|

시장보고서

상품코드

1699330

콘덴싱 식품 가공 보일러 시장 기회, 성장 촉진요인, 산업 동향 분석, 예측(2025-2034년)Condensing Food Processing Boiler Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025-2034 |

||||||

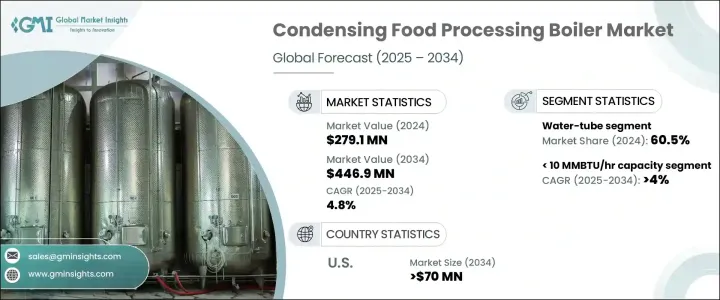

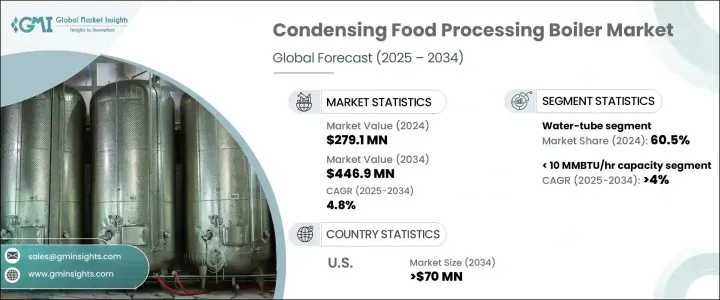

콘덴싱 식품 가공 보일러 세계 시장은 2024년 2억 7,910만 달러로 평가되며, 에너지 효율성, 지속가능성, 엄격한 규제 요건에 대한 관심이 높아짐에 따라 2025년부터 2034년까지 4.8%의 CAGR로 성장할 것으로 예상됩니다.

식품 가공 부문은 산업화, 도시화, 포장 및 가공 식품에 대한 소비자 수요 증가에 힘입어 빠르게 변화하고 있습니다. 제조업체들이 운영 효율성과 탄소발자국 감소를 우선시하는 가운데, 콘덴싱 보일러는 배출을 최소화하면서 우수한 열 효율을 제공하는 난방 솔루션으로 떠오르고 있습니다.

난방 기술의 발전과 스마트 제어 시스템의 통합은 정확한 온도 조절과 연료 소비 최적화를 통해 이러한 보일러의 매력을 더욱 높이고 있습니다. 청정에너지 도입을 촉진하는 정부 정책과 에너지 효율이 높은 산업 장비에 대한 재정적 인센티브도 시장 확대에 기여하고 있습니다. 또한, 특히 신흥국에서는 식품 가공 공장의 현대화가 진행되어 시장 참여자들에게 유리한 기회를 창출하고 있습니다. 지속가능성에 대한 관심이 높아지면서 에너지 효율이 높은 난방 시스템의 장기적인 비용 절감 효과와 함께 더 많은 기업들이 콘덴싱 보일러에 투자하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 2억 7,910만 달러 |

| 예상 금액 | 4억 4,690만 달러 |

| CAGR | 4.8% |

시장은 제품 유형에 따라 화관 보일러와 수관 보일러로 구분됩니다. 수관식 보일러는 2024년 전체 매출의 60.5%를 차지하며 업계를 지배했습니다. 수관식 보일러에 대한 수요 증가는 고도의 증기 발생 능력을 필요로 하는 자동화 된 대용량 식품 가공 시스템의 채택 증가와 관련이 있습니다. 현대화된 제조 시설로의 전환은 소비자의 식습관 변화와 함께 식품 제조 공장 전반에 걸쳐 효율적인 난방 솔루션의 채택을 촉진하고 있습니다. 또한, 엄격한 식품 안전 규정은 일관되고 안정적인 증기 공급을 요구하기 때문에 제조업체들은 규정 준수 기준을 충족하면서 생산성을 향상시키는 고성능 콘덴싱 보일러를 선택하게 되었습니다.

연료 유형에 따라 응축 식품 가공 보일러 시장은 천연가스, 석유, 석탄, 기타로 분류됩니다. 천연가스 부문은 가스 인프라 확대, 보일러 효율 혁신, 친환경 대체품에 대한 선호도 증가로 인해 2034년까지 1억 5,000만 달러에 달할 것으로 예상됩니다. 천연가스 보일러는 안정적인 증기와 온수를 생산하고 운영 비용을 절감할 수 있어 식품 가공 시설에 매력적인 선택이 될 수 있습니다. 에너지 규제가 강화됨에 따라 청정 연소 연료로의 전환이 가속화되고 있으며, 이는 시장 성장을 더욱 촉진하고 있습니다.

