|

시장보고서

상품코드

1628800

유럽의 머신비전 시스템 : 시장 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)Europe Machine Vision Systems - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

■ 보고서에 따라 최신 정보로 업데이트하여 보내드립니다. 배송일정은 문의해 주시기 바랍니다.

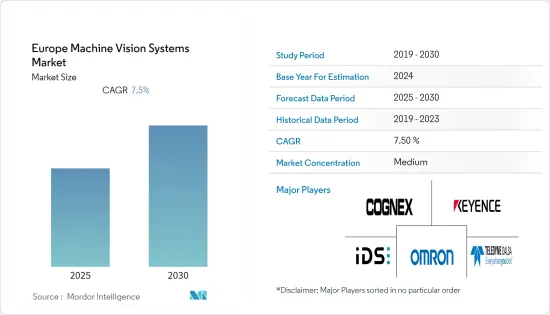

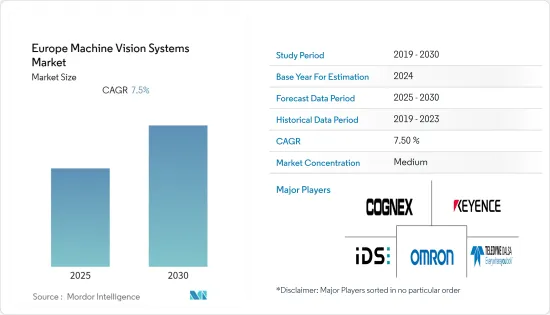

유럽의 머신비전 시스템 시장은 예측 기간 동안 CAGR 7.5%를 기록할 것으로 예상됩니다.

주요 하이라이트

- 벤더 또한 시장 시나리오를 형성하는 데 중요한 역할을 합니다. 벤더는 이미지 센서 및 이미지 처리 알고리즘, 카메라에서 센서에 이르는 비전 제품, 소프트웨어에서 시스템에 이르기까지 모든 응용 분야 및 산업 분야의 핵심 기술 개발에 참여하고 있습니다. 또한 유럽 공장에서 머신비전 장비의 국내 사용도 비교적 안정적입니다.

- 유럽은 특히 영국, 독일, 프랑스에서 가공제품에 대한 수요가 증가함에 따라 가장 유리한 시장 중 하나가 될 것으로 예상됩니다. 또한, 가공품의 품질 및 위생과 관련된 규제 기관에서 제안한 엄격한 규제가 유럽 식품 산업에서 비전 시스템에 대한 수요를 뒷받침할 것으로 예상됩니다.

- 또한 지난 10년 동안 식품 산업에서 머신비전의 일관되고 체계적인 적용은 주로 이미지 처리 및 패턴 인식과 같은 구성 방법의 지속적인 발전에 기인합니다. 또한 기술 발전으로 인해 이러한 기계를 저렴한 비용으로 도입할 수 있게 되었습니다.

- 또한 인더스트리 4.0은 산업 자동화에서 중요한 역할을 하는 로봇과 같은 기술 개발에 박차를 가하고 있으며, 산업의 많은 핵심 작업이 로봇에 의해 관리되고 있습니다. 또한 3D 머신비전은 비전 가이드 로봇과 자동 도축과 같은 새로운 애플리케이션을 지원하고 있습니다. 이러한 비전 가이드 로봇은 2D 카메라와 3D 카메라를 결합한 것입니다.

유럽의 머신비전 시스템 시장 동향

자동차 산업이 크게 성장

- 머신비전 시스템 솔루션의 주요 목적은 다양한 제조 산업에 자동화를 도입하여 인간의 노력과 기술을 회복하는 것입니다. 이 지역의 다양한 시장 공급업체들은 인간의 눈으로 인식할 수 없는 복잡한 패턴의 결함을 검사하기 위해 자동차 산업에서 유용한 머신비전 시스템을 목격하고 있습니다.

- 이 지역의 공급업체 중 검사 자동화 머신비전 솔루션 제공업체인 Samsara Inc.가 런던 쇼디치에 새로운 본사를 개설했습니다. 이 회사의 제품 엔지니어링 팀은 유럽에 특화된 새로운 기능을 구축하는 데 전념할 예정입니다.

