|

시장보고서

상품코드

1773393

균사체 벽돌 시장 기회, 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Mycelium Bricks Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

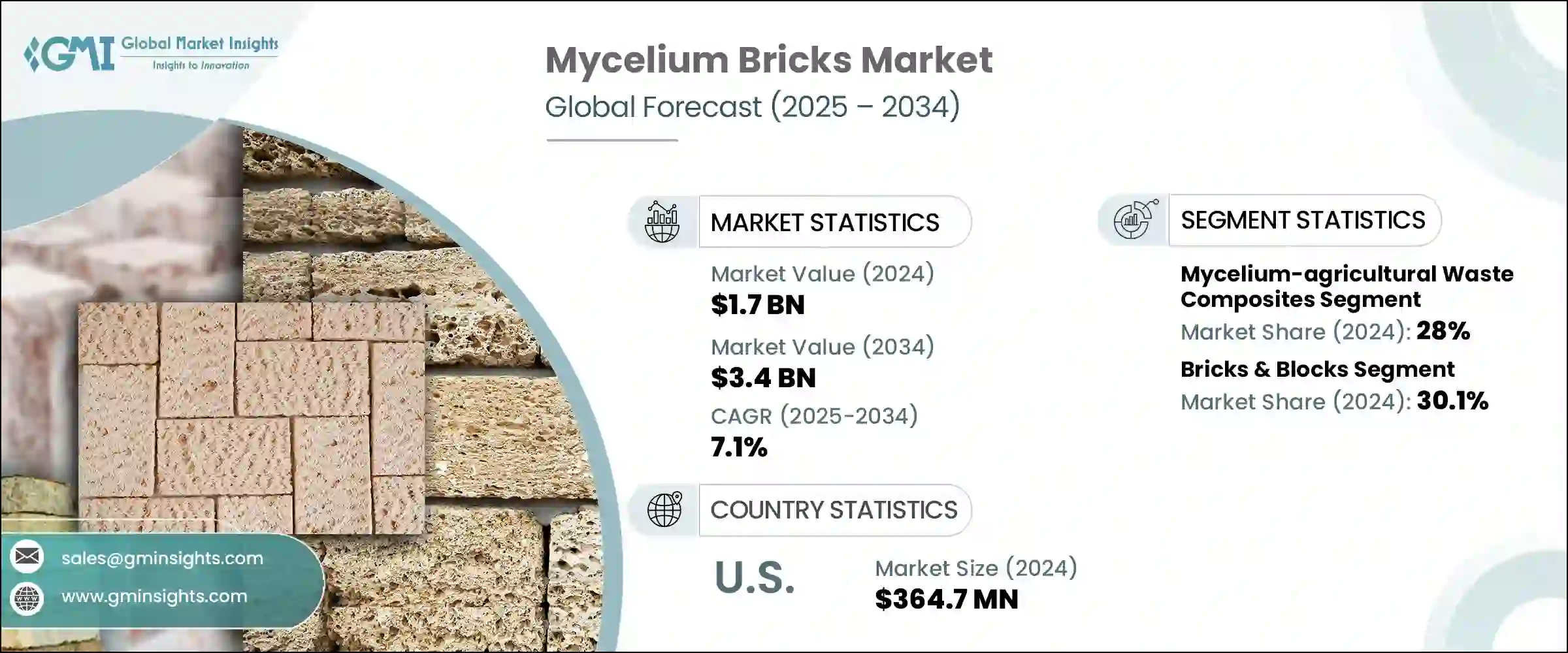

세계의 균사체 벽돌 시장 규모는 2024년에 17억 달러로 평가되었고, CAGR 7.1%를 나타내 2034년에는 34억 달러에 이를 것으로 추정됩니다.

이 성장은 지속 가능한 저탄소 건축자재로의 변화 증가를 반영합니다. 연구에 따르면 균사체 복합재는 체화 탄소가 마이너스(약 -39.5kg CO2e/m3)이며 생산 시 7.7MJ/kg만 소비하여 83.5MJ/kg의 기존 단열재보다 훨씬 적은 에너지를 소비합니다. 이 기세를 타고, 재배 방법의 진보가 균사체 베이스의 재료의 성능과 저렴한 가격을 대폭 향상시켜, 제조업체가 건설 현장에서 카본·마이너스 단열재를 직접 생산

