|

시장보고서

상품코드

1690118

인더스트리 4.0 - 시장 점유율 분석, 산업 동향, 통계, 성장 예측(2025-2030년)Industry 4.0 - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

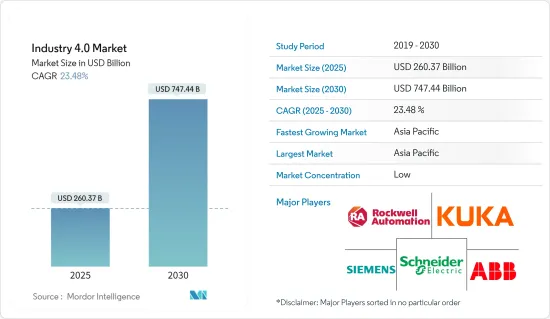

인더스트리 4.0 시장 규모는 2025년에 2,603억 7,000만 달러, 2030년에는 7,474억 4,000만 달러에 달할 것으로 예측되고 있습니다. 예측 기간(2025-2030년) CAGR은 23.48%를 나타낼 전망입니다.

급속도로 성장하는 세계 인더스트리 4.0 시장은 세계 수많은 산업을 변화시키고 있습니다.

주요 하이라이트

- 인더스트리 4.0 시장은 스마트 매뉴팩처링의 보급, 커넥티드 디바이스의 급증, 민첩한 의사결정을 강화하는 실시간 데이터 분석에 대한 수요 증가에 힘입어 급성장 달성하고 있습니다. 급속하게 진화하는 산업 정세 중, 기업은 인더스트리 4.0 솔루션에 눈을 돌리고, 업무의 합리화, 자산 이용의 최적화, 새로운 수익원의 개척의 기회를 파악하려고 하고 있습니다.

- 제조업은 인더스트리 4.0을 향한 디지털 전환을 받아들이고, 유연성, 민첩성, 고객의 요구에 대한 대응력을 강화하는 것이 필수적입니다.

- 예를 들어, 인더스트리 4.0은 최종 고객의 요구 변화에 의해 추진되고 있습니다. 제품의 설계와 창조에 디지털 시스템을 활용함으로써 기업과 최종 사용자 모두에게 유연성을 가져다줍니다.

- 그러나 조사된 시장이 지속적으로 성장하기 위해서는 몇 가지 장애물을 다루어야 합니다.

- COVID-19의 발생은 인프라, 운송, 제조 등 다양한 부문에 영향을 미쳤습니다. 기계명령과 사회적 거리를 두는 가이드라인에 거의 따랐습니다. 지역 공업기업 중 일부는 팬데믹의 과제를 극복하는 수단으로 오토메이션에 눈을 돌렸습니다.

인더스트리 4.0 시장 동향

IIoT 기술 부문이 큰 시장 점유율을 차지

- 인더스트리 4.0의 기초로서, 사물인터넷(IoT)은 제조업과 서비스업 모두의 생산시스템을 모니터링하는데 있어서 매우 중요한 역할을 하고 있습니다. 제조업체는 IoT를 활용하여 혁신적인 길을 열어 성능을 향상시킬 수 있습니다. IoT의 핵심은 인터넷에 연결된 기계와 장치를 통해 데이터를 수집하고 발신에 있습니다.

- 이 기술의 주요 컴포넌트는 소프트웨어와 하드웨어로 구성되어 데이터를 수집하고 변경하기 위해 네트워크를 통해 상호연결되어 있습니다.

- IIoT 기술은 인더스트리 4.0의 이니셔티브를 추진하는데 있어 매우 중요한 역할을 하며, 다양한 형태로 그 영향을 나타내고 있습니다. 대표적인 사례는 센서와 상호 연결된 모니터링 분석 장치가 데이터를 교환하여 실시간 향상을 가능하게 하는 스마트 팩토리 접근 방식입니다. 이 원활한 통신은 5G 네트워크의 신속한 채택으로 강화되고 신속한 데이터 전송을 보장하고 이러한 연결을 보호하는 강력한 사이버 보안 조치로 강화되었습니다.

- 제조, 자동차, 의료의 각 부문에서 산업용 IoT 기술의 채용이 확대되고 있는 것이 시장 확대를 뒷받침하고 있습니다.전통적인 제조 부문이 디지털 전환을 겪으면서 IIoT는 지능형 연결성이라는 새로운 산업혁명의 도래를 고하고 있습니다.

