|

시장보고서

상품코드

1687796

MEMS 압력 센서 시장 : 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)MEMS Pressure Sensors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

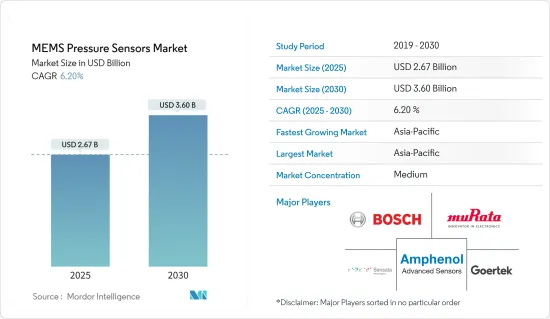

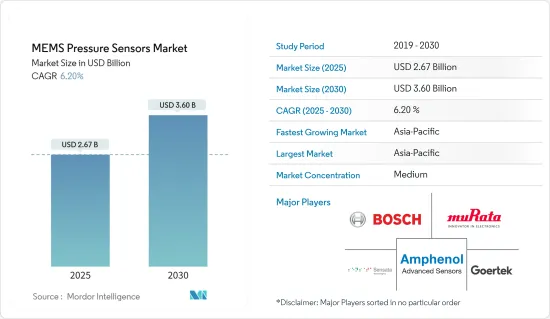

세계의 MEMS 압력 센서 시장 규모는 2025년 26억 7,000만 달러로 추정되며, 예측기간 중(2025-2030년) CAGR 6.2%를 나타낼 전망이며, 2030년에는 36억 달러에 달할 것으로 예측되고 있습니다.

산업 자동화와 웨어러블 및 IoT 연결 장치 등 각 지역에서 소형화된 소비자용 장치에 대한 수요가 MEMS 압력 센서 시장을 견인하는 중요한 요소 중 하나가 되었습니다.

주요 하이라이트

- MEMS 센서는 정밀도나 신뢰성 등의 이점에 더해, 전자 디바이스의 소형화가 가능하기 때문에 각 분야에서 인기를 모으고 있어 최근 몇 년간 큰 견인력이 되고 있습니다. 산업 자동화와 웨어러블 기기, IoT 접속 기기 등 각 지역에서 소형화된 소비자용 기기 수요는 MEMS 압력 센서 시장을 견인하는 중요한 요인 중 하나입니다.

- 또한 현재 안전성, 쾌적성, 엔터테인먼트 향상에 중점을 둔 기술 전환기를 맞이하고 있는 자동차 산업은 MEMS 압력 센서에 충분한 기회를 제공합니다. 자율주행차, 드론, AR/VR 기기 등 센서가 풍부한 용도의 출현은 MEMS 압력 센서의 요구를 더욱 가속화합니다.

- 게다가 MEMS 기술은 소형화, 비용 효율성, 신뢰성 있는 센서를 가능하게 하며, 그 일부는 고온과 혹독한 환경에도 견디며 반도체 디바이스의 범위를 확대하고 있습니다. 이러한 MEMS 디바이스의 다양성과 제조와 관련된 다양한 기술은 설계에서 테스트에 이르기까지 복잡하지만 지속 가능한 공급망을 형성합니다.

- 인터페이스는 센서 기반 시스템 설계에서 가장 심각한 문제의 원인이 되었습니다. 센서 인터페이스와 관련된 여러 가지 장애는 설계 및 제조를 복잡하게 하기에 충분합니다. 부품을 분리하고 서로 다른 실장간에 재사용을 가능하게 하는데 매우 귀중하지만, 설계 및 제조를 어렵게 하기에 충분합니다. 실제로 Fierce Electronics가 최근에 실시한 센서 설계에 대한 조사는 응답자의 3분의 1 이상이 센서를 계획에 통합하는 것이 가장 어려운 문제라고 대답합니다. 이것은 시장의 성장을 방해할 것으로 예상됩니다.

- 게다가 COVID-19의 대유행은 2020년과 2021년 MEMS 압력 센서 시장에 타격을 주었고, MEMS 압력 센서는 약간 떨어지는 결과를 낳았습니다. 그러나 COVID-19 팬데믹 이후, 조사된 시장은 성장할 가능성이 높으며, 제한의 용이성은 소비자가 IoT 지원 장치에 대한 지출을 결정하기 위해 끌려가며, 대부분은 MEMS 압력 센서를 포함합니다.

