|

시장보고서

상품코드

1565778

<2024> 리튬이차전지 건식 전극(Dry Battery Electrode) 공정 기술동향 및 전망<2024> Technology Development Trends and Prospects of Dry Battery Electrode Process for LIBs |

||||||

전기차 자체는 온실가스를 배출하지 않지만 전기차 제조 과정에서 탄소를 배출하고 환경을 파괴한다는 비난을 받아왔습니다. 대표적인 것이 전기차 제조 원가의 약 40%를 차지하는 배터리입니다.

배터리 제조 공정 중 특히 NMP를 건조하고 회수하는데 상당한 전기 에너지를 소모하게 되는데 이는 온실가스 배출의 원인이 됩니다. 일례의 연구 결과에 의하면 습식 제조 과정에서 용매 건조로 인해 1kWh당 42kg의 CO2가 발생한다고 하며, 대기중으로 환경오염물질인 휘발성유기화합물(VOC, Volatile Organic Compound)을 배출하기도 합니다. 이에 비해 건식 전극은 용매를 건조하고 회수하는 과정이 없어 전기 에너지 소모가 적고 VOC를 배출하지 않기 때문에 친환경적인 공정이라고 할 수 있습니다.

에너지밀도를 높이기 위해서는 전극이 두꺼운 >100㎛ 이상의 후막 전극이 필요합니다. 현재의 습식 공정에서는 용매와 소재 간 층 분리 현상으로 인해 후막 전극을 만들기 어렵습니다. 활물질, 도전재, 바인더 등 각 소재의 비중이 서로 다르기 때문에 두껍게 코팅하면 바인더와 도전재가 전극 표면으로 떠오릅니다. 습식 공정에서는 약 100㎛ 이상의 두께로 전극을 코팅하기 어렵습니다.

건식 공정을 이용하면 이 같은 층 분리 현상 없이 활물질-도전재-바인더를 골고루 분산할 수 있기 때문에 후막 전극을 만들 수 있고 이를 통해 배터리의 용량과 에너지 밀도를 끌어 올릴 수 있습니다.

Tesla는 2019년 건식 전극 기술을 보유한 수퍼캐퍼시터 기업인 Maxwell Technologies를 인수하였고 이듬해인 2020년 9월 Battery Day에서 건식 전극을 도입하겠다고 발표했습니다. Tesla는 2년 만인 2021년 Maxwell을 UCAP에 재매각했지만 건식 전극 기술을 확보할 수 있었습니다. 전문가들이 직접 테슬라 4680 배터리를 입수해 분석한 바에 따르면 이 배터리에는 음극에만 건식 전극을 적용하고 양극은 기존 습식 전극을 채택한 것으로 나타났습니다.

Tesla가 왜 아직 양극에 건식 전극 공정을 적용하지 못하고 있는지에 대해서는 알려진 바 없으나, 다만 건식 전극 공정의 수율(양품률)이 낮아 대량 생산할 정도 수준에 이르지 못한 것 아니냐는 분석이 나오고 있습니다. 4680 배터리의 낮은 수율이 사이버트럭 생산에까지 영향을 미치고 있다는 외신이 전해지기도 했습니다.

건식 코팅 공정의 원리는 간단하지만 실제 이를 구현하는 데는 각 단계마다 상당한 난제들이 존재합니다. 용매를 쓰지 않고 활물질, 도전재, 바인더를 균일하게 믹싱하는 것부터가 쉽지 않습니다. 점성이 없는 분말을 집전체에 고르게 도포하는 것은 더욱 어렵습니다. 수율이 낮으면 생산 원가가 상승하게 됩니다. 비용을 낮추기 위해 건식 전극을 도입했는데 오히려 비용 상승 요인으로 작용할 수 있는 것입니다.

Tesla 이외에 현재 국내외 기업들은 P/P 규모의 건식공정을 개발한다고 발표하고 있으나, 초기에 생산되는 46파이 원통형 배터리들은 모두 습식 공정으로 생산될 것으로 예상되고 있습니다. LG엔솔이 ’24년 4분기 P/P 규모 생산하는 4680 배터리는 양극과 음극에 모두 습식을 적용하며, 이 배터리는 테슬라에 공급될 예정입니다. 최근 LG엔솔은 ’24년 4분기에 오창 에너지플랜트내에 건식 전극공정 P/P라인 구축을 완료할 예정이며 ’28년부터 적용할 예정입니다. 최근 발표한 삼성SDI, SK온, 파나소닉, CATL, 금양도 건식 전극기술을 개발 중 입니다.