- 스마트 공장 자동화이라고 불리는 물류 체인의 개발, 생산, 관리의 중심에는 인더스트리 4.0과 IIoT가 있습니다. 인더스트리 4.0과 IIoT의 도입으로 인해 제조업이 큰 변화를 겪으면서 기업들은 민첩하고 혁신적인 방법을 채택해야 합니다. 이 방법은 인간의 노동력을 로보틱스로 보완하는 기술에 의해 생산을 강화하는 것뿐만 아니라 프로세스의 결함에 기인하는 노동 재해를 억제하는 것도 목적으로 하고 있습니다.

- 2022년부터 2028년까지 세계 연결을 통해 생산되는 데이터 포인트의 폭발적인 증가로 이어지는 제조업의 연결 장치, 센서 및 M2M 통신이 급속히 증가했습니다. 디바이스 수는 약 배가 증가할 것으로 예측되고 있습니다.

- 이러한 데이터 포인트는 재료가 공정 사이클을 완료하는 데 걸리는 시간과 같은 기본 지표에서 자동차 부문의 재료 응력 능력 평가와 같은 고급 계산에 이르기까지 다양합니다.

큰 성장을 이루는 아시아태평양

- 수년 전, 인도는 제조 및 수출 대국으로 전환하는 비전에 착수했습니다.

- "Make In India"와 "Atmanirbhar Bharat」이라는 캠페인은 제조업을 강화하기 위해 도입된 것으로, 2025년까지 GDP 공헌도를 현재의 16%에서 25%로 끌어올리는 것을 목표로 하고 있습니다. 첨단 기술과 방대한 내부 소비자 기반을 갖춘 인도는 품질과 가격 면에서 전 세계적으로 경쟁력 있는 제품을 생산할 준비가 되어 있습니다. 그러나 이 가능성을 실현하기 위해서는 인도는 단순한 야심이 아니고, 인더스트리 4.0을 도입할 필요가 있습니다.

- 세계적으로, 산업은 인더스트리 4.0의 혜택을 목격하고 있습니다. 특히, 세계의 정치 정세가 변화해, 선진국이 전통적인 제조 거점으로부터의 탈각에 다시 관심을 갖고 있는 것을 생각하면, 인도에 있어서, 이것은 자국의 이야기를 재구축하는 시기 적절한 기회가 됩니다.

- 지정학적 변화, 기술적인 지연, 경쟁우위성 속에서 중국의 산업은 변혁의 시기를 맞이하고 있습니다.

- 중국 정부는 '메이드 인 차이나 2025'와 같은 이니셔티브를 내걸고 인더스트리 4.0 기술의 채용을 추진하여 제조 능력 향상과 하이테크 산업 육성을 목표로 하고 있습니다. 인더스트리 4.0으로부터 힌트를 얻은 「메이드 인 차이나 2025」는 클라우드를 활용한 IoT와 오더 메이드의 산업용 오토메이션 시스템의 개발에 중점을 두고 있습니다.

- 세계의 발자취를 강화하기 위해 일본의 로봇 오토메이션 공급자는 생산 능력을 증강할 뿐만 아니라 해외에 제조 거점을 설립하고 있습니다. 2024년 7월, Fanuc의 미국 자회사는 미시간주에 1억 1,000만 달러의 시설을 개설했습니다.

인더스트리 4.0 산업 개요

인더스트리 4.0 시장은 세분화되어 있으며 ABB, SiemensAG, Robert Bosch GmbH, Rockwell Automation 등의 대기업이 존재합니다.

- 2024년 8월 - Schneider Electric은 여러 도시에서 개최된 INNOVATION DAYS 2024에서 8개의 최첨단 제품과 솔루션을 발표했습니다. Electric이 최신의 혁신을 발표하는 역동적인 플랫폼으로서 기능하고, 효율성, 신뢰성, 지속성, 안전성의 향상에 하이라이트를 가합니다. 또한, 에코시스템 전체의 변화를 촉진하는 것을 목적으로, 산업의 전문가에 의한 세션도 개최됩니다.

