로 가동하고 있습니다. 드 하빌랜드 캐나다는 단계적으로 항공기 생산을 시작할 예정입니다. 주요 항공우주 기업은 이 지역의 인베스트먼트 주조에 대한 수요를 높이기 위해 사업의 잠재력을 넓히는 것으로 보입니다. 예를 들어, 2022년 11월 항공기 엔진 제조업체인 플랫 앤 휘트니는 미국에 새로운 터빈 날개형 시설을 개설할 것이라고 발표했습니다. 이 시설에는 총 6억 5,000만 달러를 투자하는 고급 파운드리이 설치됩니다.

또한 주요 주물 제조업체는 수요가 증가함에 따라 북미에서 인베스트먼트 주조의 가능성을 넓히고 판매망을 확대하고 있습니다. 예를 들어, 2022년 9월, 주조 기술 회사인 시그니캐스트 코퍼레이션은 최신 인베스트먼트 주조 시설의 개설을 발표했습니다.

이러한 요인과 개발 수요를 고려할 때 인베스트먼트 주조는 널리 보급되는 응용 분야 때문에 북미에서 높은 성장 가능성을 유지할 것으로 예상됩니다.

인베스트먼트 주조 산업 개요

인베스트먼트 주조 시장은 국제 및 지역 인베스트먼트 주조 제조업체의 존재로 인해 단편화됩니다. 인베스트먼트 주조 시장은 Alcoa Corporation, ThyssenKrupp AG, Zollern GmbH and Co.KG, Georg Fischer Ltd, Signast, Milwaukee Precision Casting, RLM Industries입니다.

시장은 세분화되어 있기 때문에 각 회사는 경쟁을 이기기 위해 투자, 제휴, 합작 투자, 인수 등을 실시했습니다. 예를 들어, 2021년 10월, 알코아 코퍼레이션은 2050년까지 세계 사업 전체에서 온실가스(GHG) 배출량 넷 제로를 달성할 계획을 발표했습니다. 직접 배출(스코프 1)과 간접 배출(스코프 2)의 GHG 배출량을 2050년까지 넷 제로를 달성한다는 목표는 지속가능한 발전을 목표로 하는 회사의 전략적 우선사항에 따른 것으로, 알루미늄 제련과 알루미나 정제 사업으로부터의 직접·간접 GHG 배출량을 2025년까지 30%, 2030년까지 50% 감축하는 등 기존 목표를 보완합니다.

기타 혜택 :

- 엑셀 형식 시장 예측(ME) 시트

- 애널리스트에 의한 3개월간의 지원

목차

제1장 서론

- 조사의 전제조건

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 역학

- 시장 성장 촉진요인

- 시장 성장 억제요인

- Porter's Five Forces 분석

- 신규 참가업체의 위협

- 구매자·소비자의 협상력

- 공급기업의 협상력

- 대체품의 위협

- 경쟁 기업간 경쟁 관계의 강도

제5장 시장 세분화

- 유형별

- 규산 나트륨 공정

- 테트라 에틸 오르토 실리케이트/실리카 솔 공정

- 최종 사용자별

- 자동차

- 항공우주 및 군사

- 일반산업기계

- 의료

- 기타 최종 사용자

- 지역별

- 북미

- 미국

- 캐나다

- 기타 북미

- 유럽

- 독일

- 영국

- 프랑스

- 스페인

- 기타 유럽

- 아시아태평양

- 인도

- 중국

- 일본

- 한국

- 기타 아시아태평양

- 세계 기타 지역

- 브라질

- 아르헨티나

- 멕시코

- 아랍에미리트(UAE)

- 기타 국가

- 북미

제6장 경쟁 구도

- 벤더의 시장 점유율

- 기업 프로파일

- Signicast

- MetalTek International

- Milwaukee Precision Casting Inc.

- Impro Precision Industries Limited

- Alcoa Corporation

- Zollern GmbH and Co. KG

- Precision Castparts Corp(Berkshire Hathaway)

- Georg Fischer Ltd

- Dongying Giayoung Precision Metal

- Taizhou Xinyu Precision Manufacture Co. Ltd

제7장 시장 기회와 앞으로의 동향

KTH 25.04.09The Investment Casting Market is expected to register a CAGR of 4.58% during the forecast period.

The COVID-19 outbreak has had a swift and severe impact on many industries globally. The pandemic placed intense pressure on industries with a downward shift in global demand. With declining demand, the companies are examining their strategies and operational plans for the post-pandemic period. As economies are recovering slowly, the investment casting market is expected to grow positively during the forecast period.

The demand for investment casting is majorly driven by the growing aerospace and military industry, as there are many different applications and parts of aircraft, helicopters, and jets that are produced through investment casting. These include flight critical and safety components, landing and braking components, and hydraulic fluid system components, all of which are vital to the safety of the aircraft.

A few factors are hindering the demand for investment castings, such as manufacturing cost and high energy consumption. However, foundries are trying to overcome these challenges by collaborating to innovate advanced casting technologies using simulations, which is likely to reduce the shop-floor time and increase the casting yield.

North America is currently leading the investment casting market. The factors attributable to the region's growth are the expansion of the manufacturing, medical, and aerospace and military sectors. Asia-Pacific is projected to be the fastest-growing region over the forecast period. China is likely to lead the region as it is one of the significant countries that majorly contribute to the growth of the investment casting industry.

Investment Casting Market Trends

Sodium Silicate Process To Exhibit The Highest Growth Rate

Silica sol casting gives the investment castings better dimensional accuracy and surface finish with minimal defects. Hence, the cost of the process is higher than that of the water glass casting. Silica sol zircon sand is very expensive, and the preparation required is also higher, which is a prime reason for the higher costs.

