|

시장보고서

상품코드

1750573

식품 가공용 연관 콘덴싱 보일러 시장 : 기회, 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Condensing Fire-Tube Food Processing Boiler Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

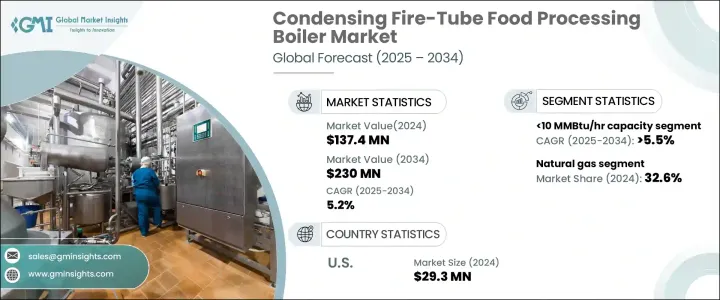

세계의 식품가공용 연관 컨덴싱 보일러 시장은 2024년에 1억 3,740만 달러로 평가되었고, 지속 가능한 가열 기술에 대한 주목 증가와 산업 인프라의 현대화로 인해 2034년에는 2억 3,000만 달러에 달할 것으로 예측되며, CAGR 5.2%로 성장할 전망입니다.

배출량에 대한 우려와 더 깨끗하고 에너지 효율적인 시스템의 필요성이 식품 가공 시설들이 고효율 연관 콘뎅싱 보일러를 도입하도록 이끌고 있습니다. 이러한 시스템은 에너지 사용을 최적화하면서 일정한 열 출력을 제공하도록 설계되어, 변화하는 환경 기준과 에너지 절약 목표와 일치합니다.

더 엄격한 규제 프레임워크가 노후화된 보일러 시스템의 교체 또는 업그레이드를 장려함에 따라 시장이 더욱 활성화되고 있습니다. 이러한 규제는 제조업체와 공장 운영자들이 규제 준수 및 성능 중심의 고급 난방 장치에 투자하도록 촉진하고 있습니다. 식품 제조에서 신뢰성 있고 지속적인 증기 생산의 중요성이 증가함에 따라 현대적인 보일러 기술에 대한 수요도 증가하고 있습니다. 또한 산업 시설이 확장되고 현대화되는 과정에서, 특히 도시 및 준도시 지역에서 컴팩트하고 비용 효율적이며 에너지 절약형 솔루션에 대한 수요가 증가하고 있으며, 이는 연관 콘뎅싱 보일러가 잘 대응할 수 있는 분야입니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 1억 3,740만 달러 |

| 예측 금액 | 2억 3,000만 달러 |

| CAGR | 5.2% |

제어 시스템, 원격 모니터링, 디지털 통합 분야의 혁신은 운영 효율성을 향상시키고 가동 중지 시간을 최소화하는 데 중요한 역할을 하고 있습니다. 스마트 기술의 도입은 운영자가 실시간으로 성능을 추적하고 문제를 신속하게 식별하며 에너지 소비를 최적화할 수 있도록 합니다. 이러한 혁신은 탄소 배출량을 줄이면서 높은 생산성을 유지하려는 기업들에게 연관 콘뎅싱 보일러를 매력적인 옵션으로 만들고 있습니다.

용량면에서 10 MMBtu/hr의 능력을 가진 식품 가공용 연관 컨덴싱 보일러는 2034년까지 5.5% 이상의 CAGR로 성장할 것으로 예상되고 있습니다. 이 보일러는 컴팩트한 크기, 설치 용이성, 높은 운영 효율성으로 인해 오래된 비응축형 보일러의 이상적인 대체품으로 자리매김하고 있습니다. 공간을 많이 차지하지 않으면서도 신뢰성 있고 일관된 성능을 제공할 수 있다는 점은 대규모 공간 재편 없이 업그레이드를 원하는 식품 가공 시설에 특히 매력적입니다.

연료 유형별로 구분하면 시장에는 천연가스, 석유, 석탄 등이 포함됩니다. 우수한 에너지 효율성, 깨끗한 연소, 재생 에너지와의 호환성으로 인해 향후 몇 년간 상당한 성장이 예상됩니다. 천연가스로의 전환은 석탄과 석유에 대한 의존도를 줄이려는 전 세계적인 노력과도 맞물려 있습니다.

미국에서는 식품 가공용 연관 컨덴싱 보일러 시장이 최근 몇 년간 지속적인 성장을 기록했습니다. 이 상승세는 주로 청정 기술과 에너지 절약 솔루션 채택을 촉진하는 정책 주도형 노력에 기인합니다. 연방 및 주 정부 차원의 프로그램은 고효율 장비 설치에 대한 인센티브를 계속 제공하며, 식품 제조 시설 전반에서 현대식 응축식 보일러 시스템에 대한 수요를 강화하고 있습니다.