이 기술 혁신은 비용을 줄일뿐만 아니라 운송시 배출량도 크게 줄이기 때문에 지속 가능한 건설 기법의 중요한 요소가 되고 있습니다. 따라서 부피가 큰 재료의 장거리 운송이 불필요 해지고 기존공급 체인과 관련된 탄소발자국이 줄어 듭니다. 건축 공정에 공헌해, 저부하로 환경 친화적인 건축에의 고조와 일치합니다.또, 균사체 베이스의 제품을 현지에서 생산할 수 있으므로, 납기가 단축되어 공급 체인의 유연성이 높아지는 동시에 지역 경제도 지원할 수 있습니다. 이러한 합리적인 생산 접근법은 전반적인 지속가능성을 향상시킬뿐만 아니라 기존 건축자재를 대체 할 수 있는 대안으로 균사체의 확장 성을 향상시킵니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 17억 달러 |

| 예측 금액 | 34억 달러 |

| CAGR | 7.1% |

2024년에 28%의 점유율을 차지한 균사체-농업 폐기물 복합재 분야는 그 비용 효율과 아시아태평양 선진국에서 밀짚과 옥수수 껍질과 같은 원료를 곧바로 입수할 수 있기 때문에 계속 성장하고 있습니다.

균사체 벽돌 시장의 벽돌 블록 분야는 2024년에 30.1%의 점유율을 차지했고 규격화된 치수와 견고한 구조 품질이 지지되고 있습니다.

2024년 미국의 균사체 벽돌 시장 규모는 3억 6,470만 달러로 그린빌딩 장려금과 LEED 인증 등 강력한 규제환경의 혜택을 받았습니다. 센터의 존재감이 높아지고 있는 것 외에, 특히 환경의식이 높은 젊은 세대를 중심으로 한 도시에서 수요가 증가하고 있는 것이, 생분해성으로 미관이 뛰어난 균사체 벽돌의 사용이 전미에서 꾸준히 성장하고 있는 요인이 되고 있습니다.

Biohm, MycoWorks, Ecovative Design, Grown Bio, Mogu Srl사 등이 대표적인 기업입니다. 균사체 벽돌 업계의 기업은 재배나 생산 공정를 개량하기 위한 연구 제휴를 맺고, 내화성이나 구조 성능을 향상시키기 위한 연구 개발에 투자해, 확장 가능한 제조 시스템을 개발하는 것으로, 그 지위를 강화하고 있습니다. 신뢰도를 높이기 위해 인증(LEED, BREEAM 등)을 취득하여 패널, 단열재, 모듈러 솔루션 등 제품 라인을 다양화하여 건축가나 건설업자와의 협업을 추구하여 채용을 늘리고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 공급자의 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 주는 요인

- 파괴적 혁신

- 업계에 미치는 영향요인

- 성장 촉진요인

- 업계의 잠재적 위험 및 과제

- 시장 기회

- 성장 가능성 분석

- 규제 상황

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- Porter's Five Forces 분석

- PESTEL 분석

- 가격 동향

- 지역별

- 제품 유형별

- 향후 시장 동향

- 기술과 혁신의 상황

- 현재의 기술 동향

- 신흥기술

- 특허 상황

- 무역 통계(HS코드)(참고 : 무역 통계는 주요 국가에서만 제공됨)

- 주요 수입국

- 주요 수출국

- 지속가능성과 환경 측면

- 지속가능한 관행

- 폐기물 감축 전략

- 생산에 있어서의 에너지 효율

- 환경 친화적인 노력

- 탄소발자국의 고려

제4장 경쟁 구도

- 서론

- 기업의 시장 점유율 분석

- 지역별

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- 지역별

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 주요 발전

- 합병과 인수

- 파트너십 및 협업

- 신제품 발매

- 확장 계획

제5장 시장 추계·예측 : 제품 유형별(2021-2034년)

- 주요 동향

- 순수 균사체 벽돌

- 균사체-농업 폐기물 복합재

- 짚 기반 복합재

- 옥수수 껍질 및 줄기 복합재

- 쌀 껍질 및 작물 잔류물 복합재

- 기타

- 균사체-목재 폐기물 복합재

- 톱밥 및 목재 칩 복합재

- 종이 및 판지 폐기물 복합재

- 기타

- 균사체 강화 복합재

- 섬유 강화 복합재

- 미네랄 강화 복합재

- 기타

- 특수 및 엔지니어링 균사체 제품

제6장 시장 추계·예측 : 형태별(2021-2034년)