이외에 독일의 폭스바겐은 ’23년 6월 독일 인쇄기기 전문업체인 Koenig & Bauer와 함께 건식 전극 공정을 개발한다고 밝힌 바 있습니다. 폭스바겐은 ’27년까지 산업 생산에 나설 계획입니다. 폭스바겐과 Koenig & Bauer가 어떻게 건식 전극을 개발하고 있는지는 정확히 알려지지 않았습니다.

건식공정은 건조공정이 불필요해 에너지 비용을 30% 절감할 수 있으며, 건조에 필요한 면적도 50% 줄일 수 있다며 건식공정을 적용한 4680 배터리는 이론적으로 LFP 배터리보다 저렴해질 수 있지만, 아직 기술 개발이 성공적이지 못한 상태라고 합니다.

건식 공정의 도입은 리튬이차전지 제조를 위한 탄소중립형 공정으로써 매우 잠재력을 가지고 있으며, 건식 전극 기술의 상용화는 배터리 제조 비용 절감과 동시에 성능 향상에 큰 기여를 할 것으로 기대되며 현재까지 대량 양산화에 성공한 기업은 없지만, 주요 기업들이 기술 개발에 박차를 가하고 있는 만큼 머지않아 건식 전극공정이 트렌드가 될 가능성은 매우 높아 보입니다. 또한 건식 전극 공정의 개발은 차세대 전지인 전고체 전지 제조 공정에 적용될 수 있으며 실제로 해외 및 국내에서 전고체 전지에 대한 관심이 높아지고 있으며 양산화에 대한 계획이 수립되고 있습니다.

본 리포트는 이차전지 산업의 탄소중립형 공정 개발의 필요성, 기존 습식공정의 이슈, 현재 건식공정의 이슈 등 기술적인 내용과 최근 이차전지 관련 업체 건식 전극 공정 개발 동향과 전고체 전지 개발 동향에 대한 많은 업체들의 정보를 제공하여 건식공정의 현재와 가까운 미래의 현황을 전망하고자 하였습니다.