보다 넓은 북미 전체에서 시장은 2034년까지 연평균 성장률(CAGR) 4.7% 이상의 성장이 예상되고 있으며, 기후 변화에 대한 인식 확산과 지역별 온실가스 배출 감축에 대한 강력한 의지가 에너지 효율적인 보일러 기술의 광범위한 도입을 지원하고 있습니다. 특히 식품 가공 산업은 운영 비용 절감과 환경 기준 준수라는 두 가지 목표를 우선시하고 있으며, 이는 연관 콘뎅싱 보일러가 제공하는 혜택과 일치합니다.

시장 환경은 적당히 통합되어 있으며, 상위 5개 제조업체가 전 세계 점유율의 약 40%를 차지하고 있습니다. 이러한 주요 업체들은 치열한 경쟁 환경에서 입지를 강화하기 위해 제품 혁신, 전략적 파트너십, 지리적 확장에 주력하고 있습니다. 식품 가공 분야에서 지속 가능한 난방 솔루션에 대한 수요가 계속 증가함에 따라, 이러한 시장 선두 기업들이 미래 트렌드를 형성하는 데 있어 그 역할이 점점 더 중요해질 것입니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 트럼프 정권의 관세 분석

- 무역에 미치는 영향

- 무역량의 혼란

- 보복 조치

- 업계에 미치는 영향

- 공급측의 영향(원자재)

- 주요 원자재의 가격 변동

- 공급망 재구성

- 생산 비용에 미치는 영향

- 수요측의 영향(판매가격)

- 최종 시장에의 가격 전달

- 시장 점유율 동향

- 소비자의 반응 패턴

- 공급측의 영향(원자재)

- 영향을 받는 주요 기업

- 전략적인 업계 대응

- 공급망 재구성

- 가격 설정 및 제품 전략

- 정책관여

- 전망과 향후 검토 사항

- 무역에 미치는 영향

- 규제 상황

- 업계에 미치는 영향요인

- 성장 촉진요인

- 업계의 잠재적 위험 및 과제

- 성장 가능성 분석

- Porter's Five Forces 분석

- 공급기업의 협상력

- 구매자의 협상력

- 신규 참가업체의 위협

- 대체품의 위협

- PESTEL 분석

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 전략적 대시보드

- 전략적 노력

- 경쟁 벤치마킹

- 혁신과 지속가능성의 정세

제5장 시장 규모와 예측 : 용량별(2021-2034년)

- 주요 동향

- 10MMBtu/매시 미만

- 10-25MMBtu/매시

- 25-50MMBtu/매시

- 50-75MMBtu/매시

- 75-100MMBtu/매시

- 100-175MMBtu/매시

- 175-250MMBtu/매시

- 250MMBtu/매시 이상

제6장 시장 규모와 예측 : 연료별(2021-2034년)

- 주요 동향

- 천연가스

- 석유

- 석탄

- 기타

제7장 시장 규모와 예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 멕시코

- 유럽

- 영국

- 프랑스

- 독일

- 이탈리아

- 러시아

- 스페인

- 아시아태평양

- 중국

- 호주

- 인도

- 일본

- 한국

- 중동 및 아프리카

- 사우디아라비아

- 아랍에미리트(UAE)

- 튀르키예

- 남아프리카

- 이집트

- 라틴아메리카

- 브라질

- 아르헨티나

제8장 기업 프로파일

- Babcock and Wilcox

- Babcock Wanson

- BM GreenTech

- Bosch Industriekessel

- Clayton Industries

- Cleaver-Brooks

- Cochran

- Forbes Marshall

- Fulton

- Hoval

- Hurst Boiler

- Johnston Boiler

- Miura America

- Thermax

- Thermodyne Boilers

- Viessmann

The Global Condensing Fire-Tube Food Processing Boiler Market was valued at USD 137.4 million in 2024 and is estimated to grow at a CAGR of 5.2% to reach USD 230 million by 2034, driven by the increasing focus on sustainable heating technologies and the modernization of industrial infrastructure. Growing concerns over emissions and the need for cleaner, more energy-efficient systems are leading food processing facilities to adopt high-efficiency condensing fire-tube boilers. These systems are engineered to optimize energy use while delivering consistent thermal output, aligning with evolving environmental norms and energy conservation goals.

The market is further propelled by stricter regulatory frameworks that encourage the replacement or enhancement of aging boiler systems. These regulations are pushing manufacturers and plant operators to invest in advanced heating units that are both compliant and performance-focused. The rising demand for reliable and continuous steam production, a critical component in food manufacturing, is also fueling the demand for modern boiler technologies. In addition, as industrial setups expand and modernize, particularly in urban and semi-urban regions, there is a growing need for compact, cost-effective, and energy-saving solutions-needs that condensing fire-tube boilers are well-positioned to meet.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $137.4 Million |

| Forecast Value | $230 Million |

| CAGR | 5.2% |

Innovations in control systems, remote monitoring, and digital integration are playing a crucial role in enhancing operational efficiency and minimizing downtime. The incorporation of smart technologies allows operators to track performance in real time, identify issues quickly, and optimize energy consumption. These advancements are making condensing fire-tube boilers an attractive option for businesses aiming to reduce their carbon footprint while maintaining high productivity levels.

