|

시장보고서

상품코드

1797708

건설 규모 3D 프린팅용 폴리머 필라멘트 시장 : 기회, 성장 촉진요인, 산업 동향 분석, 예측(2025-2034년)Polymer Filaments for Construction-Scale 3D Printing Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

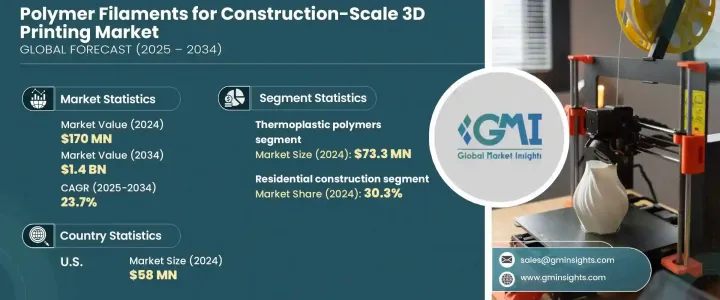

세계의 건설 규모 3D 프린팅용 폴리머 필라멘트 시장은 2024년 1억 7,000만 달러로 평가되었으며 CAGR 23.7%로 성장하여 2034년까지 14억 달러에 이를 것으로 추정되고 있습니다.

이 급성장의 배경에는 혁신적이고 지속 가능한 건축 방법에 대한 수요가 증가하고 있습니다. ABS, PLA, PET 등의 엔지니어링 열가소성 플라스틱은 구조 부품에서 전체 건물에 이르기까지 대형 적층 성형 용도에 최적화되고 있습니다. 3D 프린팅의 다목적성을 통해 건축가와 엔지니어는 기존의 방법으로는 대응할 수 없는 가볍고 복잡한 구조를 만들 수 있습니다. 이 능력은 첨단 고분자 필라멘트의 신속한 채용을 촉진합니다.

정부가 지원하는 인프라 개발 이니셔티브와 지속가능성 기준이 이 기술에 대한 관심을 가속화하고 있습니다. 또한 3D 프린팅의 자동화 기능은 재료 낭비와 수작업을 줄여 건설에 비용 효율적인 솔루션을 제공합니다. 세계적으로 스마트 인프라가 중시되고 있으며, 특히 아시아태평양의 급속히 도시화되고 있는 지역에서는 인도, 중국, 일본 등의 국가들이 건축 및 개발 프로젝트에 고성능 3D 프린팅 재료를 채용하는 리더적 존재가 되고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 1억 7,000만 달러 |

| 예측 금액 | 14억 달러 |

| CAGR | 23.7% |

2024년 주택 건설 부문의 점유율은 30.3%를 차지했습니다. 이 용도는 주택 부족과 합리적인 느낌을 다루는 역할을 하는 것으로 지지를 모으고 있습니다. 고분자 필라멘트를 사용하면 구성 요소를 신속하게 제조할 수 있으며 건설 일정과 인건비를 모두 줄일 수 있습니다. 또한 이 소재는 리모델링과 모듈 건축에도 대응하고 있으며, 시장의 요구에 맞춘 폭넓은 주택 솔루션에 이상적입니다.

대규모 용융 적층 성형(FDM) 기술 분야는 2024년에 주목할만한 점유율을 차지했으며, 작업의 간편성과 비교적 낮은 설치 비용으로 2024년에 주목했습니다. 확장 가능한 특성으로 인해 기본 부품부터 본격적인 주택 및 상업용 건물까지 다양한 수준의 건설에 이상적인 솔루션이 되었습니다. 압출성형기반의 설비는 입수하기 쉽기 때문에 그 보급과 성능의 신뢰성에 공헌하고 있습니다.

미국의 건설 규모 3D 프린팅용 폴리머 필라멘트 시장은 2024년 5,800만 달러 규모를 창출했습니다. 이 강력한 시장 존재는 견고한 혁신 생태계, R&D 노력 증가, 지속 가능한 건설 기법에 대한 수요에 의해 야기됩니다. 미국 기업들은 환경과 비용 효율성의 목표에 따라 대규모 건축의 기술적 요구를 충족시키는 첨단 필라멘트 재료의 개발을 가속화하고 있습니다. 이 초점은 이 분야에서 미국의 리더십을 계속 강화하고 있습니다.