MEMS 압력 센서 시장 동향

자동화와 인더스트리 4.0의 출현이 시장을 견인

- 스마트 산업을 지원하는 MEMS의 주요 특징은 정확성, 신뢰성, 수명입니다. Industry 4.0에서 MEMS 센서는 진동, 온도, 압력, 소리 및 음향 분석이 필요한 조기 고장 감지 및 예보 유지 보수 시스템에 적용될 수 있으므로 자동화 및 Industry 4.0 용도에서의 사용을 촉진합니다.

- Industry 4.0과 IoT 도입으로 인한 제조업의 큰 변화는 기업이 자동화를 통해 인간 노동을 보완하고 확장하고 공정 실패로 인한 노동재해를 줄이는 기술로 생산을 전진시키기 위해 유연하고 창조적인 전략을 채택해야 합니다. 커넥티드 디바이스와 센서가 널리 채용되고 M2M 통신이 촉진됨에 따라 제조업에서 생성되는 데이터 포인트의 수가 증가하고 있습니다.

- 또한 다양한 산업에서 자동화 도입이 진행됨에 따라 산업용 로봇에 대한 관심이 크게 높아지고 있습니다. 국제로봇연맹(IFR)의 추계에 따르면 2020년 세계 산업용 로봇 출하 대수는 약 38만 4,000대에 달하고, 2019년부터 약간 증가하는 데 그쳤습니다. 산업용 로봇의 출하 대수는 향후 수년간 급증할 것으로 예상되며, 피크였던 2018년(세계에서 약 42만 2,000대)을 상회할 가능성도 있습니다. 산업용 로봇의 세계 출하 대수는 2024년에는 51만 8,000대에 달할 것으로 예측되고 있습니다.

- 산업용 로봇은 다양한 작업을 위해 점점 더 많은 산업에서 사용되고 있습니다. 2020년에는 고도로 자동화된 자동차 산업이 계속 전기 기계의 최대 시장 중 하나임에도 불구하고 전기 및 전자산업이 가장 많은 산업용 로봇을 도입하고 있습니다. 이러한 산업용 로봇 증가는 MEMS 압력 센서 수요를 세계적으로 밀어올릴 것으로 보입니다.

- 또한 Cisco에 따르면 2022년까지 IoT 용도을 지원하는 M2M(Machine-to-Machine) 연결이 전 세계 연결 장비 285억대의 절반 이상을 차지할 것으로 예상됩니다. 세계 제조업체들은 차세대 로봇 공학 및 자동화 기술이 생산성, 품질, 안전성 및 비용 지표 측면에서 제조업을 업그레이드할 수 있는 획기적인 기회임을 알고 있습니다. 또한 매년 증가하는 로봇 자동화 지출은 주로 조사 대상 시장의 범위를 확대하고 있습니다.

아시아태평양이 주요 시장 점유율을 차지

- 아시아태평양은 제조업의 중심지로 알려져 있으며 빠르게 성장하고 있습니다. 자동차 산업에서는 더 많은 안전 규정이 필요합니다. 스마트폰, 스마트 디바이스, 가정용 전자 기기에 MEMS 압력 센서가 널리 사용되고 있기 때문에 소비자용 전자 기기 분야가 이 지역의 MEMS 압력 센서 시장을 독점할 것으로 예측되고 있습니다.

- 또한 아시아태평양의 자동차 산업은 세계 최대 규모의 규모를 자랑하고 있으며 지난 수십년동안 소규모 정부 관리 부문에서 대규모 다국적 기업이 관리하는 부문으로 성장했습니다. 한국에는 Kia, Hyundai, Renault 등 대기업이 있어 자동차 수요의 꾸준한 성장이 전망되고 있습니다. 이러한 자동차의 성장은 이 지역에서 MEMS 압력 센서 수요를 증가시킬 것입니다.

- MEMS 압력 센서는 안전성, 쾌적성, 엔터테인먼트성 향상을 주요 목표로 하여 기술적 변혁이 진행되는 자동차 산업에서 다양한 용도가 있습니다. 이러한 센서는 MEMS와 마찬가지로 소형이기 때문에 자동차 산업에서 높은 수요가 있으며, 이것이 널리 채용되는 주요 요인이 되고 있습니다.

