|

시장보고서

상품코드

1801813

적층 제조용 하이브리드 복합재료 시장 : 기회, 성장 촉진요인, 산업 동향 분석 및 예측(2025-2034년)Hybrid Composite for Additive Manufacturing Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

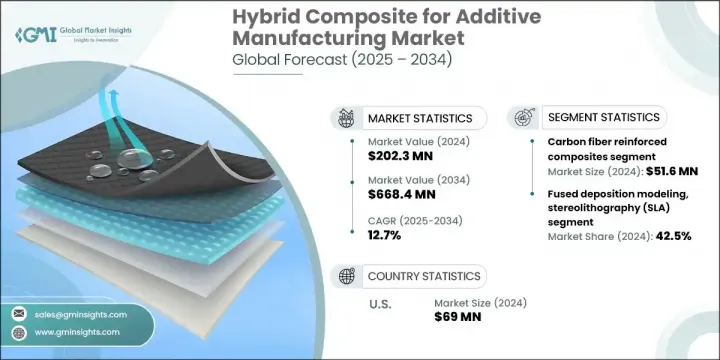

세계의 적층 제조용 하이브리드 복합재료 시장은 2024년에는 2억 230만 달러에 달하고, CAGR 12.7%로 성장할 전망이며 2034년에는 6억 6,840만 달러에 이를 것으로 예측되고 있습니다.

이 시장은 정밀성과 효율성을 갖춘 복잡하고 가벼우며 고강도 부품에 대한 수요 증가로 급속히 발전하고 있습니다. 적층 제조용 하이브리드 복합재료는 전통적인 절삭 가공법과 적층 기술을 결합하여 엄격한 품질 및 강도 요건을 충족하는 정교한 구조물을 생산합니다. 그 용도는 특히 우수한 표면 마감, 복잡한 형상, 최적화된 기계적 성능을 요구하는 부품을 필요로 하는 여러 고수요 산업에 걸쳐 있습니다.

항공우주, 의료, 자동차 산업이 이러한 성장을 촉진하고 있습니다. 특히 항공 분야에서는 연료 효율적이고 경량화된 부품에 대한 집중으로 인해 제조업체들이 지속가능성 목표와 배출 규제를 충족시키기 위해 하이브리드 적층 제조에 대규모 투자를 진행하고 있습니다. 또한 정부가 녹색 기술 이니셔티브를 지속적으로 장려함에 따라 시장이 주목받고 있습니다. 환경 기준이 강화됨에 따라 하이브리드 제조는 전 세계 지속가능성 노력과 부합하는 신뢰할 수 있는 솔루션을 제공하면서 제조 속도와 재료 효율성을 향상시킵니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시작 금액 | 2억230만 달러 |

| 예측 금액 | 6억 6,840만 달러 |

| CAGR | 12.7% |

탄소섬유 강화 복합재료는 2024년에는 5,160만 달러의 뛰어난 강도 대 중량비와 탄력성으로 이 분야를 선도합니다. 경량이면서도 내구성이 뛰어난 부품이 요구되는 산업에서 특히 두드러진 우위를 보이며, 제조업체들이 높아지는 연비 및 성능 기준을 충족하는 데 기여하고 있습니다. 이러한 복합재는 고급 스포츠 장비, 자동차 성능 부품, 항공우주 구조 부품과 같은 용도에서 핵심 소재로 자리매김하고 있습니다.

융착 적층 모델링(FDM) 및 스테레오리소그래피(SLA)와 같은 기술은 2024년 시장 점유율 42.5%를 차지했습니다. FDM은 비용 효율성, 다용도성, 다양한 분야에서의 사용 편의성 덕분에 인기를 지속하고 있습니다. FDM은 프로토타입 및 최종 사용 부품의 신속한 생산을 가능하게 하여 자동차, 의료, 산업용 공구 등 신속한 설계 반복을 중시하는 산업에 이상적입니다.

미국의 적층 제조용 하이브리드 복합재료 시장 규모는 2024년 6,900만 달러를 창출했습니다. 고급 제조의 견고한 생태계와 최종 사용 부문의 강력한 입지를 바탕으로 미국은 하이브리드 복합재의 혁신과 채택의 중심지가 되었습니다. 지속 가능한 소재에 대한 정부 지원, 청정 기술에 대한 집중도 증가, 향후 제조 이니셔티브에 대한 자금 지원이 미국 내 시장 발전을 주도하는 핵심 촉진 요인입니다.