건설 규모 3D 인쇄용 폴리머 필라멘트 시장의 주요 기업으로는 Coex 3D, Arkema, BASF SE, Sika AG, Skanska AB, Covestro, MudBots, Mighty Buildings, Tvasta Manufacturing Solutions, Manlon Polymers 등이 있습니다. 건설 규모 3D 프린팅용 폴리머 필라멘트 시장의 각 회사는 건설 부문의 진화하는 요구에 대응하기 위해 고성능, 재활용 가능, 기후 변화에 강한 재료의 개발에 주력하고 있습니다. R&D 투자는 필라멘트 조성물의 강도, 내구성 및 내열성을 향상시키는 데 도움이 됩니다. 많은 업체들이 건설기술기업과 학술기관과 협력관계를 맺어 기술 혁신과 상업화 준비를 가속화하고 있습니다. 또한 세계 유통 및 현지 생산 능력 개발로 기업은 빠르게 발전하는 지역의 인프라 프로젝트에 대응할 수 있습니다. 전략적 합병 및 기술 라이선싱은 독자적인 추가 제조 플랫폼에 대한 액세스를 얻기 위해 사용됩니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 업계 생태계 분석

- 공급자의 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 주는 요인

- 혁신

- 업계에 미치는 영향요인

- 성장 촉진요인

- 업계의 잠재적 리스크 및 과제

- 시장 기회

- 성장 가능성 분석

- 규제 상황

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- Porter's Five Forces 분석

- PESTLE 분석

- 기술과 혁신의 상황

- 현재의 기술 동향

- 신흥기술

- 가격 동향

- 지역별

- 소재 유형별

- 미래 시장 동향

- 기술과 혁신의 상황

- 현재의 기술 동향

- 신흥기술

- 특허 상황

- 무역 통계(HS코드)

(참고: 무역 통계는 주요 국가에서만 제공됩니다)

- 주요 수입국

- 주요 수출국

- 지속가능성과 환경 측면

- 지속가능한 관행

- 폐기물 감축 전략

- 생산에서의 에너지 효율

- 환경 친화적인 노력

- 탄소발자국의 고려

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 지역별

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- 지역별

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 주요 발전

- 합병 및 인수

- 파트너십 및 협업

- 신제품 발매

- 확장 계획

제5장 시장 추계 및 예측 : 재질별, 2021-2034년

- 주요 동향

- 열가소성 폴리머

- PLA(폴리유산) 및 바이오의 열가소성 플라스틱

- ABS(아크릴로니트릴부타디엔스티렌) 및 엔지니어링 플라스틱

- PETG(폴리에틸렌테레프탈레이트글리콜) 및 특수 폴리머

- 고성능 엔지니어링 플라스틱(PEEK, PEI, PEKK)

- 섬유 강화 복합재료

- 탄소섬유 강화 폴리머(CFRP)

- 유리 섬유 강화 폴리머(GFRP)

- 천연섬유 강화 복합재료

- 상용 섬유 강화 시스템

- 지속 가능한 바이오 소재

- 바이오 베이스 폴리머 배합

- 재활용 소재 및 사용후 소재

- 생분해성 및 퇴비화 가능한 폴리머

- 폐기물 유래 및 순환형 경제 재료

- 특수기능재료

- 내화성 및 난연성 폴리머

- 단열재 및 에너지 절약 재료

- 전도성 및 스마트 재료 시스템

- 다기능 및 하이브리드 재료 솔루션

- 신흥 및 첨단 재료

- 나노복합재료 및 고성능재료

- 형상 기억 및 응답성 폴리머 시스템

- 자기 수리 및 적응형 재료 기술

- 생체 모방 및 자연에서 영감을 얻은 재료 솔루션

제6장 시장 추계 및 예측 : 용도별, 2021-2034년

- 주요 동향

- 주택건설

- 상업건설

- 인프라 및 토목공학

- 건축 및 장식 요소

- 특수 용도 및 틈새 용도

제7장 시장 추계 및 예측 : 기술별, 2021-2034년

- 주요 동향

- 대규모 열용해 적층법(FDM)