- 자동차 산업은 압력 센서 시장의 상당 부분을 차지하기 때문에 이 지역은 앞으로 몇 년동안 절호의 기회를 제공합니다. MEMS 압력 센서의 채용은 커넥티드카의 사고방식의 확산과 자동차 안전에 관한 중국의 규제에도 영향을 받을 것으로 예상됩니다.

- 향후 수년간 기술개척 확대, 대규모 IoT 채용, 정부의 제품촉진 규제 등이 압력 센서 시장의 성장에 기여하게 될 것입니다. 그러나 압력 센서 시장은 높은 규제 장벽으로 인해 추가 과제에 직면 할 수 있습니다.

MEMS 압력 센서 산업 개요

MEMS 압력 센서 시장은 후방 및 전방 통합이 가능한 많은 대규모 벤더로 구성되어 있으며, 큰 수익 창출 능력을 가지고 있습니다. 시장은 비교적 통합되어 벤더는 기술력과 타사에 대한 경쟁력을 얻기 위해 연구개발에 대한 지출을 늘리고 있습니다. 시장 벤더는 기술과 품질로 경쟁하지만 가격은 경쟁하지 않습니다. 시장에서 경쟁업체들 간의 적대관계는 중간 정도로 강하고 앞으로 수년간 강해질 것으로 예상됩니다.

- 2022년 7월 - Bosch Sensortec는 Edge Impulse의 머신러닝 플랫폼이 Arduino NiclaSense ME 마이크로 컴퓨터의 센서를 지원한다고 발표했습니다. 이 회사의 발표에 따르면 최초의 Arduino Pro 제품은 Bosch Sensortec와의 제휴에 의해 개발된 것으로 Bosch Sensortec가 제공하는 센서는 압력 센서 BMP390을 이용하여 수많은 고정밀 데이터 수집 및 분석 방법을 제공합니다.

- 2022년 2월 - 마이크로 전기 기계 시스템(MEMS)의 제조업체인 STMicroelectronics는 3세대 MEMS 센서를 출시합니다. 이 새로운 센서는 개인용 모바일 기기, 지능형 산업, 의료 및 소매용으로 성능과 기능을 획기적으로 향상시킵니다. 판매자는 곧 2.8mm x 2.8mm x 1.95mm 7 리드 LGA의 LPS28DFW 압력 센서와 2.0mm x 2.0mm x 0.73mm 10 리드 LGA 패키지의 LPS22DF 압력 센서를 구입할 수 있습니다.

기타 혜택:

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트 서포트

목차

제1장 서론

- 조사의 전제조건과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 인사이트

- 시장 개요

- 업계의 매력도 - Porter's Five Forces 분석

- 공급기업의 협상력

- 구매자의 협상력

- 신규 참가업체의 위협

- 대체품의 위협

- 경쟁 기업간 경쟁 관계

- 업계 밸류체인 분석

- 기술 스냅샷

- 시장에 대한 COVID-19의 영향 평가

- MEMS 압력 센서에 있어서의 파릴렌 사용의 개요

제5장 시장 역학

- 시장 성장 촉진요인

- 자동화와 인더스트리 4.0의 출현

- 센서 리치 용도 수요 증가

- 시장 성장 억제요인

- 여러 인터페이스에 대한 복잡성

제6장 시장 세분화

- 용도별

- 의료

- 자동차

- 산업용

- 항공우주 및 방위

- 컨슈머 일렉트로닉스

- 유형별

- 실리콘압저항

- 실리콘 정전 용량식

- 지역별

- 북미

- 유럽

- 아시아태평양

- 라틴아메리카

- 중동 및 아프리카

제7장 경쟁 구도

- 기업 프로파일

- Bosch Sensortec GmbH

- Murata Manufacturing Co. Ltd

- Amphenol Advanced Sensors(Amphenol Corporation)

- Sensata Technologies Inc.

- Goertek INC.

- STMicroelectronics NV

- Omron Corporation

- Alps Alpine Co. Ltd

- Infineon Technologies AG

- TE Connectivity Ltd

- NXP Semiconductors NV(Freescale)

- InvenSense Inc.(TDK Corporation)

- ROHM Co. Ltd

- Honeywell International Inc.