- 노동집약적인 이탈리아의 봉제 산업은 인건비를 절감하고 수익률을 높이기 위해 스마트 팩토리 솔루션을 도입하고 있습니다. 이탈리아는 아직 세계 경기 침체에서 벗어나지 못했고, 지난 10년간 경제가 침체되어 있었습니다. 이탈리아의 자동차 부문이 점차 회복되고 섬유 제조업이 성장함에 따라 이탈리아의 머신비전 시장은 완만하게 성장할 것으로 보입니다.

- 자동화, 로봇공학, 인더스트리 4.0 기술에 대한 투자 증가, 안전 및 검사 비전 시스템에 대한 수요 증가, 제품 혁신의 높은 비율은 유럽의 머신비전 시스템 시장의 성장을 촉진하는 중요한 요인입니다. 열악한 환경에서의 실시간 검사 및 등급 분류 작업에 대한 존재 감지 같은 머신비전 애플리케이션은 자동차 산업 전반에 걸쳐 표준이 되고 있습니다.

눈에 띄는 성장세가 기대되는 영국

- 머신비전 시스템은 더 높은 정밀도와 품질 보증을 위해 산업 자동화에 필수적인 요소로 자리 잡았습니다. 고품질 제품 검사가 필수적이기 때문에 머신비전 시스템 및 서비스에 대한 수요가 증가하고 있습니다.

- 또한, 제조업의 높은 생산 수율에 대한 요구가 강화되면서 머신비전 기술 수요 강화의 중요한 촉진제가 될 것으로 예상됩니다. 또한, 산업용 애플리케이션은 높은 생산성을 요구하고 있으며, 이는 국내 생산 단위의 성능을 향상시킬 것으로 예상됩니다.

- 또한 다양한 혁신이 영국 시장의 성장을 주도하고 있습니다. 예를 들어, 2020년 9월 영국에 본사를 둔 Industrial Vision Systems(IVS)는 고속 자동 외관 검사를 위한 인라인 검사 솔루션인 IVS-COMMAND-Ai를 출시했습니다. 시스템과 직접 통신하여 완벽한 부품 검사, 안내, 추적, 추적성, 내장된 이미지 및 데이터 저장을 가능하게 합니다.

- 산업과 제조업은 스마트 카메라의 중요한 촉진제이며, 드론과 같은 기술의 채택 증가는 더욱 확대될 것으로 예상되며, 2021년에는 핀란드의 VTT 그룹이 주도하는 유럽 연구 프로젝트가 자율형 드론과 로봇을 지원하는 머신비전 시스템을 개발하고 있습니다.

유럽의 머신비전 시스템 산업 개요

유럽의 머신비전 시스템 시장은 적당한 경쟁 상태에 있습니다. 제품 출시, 연구 개발, 제휴 및 인수는 이 지역의 기업들이 치열한 경쟁을 유지하기 위해 채택하는 주요 성장 전략입니다.

- 2021년 8월 - 키엔스는 고품질 고속 검사 및 제어를 위한 3D 및 라인 스캔 기능을 갖춘 맞춤형 비전 시스템 XG-X 시리즈 고급 프로그래밍 인터페이스를 출시했습니다. XG-X 시리즈는 고정밀 검사를 위한 고속, 고해상도 카메라를 제공하여 다양한 제조 문제에 대한 강력한 솔루션을 제공합니다.

- 2021년 1월 - 코그넥스는 In-Sight 3D-L4000 임베디드 비전 시스템을 발표했습니다. 3D 레이저 변위 기술이 적용된 이 스마트 카메라를 통해 엔지니어는 자동화된 생산 라인에서 다양한 검사 및 테스트를 신속하고 효과적이며 경제적으로 해결할 수 있습니다.

