|

시장보고서

상품코드

1766253

퀵 체인지 툴링 시스템 시장 : 기회, 성장 촉진요인, 산업 동향 분석, 예측(2025-2034년)Quick-change Tooling System Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

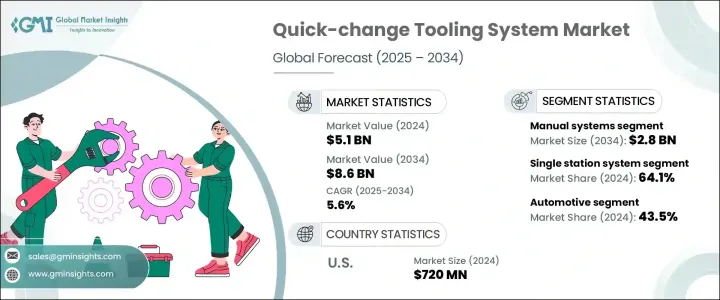

세계의 퀵 체인지 툴링 시스템 시장 규모는 2024년 51억 달러에 달했고, CAGR 5.6%로 성장해 2034년까지 86억 달러에 이를 것으로 예측되고 있습니다.

생산 유연성, 작업 속도, 셋업 시간 단축, 전반적인 생산성에 대한 요구가 높아짐에 따라 자동차, 항공우주, 일렉트로닉스, 의료기기의 각 분야의 기업에 보다 신속하고 응답성이 높은 툴링 솔루션에 대한 투자를 촉구하고 있습니다.

퀵 체인지 툴링 시스템은 공구 교환의 가속화와 교체 시간의 상당한 단축을 가능하게 하며, 안정적인 생산 수준 유지에 기여합니다. 인더스트리 4.0이 기세를 늘리는 가운데 차세대 시스템은 현재 IoT와 센서 기술을 통합하여 공구의 성능, 마모, 교환 간격에 대한 실시간 통찰을 가능하게 하고, 보다 예측적이고 데이터 구동형의 오퍼레이션을 가능하게 하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 51억 달러 |

| 예측 금액 | 86억 달러 |

| CAGR | 5.6% |

수동 퀵 체인지 시스템은 2024년에는 19억 달러의 평가 금액으로 시장을 선도했고, 2034년에는 28억 달러에 이를 것으로 예측됩니다. 독립 운영에 이상적이며 중소기업에 실용적인 솔루션을 제공하고 있으며, 목공, 플라스틱 성형, 금속 가공 등 범용성과 단순성이 중시되는 분야에서도 지지되고 있습니다.

2024년에는 싱글 스테이션 툴링 시스템 부문이 64.1%의 점유율을 차지했으며, 2034년까지 연평균 복합 성장률(CAGR)은 5%로 예측됩니다. 유지보수가 용이하기 때문에 제조업 분야의 중견기업에 적합합니다.

미국의 퀵 체인지 툴링 시스템 시장은 2024년에 7억 2,000만 달러로 평가되었고, 2025년부터 2034년까지 연평균 복합 성장률(CAGR) 6.1%를 보일 것으로 예측됩니다. 이 지역의 견조한 자동차, 항공우주, 방위 제조 부문이 채용의 주요 촉진요인이 되고 있습니다. 최첨단 R&D 능력, 혁신에 대한 강한 수요에 힘입어 정교한 산업 환경의 혜택을 누리고 있습니다.

퀵 체인지 툴링 시스템 업계의 주요 기업은 AMETEK, Inc., Nachi-Fujikoshi Corp, Illinois Tool Works Inc.(ITW), THK Co., Ltd., and Kennametal Inc 등이 있습니다. 시장 포지션을 강화하기 위해, 각사는 자동화 기계와의 호환성을 높이는 모듈식으로 스케일러블한 공구 시스템을 개발해, 기술 혁신에 투자하고 있습니다. 실시간 모니터링을 위한 IoT 대응 기능으로 제품 라인을 강화하고 있는 기업도 있습니다. 지속적인 업그레이드, 인체공학을 기반으로 한 설계에 주력, 신흥국에의 진출은 주요 기업의 경쟁력 유지에 도움이 되고, 동시에, 고속으로 유연하고 효율적인 툴링 솔루션에 수요에도 응하고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 공급자의 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 주는 요인