본 보고서의 Strong Point

- ① 건식전극 공정에 대한 배경 및 개발에 관한 풍성한 기술내용 수록

- ② 건식전극 공정 종류의 자세한 설명 및 전극 공정 이슈 내용 수록

- ③ 건식 공정과 습식 공정의 장?단점을 물론 전지 적용까지의 상세한 비교내용 수록

- ④ 차세대 전지인 전고체전지의 건식 전극 공정 적용에 대한 상세 기술내용 수록

- ⑤ 국내외 산업계의 전극 공정, 소재, 장비업체의 개발 동향에 대한 상세한 정보 수록

- ⑥ 국내외 기업의 건식전극 공정관련 특허 리스트 및 주요 특허 분석 수록

- ⑦ 건식전극관련 국가별 연구지원 프로젝트 및 주요 내용 수록

- ⑧ 건식전극 공정에 관한 주요 리서치사의 시장 전망 수록

목 차

1. 리튬이차전지 후막 전극용 건식 전극 공정

- 1.1 이차전지 산업 탄소 중립형 공정 개발 필요성

- 1.1.1 탄소 중립 규제로 인한 전기차 수요 확대

- 1.1.2 탄소배출 제한 및 내연기관 차량 판매 금지 계획

- 1.1.3 전기차 전환 계획 및 이차전지 업체 수직계열화

- 1.1.4 탄소 중립 규제 대응을 위한 이차전지 산업 이슈

- 1.1.5 이차전지 전극 공정, 공정 비용 및 에너지 소

- 1.2 리튬이차전지 후막 전극 개발 필요성

- 1.3 습식 기반 전극 제조 공정 이슈

- 1.4 건식 전극(DBE) 공정 배경 및 개발

- 1.4.1 건식 전극 기술의 역사적, 기술적 진보

- 1.4.2 Dry film 기술 주요 개발 역사

- 1.4.3 건식 전극 기술 : 습식 코팅의 한계 극복

- 1.4.4 건식 공정 및 바인더 개발 : 논문 및 특허수

- 1.4.5 건식 공정 및 바인더 개발 : 특허 분석

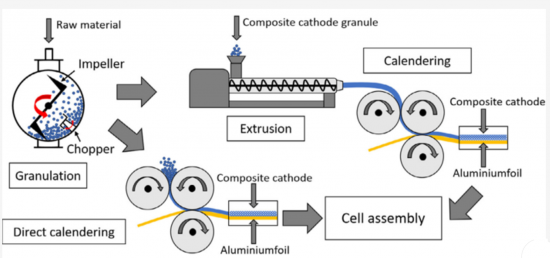

- 1.4.6 압출 기술을 적용한 전극 제조

- 1.4.7 압출 및 용융 가공

- 1.4.8 용융 압출 : 용매 vs. 무용매 적용 차이점

- 1.4.9 건식 전극 적용 : Tesla 음극

- 1.4.10 건식 전극 적용 : Tesla 양극

- 1.4.11 건식 전극 적용 : 복합 양극

- 1.4.12 건식 전극 적용 : Pre-lithiation(사전 리튬화)

- 1.4.13 배터리 바인더 특성 : 7가지 종류 비교

- 1.4.14 건식공정에 사용되는 바인더 종류

- 1.4.15 건식공정에 사용되는 바인더 특성

- 1.4.16 수성 바인더(PTFE,PAA) vs. PVDF :성능 및 장단점 비교

- 1.4.17 PTFE 바인더 적용

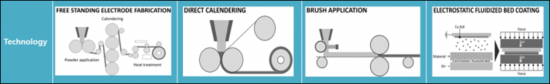

- 1.5 건식 전극 공정 종류

- 1.5.1 건식 전극용 Dry coating 기술 선정

- 1.5.2 주요 Dry coating 기술 종류 및 비교

- 1.5.3 건식 혼합 및 코팅

- 1.5.4 건식전극 vs.습식전극의 전기화학적 거동 비교

- 1.5.5 건식 전극 제조기술의 LIB 적용 시 각각의 특성

- 1.5.6 Free standing electrode 기술

- 1.5.7 Direct Calendaring 기술

- 1.5.8 Brush application 기술

- 1.5.9 Electrostatic spraying 기술

- 1.5.10 용융 증착 기술

- 1.5.11 분말 압축 기술

- 1.5.12 용융 압출 기술

- 1.6 건식 전극 공정 이슈

- 1.6.1 건식공정 기술의 기술적 허들

- 1.6.2 LIB 제조 시 건식 공정의 과제

- 1.6.3 PTFE의 전기적 특성

- 1.7 건식 공정 vs. 습식 공정 비교

- 1.7.1 습식공정과 건식공정 제조 기술의 비교

- 1.7.2 건식 vs. 습식 공정기술의 전지 특성 비교

- 1.7.3 습식 공정의 단점

- 1.7.4 습식 공정 대체 option의 장단점

- 1.7.5 건식공정 기술 도입의 장점

- 1.7.6 건식공정 기술 도입의 장점(속도 성능)

- 1.7.7 건식공정 기술 도입의 장점(이온 채널)

- 1.7.8 건식공정 기술 도입의 장점(낮은 비용)

- 1.7.9 건식공정 기술 도입의 장점(기계 특성)

- 1.7.10 건식 vs. 습식 특성 비교: 양극, 음극에 적용

- 1.7.11 전식 전극의 셀 성능

- 1.7.12 LIB용 건식 전극의 제조 및 특성 분석

- 1.7.13 건식 전극 적용 : (LFP + CNT + PTFE) 양극

- 1.7.14 건식 전극 적용 : (NCM622 + PVDF) 양극

- 1.7.15 건식 vs. 습식 공정기술의 종합비교

- 1.8 PTFE 섬유화(Fibrilization)