- Melexis

- Vendor Ranking for the Top 5 Vendors Across the End-user Verticals

- 2021년 상위 15개사의 벤더의 시장 점유율

제8장 투자 분석

제9장 시장의 미래

JHS 25.04.01The MEMS Pressure Sensors Market size is estimated at USD 2.67 billion in 2025, and is expected to reach USD 3.60 billion by 2030, at a CAGR of 6.2% during the forecast period (2025-2030).

Industrial automation and demand for miniaturized consumer devices across regions, such as wearables and IoT-connected devices, are among the significant factors driving the MEMS pressure sensors market.

Key Highlights

- MEMS sensors are gaining popularity across sectors, due to their advantages, such as accuracy and reliability, in addition to the scope for making smaller electronic devices, which have gained significant traction in the past few years. Industrial automation and demand for miniaturized consumer devices across regions, such as wearables and IoT-connected devices, are among the crucial factors driving the MEMS pressure sensors market.

- Also, The automotive industry, which is presently undergoing a technology transition with a significant focus on increasing safety, comfort, and entertainment, provides ample opportunities for MEMS pressure sensors. Emerging sensor-rich applications, such as autonomous vehicles, drones, and AR/VR equipment, further accelerate the need for MEMS pressure sensors.

- In addition, MEMS technologies have enabled miniaturized, cost-effective, and reliable sensors, some of which can withstand high temperatures and harsh environments, expanding the scope of semiconductor devices. Such diversity in MEMS devices and the different technologies involved in their manufacture have led to a complex but sustainable supply chain, from design to testing.

- The interfaces are a source of some of the most severe issues in the design of sensor-based systems. The multiple obstacles connected with sensor interfaces are enough to make design and manufacture complicated. While invaluable for decoupling parts and allowing reuse across different implementations, they are enough to make design and manufacturing difficult. Indeed, more than a third of respondents in a recent Fierce Electronics study on sensor design said that incorporating sensors into a plan is their most demanding issue. This is expected to challenge the market's growth.

- Moreover, the COVID-19 pandemic hurt the MEMS pressure sensors market in 2020 and 2021, which resulted in a slight drop in the MEMS pressure sensors. However, the market studied is likely to grow after the COVID-19 pandemic; the ease of restrictions attracted consumers to make spending decisions on IoT-enabled devices, which mostly come with MEMS pressure sensors.

MEMS Pressure Sensors Market Trends

Emergence of Automation and Industry 4.0 to Drive the Market

- MEMS's key features to support the smart industry are accuracy, reliability, and longevity. For Industry 4.0, MEMS sensors can be applied in early-failure-detection and predictive-maintenance systems where vibration, temperature, pressure, sound, and acoustics analyses are needed, thus, driving its usage in automation and Industry 4.0 applications.

- Massive changes in the manufacturing industry brought by Industry 4.0 and the adoption of IoT demand that businesses adopt flexible and creative strategies to advance production with technologies that complement and augment human labor with automation and lower industrial accidents brought on by process failure. There has been an increase in the number of data points generated in the manufacturing sector as a result of the widespread adoption of connected devices and sensors and the facilitation of M2M communication.

- In addition, the increased adoption of automation across a variety of industries has significantly increased interest in industrial robotics. The International Federation of Robotics (IFR) estimates that industrial robot shipments worldwide reached about 384,000 in 2020, only slightly up from 2019. Industrial robot shipments are anticipated to rise sharply in the years to come, possibly even exceeding the peak year of 2018, when about 422,000 industrial robots were shipped globally. Global shipments of industrial robots are predicted to reach 518,000 units in 2024.

- Industrial robots can be used in a growing number of industries for a variety of tasks. The electrical and electronic industries installed the most industrial robots in 2020, despite the highly automated auto industry continuing to be one of the largest markets for electro-mechanical machines. Such a rise in industrial robots would also boost the demand for MEMS pressure sensors globally.

- Additionally, According to Cisco, by 2022, machine-to-machine (M2M) connections that support IoT applications are expected to account for over half of the world's 28.5 billion connected devices. Manufacturers worldwide also understand that the next generation of robotics and automation technologies is a revolutionary opportunity to upgrade manufacturing in terms of productivity, quality, safety, and cost metrics. Also, increased year-on-year robotic automation expenditure mainly expands the scope of the studied market.

Asia Pacific to Hold Major Market Share

- Asia-Pacific is a well-known manufacturing hub and rapidly growing. There is a need for more safety regulations in the automotive industry. Due to the widespread use of MEMS pressure sensors in smartphones, smart devices, and home electronics, the consumer electronics segment is predicted to dominate the regional MEMS pressure sensor market.