- 혁신

- 업계에 미치는 영향요인

- 성장 촉진요인

- 업계의 잠재적 위험 및 과제

- 기회

- 성장 가능성 분석

- 미래 시장 동향

- 기술과 혁신의 상황

- 현재의 기술 동향

- 신흥기술

- 가격 동향

- 지역별

- 제품 유형별

- 규제 프레임워크

- 규격과 인증

- 환경규제

- 수출입 규제

- 무역 통계

- 주요 수입국

- 주요 수출국

- Porter's Five Forces 분석

- PESTEL 분석

- 소비자 행동 분석

- 구입 패턴

- 선호 분석

- 소비자 행동의 지역차

- 전자상거래가 구매결정에 미치는 영향

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 지역별

- 북미

- 유럽

- 아시아태평양

- 지역별

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 주요 발전

- 합병인수

- 파트너십 및 협업

- 신제품 발매

- 확장 계획

제5장 시장 추계 및 예측 : 유형별, 2021-2034년

- 주요 동향

- 수동 시스템

- 자동 시스템

- 유압 시스템

- 기타

제6장 시장 추계 및 예측 : 동작 모드별, 2021-2034년

- 주요 동향

- 싱글 스테이션 시스템

- 멀티 스테이션 시스템

제7장 시장 추계 및 예측 : 용도별, 2021-2034년

- 주요 동향

- 사출 성형

- 스탬핑 및 프레스 툴

- 로봇 도구

- 용접 시스템

- 조립 라인

- 포장 기계

- 기타

제8장 시장 추계 및 예측 : 최종 용도별, 2021-2034년

- 주요 동향

- 자동차

- 항공우주 및 방위

- 가전

- 의료기기

- 포장

- 산업기계

- 플라스틱 및 고무

- 기타

제9장 시장 추계 및 예측 : 유통 채널별, 2021-2034년

- 주요 동향

- 직접 판매

- 간접 판매

제10장 시장 추계 및 예측 : 지역별, 2021-2034년

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 영국

- 독일

- 프랑스

- 이탈리아

- 스페인

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 호주

- 라틴아메리카

- 브라질

- 멕시코

- 중동 및 아프리카

- 남아프리카

- 아랍에미리트(UAE)

- 사우디아라비아

제11장 기업 프로파일

- AMETEK, Inc.

- BIG DAISHOWA

- Destaco

- Diebold Goldring-Werkzeugfabrik

- Erowa AG

- Illinois Tool Works Inc.(ITW)

- Jergens Inc.

- Kennametal Inc. Co., Ltd

- LANG Technik GmbH

- Mate Precision Technologies

- Nachi-Fujikoshi Corp

- Rohm GmbH

- SCHUNK GmbH & Co. KG

- SMW Autoblok

- THK Co., Ltd.

The Global Quick-change Tooling System Market was valued at USD 5.1 billion in 2024 and is estimated to grow at a CAGR of 5.6% to reach USD 8.6 billion by 2034. The rise in demand for manufacturing flexibility, operational speed, reduced setup times, and overall productivity is pushing companies across the automotive, aerospace, electronics, and medical device sectors to invest in quicker, more responsive tooling solutions. These industries face increasing pressure to streamline operations and reduce downtime while meeting evolving production goals.

Quick-change tooling systems allow faster tool replacements and significantly cut changeover durations, helping maintain consistent output levels. Their widespread use in CNC centers, molding units, stamping facilities, and other precision-driven environments underscores their value in smart manufacturing. As Industry 4.0 gains momentum, next-generation systems now integrate IoT and sensor technologies to enable real-time insights into tool performance, wear, and change intervals, allowing more predictive and data-driven operations. This growing shift toward automation and real-time monitoring is setting the stage for innovation and continuous improvement in tooling infrastructure.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $5.1 Billion |

| Forecast Value | $8.6 Billion |

| CAGR | 5.6% |

Manual quick-change systems led the market in 2024 with a valuation of USD 1.9 billion and are projected to hit USD 2.8 billion by 2034. Their popularity stems from easy integration with existing machinery, cost efficiency, and minimal training requirements. These systems remain ideal for operations that do not depend heavily on high-speed automation, offering a practical solution for small and medium businesses. They're also favored in segments like woodworking, plastic molding, and metal fabrication, where versatility and simplicity matter. The ability to function effectively in legacy machines further enhances their relevance in regions where modernization is slower and infrastructure investments are limited.

