|

시장보고서

상품코드

1794015

고체 냉각 재료 및 시스템 시장 및 기술 동향(2026-2046년) : 방사 냉각, PDRC, 칼로릭 냉각, 열전 냉각, 멀티 모드, 다목적, 기타Solid State Cooling Materials and Systems Radiative, PDRC, Caloric, Thermoelectric, Multimode, Multipurpose, Other: Markets, Technology 2026-2046 |

||||||

요약

지구온난화, AI 데이터센터, 전기자동차, 제로에미션 전력 생산 등의 요인에 의해 2026년부터 2046년까지 냉각 기술 수요가 급증할 전망입니다. 솔리드 스테이트 냉각은 다기능 스마트 재료의 동향에 부합하여 신뢰성이 높고 가동 가능하며 수명이 길고 시스템 수준에서 가장 저렴한 비용을 달성할 수 있는 잠재력을 갖추어 중심적인 역할을 하는 것으로 예측됩니다.

이 보고서는 고체 냉각 재료 및 시스템 시장 및 기술을 조사한 결과, 부가 가치를 제공하는 재료 공급업체, 제품 통합 업체 및 밸류체인 전체에 대한 종합적이고 최신 분석을 제공합니다. 8장 구성, 11개의 SWOT 평가, 2026-2046년의 33개 예측 라인, 36개의 인포그램, 총 472페이지로 구성되어 있으며, 이 급속히 진전하는 분야에 대해 2025년까지의 진보를 완전히 망라하고, 2025년까지 발표된 최중의 조사서 97개를 다루고 있습니다.

목차

제1장 본 보고서의 목적

- 이 분석의 조사 방법

- 냉각 수요가 높아지는 이유

- 고체 냉각의 성질과 왜 지금 우선 과제인지

- 냉각 툴킷과 현시점에서의 유망 분야

- 주요 결론 20가지

- 9개 유형의 후보 고체 냉각 기술 비교 및 평가

- 최신 연구가 대상으로 하는 주요 용도

- 고체 냉각에서의 유망한 재료와 원리

- 2022-2025년 94개 조사서에서 볼 수 있는 칼로릭 냉각의 언급 : 유형별

- 2024-2025년의 고체 냉각에 관한 292건의 조사에 있어서의 주요 재료

- 증기 압축 냉각의 대체 가능성

- 태양광 패널의 효율 향상을 목적으로 한 냉각의 가능성

- 6G 통신 인프라 및 클라이언트 디바이스 냉각 가능성

- 자가냉각형 레이저의 가능성

- 2000-2046년에 있어서의 각종 고체 냉각 기술의 온도 저하 폭

- 패시브 주간 방사 냉각(PDRC) 및 관련 방사 냉각 기술 평가

- 주요 칼로리 냉각법의 평가

- 열전 냉각의 SWOT 평가 및 재료 분석

- 고체 냉각 로드맵 : 시장 및 기술별

- 시장 예측 : 2026-2046년

- 냉각 모듈 세계 시장 : 7개 기술별

- 상용 제품에서의 지상 방사 냉각 성능

- 시장 규모 : 에어컨

- HVAC, 냉장고, 냉동고, 기타 냉각 세계 시장

- 시장 규모 : 냉장고 및 냉동고

- 고정형 배터리 시장과 냉각 수요

- 6G 통신 인프라 및 클라이언트 기기용 열 관리 재료·구조 시장

- 6G용 유전체 및 열재료 시장(지역별)

- 5G vs 6G 열 인터페이스 재료 시장

- 6G vs 5G 기지국 시장

- 시장 규모 : 6G기지국

- 시장 규모 : 6G RIS

- 세계 스마트폰 판매 대수

- 열 메타 디바이스 시장 : 용도별

제2장 소개

- 개요

- 냉각 수요의 확대와 그 성질의 변화

- 2026년부터 2046년까지 냉각 요건의 극적인 변화의 예

- 2026년부터 2046년까지 냉각 기술이 스마트 재료로 향하는 경향

- 저전력으로 환경 친화적이고, 보다 저렴한 공조의 재발명

- 널리 사용 및 제안되고 있는 바람직하지 않은 재료 : 사업 기회

- 고체 냉각에 대한 경쟁 기술의 예

제3장 패시브 주간 방사 냉각(PDRC)

- 개요

- PDRC의 기초

- 방사 냉각 재료의 조사 분석 : 구조 및 배합별

- 잠재적인 이점과 응용

- 2025년 이전의 기타 중요한 진보

- PDRC를 상업화하는 기업

- 3M USA

- BASF Germany

- i2Cool USA

- LifeLabs USA

- Plasmonics USA

- Radicool Japan, Malaysia etc.

