|

시장보고서

상품코드

1521908

식품용 PCR(Post-Consumer Recycled) 포장 시장 :시장 점유율 분석, 산업 동향, 성장 예측(2024-2029년)Food-grade Post-Consumer Recycled (PCR) Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

식품용 PCR 포장 시장 규모는 출하량 기준으로 2024년 586만톤으로 추정되고, 2029년 837만톤으로 성장이 전망되며, 예측기간(2024-2029년)의 CAGR은 7.38%로 성장할 것으로 예측됩니다.

주요 하이라이트

- 에너지 사용 삭감, 배출 감축, 순환 경제 추진, 지속가능성 목표 달성, 포장 폐기물 삭감, 접촉에 민감한 용도에 대한 FDA 및 기타 규제, 규제 압력 등의 요구 증가, 식품 소비자 재활용 후 포장 솔루션 수요를 촉진하는 주요 요인입니다.

- 재활용 인프라 정비, 첨단 재활용 프로세스, 효과적인 처리 기술, 정부의 적극적인 대응으로 포장 재활용률은 세계적으로 상승하고 있습니다. 그 결과 PCR 재료의 가용성이 높아지고 있습니다. 환경청에 따르면 영국의 포장재활용 목표는 2023년 77%에 비해 2024년 말 80%를 나타낼 것으로 예상됩니다. 재활용률 증가는 식품용 PCR 포장 솔루션의 성장을 도울 것으로 예상됩니다.

- 최종사용자인 브랜드는 경쟁에서 이기고 소비자의 소비후 재활용(PCR) 포장에 대한 의식이 높아지도록 규제조치를 준수하려고 합니다. 예를 들어, 미국 음료 회사인 Keurig Dr Pepper는 2025년까지 기업의 제품 포장 및 포트폴리오 전체에서 처녀 플라스틱 사용량을 20% 줄이고 플라스틱 포장의 재활용 함량을 늘릴 것을 약속합니다.

- 포장 제조업체는 첨단 기술을 활용하여 혁신적인 접촉 감응형 PCR 포장 솔루션을 개발하고 있습니다. 또한 원료 제조업체, 공급업체 및 컨버터는 최신 재활용 기술을 채택하고 식품용 PCR 재료를 제공합니다.

- 2024년, Borealis AG는 식품 포장에 사용되는 PCR 'Borcycle M'에 대해 미국 식품의약국(FDA)으로부터 이의 없음(LNO) 통지를 받았습니다. 이 재료는 화장품, 개인 관리, 식품 접촉과 같은 포장 용도에 민감합니다. 이 회사는 혁신적인 기계 재활용 기술을 사용하여 Borcycle M 소비자 재생 플라스틱(PCR)을 개발했습니다. 이 기술은 에너지 효율적인 방식으로 소비자 사용 후 플라스틱 폐기물에 새로운 생명을 제공합니다.

- 이 외에도 플라스틱 재료의 부적절한 재활용으로 인해 더 많은 재료 가용성에 대한 필요성이 공급 문제를 야기합니다. 부적절하게 폐기된 포장재는 재활용 시 오염 문제를 일으켜 시장 성장을 방해할 수 있습니다. 재활용업체의 지속적인 노력과 EPR의 투자 증가는 재활용 회수와 인프라를 개선할 것으로 예상됩니다. 이로 인해 재료 입수에 대한 우려를 극복할 수 있을 것으로 기대됩니다.

식품용 PCR 포장 시장 동향

식품 및 식품 산업에서 재활용(PCR) 포장 솔루션 채택 증가

- 음식품은 품질을 유지하고 포장 용액과의 접촉으로 인한 화학 반응을 피하기 위해 대부분 식품 포장으로 포장됩니다. 이러한 솔루션에는 플라스틱, 유리, 금속, 종이로 만든 병, 캔, 파우치, 액체 카톤 등이 포함됩니다.