적층 제조용 하이브리드 복합재료 시장의 주요 기업은 SGL Carbon, Arris Composites, Ultimaker, EOS, 3D Systems, Hewlett-Packard, Formlabs, Markforged, Phillips, Stratasys를 포함합니다. 주요 업체들은 속도, 정확도, 소재 다양성을 균형 있게 제공하는 솔루션을 제공하기 위해 기존 3D 프린팅 플랫폼에 하이브리드 기능을 통합하는 데 주력하고 있습니다. OEM 및 최종 사용 산업과의 전략적 파트너십은 제조업체들이 항공우주 및 자동차 분야에서 용도별 부품을 공동 개발하는 데 도움을 주고 있습니다. 기업들은 또한 강화 폴리머 및 탄소 기반 복합재료와 같은 향후 소재 개발을 위해 연구개발 투자를 확대하고 있습니다. 지속 가능한 제품 라인으로의 확장 및 친환경 규정 준수는 환경 의식이 높은 부문을 공략하기 위한 다른 주요 전략입니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 공급자의 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 주는 요인

- 혁신

- 업계에 미치는 영향요인

- 성장 촉진요인

- 업계의 잠재적 위험 및 과제

- 시장 기회

- 성장 가능성 분석

- 규제 상황

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- Porter's Five Forces 분석

- PESTEL 분석

- 기술과 혁신 미래

- 현재의 기술 동향

- 신흥기술

- 가격 동향

- 지역별

- 소재별

- 장래 시장 동향

- 기술과 혁신 미래

- 현재의 기술 동향

- 신흥기술

- 특허 상황

- 무역 통계(HS코드)

(참고 : 무역 통계는 주요 국가에서만 제공됩니다)

- 주요 수입국

- 주요 수출국

- 지속가능성과 환경 측면

- 지속가능한 관행

- 폐기물 감축 전략

- 생산 에너지 효율

- 친환경 이니셔티브

- 탄소발자국의 고려

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 지역별

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

- 지역별

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 주요 발전

- 합병과 인수

- 파트너십 및 협업

- 신제품 발매

- 확장 계획

제5장 시장 추계 및 예측 : 재료별(2021-2034년)

- 주요 동향

- 탄소섬유 강화 복합재료

- 유리 섬유 강화 복합재료

- 금속-폴리머 하이브리드 복합재료

- 세라믹 매트릭스 복합재료

- 아라미드 섬유 복합재

- 천연섬유 하이브리드 복합재

제6장 시장 추계 및 예측 : 기술별(2021-2034년)

- 주요 동향

- 융착 적층 모델링(FDM)

- 스테레오 리소그래피(SLA) 및 디지털 광처리(DLP)

- 선택적 레이저 소결(SLS)

- 하이브리드 제조 시스템

제7장 시장 추계 및 예측 : 용도별(2021-2034년)

- 주요 동향

- 항공우주 및 방위

- 상업용 항공 부품

- 군사 및 방위

- 우주 및 위성 시스템

- eVTOL과 도시형 항공 모빌리티

- 자동차산업

- 전기자동차 부품

- 하이브리드 자동차 용도

- 고성능 및 레이스 용도

- 공구 및 제조 지원

- 의료 및 헬스케어

- 의지장비

- 수술기구

- 의료기기 부품

- 치과용도

- 산업 및 제조업

- 공구와 지그

- 최종 용도 부품 생산

- 시작과 개발

- 소비재 및 스포츠 용품

- 에너지와 재생에너지 응용

- 풍력에너지 부품

- 태양광 패널

- 에너지 저장 시스템

제8장 시장 추계 및 예측 : 지역별(2021-2034년)

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 독일

- 영국

- 프랑스

- 스페인

- 이탈리아

- 기타 유럽

- 아시아태평양

- 중국

- 인도

- 일본

- 호주

- 한국

- 기타 아시아태평양

- 라틴아메리카

- 브라질

- 멕시코

- 아르헨티나

- 기타 라틴아메리카

- 중동 및 아프리카

- 사우디아라비아

- 남아프리카

- 아랍에미리트(UAE)

- 기타 중동 및 아프리카

제9장 기업 프로파일

- 3D Systems

- Arris Composites

- EOS

- Formlabs

- Hewlett-Packard

- Markforged

- Philips

- SGL Carbon

- Stratasys

- Ultimaker

The Global Hybrid Composite for Additive Manufacturing Market was valued at USD 202.3 million in 2024 and is estimated to grow at a CAGR of 12.7% to reach USD 668.4 million by 2034. This market is advancing rapidly due to the increasing need for manufacturing complex, lightweight, and high-strength components with precision and efficiency. Hybrid composite additive manufacturing brings together traditional subtractive methods with additive techniques to produce intricate structures that meet rigorous quality and strength requirements. Its applications span across several high-demand sectors, especially those that require parts with superior surface finish, complex geometries, and optimized mechanical performance.

Industries such as aerospace, healthcare, and automotive are driving this growth. In aviation, particularly, the focus on fuel-efficient, lightweight parts has pushed manufacturers to invest heavily in hybrid AM to meet sustainability goals and emission regulations. The market is also gaining traction as governments continue to encourage green technology initiatives. As environmental standards tighten, hybrid manufacturing offers a reliable solution that aligns with global sustainability efforts, while enhancing manufacturing speed and material efficiency.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $202.3 Million |

| Forecast Value | $668.4 Million |

| CAGR | 12.7% |

Carbon fiber-reinforced composites led the segment with USD 51.6 million in 2024 due to their excellent strength-to-weight ratio and resilience. Their dominance is especially visible in industries that demand lightweight yet durable components, helping manufacturers meet rising fuel economy and performance standards. These composites are becoming foundational in applications like high-end sporting gear, automotive performance parts, and structural aerospace components.