Due to its higher costs, the silica sol process has comparatively less adoption in foundries. The silica sol investment casting used in automotive or industrial components costs around 6.5 USD/kg on average.

Several companies have now identifed the sodium silicate casting as the economical cause over the ceramic casting. However, this process is preferred if the highest casting quality and the low repair rate are the main focus of the end user. Compared to the water glass process, the silica sol process can produce extra-large parts weighing 50-100 kg. Hence, this process is used for producing larger and heavier parts, like water pumps, impellers, diversion shells, pump bodies, ball valve bodies, and valve plates. At the same time, this process is widely used to produce extra small parts (2-1000 g) that require high dimensional accuracy.

The sodium silicate process is slowly becoming more popular in regions like Asia-Pacific, where Japan has showcased itself to lead the production demand from forefront. As a result of the ongoing efforts to improve the quality and dimensional accuracy of the components produced.

North America Leads the Investment Casting Market

North America is leading the investment casting market and is likely to hold the top position, followed by Asia-Pacific and Europe. The factors attributable to North America's growth are the expanding manufacturing industry, primarily industrial gas and aerospace and defense applications, and the presence of significant defense aircraft and component manufacturers in the region, including Lockheed Martin, Raytheon, and Northrop Grumman.

Aerospace manufacturing is one of the major sectors in the United States, with production plants for major aircraft programs, like Boeing 737, Boeing 777, Boeing 787, and Airbus A220 located in the region. The manufacturing of military aircraft programs, like the F-35, in the country is expected to generate demand for investment casting parts.

The United States is one of the major automotive industries in the world, which contributes at least 3% to the overall gross domestic product (GDP) of the country. In addition, the country is one of the largest manufacturers of the luxury car market with net revenue of USD 5 billion in 2021. Luxury car maker BMW in 2021, reported record-breaking sales of over 336,600 units vehicles.

However, the automotive industry in the United States witnessed a hit due to the COVID-19 pandemic, as the majority of the production sites were either closed or operating at reduced capacity. In April 2022, United States new vehicles sales were reported 1,256, 224 units with a 18% decline compared to April 2021 figures. In addition, during April, passenger car sales dropped down to 23.3% with reporting 278,827 units, while SUV and truck sales also decreased 16.3% with 977,397 units. Q1 2022, has been less favorable for United States automotive sector. These expanding auto sector evoke high utilization of investment casting application for automotive parts and compnents will would likely to elevate the demand for investment casting during long term period.

Further, according to the Aerospace Industries Association of Canada, Airbus, Boeing, De Havilland Canada, and Bombardier Inc. are some of the major aerospace manufacturers in the countrywith 95% of companies running at partial capacity. De Havilland Canada plans to gradually begin the production of aircraft in phases. Key aersopace companies are seen expansing their business potential in order to elevate the demand for investment casting in the region. For instance, In November 2022, Aircraft engine manufacturer Pratt & Whitney announced the opening of their new turbine airfoil facility in United States. The fcility would be equipped with advance casting foundry with combined investment of USD 650 million.

Morover, key casting companies are also seeking oppotunities to expans their investment casting potnetial in North America to resonate elevated sales bars amid rising demand. For instance,In September 2022, Signicast Corporation which is form technology company announced the celebration of its new opening of latest investment casting facility.

Cosidering these factors and development demand for investment casting is anticipated to hold high potential for growth in North America owing to widely spread application.

Investment Casting Industry Overview

The investment casting market is fragmented due to the presence of international and regional investment casting manufacturers. The investment casting market is led by Alcoa Corporation, ThyssenKrupp AG, Zollern GmbH and Co. KG, Georg Fischer Ltd, Signicast, Milwaukee Precision Casting, and RLM Industries.

As the market is fragmented, companies are making investments, partnerships, joint ventures, acquisitions, etc., to stay ahead of the competition. For instance, In October 2021, Alcoa Corporation announced its plans to achieve net-zero greenhouse gas (GHG) emissions across its global operations by 2050. The aim to reach net-zero GHG emissions by 2050 for direct (scope 1) and indirect (scope 2) emissions aligns with the company's strategic priority to advance sustainably and complements its existing targets, which include reducing direct and indirect GHG emissions from aluminum smelting and alumina refining operations by 30% by 2025 and 50% by 2030.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Drivers

- 4.2 Market Restraints

- 4.3 Porter's Five Forces Analysis

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION (Market Size in Value USD Billion)

- 5.1 By Type

- 5.1.1 Sodium Silicate Process

- 5.1.2 Tetraethyl Orthosilicate/Silica Sol Process

- 5.2 By End-user Type

- 5.2.1 Automotive

- 5.2.2 Aerospace and Military

- 5.2.3 General Industrial Machinery

- 5.2.4 Medical

- 5.2.5 Other End-user Types

- 5.3 By Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Rest of North America

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 United Kingdom

- 5.3.2.3 France

- 5.3.2.4 Spain

- 5.3.2.5 Rest of Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 India

- 5.3.3.2 China

- 5.3.3.3 Japan

- 5.3.3.4 South Korea

- 5.3.3.5 Rest of Asia-Pacific

- 5.3.4 Rest of the World

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Mexico

- 5.3.4.4 United Arab Emirates

- 5.3.4.5 Other Countries

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Company Profiles

- 6.2.1 Signicast

- 6.2.2 MetalTek International

- 6.2.3 Milwaukee Precision Casting Inc.

- 6.2.4 Impro Precision Industries Limited

- 6.2.5 Alcoa Corporation

- 6.2.6 Zollern GmbH and Co. KG

- 6.2.7 Precision Castparts Corp (Berkshire Hathaway)

- 6.2.8 Georg Fischer Ltd

- 6.2.9 Dongying Giayoung Precision Metal

- 6.2.10 Taizhou Xinyu Precision Manufacture Co. Ltd