- SkyCool Systems USA

- SolCold Israel

- Spinoff from University of Massachusetts Amherst USA

- SRI USA

- PDRC의 SWOT 평가

제4장 방사 냉각의 광범위한 전망 : 자기 적응형, 스위치 가능형, 조정형, 야누스, 안티스토크스, 첨단 포토닉스 고체 냉각을 포함

- SWOT 분석을 수반하는 전체상의 개요

- 2025년 방사 냉각의 22의 광범위한 진전

- 2026년 방사 냉각 기술의 성숙도 곡선

- 자기 적응형 및 스위치 가능 방사 냉각

- 양방향을 이용한 조정형 방사 냉각 : 야누스 방사체(JET)의 2024-2025년의 진전·SWOT 평가

- 안티스토크스 형광 냉각의 2024-2025년의 진전과 SWOT 평가

- 첨단 포토닉스 냉각 및 가열 방지

제5장 강유전상 변화에 의한 칼로릭 냉각

- 구조적 및 강유전상 변화를 이용한 냉각 모드와 재료

- 고체상 변화 냉각이 특정 용도로 다른 방식과 경쟁할 수 있는 가능성

- 칼로릭 냉각과 관련된 물리적 원리

- 칼로릭 냉각의 동작 원리

- 열전 냉각과의 비교 및 유망한 칼로릭 기술의 특정

- 칼로릭 냉각의 이용 확대를 위한 연구 제안

- 전기 칼로릭 냉각

- 자기 열량 냉각·SWOT 평가

- 기계 칼로릭 냉각(엘라스토 칼로릭, 바로컬로릭, 트위스트 칼로릭 냉각)

- 2025년 멀티 칼로릭 냉각의 진전

제6장 실현 기술 : 메타물질 냉각 재료와 디바이스

- 개요

- 메타아톰, 패터닝, 정적에서 동적으로의 열전달

- 주요 결론 : 시장에서의 위치

- 주요 결론 : 대표적인 배합, 기능성, 제조 기술

- 최신의 열 메타물질 연구 132례에서 배합의 인기 동향

- 2025년 및 2024년의 다른 메타물질 냉각 및 관련 연구의 진전

- 부가제조에 의한 설계, 제조, 특성, 응용

제7장 장래의 열전 냉각 및 열전 발전(다른 고체 냉각의 이용자 및 전력 공급원으로서)

- 기본 사항

- 열전 재료

- 광역 및 플렉서블 열전 냉각은 시장에 존재하는 미충족 요구이며, 대응해야 할 과제

- 건축물의 방사 냉각 : 열전 발전을 조합한 다기능 이용

- TEC 및 TEG의 방열 문제 : 진화하는 해결책

- 냉각을 수반하는 열전 냉각 및 발전에 관한 20의 진전

- 과거의 진전

- 펠티에 냉각열전모듈 및 제품의 제조기업 82사

제8장 열 인터페이스 재료(TIM) 및 기타 열전도 재료·구조

- 개요 : 열전도 접착제에서 열전도 콘크리트까지

- 열전도 재료로 냉각 과제를 해결할 때의 중요한 고려 사항

- 열 인터페이스 재료(TIM)

- 폴리머 옵션 : 실리콘 또는 탄소 기반

- 2025년 및 그 이전에 있어서의 열전도성 폴리머의 진전

Summary

The period 2026-2046 will be marked by a surge in demand for cooling technology, reasons including global warming, AI datacenters, electric vehicles and zero-emission electricity production. Solid-state cooling will come center stage because it serves the trend to multifunctional smart materials and it tends to be more reliable, applicable and longer-lived, with potential for lowest cost at system level.

Unique report

The unique Zhar Research report, "Solid State Cooling Materials and Systems Radiative, PDRC, Caloric, Thermoelectric, Multimode, Multipurpose, Other: Markets, Technology 2026-2046" is the only comprehensive, up-to-date analysis of these opportunities for added value materials suppliers, product integrators and all in the value chain. It has 8 chapters, 11 SWOT appraisals, 33 forecast lines 2026-2046, 36 infograms and 472 pages. Essentially, for such a fast-moving subject, it has full coverage of the surge of advances through 2025, including the 97 most important research papers through 2025.