- 지속가능한 포장 솔루션에 대한 주목이 높아짐에 따라 규제와 소비자의 의식이 높아짐에 따라 브랜드 소유자는 PCR 포장 솔루션을 요구하고 있습니다. 예를 들어, 2023년 10월, Coca-Cola India는 250mL와 750mL의 rPET 병이 들어간 코카콜라를 출시했습니다. 또한 2024년 4월, Coca-Cola는 홍콩에서 rPET로 만든 500ml 병을 출시했습니다. 이 회사는 2030년까지 포장 라인 전반에 걸쳐 50%의 재생 재료를 사용하는 것을 목표로 하고 있습니다. 이는 순환형 경제와 지속가능하고 환경친화적인 미래를 향한 회사의 행보를 보여줍니다.

- 패키징 제조업체 각 회사는 확장된 비즈니스 기회를 활용하기 위해 식품 접촉 포장을 위한 혁신적인 PCR 포장 솔루션을 제공하려고 합니다. 각 회사는 식품 접촉 포장 및 접촉에 민감한 용도의 규제 요구 사항을 수용하기 위해 첨단 재활용 프로세스를 채택하는 데 주력하고 있습니다.

- 2024년 3월 Amcor Group GmbH는 INEOS Olefins & Polymers Europe 및 PepsiCo와 공동으로 PepsiCo의 스낵 브랜드 'Sunbites Crisps'의 새로운 스낵 포장을 출시했습니다. 이 새로운 포장에는 재생 플라스틱이 50% 사용됩니다. 플라스틱 에너지 기술은 소비자로부터 배출되는 플라스틱 포장 폐재를 변환합니다. 기존의 화석 원료의 대안으로 열분해 오일을 사용하여 재생 재료를 제조하고 식품 접촉 성능 요구 사항을 충족하도록 컴파일합니다.

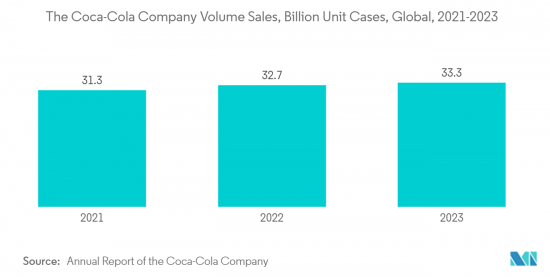

- 음료 및 식품 소비 증가와 지속 가능한 포장에 대한 브랜드의 관심은 식품 PCR 포장 솔루션의 성장을 뒷받침하고 있습니다. 음료 및 식품 브랜드의 판매 수량의 급증이 시장의 성장을 돕고 있습니다. 주요 비알코올 음료 브랜드인 Coca-Cola는 2022년에 327억 유닛 케이스를 판매한 반면, 2023년에는 333억 유닛 케이스(1 유닛 케이스는 완성 음료 192 미국 액량 온스에 상당) 을 판매했습니다.

포장 제품에 재활용률을 포함하도록 요구하는 각 지역의 규제 압력 증가

- 다양한 환경 문제로 이어지는 포장 폐기물 증가로 인해 재활용 가능, PCR 재료, 생분해성 등 지속가능한 포장 솔루션이 필요합니다. 지속가능성에 대한 우려를 극복하기 위해 유럽, 캐나다, 미국 등 다양한 지역의 정부 및 기타 규제기관은 포장 솔루션에 PCR 재료를 사용하도록 압박하고 있습니다. 이는 온실가스 배출량과 에너지 소비량을 줄여 순환형 경제에 기여합니다.

- 예를 들어, 2024년 4월 유럽 의회는 순환형 경제로의 전환에 기여하는 포장 폐기물 규칙(PPWR)을 채택했습니다. PPWR에는 시장에 나오는 플라스틱 포장재에 재활용률을 최소한 포함시키는 등 포장 솔루션에 관한 다양한 규정이 포함되어 있습니다.

- 예를 들어, 일회용 음료용 플라스틱 병은 30% PCR, 접촉에 민감한 PET 포장은 30% PCR, 접촉에 민감한 기타 플라스틱 포장은 10% PCR입니다. 이러한 최소 비율은 2040년 이후 증가합니다. 이 지역의 이러한 규정은 식품 PCR 포장 솔루션에 대한 수요를 촉진할 것으로 예상됩니다.