In terms of capacity, condensing fire-tube food processing boilers with a 10 MMBtu/hr capacity are anticipated to grow at a CAGR exceeding 5.5% by 2034. Their compact footprint, ease of installation, and high operational efficiency make them an ideal replacement for older, non-condensing units. Their ability to deliver reliable and consistent performance without occupying much space is particularly appealing to food processing facilities looking to upgrade without major spatial reconfigurations.

When segmented by fuel type, the market includes natural gas, oil, coal, and others. In 2024, the natural gas-fired segment accounted for 32.6% of the total market share. This segment is expected to witness significant growth over the coming years due to its superior energy efficiency, cleaner combustion, and compatibility with renewable energy sources. The shift toward natural gas is also supported by the rising global focus on reducing dependence on coal and oil, both of which have higher emission footprints.

In the United States, the condensing fire-tube food processing boiler market has shown consistent growth in recent years. It reached USD 26.1 million in 2022, climbed to USD 27.6 million in 2023, and further rose to USD 29.3 million in 2024. This upward trajectory is largely attributed to policy-driven initiatives promoting the adoption of cleaner technologies and energy-saving solutions. Federal and state-level programs continue to incentivize the installation of high-efficiency equipment, reinforcing the demand for modern condensing boiler systems across food manufacturing units.

Across the broader North American region, the market is set to grow at a CAGR of more than 4.7% through 2034. Factors such as growing awareness of climate change, coupled with strong regional commitments to reducing greenhouse gas emissions, are supporting the widespread implementation of energy-efficient boiler technologies. The food processing industry, in particular, is prioritizing operational cost savings and compliance with environmental standards, both of which align with the benefits offered by condensing fire-tube boilers.

The market landscape is moderately consolidated, with the top five manufacturers collectively holding around 40% of the global share. These key players are focusing on product innovation, strategic partnerships, and geographic expansion to strengthen their foothold in a highly competitive environment. As demand for sustainable heating solutions in food processing continues to rise, the role of these market leaders in shaping future trends will become increasingly significant.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Regulatory landscape

- 3.4 Industry impact forces

- 3.4.1 Growth drivers

- 3.4.2 Industry pitfalls & challenges

- 3.5 Growth potential analysis

- 3.6 Porter's analysis

- 3.6.1 Bargaining power of suppliers

- 3.6.2 Bargaining power of buyers

- 3.6.3 Threat of new entrants

- 3.6.4 Threat of substitutes

- 3.7 PESTEL analysis

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis, 2024

- 4.3 Strategic dashboard

- 4.4 Strategic initiatives

- 4.5 Competitive benchmarking

- 4.6 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Capacity, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 5.1 Key trends

- 5.2 < 10 MMBtu/hr

- 5.3 10 - 25 MMBtu/hr

- 5.4 25 - 50 MMBtu/hr

- 5.5 50 - 75 MMBtu/hr

- 5.6 75 - 100 MMBtu/hr

- 5.7 100 - 175 MMBtu/hr

- 5.8 175 - 250 MMBtu/hr

- 5.9 > 250 MMBtu/hr

Chapter 6 Market Size and Forecast, By Fuel, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 6.1 Key trends

- 6.2 Natural gas

- 6.3 Oil

- 6.4 Coal

- 6.5 Others

Chapter 7 Market Size and Forecast, By Region, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.2.3 Mexico

- 7.3 Europe

- 7.3.1 UK

- 7.3.2 France

- 7.3.3 Germany

- 7.3.4 Italy

- 7.3.5 Russia

- 7.3.6 Spain

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 Australia

- 7.4.3 India

- 7.4.4 Japan

- 7.4.5 South Korea

- 7.5 Middle East & Africa

- 7.5.1 Saudi Arabia

- 7.5.2 UAE

- 7.5.3 Turkey

- 7.5.4 South Africa

- 7.5.5 Egypt

- 7.6 Latin America

- 7.6.1 Brazil

- 7.6.2 Argentina

Chapter 8 Company Profiles

- 8.1 Babcock and Wilcox

- 8.2 Babcock Wanson

- 8.3 BM GreenTech

- 8.4 Bosch Industriekessel

- 8.5 Clayton Industries

- 8.6 Cleaver-Brooks

- 8.7 Cochran

- 8.8 Forbes Marshall

- 8.9 Fulton

- 8.10 Hoval

- 8.11 Hurst Boiler

- 8.12 Johnston Boiler

- 8.13 Miura America

- 8.14 Thermax

- 8.15 Thermodyne Boilers

- 8.16 Viessmann