The self-sufficient Executive Summary and Conclusions (43 pages) pulls it all together with 20 primary conclusions, the forecasts, new tables, pie charts, SWOT appraisals and graphics. The Introduction (31 pages) explains why the need for cooling becomes much larger and often different in nature, from 1kW microchips to 6G Communications.

Reinventing cooling - PDRC and caloric progress

Learn the problems with the dominant vapor compression cooling in our refrigerators, freezers and air conditioning. Understand reinventing air conditioning to be lower power, greener, more affordable. See how replacing the undesirable materials widely used and proposed for cooling is an opportunity for you but recognise that there is competition for solid state cooling - examples being given.

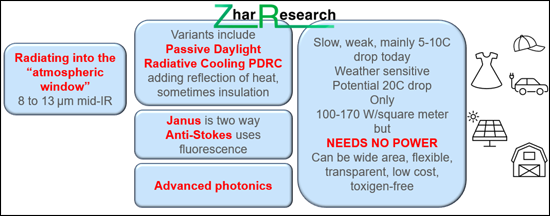

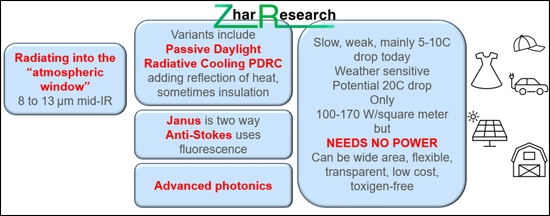

Chapter 3. "Passive Daytime Radiative Cooling (PDRC)" has 100 pages because it discusses the surge in research through 2025 targeting apparel, windows, solar panels and much more. Understand 40 important advances in 2024-5 and activities of ten companies. Chapter 4. (41 pages) gives the wider picture of radiative cooling including self-adaptive, switchable, tuned, Janus, Anti-Stokes and advanced photonic solid-state cooling. Self-cooled high-power lasers are one Anti-Stokes prospect, possibly for emerging fusion power. Twenty-two wider advances in radiative cooling in 2025 are assessed here. There is a maturity curve of radiative cooling technologies in 2026.

Chapter 5. Caloric cooling by ferroic phase change takes 76 pages due to its importance. Although magnetocaloric forms have long had some commercialisation, the research and industrial interest through 2025 has turned to electrocaloric, and, to a lesser extent, elastocaloric options. This chapter also covers several other options with many comparisons. It concludes that the new focus is commercially appropriate. It explains why multi-mode and giant-caloric versions described here should also be tracked.

Metamaterial cooling now intensely researched

Chapter 6. "Enabling Technology: Metamaterial Cooling Materials and Devices" (54 pages) tracks the enormous recent progress in this aspect, which is largely a better way of serving cooling principles already described. Research is strong but commercialisation is, so far, modest. The basics are explained plus relevance to greenhouse, window, solar panel and personal cooling. Understand the manufacturing technologies, and popularity by formulation in 132 examples of latest thermal metamaterial research.

Thermoelectric cooling reinvented for different uses

Chapter 7 covers future thermoelectric cooling and thermoelectric harvesting as a user of and power provider for other solid-state cooling (53 pages). It explains how this old technology has now progressed to commercial neck coolers, with prospects of wide-area, flexible thermoelectrics and avoidance of toxigens and expensive materials and machining. It is a strong candidate for cooling the new 1kW chips and even researched for buildings. Secondarily, there is coverage of thermoelectric harvesting to power solid-state cooling. Indeed, thermoelectric cooling can be enhanced by other forms of solid-state cooling on its cold side. 20 recent advances in thermoelectric cooling and harvesting involving solid-state cooling are highlighted and 82 manufactures of Peltier cooling thermoelectric modules and products are listed.

Thermal conduction with new materials

The report then closes with Chapter 8 (57 pages) on the allied topics of thermal Interface Materials TIM and other thermal conducting materials and structures. Much of this concerns TIM materials, issues, advances and practicalities emerging plus thermally conducting solids in general with graphics, SWOT appraisals, comparison tables. Seven current TIM options are compared against nine parameters in one table and nine important TIM research advances in 2025 and 2024 are presented. See thermally conductive polymer advances in 2025, companies making thermally conductive additives and progress to more sophisticated thermal composites.