- 1.8.1 PTFE fibrilization(섬유화) 반응

- 1.8.2 PTFE fibrilization 현상

- 1.8.3 PTFE fibrilization 적용

- 1.8.4 PTFE fibrilization에 미치는 영향 인자

- 1.8.5 PTFE 바인더의 부작용

- 1.8.6 PTFE 바인더의 부작용 차단 : 흑연 표면 코팅

- 1.8.7 PTFE 섬유화 방법에 의한 흑연 음극 제조

- 1.8.8 PTFE 변형 소재 개발

- 1.8.9 PTFE 기반 전지의 혁신적 기술과 시스템

2. 차세대 이차전지 (전고체전지) 건식 전극 공정

- 2.1 국내외 산업계 전고체 전지 개발 동향

- 2.1.1 전고체전지의 종류 및 각 시스템 구성

- 2.1.2 고에너지밀도 LIB를 위한 설계 및 솔루션

- 2.1.3 건식 복합양극 제조 방법

- 2.1.4 해외 전고체전지 개발 동향

- 2.1.5 국내 전고체전지 개발 동향

- 2.2 전고체전지 건식 전극 공정 적용 필요성 (습식 공정 이슈)

- 2.3 전고체전지 건식 전극 공정 적용 사례

- 2.3.1 국내외 기업 전고체전지 건식 공정 적용 사례

- 2.3.2 국내외 논문 전고체전지 건식 공정 적용 사례

- 2.3.3 PTFE 적용 Li-S 전지

- 2.3.4 PTFE 적용 무코발트(LNMO) 전지

- 2.3.5 PTFE 적용 전고체전지(황화물, 산화물, 할로겐화물)

- 2.3.6 PTFE 적용 전고체전지용 고체전해질 막 제조

- 2.3.7 고에너지밀도 LIB를 위한 설계 및 솔루션

- 2.3.8 건식공정 적용 고체전지(고분자 고체전해질 적용)

- 2.3.9 건식공정 적용 고체전지(400 Wh/kg)

- 2.3.10 건식공정 적용 고체전지(에너지밀도 비교 외)

3. 업체별 개발 동향

- 3.1 국내외 산업계 건식 전극 공정 개발 동향

- 3.1.1 해외 건식 공정 개발 동향

- 3.1.2 국내 건식 공정 개발 동향

- 3.1.3 건식 전극 공정에 위협적인 요소

- 3.1.4 건식 전극 공정을 둘러싼 장점 및 단점 요소

- 3.2 국내 업체 개발 동향

- 3.2.1 Lxx

- 3.2.2 Sxx

- 3.2.3 SK On

- 3.2.4 Cxxx

- 3.2.5 Dxx

- 3.3 해외 업체 개발 동향

- 3.3.1 Tesla

- 3.3.2 Sakuu

- 3.3.3 Axxx

- 3.3.4 Lixxxx

- 3.3.5 Amxxx

- 3.3.6 Poxxxx

- 3.3.7 Draxxx

- 3.3.8 Zxxxx

- 3.3.9 Daxxx

- 3.3.10 Chexxxx

- 3.3.11 Huaxxx

- 3.3.12 Baosheng Energy Technology(중)

- 3.3.13 Li Yuanheng(중)

- 3.4 장비 업체 개발 동향

- 3.4.1 한xxxx

- 3.4.2 씨xxx

- 3.4.3 PNT

- 3.4.4 윤xxxxxx

- 3.4.5 나인테크

- 3.4.6 GIxxxxx

- 3.4.7 KAxxxx

- 3.4.8 Shanghai Lianjing Automation Technology(중)

- 3.4.9 TOB New battery

- 3.4.10 TMAxxxx

- 3.4.11 Shenzhenxxxx

- 3.4.12 Huacaixxxxx

- 3.4.13 ATExxxx

- 3.4.14 EIRxxx

- 3.4.15 Fraunhofer IWS

- 3.5 학교/연구기관 개발 동향

- 3.5.1 한국에너지기술연구원

- 3.5.2 연세대

- 3.5.3 고려대

- 3.5.4 UNIST

- 3.5.5 성균관대

- 3.5.6 가천대

- 3.5.7 Fraunhofer ISIT

- 3.5.8 Karlsruhe Institute of Technology (KIT)