- 2024년 6월 - ABB Robotics는 속도, 정밀도, 지속가능성을 최우선으로 한 첨단 오토메이션 플랫폼인 OmniCore를 출시했습니다. 차세대 로봇 공학에 1억 7천만 달러 이상을 투자한 OmniCore 플랫폼은 모듈형으로 선진적인 제어 아키텍처에 있어서 매우 중요한 한 걸음이 되었습니다.

기타 혜택

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트 서포트

목차

제1장 서론

- 조사의 전제조건과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 역학

- 시장 개요

- 산업의 매력 - Porter's Five Forces 분석

- 공급기업의 협상력

- 구매자의 협상력

- 신규 참가업체의 위협

- 대체품의 위협

- 경쟁 기업간 경쟁 관계

- 시장 성장 촉진요인

- 정부의 적극적인 대처와 이해 관계자간의 제휴

- 산업용 로봇 수요의 성장

- 중소기업에 의한 디지털 변혁에의 대처

- 시장 성장 억제요인

- 인더스트리 4.0 도입과 관련된 ROI에 대한 인식의 상대적 부족

- 노동력과 표준화에 관한 과제

- 거시 경제 동향이 시장에 미치는 영향

- 기술 스냅샷

제5장 시장 세분화

- 기술 유형별

- 산업용 로봇

- IIoT

- AI와 ML

- 블록체인

- 증강현실

- 디지털 트윈

- 3D 프린팅

- 기타

- 최종 사용자 산업별

- 제조업

- 자동차

- 석유 및 가스

- 에너지 유틸리티

- 일렉트로닉스 주조

- 음식

- 항공우주 및 방위

- 기타

- 지역별

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 스페인

- 아시아

- 인도

- 중국

- 일본

- 호주 및 뉴질랜드

- 라틴아메리카

- 중동 및 아프리카

- 북미

제6장 경쟁 구도

- 기업 프로파일

- ABB Ltd

- Siemens AG

- Schneider Electric

- Swisslog Holding AG(쿠카 AG)

- Rockwell Automation Inc.

- Cognex Corporation

- Honeywell International Inc.

- Robert Bosch GmbH

- Johnson Controls International PLC

- Emerson Electric Company

- General Electric Company

- Cisco Systems Inc.

- Intel Corporation

- Fanuc Corporation

- Denso Corporation

제7장 투자 분석

제8장 시장의 미래

SHW 25.05.09The Industry 4.0 Market size is estimated at USD 260.37 billion in 2025, and is expected to reach USD 747.44 billion by 2030, at a CAGR of 23.48% during the forecast period (2025-2030).

Numerous industries all around the world are being transformed by the global Industry 4.0 market, which is growing quickly. Industry 4.0, also referred to as the fourth industrial revolution, is the process of integrating modern technologies and digital solutions into production processes in order to build intelligent factories and increase production efficiency.

Key Highlights

- The Industry 4.0 market is experiencing rapid growth, fueled by the rising adoption of smart manufacturing, the surge of connected devices, and the escalating demand for real-time data analytics to enhance agile decision-making. In a fast-evolving landscape, organizations are turning to Industry 4.0 solutions, seizing opportunities to streamline operations, optimize asset use, and tap into new revenue streams.

- Manufacturers find it imperative to embrace digital transformation toward Industry 4.0, enhancing their flexibility, agility, and responsiveness to customer needs. Key drivers for this shift include anticipated benefits, emerging market opportunities, labor challenges, evolving customer demands, competitive pressures, and the pursuit of a strong quality-centric brand image.

- For example, Industry 4.0 is being driven by the changing demands of end customers. Technologies like 3-D printing are transforming digital designs into tangible products, and this shift is gaining momentum in industrial settings. As a result, products can be tailored to individual preferences, even while being produced in masse. Leveraging digital systems for product design and creation offers flexibility for both businesses and end users. By merging human insights with real-time data analysis, the world may soon see the emergence of a digital ecosystem where human decisions are enhanced by algorithms.

- However, there are several hurdles that need to be addressed for uninterrupted growth of the studied market. For example, the 4th industrial revolution faces challenges such as tackling ethical concerns tied to artificial intelligence, safeguarding data privacy, upskilling the workforce for roles in a digital economy, and guaranteeing fair access to technology.