The Zhar Research report, "Solid State Cooling Materials and Systems Radiative, PDRC, Caloric, Thermoelectric, Multimode, Multipurpose, Other: Markets, Technology 2026-2046" is your essential guide to the multi-billion-dollar market that is emerging.

CAPTION: Best passive solid-state cooling technology for reducing temperature 5C to 20C 2026-2046 on current evidence. Source, Zhar Research report, "Solid State Cooling Materials and Systems Radiative, PDRC, Caloric, Thermoelectric, Multimode, Multipurpose, Other: Markets, Technology 2026-2046" .

Table of Contents

1.1. Purpose of this report

- 1.2. Methodology of this analysis

- 1.3. Reasons for the escalating need for cooling

- 1.4. The nature of solid-state cooling and why it is now a priority

- 1.5. Cooling toolkit and potential winners on current evidence

- 1.5.1. Cooling toolkit, trend to multimode with best solid-state cooling tools shown red

- 1.5.2. Best passive solid-state cooling technology for reducing temperature 5C to 40C 2026-2046 on current evidence

- 1.5.3. Best solid-state cooling technologies for reducing temperature 5C to 50C 2026-2046 on current evidence

- 1.6. Twenty primary conclusions

- 1.6.1. Nine candidate solid-state cooling technologies compared and appraised in columns

- 1.6.2. Primary applications targetted by latest research

- 1.6.3. Winning materials and principles for solid-state cooling generally

- 1.6.4. Primary mentions of caloric cooling by type in 94 research papers 2022 through 2025 as an indicator of relative progress

- 1.6.5. Leading materials in 292 research advances on solid state cooling 2024 through 2025

- 1.6.6. Potential for replacing vapor compression cooling

- 1.6.7. Potential for cooling solar panels to increase efficiency

- 1.6.8. Potential for cooling 6G Communications infrastructure and client devices

- 1.6.9. Potential for self-cooling lasers

- 1.7. Best reported and potential temperature drop by different solid-state technologies 2000-2046

- 1.8. Appraisal of Passive Daytime Radiative Cooling PDRC and allied radiative cooling technologies

- 1.8.1. SWOT appraisal of passive radiative cooling in general

- 1.8.2. SWOT appraisal of PDRC with materials analysis

- 1.8.3. SWOT appraisal of Janus effect for thermal management

- 1.8.4. SWOT appraisal of anti-Stokes fluorescence cooling

- 1.9. Appraisal of the leading types of caloric cooling

- 1.9.1. SWOT appraisal of electrocaloric cooling with materials analysis

- 1.9.2. SWOT appraisal of elastocaloric cooling

- 1.10. SWOT appraisal of thermoelectric cooling with materials analysis

- 1.11. Solid state cooling roadmap by market and by technology 2026-2046

- 1.12. Market forecasts as tables and graphs 2026-2046

- 1.12.1. Cooling module global market by seven technologies $ billion 2025-2046

- 1.12.2. Terrestrial radiative cooling performance in commercial products W/sq. m 2025-2046

- 1.12.3. Air conditioner value market $ billion 2024-2046

- 1.12.4. Global market for HVAC, refrigerators, freezers, other cooling $ billion 2025-2046

- 1.12.5. Refrigerator and freezer value market $ billion 2024-2046

- 1.12.6. Stationary battery market $ billion and cooling needs 2024-2046

- 1.12.7. Thermal management material and structure for 6G Communications infrastructure and client devices $ billion if 6G is successful 2026-2046

- 1.12.8. Dielectric and thermal materials for 6G value market % by location 2029-2046

- 1.12.9. 5G vs 6G thermal interface material market $ billion 2025-2046

- 1.12.10. Market for 6G vs 5G base stations units millions yearly 2025-2046

- 1.12.11. Market for 6G base stations market value $bn if successful 2029-2046

- 1.12.12. 6G RIS value market $ billion: active and three semi-passive categories 2029-2046

- 1.12.13. Smartphone billion units sold globally 2024-2046 if 6G is successful

- 1.12.14. Thermal meta-device market $ billion 2026-2046 by application segment

2. Introduction

- 2.1. Overview

- 2.2. Need for cooling becomes much larger and often different in nature

- 2.2.1. General situation

- 2.2.2. Infogram: Cooling needs increase for many reasons 2026-2046

- 2.3. Examples of radical changes in the requirements for cooling 2026-2046

- 2.3.1. Escalation of demand for air conditioning and forthcoming changes in requirement