- 3.5.9 Dry Coating Forum 학회

4. 특허 분석

- 4.1 해외 산업계 건식 공정 개발 특허

- 4.1.1 해외 건식 공정 개발 특허 List

- 4.1.2 Maxwell Technologies

- 4.1.3 Fraunhofer IWS

- 4.1.4 Tesla

- 4.1.5 Lxxx

- 4.1.6 Draxxx

- 4.1.7 Anxxxx

- 4.2 국내 산업계 건식 공정 개발 특허

- 4.2.1 LG화학, LG엔솔 특허 List

- 4.2.2 삼성 SDI

- 4.2.3 SK On

- 4.2.4 현xxxx

- 4.2.5 윤xxxx

- 4.2.6 코xxxx

- 4.2.7 한국xxx기술원

5. 국가별 연구 프로젝트

- 5.1 미국 DOE 프로젝트

- 5.1.1 Oxxx

- 5.1.2 Nxxx

- 5.2 EU 프로젝트

- 5.2.1 ELIxxx

- 5.2.2 HOxxxx

- 5.2.3 Batxxx

- 5.3 한국 국책 프로젝트

- 5.3.1 산업통자원부 주관

- 5.3.2 교육부 주관

- 5.3.3 과학기술부 주관

- 5.3.4 기획재정부 주관

6. 시장 전망(리서치사 전망)

- 6.1 SNE Research 전망

- 6.2 EV Tank 전망

- 6.3 ESP Analysis 전망

- 6.4 Industry ARC 전망

- 6.5 QY Research 전망

- 6.6 Verified Market Reports 전망

Electric vehicles themselves do not emit greenhouse gases, but the manufacturing process of electric vehicles has been criticized for emitting carbon and destroying the environment. A representative example is the battery, which accounts for about 40% of the manufacturing cost of electric vehicles.

During the battery manufacturing process, a considerable amount of electric energy is consumed, especially in drying and recovering NMP, which is a cause of greenhouse gas emissions. According to one research result, 42 kg of CO2 is generated per kWh due to solvent drying in the wet manufacturing process, and volatile organic compounds (VOCs), which are environmental pollutants, are also emitted into the atmosphere. In contrast, dry electrodes do not have a solvent drying and recovery process, so they consume less electric energy and do not emit VOCs, making them an environmentally friendly process.

In order to increase energy density, a thick film electrode of >100 micrometer or more is required. In the current wet process, it is difficult to make a thick film electrode due to the layer separation phenomenon between the solvent and the material. Since the specific gravity of each material such as the active material, conductive material, and binder is different, if the coating is thick, the binder and conductive material float to the electrode surface. In the wet process, it is difficult to coat the electrode with a thickness of about 100 micrometer or more.

By using a dry process, the active material-conductive material-binder can be evenly distributed without this layer separation phenomenon, so a thick-film electrode can be created, which can increase the capacity and energy density of the battery.

In 2019, Tesla acquired Maxwell Technologies, a supercapacitor company with dry electrode technology, and announced at Battery Day in September 2020 that it would introduce dry electrodes. Tesla sold Maxwell to UCAP in 2021, two years later, but was able to secure dry electrode technology. According to experts who directly obtained and analyzed the Tesla 4680 battery, the battery applied a dry electrode only to the anode, and the existing wet electrode was adopted for the cathode.

It is not known why Tesla has not yet applied the dry electrode process to the cathode, but there is analysis that the yield of the dry electrode process is low and cannot be mass-produced. There are also foreign media reports that the low yield of the 4680 battery is affecting the production of the Cybertruck.

The principle of the dry coating process is simple, but there are considerable challenges at each stage in implementing it in practice. It is not easy to evenly mix the active material, conductive material, and binder without using a solvent. It is even more difficult to evenly apply the non-viscous powder to the current collector. If the yield is low, the production cost increases. Dry electrodes were introduced to reduce costs, but they can actually act as a cost increase factor.

In addition to Tesla, domestic and foreign companies are currently announcing that they are developing a P/P scale dry process, but it is expected that all 46-phi cylindrical batteries to be initially produced will be produced using a wet process. The 4680 battery that LGES will produce in the fourth quarter of 2024 on a P/P scale will apply a wet process to both cathode and anode, and this battery will be supplied to Tesla. Recently, LGES announced that it will complete the construction of a dry electrode process P/P line in the Ochang Energy Plant in the fourth quarter of 2024 and will apply it starting in 2028. Samsung SDI, SK On, Panasonic, CATL, and Kumyang, which recently announced that they are also developing dry electrode technology.