- Additionally, Asia pacific automotive industry is among the largest worldwide, growing from a small government-controlled sector to one controlled by large multinational enterprises over the past few decades. South Korea is home to major players like Kia, Hyundai, and Renault, and it is expected to witness steady growth in the demand for automobiles. Such growth in automobiles will increase demand for MEMS pressure sensors in the region.

- MEMS pressure sensors have a variety of applications in the automotive industry, which is currently undergoing a technological transformation with the primary goal of enhancing safety, comfort, and entertainment. These sensors, like MEMS, are in high demand in the automotive industry due to their small size, which is a key driver of their widespread adoption.

- Since the automotive sector accounts for a sizable portion of the pressure sensor market, the region presents an excellent opportunity over the coming years. The adoption of MEMS pressure sensors is also anticipated to be influenced by the expanding idea of connected cars and Chinese regulations regarding automotive safety.

- In the upcoming years, expanding technological development, IoT adoption on a large scale, pro-product government regulations, and more will all contribute to the growth of the pressure sensors market. However, the market for pressure sensors may face additional challenges due to high regulatory barriers.

MEMS Pressure Sensors Industry Overview

The MEMS pressure sensor market comprises many large-scale vendors capable of both backward and forward integration and commands significant revenue generation capabilities. The market is relatively consolidated, and vendors are increasingly spending on R&D to gain technological capabilities and a competitive edge over other companies. The vendors in the market are competing on technology and quality but not on price. The intensity of competitive rivalry in the market is moderately high and is expected to increase over the coming years.

- July 2022 - Bosch Sensortec announced that Edge Impulse's machine-learning platform supports its sensors on the Arduino NiclaSense ME microcontroller. According to the company's announcement, the first Arduino Pro product was created in association with Bosch Sensortec, in which sensors offered by Bosch Sensortec offer numerous high-accuracy data collection and analysis methods by utilizing the pressure sensor BMP390.

- February 2022 - STMicroelectronics manufacturer of micro-electro-mechanical systems (MEMS), is releasing its third generation of MEMS sensors. The new sensors offer the next jump in performance and features for consumer mobile devices, intelligent industries, healthcare, and retail. Distributors will soon be able to purchase the LPS28DFW pressure sensor in a 2.8mm x 2.8mm x 1.95mm 7-lead LGA and the LPS22DF pressure sensor in a 2.0mm x 2.0mm x 0.73mm 10-lead LGA package.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Technology Snapshot

- 4.5 Assessment of Impact of COVID-19 on the Market

- 4.6 Overview of the Use of Parylene in the MEMS Pressure Sensors

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Emergence of Automation and Industry 4.0

- 5.1.2 Increasing Demand for Sensor-rich Applications

- 5.2 Market Restraints

- 5.2.1 Complexity Regarding Multiple Interface

6 MARKET SEGMENTATION

- 6.1 By Application

- 6.1.1 Medical

- 6.1.2 Automotive

- 6.1.3 Industrial

- 6.1.4 Aerospace and Defense

- 6.1.5 Consumer Electronics

- 6.2 By Type

- 6.2.1 Silicon Piezoresistive

- 6.2.2 Silicon Capacitive

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia Pacific

- 6.3.4 Latin America

- 6.3.5 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Bosch Sensortec GmbH

- 7.1.2 Murata Manufacturing Co. Ltd

- 7.1.3 Amphenol Advanced Sensors (Amphenol Corporation)

- 7.1.4 Sensata Technologies Inc.

- 7.1.5 Goertek INC.

- 7.1.6 STMicroelectronics NV

- 7.1.7 Omron Corporation

- 7.1.8 Alps Alpine Co. Ltd

- 7.1.9 Infineon Technologies AG

- 7.1.10 TE Connectivity Ltd

- 7.1.11 NXP Semiconductors NV (Freescale)

- 7.1.12 InvenSense Inc. (TDK Corporation)

- 7.1.13 ROHM Co. Ltd

- 7.1.14 Honeywell International Inc.

- 7.1.15 Melexis

- 7.2 Vendor Ranking for the Top 5 Vendors Across the End-user Verticals

- 7.3 Vendor Market Share for the Top 15 Vendors in 2021