- 2.3.2. Problems becoming severe with traditional cooling inadequate

- 2.3.3. Further reading on the problems of traditional vapor compression cooling

- 2.3.4. How 6G Communications from 2030 will bring new cooling requirements: infograms

- 2.3.5. Severe new microchip cooling requirements arriving

- 2.3.6. Other cooling problems and opportunities emerging in electronics and ICT

- 2.4. How cooling technology will trend to smart materials 2026-2046

- 2.5. Reinventing air conditioning to be lower power, greener, more affordable

- 2.6. Undesirable materials widely used and proposed: this is an opportunity for you

- 2.7. Examples of competition for solid state cooling

3. Passive daytime radiative cooling (PDRC)

- 3.1. Overview

- 3.2. PDRC basics

- 3.3. Radiative cooling materials by structure and formulation with research analysis

- 3.4. Potential benefits and applications

- 3.4.1. Overall opportunity and progress

- 3.4.2. Transparent PDRC for facades, solar panels and windows including 8 advances 2024 through 2025

- 3.4.3. Wearable PDRC, textile and fabric with 15 advances in 2024-5 and SWOT

- 3.4.4. PDRC cold side boosting power of thermoelectric generators

- 3.4.5. Color without compromise: advances in 2025 and earlier

- 3.4.6. Aerogel and porous material approaches

- 3.4.7. Environmental and inexpensive PDRC materials development

- 3.5. Other important advances in 2025 and earlier

- 3.5.1. 40 important advances in 2024-5

- 3.5.2. Other advances

- 3.6. Companies commercialising PDRC

- 3.6.1. 3M USA

- 3.6.2. BASF Germany

- 3.6.3. i2Cool USA

- 3.6.4. LifeLabs USA

- 3.6.5. Plasmonics USA

- 3.6.6. Radicool Japan, Malaysia etc.

- 3.6.7. SkyCool Systems USA

- 3.6.8. SolCold Israel

- 3.6.9. Spinoff from University of Massachusetts Amherst USA

- 3.6.10. SRI USA

- 3.7. SWOT appraisal of Passive Daytime Radiative Cooling PDRC

4. Wider picture of radiative cooling including self-adaptive, switchable, tuned, Janus, Anti-Stokes and advanced photonic solid-state cooling

- 4.1. Overview of the bigger picture with SWOT

- 4.2. Twenty-two wider advances in radiative cooling in 2025

- 4.3. Maturity curve of radiative cooling technologies in 2026

- 4.4. Self-adaptive and switchable radiative cooling

- 4.4.1. Vanadium phase change for self-adaptive versions in recent research

- 4.4.2. Alternative using liquid crystal

- 4.5. Tuned radiative cooling using both sides: Janus emitter JET advances in 2024 through 2025 with SWOT

- 4.6. Anti-Stokes fluorescence cooling advances in 2024 through 2025 with SWOT appraisal

- 4.7. Advanced photonic cooling and prevention of heating

5. Caloric cooling by ferroic phase change

- 5.1. Structural and ferroic phase change cooling modes and materials

- 5.2. Solid-state phase-change cooling potentially competing with other forms in named applications

- 5.3. The physical principles adjoining caloric cooling

- 5.4. Operating principles for caloric cooling

- 5.5. Caloric compared to thermoelectric cooling and winning caloric technologies identified

- 5.6. Some proposals for work to advance the use of caloric cooling

- 5.7. Electrocaloric cooling

- 5.7.1. Overview and SWOT appraisal

- 5.7.2. Operating principles, device construction, successful materials and form factors

- 5.7.3. Electrocaloric material popularity in latest research with explanation

- 5.7.4. Giant electrocaloric effect through 2025

- 5.7.5. Electrocaloric cooling: issues to address

- 5.7.6. 10 important advances in 2025

- 5.7.7. 58 earlier advances

- 5.8. Magnetocaloric cooling with SWOT appraisal

- 5.8.1. Overview with progress through 2035

- 5.8.2. Magnetocaloric cooling in detail with SWOT appraisal

- 5.9. Mechanocaloric cooling (elastocaloric, barocaloric, twistocaloric) cooling

- 5.9.1. Elastocaloric cooling overview: operating principle, system design, applications, SWOT