In addition, Volkswagen of Germany announced in June 2023 that it was developing a dry electrode process with Koenig & Bauer, a German printing equipment specialist. Volkswagen plans to start industrial production by 2027. It is not known exactly how Volkswagen and Koenig & Bauer are developing the dry electrode.

The dry process can reduce energy costs by 30% because the drying process is unnecessary, and the area required for drying can be reduced by 50%. The 4680 battery using the dry process can theoretically be cheaper than the LFP battery, but the technology development has not been successful yet.

The introduction of the dry process has great potential as a carbon-neutral process for manufacturing lithium secondary batteries, and the commercialization of dry electrode technology is expected to greatly contribute to reducing battery manufacturing costs while improving performance. Although no company has succeeded in mass production so far, it is very likely that the dry electrode process will become a trend in the near future as major companies are spurring technology development. In addition, the development of the dry electrode process can be applied to the manufacturing process of all-solid-state batteries, which are next-generation batteries. In fact, interest in all-solid-state batteries is increasing both domestically and internationally, and plans for mass production are being established.

This report provides technical information such as the necessity of developing a carbon-neutral process in the secondary battery industry, issues with the existing wet process, and issues with the current dry process, as well as information on recent development trends in dry electrode processes and all-solid-state battery development by many companies, with the aim of forecasting the current and near-future status of the dry process.

Strong Points of This Report:

- 1. Includes rich technical content on the background and development of the dry electrode process

- 2. Includes detailed descriptions of the types of dry electrode processes and electrode process issues

- 3. Includes detailed comparisons of the pros and cons of dry and wet processes as well as battery applications

- 4. Includes detailed technical content on the application of the dry electrode process to the next-generation battery, the all-solid-state battery

- 5. Includes detailed information on the development trends of electrode processes, materials, and equipment companies in the domestic and international industries

- 6. Includes a list of patents related to the dry electrode process of domestic and foreign companies and an analysis of major patents

- 7. Includes research support projects and main contents by country related to dry electrodes

- 8. Includes market outlooks from major research companies on the dry electrode process

[Difference between dry and wet processes for electrode manufacturing]

| Advantages | Super caps | compact | ||

| Challenges | Risk of segregation | Risk of segregation | Risk of segregation | mixing |

| Key players | Tesla(Maxwell Technologies | Technical Univ. Dresden Fraunhofer IWS | Technical Univ. Dresden Fraunhofer ISIT | Technical Univ. Braunschweig Fraunhofer IPA |

| TRL | 6 | 5 | 4->6 | 4->6 |

| References | US Patent US2006/0133012A1 10/817 590. Apr. 1. 2008. | Germany Patent DE102017208220A1. Nov. 22. 2018. | Proc. Fraunhofer ISIT - Achievements Results Annu. Rep., 2017.pp.32-33 | Energy Technol., vol. 8, no. 2. 2020. Art. no. 1900309 |