- 마찬가지로 캐나다 환경부 장관위원회의 플라스틱 폐기물 제로에 관한 행동 계획은 2030년까지 플라스틱 포장 제품에 50%의 재활용률을 요구한다고 명시한 규정을 승인했습니다. 그 범위에는 음료 포장 용기, 비음식 병, 기타 단단한 용기 및 트레이가 포함됩니다.

- 2023년 초, 캘리포니아, 워싱턴, 뉴저지, 메인은 플라스틱 포장재에 PCR 함량을 의무화하는 법을 통과했습니다. 캘리포니아 주 법률은 2025년까지 유리 및 플라스틱 음료 병에 25%, 2050년까지 50% PCR을 의무화, 워싱턴 주 법률에서는 2026년까지 플라스틱 음료 병에 25%, 2025년까지 플라스틱 와인과 유제품 용기에 15% PCR을 의무화했습니다.

- 식품과 접촉하는 제품은 손상을 피하기 위해 식품 포장을 의무화합니다. 식품 및 식품에 대한 PCR 재료의 사용에 대한 규정 및 규제 증가는 식품용 PCR 포장의 성장을 도울 것으로 예상됩니다.

식품용 PCR 포장 산업 개요

식품용 PCR 포장 시장은 부문화되어 있으며 다양한 세계 기업과 지역 기업이 존재합니다. 이 시장의 포장업자는 규제 압력 증가에 대응하고 지속가능성 목표를 달성하고 포장 유형에 대한 최소 PCR 함량 수요를 충족시키기 위해 식품용 PCR 포장 솔루션을 제공하려고 합니다. 시장의 주요 진출기업은 시장 점유율을 강화하고 경쟁사보다 우위를 차지하는 새로운 솔루션을 개발하고 있습니다.

- 2024년 4월, Amcor Group GmbH는 탄산청량음료(CSD)용 100% 소비자 재사용(PCR) 컨텐츠를 사용한 1리터 폴리에틸렌 테레프탈레이트(PET) 병 출시를 발표했습니다. 이 회사는 재활용 재료를 사용하여 책임있는 포장 제품 포트폴리오를 확장하고 고객이 지속가능성에 대한 헌신과 요구 사항을 충족하도록 지원하는 데 주력하고 있습니다.

- 2024년 4월, Klockner Pentaplast는 100% 재생 PET(rPET)를 사용한 식품 포장 트레이의 출시를 발표했습니다. 100% 재생 PET 식품 트레이의 출시로, 회사는 품질과 안전성을 손상시키지 않고 보다 지속가능한 포장 업계의 실현에 주력하고 있습니다.

- 2023년 12월, Novolex Holdings LLC는 소비자 재생 이용(PCR) 원료를 10% 이상 사용한 식품 포장 용기를 발표했습니다. 이 용기는 재활용 가능합니다. 신제품 출시로 회사는 환경에 미치는 영향을 줄이고 순환형 경제를 지원합니다.

기타 혜택

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트 서포트

목차

제1장 서론

- 조사의 전제조건 및 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 인사이트

- 시장 개요

- 산업 밸류체인 분석

- 업계의 매력-Porter's Five Forces 분석

- 공급기업의 협상력

- 소비자의 협상력

- 신규 진입업자의 위협

- 대체품의 위협

- 경쟁 기업간 경쟁 관계

- 지정학적 시나리오가 업계에 미치는 영향의 평가

제5장 시장 역학

- 시장 성장 촉진요인

- 지속가능성에 대한 우려를 극복하기 위한 소비자 의식의 고조 및 온실가스 배출량 감축의 필요성

- 포장제품에 리사이클율을 최소한 포함하도록 요구하는 규제압력 증가

- 시장 성장 억제요인

- 부족한 재활용 인프라는 부적절한 재료 공급 및 고가로 이어진다

제6장 시장 세분화

- 재료별

- 플라스틱

- 폴리에틸렌테레프탈레이트(PET)