- The COVID-19 outbreak challenged various sectors, including infrastructure, transportation, and manufacturing. In response, the government across several countries imposed lockdown restrictions. As a result, the public largely followed stay-at-home orders and social distancing guidelines. This adherence led to a significant drop in the demand for products like automobiles, forcing companies to operate at reduced capacities. Yet, amidst this turmoil, several regional industrial enterprises turned to automation as a means to navigate the pandemic's challenges. Given the advantages these technologies present, the insights gained during the pandemic are expected to motivate vendors to further embrace automation and industrial control solutions. This shift is poised to create opportunities in the market studied during the forecast period.

Industry 4.0 Market Trends

IIoT Technology Segment Holds Significant Market Share

- As a cornerstone of Industry 4.0, the Internet of Things (IoT) plays a pivotal role in monitoring production systems across both manufacturing and service sectors. By harnessing IoT, manufacturers can unlock innovative avenues, driving enhanced performance. At its core, IoT excels in gathering and disseminating data via internet-connected machines and devices. Each device is tagged with a unique identification number or code, allowing control through everyday gadgets like smartphones.

- Key components of this technology encompass software and hardware, all interconnected through a network for data collection and alteration. IoT is not just a tool; it is a catalyst for disruptive innovation in manufacturing. Recognizing the potential of IoT is essential for modern production systems. Within the realm of Industry 4.0, IoT stands out as a significant leap forward, enabling comprehensive smart monitoring of manufacturing processes.

- IIoT technologies play a pivotal role in driving Industry 4.0 initiatives, showcasing their impact in various forms. A dominant manifestation is the smart factory approach, where sensors and interconnected monitoring/analysis devices exchange data, enabling real-time enhancements. This seamless communication is bolstered by the swift adoption of 5G networks, ensuring rapid data transfer and fortified by robust cybersecurity measures to safeguard these connections.

- The growing adoption of industrial IoT technology across manufacturing, automotive, and healthcare sectors is driving positive market expansion. As the traditional manufacturing sector undergoes a digital transformation, the IIoT is spearheading this evolution, heralding a new industrial revolution of intelligent connectivity. This transformation is reshaping how businesses manage their sophisticated systems and machinery, aiming to boost productivity and minimize downtime.

- At the heart of the logistics chain's development, production, and management, termed smart factory automation, lie Industry 4.0 and IIoT. As manufacturing undergoes seismic shifts due to Industry 4.0 and the embrace of IIoT, businesses are compelled to adopt agile, innovative methods. These methods not only enhance production through technologies that complement human labor with robotics but also aim to curtail industrial accidents stemming from process failures.

- The surge in connected devices, sensors, and M2M communication in the manufacturing sector has led to an explosion of generated data points. According to Ericsson, Between 2022 and 2028, the global count of connected devices is projected to nearly double. This surge is largely attributed to the rise of short-range IoT (Internet of Things) devices, with forecasts estimating 28.72 billion of these devices by 2028.

- These data points vary widely, from basic metrics like the time taken for materials to complete a process cycle to advanced calculations, such as assessing material stress capabilities in the automotive sector. IIoT is expected to be the solution to address the requirements of such use cases.

Asia Pacific to Register Significant Growth

- Years ago, India embarked on a vision to transform into a manufacturing and export powerhouse. This initiative aimed to reduce the nation's reliance on imports and elevate India's status as a global manufacturing leader, capable of producing goods for both domestic consumption and international markets.

- Campaigns such as 'Make In India' and 'Atmanirbhar Bharat' were introduced to bolster the manufacturing sector, targeting a GDP contribution of 25% by 2025, up from the current 16%. With advanced technology and a vast internal consumer base, India stands poised to produce globally competitive products in quality and price. Yet, to realize this potential, India requires more than just ambition; and it needs to embrace Industry 4.0. The advent of IoT in India, especially under the government's "Digital India" initiative, heralds this technological revolution.

- Globally, industries are witnessing the benefits of Industry 4.0, which promises to minimize defects and wastage in production. For India, this presents a timely opportunity to reshape its narrative, especially given the shifting global political landscape and the renewed interest from developed nations in diversifying away from their traditional manufacturing hubs.