- 로봇 건설 시스템

- 상용 제조 기술

- 신흥기술 및 첨단기술

제8장 시장 추계 및 예측 : 최종 용도별, 2021-2034년

- 주요 동향

- 건설회사 및 종합 건설업자

- 건축가 및 디자인 전문가

- 부동산 개발업자 및 건물 소유자

- 조사교육기관

- 정부 및 공공 부문

제9장 시장 추계 및 예측 : 설비 규모별, 2021-2034년

- 주요 동향

- 대규모 산업 시스템

- 중규모 산업 시스템

- 컴팩트 및 휴대용 시스템

- 하이브리드 멀티 테크놀로지 시스템

제10장 시장 추계 및 예측 : 지역별, 2021-2034년

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 스페인

- 이탈리아

- 기타 유럽

- 아시아태평양

- 중국

- 인도

- 일본

- 호주

- 한국

- 기타 아시아태평양

- 라틴아메리카

- 브라질

- 멕시코

- 아르헨티나

- 기타 라틴아메리카

- 중동 및 아프리카

- 사우디아라비아

- 남아프리카

- 아랍에미리트(UAE)

- 기타 중동 및 아프리카

제11장 기업 프로파일

- Arkema

- BASF SE

- Coex 3D

- Covestro

- Manlon Polymers

- Mighty Buildings

- MudBots

- Sika AG

- Skanska AB

- Tvasta Manufacturing Solutions

The Global Polymer Filaments for Construction-Scale 3D Printing Market was valued at USD 170 million in 2024 and is estimated to grow at a CAGR of 23.7% to reach USD 1.4 billion by 2034. This rapid growth is driven by the increasing demand for innovative and sustainable building methods. Engineered thermoplastics such as ABS, PLA, and PET are being optimized for large-format additive manufacturing applications, from structural parts to entire buildings. The versatility of 3D printing enables architects and engineers to create lightweight, complex structures that traditional methods cannot support. This capability is fostering rapid adoption of advanced polymer filaments.

Government-backed infrastructure development initiatives and sustainability standards are accelerating interest in this technology. The automation capabilities of 3D printing also reduce material waste and manual labor, making it a more cost-efficient solution for construction. Global emphasis on smart infrastructure, especially across rapidly urbanizing regions in Asia-Pacific, is positioning countries like India, China, and Japan as leaders in the adoption of high-performance 3D printing materials for building and development projects.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $170 million |

| Forecast Value | $1.4 billion |

| CAGR | 23.7% |

The residential construction segment held a 30.3% share in 2024. This application is gaining traction for its role in addressing housing shortages and affordability. Using polymer filaments, components can be produced quickly, cutting down both construction timelines and labor costs. These materials also support renovation and modular builds, making them ideal for a wide range of housing solutions that respond to immediate market needs.

The large-scale fused deposition modeling (FDM) technology segment held a notable share in 2024 due to its operational simplicity and relatively low setup costs. Its scalable nature makes it an ideal solution for different levels of construction - from foundational components to full-scale residential or commercial buildings. The accessibility of extrusion-based equipment has contributed to its widespread adoption and performance reliability.

U.S. Polymer Filaments for Construction-Scale 3D Printing Market generated USD 58 million in 2024. This strong market presence is driven by a robust innovation ecosystem, increasing R&D efforts, and the demand for sustainable construction methods. Companies in the U.S. are accelerating development of advanced filament materials that meet the technical needs of large-scale construction while aligning with environmental and cost-efficiency objectives. This focus continues to strengthen the country's leadership in the sector.

Key players in Polymer Filaments for Construction-Scale 3D Printing Market include Coex 3D, Arkema, BASF SE, Sika AG, Skanska AB, Covestro, MudBots, Mighty Buildings, Tvasta Manufacturing Solutions, and Manlon Polymers. Companies in the polymer filaments for construction-scale 3D printing market are focusing on developing high-performance, recyclable, and climate-resilient materials to meet the evolving needs of the construction sector. Investments in R&D help improve the strength, durability, and thermal resistance of filament compositions. Many manufacturers are forming collaborations with construction tech firms and academic institutions to speed up innovation and commercial readiness. Expanding global distribution and localized production capabilities also allows companies to serve infrastructure projects in fast-developing regions. Strategic mergers and technology licensing are used to gain access to proprietary additive manufacturing platforms.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Material type trends

- 2.2.2 Application trends

- 2.2.3 Technology trends

- 2.2.4 End use trends

- 2.2.5 Equipment scale trends

- 2.2.6 Regional

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and Innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Price trends