In 2024, the single-station tooling systems segment held a 64.1% share and is forecasted to grow at a CAGR of 5% through 2034. These systems are especially effective in applications requiring tool changes at fixed points, such as with individual CNC units or lathes. Their affordability, minimal setup complexity, and easy maintenance make them well-suited for mid-sized enterprises across manufacturing sectors. The use of these systems is prominent in industries like fabrication, plastics, and precision metalwork, which benefit from targeted and standalone machine applications.

United States Quick-change Tooling System Market was valued at USD 720 million in 2024 and is anticipated to grow at a CAGR of 6.1% between 2025 and 2034. The region's robust automotive, aerospace, and defense manufacturing sectors are major drivers of adoption. As manufacturers emphasize speed, customization, and lean production methods, there has been a notable shift toward automation-ready tooling systems. The U.S. benefits from a sophisticated industrial environment supported by skilled labor, cutting-edge R&D capabilities, and a strong demand for innovation. This combination supports rapid turnaround and tailored tooling applications, increasing demand for both manual and automated quick-change solutions.

Leading companies in the Quick-change Tooling System Industry include AMETEK, Inc., Nachi-Fujikoshi Corp, Illinois Tool Works Inc. (ITW), THK Co., Ltd., and Kennametal Inc. To reinforce their market positions, companies are investing in innovation by developing modular and scalable tooling systems that offer greater compatibility with automated machinery. Many are forming strategic alliances with OEMs and machine manufacturers to integrate their technologies directly into new production equipment. Firms are also enhancing product lines with IoT-enabled features for remote diagnostics and real-time monitoring. Continuous upgrades, focus on ergonomic designs and expansion into emerging economies are helping key players stay competitive while meeting demand for fast, flexible, and efficient tooling solutions.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Type

- 2.2.3 Operation mode

- 2.2.4 Application

- 2.2.5 End use

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls & challenges

- 3.2.3 Opportunities

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By product type

- 3.7 Regulatory framework

- 3.7.1 Standards and certifications

- 3.7.2 Environmental regulations

- 3.7.3 Import export regulations

- 3.8 Trade statistics

- 3.8.1 Major importing countries

- 3.8.2 Major exporting countries

- 3.9 Porter's five forces analysis

- 3.10 PESTEL analysis

- 3.11 Consumer behavior analysis

- 3.11.1 Purchasing patterns

- 3.11.2 Preference analysis

- 3.11.3 Regional variations in consumer behavior

- 3.11.4 Impact of e-commerce on buying decisions

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Type, 2021 - 2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Manual systems

- 5.3 Automatic systems

- 5.4 Hydraulic systems

- 5.5 Others

Chapter 6 Market Estimates & Forecast, By Operation mode, 2021 - 2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Single-station systems

- 6.3 Multi-station systems

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Injection molding

- 7.3 Stamping & press tools

- 7.4 Robotic tooling

- 7.5 Welding systems

- 7.6 Assembly lines

- 7.7 Packaging machines

- 7.8 Others

Chapter 8 Market Estimates & Forecast, By End Use, 2021 - 2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Automotive

- 8.3 Aerospace and defense

- 8.4 Consumer electronics

- 8.5 Medical devices

- 8.6 Packaging

- 8.7 Industrial machinery

- 8.8 Plastics and rubber

- 8.9 Others

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Direct

- 9.3 Indirect

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 South Africa

- 10.6.2 UAE

- 10.6.3 Saudi Arabia

Chapter 11 Company Profiles

- 11.1 AMETEK, Inc.

- 11.2 BIG DAISHOWA

- 11.3 Destaco

- 11.4 Diebold Goldring-Werkzeugfabrik

- 11.5 Erowa AG

- 11.6 Illinois Tool Works Inc. (ITW)

- 11.7 Jergens Inc.

- 11.8 Kennametal Inc. Co., Ltd

- 11.9 LANG Technik GmbH

- 11.10 Mate Precision Technologies

- 11.11 Nachi-Fujikoshi Corp

- 11.12 Rohm GmbH

- 11.13 SCHUNK GmbH & Co. KG

- 11.14 SMW Autoblok

- 11.15 THK Co., Ltd.