Table of Contents

1. Dry Electrode Processes for Thick Film Electrodes in LIBs

- 1.1. The need for carbon-neutral processes in the LIB industry

- 1.1.1. Increased demand for EV due to carbon neutrality regulations

- 1.1.2. Plans to limit carbon emissions and ban sales of ICE vehicles

- 1.1.3. EV transition plans and verticalized secondary battery companies

- 1.1.4. Industry Issues related to carbon neutrality regulations

- 1.1.5. Secondary battery electrode process, costs and energy consumption

- 1.2. The need for thick film electrodes in Li-ion batteries

- 1.3. Wet-based electrode manufacturing process issues

- 1.4. Background on adopting dry processes

- 1.4.1. Historical and technological advances in dry electrode

- 1.4.2. History of key technology developments in dry film

- 1.4.3. Dry electrode technology: overcoming the limitations of wet coatings

- 1.4.4. Dry process and binder development: number of papers and patents

- 1.4.5. Dry process and binder development: patent analysis

- 1.4.6. Electrode manufacturing with extrusion technology

- 1.4.7. Extrusion and melt processing

- 1.4.8. Melt extrusion: solvent vs. solvent-free application differences

- 1.4.9. Dry electrode application: Tesla anode

- 1.4.10. Dry electrode application: Tesla cathode

- 1.4.11. Dry electrode application: composite cathode

- 1.4.12. Dry electrode application: Pre-lithiation

- 1.4.13. Battery binder characteristics: 7 types compared

- 1.4.14. Types of binders used in dry processes

- 1.4.15. Binder properties used in dry processes

- 1.4.16. Water (PTFE, PAA) vs. oil (PVDF) binders: Performance & tradeoffs

- 1.4.17. Applying PTFE binders

- 1.5. Dry electrode process types

- 1.5.1. Selection of a dry coating process for dry electrodes

- 1.5.2. Comparison and selection of dry coating technologies

- 1.5.3. Dry mixing and coating

- 1.5.4. Comparison of electrochemical behavior of dry and wet electrodes

- 1.5.5. Features of Dry electrode process technologies in LIB application

- 1.5.6. Free standing electrode technology

- 1.5.7. Direct calendaring technology

- 1.5.8. Powder sheeting technology

- 1.5.9. Electrostatic spraying technology

- 1.5.10. Melt deposition technology

- 1.5.11. Powder compaction technology

- 1.5.12. Melt extrusion technology

- 1.6. Issues with dry electrode process

- 1.6.1. Technical hurdles in dry process technology

- 1.6.2. Challenges of dry process in LIB manufacturing

- 1.6.3. Electrical properties of PTFE

- 1.7. Comparison of dry vs. wet processes

- 1.7.1. Comparison of wet and dry process manufacturing technologies

- 1.7.2. Comparison of cell characteristics for dry vs. wet process technologies

- 1.7.3. Disadvantages of the wet process

- 1.7.4. Pros and cons of wet process alternative options

- 1.7.5. Benefits of adopting dry process technology

- 1.7.6. Benefits of adopting dry process technology (speed performance)

- 1.7.7. Benefits of adopting dry process technology (ion channels)

- 1.7.8. Benefits of adopting dry process technology (low cost)

- 1.7.9. Benefits of adopting dry process technology (Machine characteristics)

- 1.7.10. Dry vs. wet characteristics: Applies to cathode, anode

- 1.7.11. Cell performance of electrochemical electrodes

- 1.7.12. Fabrication and characterization of dry electrodes for LIBs

- 1.7.13. Applying dry electrodes : (LFP + CNT + PTFE) cathode

- 1.7.14. Applying dry electrodes : (NCM622 + PVDF) cathode

- 1.7.15. A comprehensive comparison of dry vs. wet process technologies

- 1.8. PTFE fiberization

- 1.8.1. PTFE fiberization reaction

- 1.8.2. PTFE fiberization process

- 1.8.3. PTFE fiberization application

- 1.8.4. Factors affecting PTFE fibrillation

- 1.8.5. Side effects of PTFE binders

- 1.8.6. Blocking the adverse effects of PTFE binders: Graphite surface coat

- 1.8.7. Preparation of graphite anodes by PTFE fiberization method

- 1.8.8. Developing PTFE modified materials

- 1.8.9. Innovative technologies and systems for PTFE-based cells

2. Next Secondary Battery (All-Solid-State Battery) Dry Electrode Processes

- 2.1. Global development trends of solid-state batteries

- 2.1.1. Types and the system configurations of solid-state batteries

- 2.1.2. Design and solutions for high energy density LIBs

- 2.1.3. Dry composite cathode manufacturing methods

- 2.1.4. Overseas all-solid-state battery development trends

- 2.1.5. Korean all-solid-state battery development trends

- 2.2. The need for adopting dry electrode process in solid-state batteries

- 2.3. Examples of dry electrode process applications in solid-state batteries

- 2.3.1. Korean and international companies

- 2.3.2. Korean and international papers

- 2.3.3. Li-S batteries with PTFE

- 2.3.4. Cobalt-free (LNMO) cells with PTFE

- 2.3.5. Solid-state batteries with PTFE (sulfide, oxide, halide)