- 폴리에틸렌(PE)

- 폴리프로필렌(PP)

- 기타 플라스틱

- 유리

- 금속

- 종이 및 판지

- 플라스틱

- 제품 유형별

- 병 및 용기

- 캔

- 파우치 및 봉투

- 트레이 및 클램쉘

- 기타

- 최종 사용자 산업별

- 식품

- 음료

- 퍼스널케어 및 화장품

- 의료 및 의약품

- 기타

- 지역별

- 북미

- 미국

- 캐나다

- 유럽

- 영국

- 독일

- 프랑스

- 이탈리아

- 스페인

- 아시아

- 중국

- 일본

- 인도

- 호주 및 뉴질랜드

- 라틴아메리카

- 브라질

- 아르헨티나

- 멕시코

- 중동 및 아프리카

- 사우디아라비아

- 남아프리카

- 이집트

- 북미

제7장 경쟁 구도

- 기업 프로파일

- Berry Global Group Inc.

- Amcor Group GmbH

- Novolex Holdings LLC

- Tekni-Plex Inc.

- Klockner Pentaplast

- Coveris Management GmbH

- Hoffmann Neopac AG

- Silgan Dispensing Systems(Silgan Holdings Inc.)

- Greiner Packaging International GmbH

- Avery Dennison Corporation

- Nussbaum Matzingen AG

- Gallo Glass Company

- Great Little Box Company Ltd

제8장 투자 분석

제9장 시장의 미래

AJY 24.08.08The Food-grade Post-Consumer Recycled Packaging Market size in terms of shipment volume is expected to grow from 5.86 Million tonnes in 2024 to 8.37 Million tonnes by 2029, at a CAGR of 7.38% during the forecast period (2024-2029).

Key Highlights

- The increasing need for reducing energy use, lowering emissions, promoting a circular economy, achieving sustainability targets, reducing packaging waste, FDA and other regulations for contact-sensitive applications, and regulatory pressure are the major factors propelling the demand for food-grade post-consumer recycling packaging solutions.

- Packaging recycling rates worldwide are increasing due to the development of recycling infrastructure, advanced recycling processes, effective processing techniques, and positive government response. This will result in increased availability of post-consumer recycled material. According to the Environment Agency, the packaging recycling target in the United Kingdom is expected to reach 80% by the end of 2024, compared to 77% in 2023. The increasing recycling rate is expected to aid the growth of food-grade post-consumer recycling packaging solutions.

- End-user brands are trying to adhere to regulatory measures to stay ahead of the competition and address the growing consumer awareness for post-consumer recycled packaging. For instance, Keurig Dr Pepper, an American beverage company, committed to reducing virgin plastic use by 20% across the company's product packaging portfolio by 2025 and increasing recycled content in plastic packaging.

- Packaging manufacturers are developing innovative, contact-sensitive, post-consumer recycled packaging solutions using advanced technologies. Furthermore, raw material manufacturers, providers, and converters are adopting the latest recycling technology to offer food-grade PCR material.

- In 2024, Borealis AG received letters of no objection (LNOs) from the US Food & Drug Administration (FDA) for its Borcycle M post-consumer recycled plastics (PCR) used for food-grade packaging. This material is sensitive to packaging applications, including cosmetics, personal care, and food contact. The company developed Borcycle M post-consumer recycled plastics (PCR) using transformational mechanical recycling technology. This technology offers post-consumer plastic waste another life in an energy-efficient way.

- Besides this, the need for more material availability due to the improper recycling of plastic material creates supply issues. The improperly discarded packaging material creates contamination problems during recycling, which may hamper the market's growth. The continuous effort by the recyclers and increasing investments driven by EPR are projected to improve recycling collection and infrastructure. This is expected to overcome the concern of material availability.