- Amidst geopolitical shifts, technological lags, and competitive advantages, China's industries are in a state of transformation. With a clear trajectory toward Industry 4.0, China's manufacturing sector is set for rapid acceleration. As the world's largest manufacturing hub, China is at the helm of the digital revolution, harnessing its expansive industrial base and technological capabilities to spearhead innovation.

- The Chinese government, with initiatives like "Made in China 2025", is championing the adoption of Industry 4.0 technologies, aiming to elevate manufacturing capabilities and nurture high-tech industries. Drawing inspiration from Germany's Industry 4.0, "Made in China 2025" focuses on developing cloud-driven IoT and tailored industrial automation systems.

- In a bid to enhance their global footprint, Japanese robot and automation suppliers have not only increased their production capacities but have also established manufacturing sites overseas. For example, in July 2024, Fanuc's US subsidiary inaugurated a USD 110 million facility in Michigan. This facility is dedicated to storing, selling, and maintaining industrial robots, all manufactured in Japan, specifically catering to North American clientele.

Industry 4.0 Industry Overview

The Industry 4.0 Market is fragmented, with the presence of major players like ABB Ltd, Siemens AG, Robert Bosch GmbH, and Rockwell Automation Inc., among others. Players in the market are adopting strategies such as partnerships, investments, and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

- August 2024 - During its Multi-city INNOVATION DAYS 2024, Schneider Electric introduced eight state-of-the-art products and solutions. These events serve as a dynamic platform for Schneider Electric to present its newest innovations, highlighting improvements in efficiency, reliability, sustainability, and safety. Furthermore, the event features sessions conducted by industry experts with the goal of fostering transformative changes across the ecosystem.

- June 2024 - ABB Robotics launched OmniCore, an advanced automation platform that prioritizes speed, precision, and sustainability, with the goal of empowering businesses for the future. With over USD 170 million invested in next-gen robotics, the OmniCore platform marked a pivotal move toward a modular and forward-thinking control architecture. This architecture seamlessly integrates AI, sensors, cloud, and edge computing, setting the stage for cutting-edge autonomous robotic applications.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Market Drivers

- 4.3.1 Favorable Governmental Initiatives and Collaborations Between Stakeholders

- 4.3.2 Growth in Demand for Industrial Robotics

- 4.3.3 Digital Transformation Initiatives Undertaken by SMEs

- 4.4 Market Restraints

- 4.4.1 Relative Lack of Awareness on the ROI Related to Adoption of Industry 4.0

- 4.4.2 Workforce and Standardization Related Challenges

- 4.5 Impact of Macroeconomic Trends on the Market

- 4.6 Technology Snapshot

5 MARKET SEGMENTATION

- 5.1 By Technology Type

- 5.1.1 Industrial Robotics

- 5.1.2 IIoT

- 5.1.3 AI and ML

- 5.1.4 Blockchain

- 5.1.5 Extended Reality

- 5.1.6 Digital Twin

- 5.1.7 3D Printing

- 5.1.8 Other Technology Types

- 5.2 By End-user Industry

- 5.2.1 Manufacturing

- 5.2.2 Automotive

- 5.2.3 Oil and Gas

- 5.2.4 Energy and Utilities

- 5.2.5 Electronics and Foundry

- 5.2.6 Food and Beverage

- 5.2.7 Aerospace and Defense

- 5.2.8 Other End-user Industries

- 5.3 By Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 United Kingdom

- 5.3.2.3 France

- 5.3.2.4 Spain

- 5.3.3 Asia

- 5.3.3.1 India

- 5.3.3.2 China

- 5.3.3.3 Japan

- 5.3.4 Australia and New Zealand

- 5.3.5 Latin America

- 5.3.6 Middle East and Africa

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 ABB Ltd

- 6.1.2 Siemens AG

- 6.1.3 Schneider Electric

- 6.1.4 Swisslog Holding AG (Kuka AG)

- 6.1.5 Rockwell Automation Inc.

- 6.1.6 Cognex Corporation

- 6.1.7 Honeywell International Inc.

- 6.1.8 Robert Bosch GmbH

- 6.1.9 Johnson Controls International PLC

- 6.1.10 Emerson Electric Company

- 6.1.11 General Electric Company

- 6.1.12 Cisco Systems Inc.

- 6.1.13 Intel Corporation

- 6.1.14 Fanuc Corporation

- 6.1.15 Denso Corporation