- 5.9.2. Elastocaloric advances in 2024-5

- 5.9.3. Barocaloric cooling

- 5.10. Multicaloric cooling advances in 2025

6. Enabling technology: Metamaterial cooling materials and devices

- 6.1. Overview

- 6.1.1. Capabilities

- 6.1.2. Types of metamaterial thermal management materials by function

- 6.1.3. Three families of metamaterials overlap

- 6.1.4. Expanding choice of applications and new market drivers

- 6.1.5. Examples of thermal metamaterials in recent advances

- 6.1.6. Greenhouse, window, solar panel and personal cooling with metamaterials

- 6.1.7. SWOT assessment for metamaterials and metasurfaces generally

- 6.1.8. SWOT appraisal of thermal metamaterials

- 6.2. The meta-atom, patterning and static to dynamic thermal transfer

- 6.3. Primary conclusions; market positioning

- 6.4. Primary conclusions: leading formulations, functionality and manufacturing technologies

- 6.5. Popularity by formulation in 132 examples of latest thermal metamaterial research

- 6.6. Other metamaterial cooling and allied research advances in 2025 and 2024

- 6.7. Additive manufacturing design, fabrication, property and application

7. Future thermoelectric cooling and thermoelectric harvesting as a user of and power provider for other solid-state cooling

- 7.1. Basics

- 7.1.1. Operation, examples

- 7.1.2. Thermoelectric cooling and temperature control applications 2025 and 2045

- 7.1.3. SWOT appraisal of thermoelectric cooling, temperature control and harvesting

- 7.2. Thermoelectric materials

- 7.2.1. Requirements

- 7.2.2. Useful and misleading metrics

- 7.2.3. Quest for better zT performance which is often the wrong approach

- 7.2.4. Some alternatives to bismuth telluride being considered

- 7.2.5. Non-toxic and less toxic thermoelectric materials, some lower cost

- 7.2.6. Ferron and spin driven thermoelectrics

- 7.3. Wide area and flexible thermoelectric cooling is a gap in the market for you to address

- 7.3.1. The need and general approaches

- 7.3.2. Advances in flexible and wide area thermoelectric cooling in 2025 and earlier

- 7.3.3. Wide area or flexible TEG research 40 examples that may lead to similar TEC

- 7.4. Radiation cooling of buildings: multifunctional with thermoelectric harvesting

- 7.5. The heat removal problem of TEC and TEG - evolving solutions

- 7.6. 20 advances in thermoelectric cooling and harvesting involving cooling

- 7.7. Earlier advances

- 7.8. 82 Manufactures of Peltier cooling thermoelectric modules and products

8. Thermal Interface Materials TIM and other thermal conducting materials and structures

- 8.1. Overview: thermal adhesives to thermally conductive concrete

- 8.1.1. TIM, heat spreaders from micro to heavy industrial: activity of 17 companies

- 8.1.2. 17 examples of research advances in 2025 and 2024 relevant to 6G transistors up to buildings

- 8.1.3. Annealed pyrolytic graphite: progress in 2025 and 2024 as microelectronic TIM

- 8.1.4. Thermally conductive concrete and allied work

- 8.2. Important considerations when solving thermal challenges with conductive materials

- 8.2.1. Bonding or non-bonding

- 8.2.2. Varying heat

- 8.2.3. Electrically conductive or not

- 8.2.4. Placement

- 8.2.5. Environmental attack

- 8.2.6. Choosing a thermal structure

- 8.2.7. Research on embedded cooling

- 8.3. Thermal Interface Material TIM

- 8.3.1. General

- 8.3.2. Seven current options compared against nine parameters

- 8.3.3. Nine important research advances in 2025 and 2024

- 8.3.4. Thermal pastes compared

- 8.3.5. TIM and other examples today: Henkel, Momentive, ShinEtsu, Sekisui, Fujitsu, Suzhou Dasen

- 8.3.6. 37 examples of TIM manufacturers

- 8.3.7. Thermal interface material trends as needs change: graphene, liquid metals etc.

- 8.4. Polymer choices: silicones or carbon-based

- 8.4.1. Comparison

- 8.4.2. Silicone parameters, ShinEtsu, patents

- 8.4.3. SWOT appraisal for silicone thermal conduction materials

- 8.5. Thermally conductive polymer advances in 2025 and earlier

- 8.5.1. Overview

- 8.5.2. Examples of companies making thermally conductive additives

- 8.5.3. Thermally conductive polymers: pie charts of host materials and particulates prioritised in research

- 8.5.4. Important progress in 2025 and earlier