Technologies like fused deposition modeling and stereolithography collectively held 42.5% of the market in 2024. Fused deposition modeling (FDM) continues to gain popularity thanks to its cost-effectiveness, versatility, and ease of use across multiple sectors. FDM enables faster production of prototypes and End use parts, making it ideal for industries that prioritize rapid design iterations, including automotive, healthcare, and industrial tooling.

United States Hybrid Composite for Additive Manufacturing Market generated USD 69 million in 2024. With a robust ecosystem of advanced manufacturing and a strong presence of End use sectors, the U.S. has become a hotspot for innovation and adoption of hybrid composites. Government support for sustainable materials, increased focus on clean tech, and funding for next-gen manufacturing initiatives are key drivers pushing market development in the country.

Leading players in the Hybrid Composite for Additive Manufacturing Market include SGL Carbon, Arris Composites, Ultimaker, EOS, 3D Systems, Hewlett-Packard, Formlabs, Markforged, Phillips, and Stratasys. Major players are focusing on integrating hybrid capabilities into their existing 3D printing platforms to offer solutions that balance speed, accuracy, and material versatility. Strategic partnerships with OEMs and End use industries are helping manufacturers co-develop application-specific components in aerospace and automotive. Companies are also increasing R&D investment to develop next-generation materials like reinforced polymers and carbon-based composites. Expansion into sustainable product lines and compliance with green regulations are other major strategies to appeal to eco-conscious sectors.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Material trends

- 2.2.2 Technology trends

- 2.2.3 Application trends

- 2.2.4 Regional trends

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter’s analysis

- 3.6 PESTEL analysis

- 3.7 Technology and innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Price trends

- 3.8.1 By region

- 3.8.2 By material

- 3.9 Future market trends

- 3.10 Technology and innovation landscape

- 3.10.1 Current technological trends

- 3.10.2 Emerging technologies

- 3.11 Patent landscape

- 3.12 Trade statistics (HS code)

( Note: the trade statistics will be provided for key countries only)

- 3.12.1 Major importing countries

- 3.12.2 Major exporting countries

- 3.13 Sustainability and environmental aspects

- 3.13.1 Sustainable practices

- 3.13.2 Waste reduction strategies

- 3.13.3 Energy efficiency in production

- 3.13.4 Eco-friendly initiatives

- 3.14 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Material, 2021-2034 (USD Million) (Kilo Tons)

- 5.1 Key trends

- 5.2 Carbon fiber reinforced composites

- 5.3 Glass fiber reinforced composites

- 5.4 Metal-polymer hybrid composites

- 5.5 Ceramic matrix composites

- 5.6 Aramid fiber composites

- 5.7 Natural fiber hybrid composites

Chapter 6 Market Estimates and Forecast, By Technology, 2021-2034 (USD Million) (Kilo Tons)

- 6.1 Key trends

- 6.2 Fused deposition modeling

- 6.3 Stereolithography (SLA) and digital light processing (DLP)

- 6.4 Selective laser sintering (SLS)

- 6.5 Hybrid manufacturing systems

Chapter 7 Market Estimates and Forecast, By Application, 2021-2034 (USD Million) (Kilo Tons)

- 7.1 Key trends

- 7.2 Aerospace and defense

- 7.2.1 Commercial aviation components

- 7.2.2 Military and defense applications

- 7.2.3 Space and satellite systems

- 7.2.4 eVTOL and urban air mobility

- 7.3 Automotive industry

- 7.3.1 Electric vehicle components

- 7.3.2 Hybrid vehicle applications

- 7.3.3 Performance and racing applications

- 7.3.4 Tooling and manufacturing aids

- 7.4 Medical and healthcare

- 7.4.1 Prosthetics and orthotics

- 7.4.2 Surgical instruments

- 7.4.3 Medical device components

- 7.4.4 Dental applications

- 7.5 Industrial and manufacturing

- 7.5.1 Tooling and fixtures

- 7.5.2 End use parts production

- 7.5.3 Prototyping and development

- 7.6 Consumer goods and sports equipment

- 7.7 Energy and renewable applications

- 7.7.1 Wind energy components

- 7.7.2 Solar panel applications

- 7.7.3 Energy storage systems

Chapter 8 Market Estimates and Forecast, By Region, 2021-2034 (USD Million) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 3D Systems

- 9.2 Arris Composites

- 9.3 EOS

- 9.4 Formlabs

- 9.5 Hewlett-Packard

- 9.6 Markforged

- 9.7 Philips

- 9.8 SGL Carbon

- 9.9 Stratasys

- 9.10 Ultimaker