미국의 콘덴싱 식품 가공 보일러 시장은 2024년 4,530만 달러 규모이며, 2034년에는 7,000만 달러에 달할 것으로 예상됩니다. 이러한 성장은 주로 산업안전보건청(OSHA) 및 환경보호청(EPA)과 같은 기관에서 부과하는 엄격한 배출 규제에 의해 뒷받침되고 있습니다. 이러한 규제는 식품 가공 부문 전반에 걸쳐 첨단 저배출 가열 시스템의 채택을 장려하고 있습니다. 규정 준수 요건이 강화됨에 따라 식품 제조업체들은 최적의 생산 효율을 보장하면서 환경 기준을 충족하기 위해 고효율 콘덴싱 보일러로 전환하고 있습니다. 지속적인 기술 발전과 규제 압력이 증가함에 따라 시장은 향후 몇 년 동안 꾸준히 확대될 것으로 예상됩니다.

목차

제1장 조사 방법과 조사 범위

- 시장 범위와 정의

- 시장 추정과 예측 파라미터

- 예측 계산

- 데이터 소스

- 1차

- 2차

- 유료

- 공적

제2장 주요 요약

제3장 업계 인사이트

- 업계 생태계 분석

- 규제 상황

- 업계에 대한 영향요인

- 성장 촉진요인

- 업계의 잠재적 리스크·과제

- 성장 가능성 분석

- Porters 분석

- PESTEL 분석

제4장 경쟁 구도

- 소개

- 전략적 전망

- 혁신과 지속가능성 전망

제5장 시장 규모 및 예측 : 용량별, 2021-2034년

- 주요 동향

- 10 MMBTU/hr 이하

- 10-25 MMBTU/hr

- 25-50 MMBTU/hr

- 50-75 MMBTU/hr

- 75-100 MMBTU/hr

- 100-175 MMBTU/hr

- 175-250 MMBTU/hr

- 250 MMBTU/hr 이상

제6장 시장 규모 및 예측 : 제품별, 2021-2034년

- 주요 동향

- 화관

- 수관

제7장 시장 규모 및 예측 : 연료별, 2021-2034년

- 주요 동향

- 천연가스

- 석유

- 석탄

- 기타

제8장 시장 규모 및 예측 : 지역별, 2021-2034년

- 주요 동향

- 북미

- 미국

- 캐나다

- 멕시코

- 유럽

- 프랑스

- 영국

- 폴란드

- 이탈리아

- 스페인

- 오스트리아

- 독일

- 스웨덴

- 러시아

- 아시아태평양

- 중국

- 인도

- 필리핀

- 일본

- 한국

- 호주

- 인도네시아

- 중동 및 아프리카

- 사우디아라비아

- 이란

- 아랍에미리트

- 나이지리아

- 남아프리카공화국

- 라틴아메리카

- 아르헨티나

- 칠레

- 브라질

제9장 기업 개요

- ALFA LAVAL

- Babcock & Wilcox Enterprises

- Babcock Wanson

- BM GreenTech

- Bosch Industriekessel

- Clayton Industries

- Cleaver-Brooks

- Cochran

- Forbes Marshall

- Hurst Boiler

- Miura America

- Rentech Boiler Systems

- Thermax

- Thermodyne Boilers

- Viessmann

The Global Condensing Food Processing Boiler Market, valued at USD 279.1 million in 2024, is projected to expand at a CAGR of 4.8% between 2025 and 2034, driven by a rising emphasis on energy efficiency, sustainability, and stringent regulatory requirements. The food processing sector is witnessing a rapid transformation, fueled by increasing industrialization, urbanization, and growing consumer demand for packaged and processed foods. As manufacturers prioritize operational efficiency and carbon footprint reduction, condensing boilers are emerging as a preferred heating solution, delivering superior thermal efficiency while minimizing emissions.