Food-grade Post-Consumer Recycled (PCR) Packaging Market Trends

Rising Adoption of Recycled Packaging Solutions in the Food and Beverage Industry

- Food and beverage products are mostly packed in food-grade packaging to maintain their quality and avoid any chemical reaction when in contact with the packaging solution. These solutions include bottles, cans, pouches, and liquid cartons made from plastic, glass, metal, or paper.

- Considering the increasing focus on sustainable packaging solutions, along with propelling regulation and consumer awareness, brand owners are looking for post-consumer recycled packaging solutions. For instance, in October 2023, Coca-Cola India launched Coca-Cola in 250-mL and 750-mL rPET bottles. Furthermore, in April 2024, Coca-Cola rolled out 500-ml bottles made from rPET in Hong Kong. The company aims to implement 50% recycled material across its packaging lines by 2030. This showcases the company's journey toward a circular economy and a sustainable and greener future.

- Packaging manufacturers are also trying to offer innovative post-consumer recycled packaging solutions for food contact packaging to take advantage of growing opportunities. The companies are focusing on adopting an advanced recycling process to cater to the regulatory requirements for food contact packaging and contact-sensitive applications.

- In March 2024, Amcor Group GmbH collaborated with INEOS Olefins & Polymers Europe and PepsiCo to launch a new snack packaging for PepsiCo's snack brand, Sunbites Crisps. The new packaging contains 50% recycled plastic. Post-consumer plastic packaging waste is converted using Plastic Energy's technology. Pyrolysis oil is used as an alternative to traditional fossil feedstock to produce recycled material and compile it to meet food contact performance requirements.

- The increasing consumption of food and beverage products and the brand's focus on sustainable packaging fuel the growth of food-grade post-consumer recycled packaging solutions. The surge in the unit volume sales of the beverage and food brands aids the market's growth. The major non-alcoholic beverage brand, the Coca-Cola Company, sold 33.3 billion unit cases (one unit case equal to 192 US fluid ounces of finished beverage) in 2023 compared to 32.7 billion unit cases in 2022.

Increasing Regulatory Pressure in Various Regions to Include a Minimum Percentage of Recycled Content for Packaging Products

- Increasing packaging waste, which leads to various environmental problems, has created the need for sustainable packaging solutions such as recyclable, post-consumer recycled material, biodegradable, and others. To overcome the sustainability concern, governments and other regulatory agencies in various regions, such as Europe, Canada, the United States, and others, are putting pressure on using post-consumer recycled material for packaging solutions. This would result in lower greenhouse gas emissions and lower energy consumption and contribute to a circular economy.

- For instance, in April 2024, the European Parliament adopted the Packaging and Packaging Waste Regulation (PPWR), which would contribute to the transition to a circular economy. It includes various provisions for packaging solutions, such as the requirement that any plastic packaging placed on the market contain a minimum percentage of recycled content.

- The minimum percentage of recycled content will depend upon the packaging type, such as 30% PCR for single-use plastic beverage bottles, 30% PCR for contact-sensitive PET packaging, and 10% PCR for contact-sensitive other plastic packaging. These minimum percentages would increase from 2040. Such provision in the region is expected to drive the demand for food-grade post-consumer recycled packaging solutions.

- Similarly, the Action Plan on Zero Plastic Waste by the Canadian Council of Ministers of the Environment endorsed a provision stating a 50% recycled content requirement in plastic packaging products by 2030. The scope includes beverage packaging containers, non-food bottles, and other rigid containers and trays.

- In early 2023, California, Washington, New Jersey, and Maine passed laws requiring post-consumer recycled content in plastic packaging. California's law requires 25% PCR for glass and plastic beverage bottles by 2025 and 50% by 2050, while Washington's law requires 25% PCR for plastic beverage bottles by 2026 and 15% PCR for plastic wine and dairy containers by 2025.

- Food-grade packaging is required for products that come in contact with it to avoid damage. The increasing provision and regulation over the use of post-consumer recycled material for beverage products is expected to aid the growth of food-grade post-consumer recycled packaging.