- 2.3.6. Solid-state electrolyte membranes for solid-state batteries with PTFE

- 2.3.7. Application of inorganic solid electrolytes

- 2.3.8. Application of polymeric solid-state electrolytes

- 2.3.9. Solid-state batteries with dry process (400 Wh/kg)

- 2.3.10. Solid-state batteries with dry process (energy density comparison)

3. Development Trends by Company

- 3.1. Dry electrode process development trends in Korean and international industry

- 3.1.1. International dry process development trends

- 3.1.2. Korean dry process development trends

- 3.1.3. Challenges to dry electrode processes

- 3.1.4. Pros and cons of the dry electrode process

- 3.2. Korean company development trends

- 3.2.1. LG Energy Solutions

- 3.2.2. Samsung SDI

- 3.2.3. SK On

- 3.2.4. Cosmos Lab

- 3.2.5. CNP Solutions

- 3.3. Overseas company development trends

- 3.3.1. TESLA

- 3.3.2. Sakuu (USA)

- 3.3.3. Anaphite (UK)

- 3.3.4. LiCap Technology (USA)

- 3.3.5. AM Batteries (USA)

- 3.3.6. PowerCo SE

- 3.3.7. Dragonfly Energy (USA)

- 3.3.8. ZEON

- 3.3.9. Daikin

- 3.3.10. Chemours (USA)

- 3.3.11. Huacai Technology (China)

- 3.3.12. Baosheng Energy Technology (China)

- 3.3.13. Li Yuanheng (China)

- 3.4. Equipment manufacturer development trends

- 3.4.1. Hanwha Momentum

- 3.4.2. CIS

- 3.4.3. PNT

- 3.4.4. Yunsung F&C

- 3.4.5. NainTech

- 3.4.6. GITech (Korea)

- 3.4.7. KATOP (China)

- 3.4.8. Shanghai Lianjing Automation Technology

- 3.4.9. TOB New battery

- 3.4.10. TMAX Battery Equipment

- 3.4.11. Shenzhen Tsingyan Electronic Technology

- 3.4.12. Huacai Technology

- 3.4.13. ATEIOS System (USA)

- 3.4.14. EIRICH (Germany)

- 3.4.15. Fraunhofer IWS

- 3.5. Development trends in academic and research institutions

- 3.5.1. Korea Institute of Energy Technology

- 3.5.2. Yonsei University

- 3.5.3. Korea University

- 3.5.4. Ulsan Institute of Science and Technology

- 3.5.5. Sungkyunkwan University

- 3.5.6. Gacheon University

- 3.5.7. Fraunhofer ISIT

- 3.5.8. Karlsruhe Institute of Technology (KIT)

- 3.5.9. Dry Coating Forum

4. Patent Analysis

- 4.1. Overseas dry process development patents

- 4.1.1. Overseas dry process development patent list

- 4.1.2. Maxwell Technologies

- 4.1.3. Fraunhofer IWS

- 4.1.4. TESLA

- 4.1.5. Licap New Energy Technologies

- 4.1.6. Dragonfly Energy

- 4.1.7. Anaphite Ltd

- 4.2. Korean dry process development patents

- 4.2.1. LG Chem, LG Energy Solution patents

- 4.2.2. Samsung SDI

- 4.2.3. SK On

- 4.2.4. Hyundai Kia

- 4.2.5. Yunsung F&C

- 4.2.6. Cosmos Lab

- 4.2.7. Korea Ceramic Technology Institute

5. Research Projects by Country

- 5.1. US DOE projects

- 5.1.1. Oak Ridge National Lab

- 5.1.2. NAVITAS Systems

- 5.2. EU projects

- 5.2.1. ELIBAMA program

- 5.2.2. HORIZON Europe : NOVOC project

- 5.2.3. Horizon Europe : BatWoMan

- 5.3. Korean national projects

- 5.3.1. Ministry of Trade and Industry

- 5.3.2. Ministry of Education

- 5.3.3. Ministry of Science and Technology

- 5.3.4. Ministry of Economy and Finance

6. Market outlook (research outlook)

- 6.1. SNE Research

- 6.2. EV Tank

- 6.3. ESP Analysis

- 6.4. Industry ARC

- 6.5. QY Research

- 6.6. Verified Market Reports

(주말 및 공휴일 제외)