Advancements in heating technology and the integration of smart control systems further enhance the appeal of these boilers, enabling precise temperature regulation and optimized fuel consumption. Government policies promoting cleaner energy adoption and financial incentives for energy-efficient industrial equipment are also contributing to market expansion. In addition, the ongoing modernization of food processing plants, particularly in emerging economies, is creating lucrative opportunities for market players. The heightened focus on sustainability, coupled with the long-term cost benefits of energy-efficient heating systems, is pushing more companies to invest in condensing boilers.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $279.1 Million |

| Forecast Value | $446.9 Million |

| CAGR | 4.8% |

The market is segmented by product type into fire-tube and water-tube boilers. Water-tube boilers dominated the industry in 2024, accounting for 60.5% of total revenue. Their rising demand is linked to the increased adoption of automated and high-capacity food processing systems, which require advanced steam generation capabilities. The shift toward modernized manufacturing facilities, coupled with evolving consumer eating habits, is fueling the adoption of efficient heating solutions across food production plants. Additionally, strict food safety regulations necessitate consistent and reliable steam supply, prompting manufacturers to opt for high-performance condensing boilers that enhance productivity while meeting compliance standards.

Based on fuel type, the condensing food processing boiler market is categorized into natural gas, oil, coal, and others. The natural gas segment is projected to reach USD 150 million by 2034, driven by expanding gas infrastructure, technological innovations in boiler efficiency, and the rising preference for eco-friendly alternatives. Natural gas boilers offer consistent steam and hot water production with reduced operational costs, making them an attractive choice for food processing facilities. As energy regulations tighten, the transition toward cleaner-burning fuels is accelerating, further propelling market growth.

In the United States, the condensing food processing boiler market generated USD 45.3 million in 2024 and is expected to reach USD 70 million by 2034. This growth is primarily supported by stringent emissions regulations imposed by agencies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA). These regulations encourage the adoption of advanced, low-emission heating systems across the food processing sector. As compliance requirements become more rigorous, food manufacturers are transitioning to high-efficiency condensing boilers to meet environmental standards while ensuring optimal production efficiency. With ongoing technological advancements and increasing regulatory pressure, the market is set to witness steady expansion in the coming years.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Regulatory landscape

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.2 Industry pitfalls & challenges

- 3.4 Growth potential analysis

- 3.5 Porter's analysis

- 3.5.1 Bargaining power of suppliers

- 3.5.2 Bargaining power of buyers

- 3.5.3 Threat of new entrants

- 3.5.4 Threat of substitutes

- 3.6 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Strategic outlook

- 4.3 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Capacity, 2021 – 2034 (USD Million, MMBTU/hr & Units)

- 5.1 Key trends

- 5.2 < 10 MMBTU/hr

- 5.3 10 - 25 MMBTU/hr

- 5.4 25 - 50 MMBTU/hr

- 5.5 50 - 75 MMBTU/hr

- 5.6 75 - 100 MMBTU/hr

- 5.7 100 - 175 MMBTU/hr

- 5.8 175 - 250 MMBTU/hr

- 5.9 > 250 MMBTU/hr

Chapter 6 Market Size and Forecast, By Product, 2021 – 2034 (USD Million, MMBTU/hr & Units)

- 6.1 Key trends

- 6.2 Fire-tube

- 6.3 Water-tube

Chapter 7 Market Size and Forecast, By Fuel, 2021 – 2034 (USD Million, MMBTU/hr & Units)

- 7.1 Key trends

- 7.2 Natural gas

- 7.3 Oil

- 7.4 Coal

- 7.5 Others

Chapter 8 Market Size and Forecast, By Region, 2021 – 2034 (USD Million, MMBTU/hr & Units)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.2.3 Mexico

- 8.3 Europe

- 8.3.1 France

- 8.3.2 UK

- 8.3.3 Poland

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Austria

- 8.3.7 Germany

- 8.3.8 Sweden

- 8.3.9 Russia

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Philippines

- 8.4.4 Japan

- 8.4.5 South Korea

- 8.4.6 Australia

- 8.4.7 Indonesia

- 8.5 Middle East & Africa

- 8.5.1 Saudi Arabia

- 8.5.2 Iran

- 8.5.3 UAE

- 8.5.4 Nigeria

- 8.5.5 South Africa

- 8.6 Latin America

- 8.6.1 Argentina

- 8.6.2 Chile

- 8.6.3 Brazil

Chapter 9 Company Profiles

- 9.1 ALFA LAVAL

- 9.2 Babcock & Wilcox Enterprises

- 9.3 Babcock Wanson

- 9.4 BM GreenTech

- 9.5 Bosch Industriekessel

- 9.6 Clayton Industries

- 9.7 Cleaver-Brooks

- 9.8 Cochran

- 9.9 Forbes Marshall

- 9.10 Hurst Boiler

- 9.11 Miura America

- 9.12 Rentech Boiler Systems

- 9.13 Thermax

- 9.14 Thermodyne Boilers

- 9.15 Viessmann