- 3.8.1 By region

- 3.8.2 By material type

- 3.9 Future market trends

- 3.10 Technology and Innovation landscape

- 3.10.1 Current technological trends

- 3.10.2 Emerging technologies

- 3.11 Patent Landscape

- 3.12 Trade statistics (HS code)

( Note: the trade statistics will be provided for key countries only

- 3.12.1 Major importing countries

- 3.12.2 Major exporting countries

- 3.13 Sustainability and environmental aspects

- 3.13.1 Sustainable practices

- 3.13.2 Waste reduction strategies

- 3.13.3 Energy efficiency in production

- 3.13.4 Eco-friendly initiatives

- 3.14 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Material Type, 2021-2034 (USD Million) (Units)

- 5.1 Key trends

- 5.2 Thermoplastic polymers

- 5.2.1 PLA (polylactic acid) and bio-based thermoplastics

- 5.2.2 ABS (acrylonitrile butadiene styrene) and engineering plastics

- 5.2.3 PETG (polyethylene terephthalate glycol) and specialty polymers

- 5.2.4 High-performance engineering plastics (PEEK, PEI, PEKK)

- 5.3 Fiber-reinforced composites

- 5.3.1 Carbon fiber reinforced polymers (CFRP)

- 5.3.2 Glass fiber reinforced polymers (GFRP)

- 5.3.3 Natural fiber reinforced composites

- 5.3.4 Continuous fiber reinforcement systems

- 5.4 Sustainable and bio-based materials

- 5.4.1 Bio-based polymer formulations

- 5.4.2 Recycled content and post-consumer materials

- 5.4.3 Biodegradable and compostable polymers

- 5.4.4 Waste-derived and circular economy materials

- 5.5 Specialty and functional materials

- 5.5.1 Fire-resistant and flame-retardant polymers

- 5.5.2 Thermal insulation and energy-efficient materials

- 5.5.3 Conductive and smart material systems

- 5.5.4 Multi-functional and hybrid material solutions

- 5.6 Emerging and advanced materials

- 5.6.1 Nanocomposite and enhanced performance materials

- 5.6.2 Shape memory and responsive polymer systems

- 5.6.3 Self-healing and adaptive material technologies

- 5.6.4 Biomimetic and nature-inspired material solutions

Chapter 6 Market Estimates and Forecast, By Application, 2021-2034 (USD Million) (Units)

- 6.1 Key trends

- 6.2 Residential construction

- 6.3 Commercial construction

- 6.4 Infrastructure and civil engineering

- 6.5 Architectural and decorative elements

- 6.6 Specialty and niche applications

Chapter 7 Market Estimates and Forecast, By Technology, 2021-2034 (USD Million) (Units)

- 7.1 Key trends

- 7.2 Large-scale fused deposition modelling (FDM)

- 7.3 Robotic construction systems

- 7.4 Continuous manufacturing technologies

- 7.5 Emerging and advanced technologies

Chapter 8 Market Estimates and Forecast, By End Use, 2021-2034 (USD Million) (Units)

- 8.1 Key trends

- 8.2 Construction companies and general contractors

- 8.3 Architects and design professionals

- 8.4 Real estate developers and building owners

- 8.5 Research and educational institutions

- 8.6 Government and public sector

Chapter 9 Market Estimates and Forecast, By Equipment Scale, 2021-2034 (USD Million) (Units)

- 9.1 Key trends

- 9.2 Large-scale industrial systems

- 9.3 Medium- scale industrial systems

- 9.4 Compact and portable systems

- 9.5 Hybrid and multi-technology systems

Chapter 10 Market Estimates and Forecast, By Region, 2021-2034 (USD Million) (Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Spain

- 10.3.5 Italy

- 10.3.6 Rest of Europe

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.4.6 Rest of Asia Pacific

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.5.4 Rest of Latin America

- 10.6 Middle East and Africa

- 10.6.1 Saudi Arabia

- 10.6.2 South Africa

- 10.6.3 UAE

- 10.6.4 Rest of Middle East and Africa

Chapter 11 Company Profiles

- 11.1 Arkema

- 11.2 BASF SE

- 11.3 Coex 3D

- 11.4 Covestro

- 11.5 Manlon Polymers

- 11.6 Mighty Buildings

- 11.7 MudBots

- 11.8 Sika AG

- 11.9 Skanska AB

- 11.10 Tvasta Manufacturing Solutions