- 주요 동향

- 벽돌 및 블록

- 표준 벽돌

- 연동 블록

- 맞춤형 블록

- 패널 및 보드

- 평면 패널

- 음향 패널

- 구조 패널

- 단열재

- 완충재

- 경질 단열 보드

- 스프레이 적용 단열재

- 3D 프린팅 및 맞춤형 양식

- 기타

제7장 시장 추계·예측 : 용도별(2021-2034년)

- 주요 동향

- 건물 건설

- 내부 무하중 벽체

- 단열

- 음향

- 구조적 구성 요소

- 기타

- 인테리어 디자인 및 가구

- 장식 요소

- 가구 구성 요소

- 기타

- 가설 구조물 및 전시

- 전시 디스플레이

- 임시 설치물

- 이벤트 구조물

- 포장 및 보호재

- 예술 및 디자인 용도

- 기타

제8장 시장 추계·예측 : 최종 용도별(2021-2034년)

- 주요 동향

- 주택건설

- 상업건설

- 사무실 건물

- 소매 및 접객

- 기타

- 기관 및 공공시설

- 교육시설

- 문화 및 커뮤니티 시설

- 의료시설

- 기타

- 산업 및 제조

- 기타

제9장 시장 추계·예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 스페인

- 이탈리아

- 기타 유럽

- 아시아태평양

- 중국

- 인도

- 일본

- 호주

- 한국

- 기타 아시아태평양

- 라틴아메리카

- 브라질

- 멕시코

- 아르헨티나

- 기타 라틴아메리카

- 중동 및 아프리카

- 사우디아라비아

- 남아프리카

- 아랍에미리트(UAE)

- 기타 중동 및 아프리카

제10장 기업 프로파일

- Biohm

- Biomyc

- Ecovative Design

- Grown Bio

- Mogu Srl

- Mycel

- Mycovation

- MycoWorks

The Global Mycelium Bricks Market was valued at USD 1.7 billion in 2024 and is estimated to grow at a CAGR of 7.1% to reach USD 3.4 billion by 2034. This growth reflects a growing shift toward sustainable, low-carbon construction materials. Made from fungal mycelium grown on agricultural waste, these biodegradable bricks deliver outstanding insulation and reduce environmental pollution while aligning with circular bioeconomy principles. Studies show mycelium composites have negative embodied carbon (approximately -39.5 kg CO2e/m3) and consume only 7.7 MJ/kg in production, far less than conventional insulation materials at 83.5 MJ/kg. Building on this momentum, advancements in cultivation methods are significantly enhancing the performance and affordability of mycelium-based materials, allowing manufacturers to produce carbon-negative insulation directly at construction sites.

This innovation not only reduces costs but also significantly lowers transportation emissions, making it a key component of sustainable construction practices. By enabling on-site production of carbon-negative insulation, it eliminates the need for long-distance transportation of bulky materials, thereby decreasing the carbon footprint associated with traditional supply chains. Furthermore, the reduction in manufacturing and transportation-related emissions contributes to greener building processes, aligning with the growing push toward low-impact, eco-friendly construction. The ability to produce mycelium-based products locally also ensures faster turnaround times and greater supply chain flexibility, while simultaneously supporting regional economies. This streamlined production approach not only improves overall sustainability but also enhances the scalability of mycelium as a viable alternative to conventional building materials.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.7 Billion |

| Forecast Value | $3.4 Billion |

| CAGR | 7.1% |

The mycelium-agricultural waste composites segment, holding a 28% share in 2024, continues to thrive due to its cost efficiency and the ready availability of raw materials like wheat straw and corn husks in developed Asia-Pacific countries. Their seamless integration into modular panel systems and insulation applications has made them a cornerstone of eco-friendly construction projects.

The bricks and blocks segment from the mycelium bricks market accounted for a 30.1% share in 2024, favored for their standardized dimensions and robust structural qualities. These attributes make them a straightforward substitute for traditional materials, allowing builders to adopt greener alternatives without compromising established construction workflows.

U.S. Mycelium Bricks Market, valued at USD 364.7 million in 2024, benefits from a strong regulatory environment, including green building incentives and LEED certifications. The growing presence of architecture firms and innovation centers focused on sustainable design, coupled with increasing urban demand-especially from environmentally conscious younger generations-is fueling steady growth in the use of biodegradable, aesthetically pleasing mycelium bricks across the country.