Food-grade Post-Consumer Recycled (PCR) Packaging Industry Overview

The food-grade post-consumer recycled (PCR) packaging market is fragmented, with various global and local players. The packaging players in the market are trying to offer food-grade post-consumer recycled packaging solutions to adhere to the growing regulatory pressure, attain sustainability targets, and cater to the demand for minimum PCR content for packaging type. The key players in the market are developing new solutions to strengthen the market share and stay ahead of the competitors.

- In April 2024, Amcor Group GmbH announced the launch of a one-liter polyethylene terephthalate (PET) bottle made from 100% post-consumer recycled (PCR) content for carbonated soft drinks (CSD). The company focuses on expanding the product portfolio for responsible packaging made from recycled content and helping customers meet sustainability commitments and requirements.

- In April 2024, Klockner Pentaplast announced the launch of food packaging trays made with 100% recycled PET (rPET). With the launch of 100% recycled PET food trays, the company is focusing on creating a more sustainable packaging industry without compromising quality or safety.

- In December 2023, Novolex Holdings LLC introduced packaging containers for food made with a minimum of 10% post-consumer recycled (PCR) content. These containers are recyclable. The launch of new products will help the company reduce the environmental impact and support the circular economy.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of the Geopolitical Scenario Impact on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rising Consumer Awareness and Need for Lowering Greenhouse Gas Emissions to Overcome the Sustainability Concerns

- 5.1.2 Increasing Regulatory Pressure to Include a Minimum Percentage of Recycled Content for Packaging Products

- 5.2 Market Restraint

- 5.2.1 Inadequate Recycling Infrastructure Leads to Improper Supply of Materials and Results in High Prices

6 MARKET SEGMENTATION

- 6.1 By Material

- 6.1.1 Plastic

- 6.1.1.1 Polyethylene Terephthalate (PET)

- 6.1.1.2 Polyethylene (PE)

- 6.1.1.3 Polypropylene (PP)

- 6.1.1.4 Other Plastics

- 6.1.2 Glass

- 6.1.3 Metal

- 6.1.4 Paper & Paperboard

- 6.1.1 Plastic

- 6.2 By Product Type

- 6.2.1 Bottles and Containers

- 6.2.2 Cans

- 6.2.3 Pouches and Bags

- 6.2.4 Trays and Clamshells

- 6.2.5 Other Product Types

- 6.3 By End-user Industry

- 6.3.1 Food

- 6.3.2 Beverage

- 6.3.3 Personal Care and Cosmetics

- 6.3.4 Healthcare and Pharmaceuticals

- 6.3.5 Other End User Industry

- 6.4 Geography***

- 6.4.1 North America

- 6.4.1.1 United States

- 6.4.1.2 Canada

- 6.4.2 Europe

- 6.4.2.1 United Kingdom

- 6.4.2.2 Germany

- 6.4.2.3 France

- 6.4.2.4 Italy

- 6.4.2.5 Spain

- 6.4.3 Asia

- 6.4.3.1 China

- 6.4.3.2 Japan

- 6.4.3.3 India

- 6.4.3.4 Australia and New Zealand

- 6.4.4 Latin America

- 6.4.4.1 Brazil

- 6.4.4.2 Argentina

- 6.4.4.3 Mexico

- 6.4.5 Middle East and Africa

- 6.4.5.1 Saudi Arabia

- 6.4.5.2 South Africa

- 6.4.5.3 Egypt

- 6.4.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles*

- 7.1.1 Berry Global Group Inc.

- 7.1.2 Amcor Group GmbH

- 7.1.3 Novolex Holdings LLC

- 7.1.4 Tekni-Plex Inc.

- 7.1.5 Klockner Pentaplast

- 7.1.6 Coveris Management GmbH

- 7.1.7 Hoffmann Neopac AG

- 7.1.8 Silgan Dispensing Systems (Silgan Holdings Inc.)

- 7.1.9 Greiner Packaging International GmbH

- 7.1.10 Avery Dennison Corporation

- 7.1.11 Nussbaum Matzingen AG

- 7.1.12 Gallo Glass Company

- 7.1.13 Great Little Box Company Ltd