Prominent players include Biohm, MycoWorks, Ecovative Design, Grown Bio, and Mogu S.r.l. Companies in the mycelium bricks industry are strengthening their position by forming research partnerships to refine cultivation and production processes, investing in R&D to improve fire resistance and structural performance, and developing scalable manufacturing systems. They're also securing certifications (e.g., LEED, BREEAM) to enhance credibility in green construction markets, diversifying product lines with panel, insulation, and modular solutions, and pursuing collaborations with architects and builders to increase adoption. These strategies enhance market trust and ensure long-term growth.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Product type

- 2.2.2 Form method

- 2.2.3 Application

- 2.2.4 End use

- 2.2.5 Regional

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.6.1 Technology and Innovation landscape

- 3.6.2 Current technological trends

- 3.6.3 Emerging technologies

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By product type

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Product Type, 2021–2034 (USD Billion) (Cubic Meters)

- 5.1 Key trends

- 5.2 Pure mycelium bricks

- 5.3 Mycelium-agricultural waste composites

- 5.3.1 Straw-based composites

- 5.3.2 Corn husk & stalk composites

- 5.3.3 Rice hulls & crop residue composites

- 5.3.4 Others

- 5.4 Mycelium-wood waste composites

- 5.4.1 Sawdust & wood chip composites

- 5.4.2 Paper & cardboard waste composites

- 5.4.3 Others

- 5.5 Mycelium-reinforced composites

- 5.5.1 Fiber-reinforced composites

- 5.5.2 Mineral-reinforced composites

- 5.5.3 Others

- 5.6 Specialized & engineered mycelium products

Chapter 6 Market Estimates and Forecast, By Form, 2021–2034 (USD Billion) (Cubic Meters)

- 6.1 Key trends

- 6.2 Bricks & blocks

- 6.2.1 Standard bricks

- 6.2.2 Interlocking blocks

- 6.2.3 Custom-shaped blocks

- 6.3 Panels & boards

- 6.3.1 Flat panels

- 6.3.2 Acoustic panels

- 6.3.3 Structural panels

- 6.4 Insulation materials

- 6.4.1 Loose fill insulation

- 6.4.2 Rigid insulation boards

- 6.4.3 Spray-applied insulation

- 6.5 3D-printed & custom forms

- 6.6 Others

Chapter 7 Market Estimates and Forecast, By Application, 2021–2034 (USD Billion) (Cubic Meters)

- 7.1 Key trends

- 7.2 Building construction

- 7.2.1 Interior non-load bearing walls

- 7.2.2 Insulation

- 7.2.3 Acoustic

- 7.2.4 Structural components

- 7.2.5 Others

- 7.3 Interior design & furniture

- 7.3.1 Decorative elements

- 7.3.2 Furniture components

- 7.3.3 Others

- 7.4 Temporary structures & exhibitions

- 7.4.1 Exhibition displays

- 7.4.2 Temporary installations

- 7.4.3 Event structures

- 7.5 Packaging & protective materials

- 7.6 Art & design applications

- 7.7 Others

Chapter 8 Market Estimates and Forecast, By End Use, 2021–2034 (USD Billion) (Cubic Meters)

- 8.1 Key trends

- 8.2 Residential construction

- 8.3 Commercial construction

- 8.3.1 Office buildings

- 8.3.2 Retail & hospitality

- 8.3.3 Others

- 8.4 Institutional & public buildings

- 8.4.1 Educational facilities

- 8.4.2 Cultural & community buildings

- 8.4.3 Healthcare facilities

- 8.4.4 Others

- 8.5 Industrial & manufacturing

- 8.6 Others

Chapter 9 Market Estimates and Forecast, By Region, 2021–2034 (USD Billion) (Cubic Meters)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Spain

- 9.3.5 Italy

- 9.3.6 Rest of Europe

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.4.6 Rest of Asia Pacific

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.5.4 Rest of Latin America

- 9.6 Middle East and Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

- 9.6.4 Rest of Middle East and Africa

Chapter 10 Company Profiles

- 10.1 Biohm

- 10.2 Biomyc

- 10.3 Ecovative Design

- 10.4 Grown Bio

- 10.5 Mogu S.r.l.

- 10.6 Mycel

- 10.7 Mycovation

- 10.8 MycoWorks