기타 혜택

- 엑셀 형식의 시장 예측(ME) 시트

- 3개월간의 애널리스트 지원

목차

제1장 소개

- 조사 가정과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 인사이트

- 시장 개요

- 업계의 매력 - Porter's Five Forces 분석

- 공급 기업의 교섭력

- 소비자의 협상력

- 신규 참여업체의 위협

- 대체품의 위협

- 경쟁 기업 간의 경쟁 강도

- COVID-19의 시장에 대한 영향 평가

제5장 시장 역학

- 시장 성장 촉진요인

- 품질 검사와 자동화에 대한 요구 상승

- 정확한 결함 검출에 대한 수요 증가

- 시장 과제

- Mv 시스템 도입의 복잡성

제6장 시장 세분화

- 구성요소별

- 하드웨어

- 비전 시스템

- 카메라

- 광학·조명 시스템

- 프레임 그래버

- 기타 하드웨어

- 소프트웨어

- 하드웨어

- 제품별

- PC 기반

- 스마트 카메라 기반

- 최종 이용 산업별

- 식품 및 음료

- 헬스케어·의약품

- 물류·소매

- 자동차

- 일렉트로닉스·반도체

- 기타 최종 이용 산업

- 국가별

- 영국

- 독일

- 이탈리아

- 기타 유럽

제7장 경쟁 구도

- 기업 개요

- Cognex Corporation

- Keyence Corporation

- Omron Corporation

- Basler AG

- National Instruments Corporation

- Teledyne DALSA

- Datalogic SpA

- Perceptron Inc

- Uss Vision Inc

- IDS Imaging Development Systems GmbH

제8장 투자 분석

제9장 시장 전망

ksm 25.01.20The Europe Machine Vision Systems Market is expected to register a CAGR of 7.5% during the forecast period.

Key Highlights

- The vendors also play a significant role in shaping the market scenario. Players are involved in developing core technology, such as image sensors and image-processing algorithms, vision products from cameras to sensors, from software to systems, for all kinds of applications and industries. Moreover, the domestic use of machine vision equipment in factories in Europe is also relatively stable.

- Europe is expected to be one of the most lucrative markets due to the growing demand for processed products, especially in the United Kingdom, Germany, and France. Moreover, stringent regulations proposed by the regulating bodies pertaining to the quality and hygiene of the processed items are expected to support the demand for vision systems in the European food industry.

- Furthermore, over the last decade, the consistent and systematic application of machine vision in the food industry is mainly attributed to ongoing advancements in constituent methodologies such as image processing and pattern recognition. Also, technological advancements have made it possible to implement these machines at a lower cost.

- Also, Industry 4.0 fueled the development of technologies like robots playing a crucial role in industrial automation, with many core operations in industries being managed by robots. Also, 3D machine vision supports new applications, such as vision-guided robotics and automated butchering. These vision-guided robots are a combination of 2D and 3D cameras.

Europe Machine Vision Systems Market Trends

Automotive Industry to Witness Significant Growth

- The primary goal of machine vision system solutions was to restore human efforts and skills by incorporating automation into various manufacturing industries. Various market vendors in the region are witnessing machine vision systems that are useful in the automotive industry for examining flaws in patterns that are complex for the human eye to recognize.

- Vendors in the region, such as Samsara Inc, a provider of machine vision solutions designed to automate inspections, opened its new headquarters in London, Shoreditch. Its Product and Engineering team will be dedicated to building new features specific to Europe.

- The Italian garment industry, which is labor-intensive, is adopting smart factory solutions to reduce labor costs and increase its profit margin. The country is still emerging from the global recession, and its economy has been stagnant over the last decade. The gradual recovery of the automotive sector in Italy and the growth of textile manufacturing will lead to the moderate growth of the country's machine vision market.

- The growing investment in automation, robotics, and Industry 4.0 technologies, increasing need for safety and inspection vision systems, and high rate of product innovation are significant factors driving the growth of the European machine vision systems market. Machine vision applications like presence detection to real-time inspection and grading tasks in harsh environments are becoming standard across the automotive industry

United Kingdom Expected to Witness Significant Growth

- Machine vision systems have become an indispensable element of industrial automation to gain greater precision and quality assurance in the country. The vital requirement for high-quality product inspection is witnessing the demand for machine vision systems and services.

- Further, strengthening the requirement for high production yield in the manufacturing industry is anticipated to remain a significant driver for enhanced demand in machine vision technology. Also, Industrial applications demand higher productivity expected to boost the performance of production units in the country.

- Also, various innovations are driving the market growth in the united kingdom. For instance, in September 2020, Industrial Vision Systems (IVS), based in the United Kingdom, introduced the IVS-COMMAND-Ai in-line inspection solution for high-speed automated visual inspection. The IVS-COMMAND-Ai Vision Sensors communicate directly with all factory information and control systems, enabling complete part inspection, guidance, tracking, traceability, built-in image, and data saving.

- Industrial and manufacturing will be significant growth drivers for smart cameras, and rising adoptions of technologies like drones are further expected to expand the scope. In 2021, a European research project led by Finnish group VTT is developing machine vision systems to support autonomous drones and robots.

Europe Machine Vision Systems Industry Overview

The Europe Machine Vision Systems Market is moderately competitive in nature. Product launches, high expense on research and development, partnerships, and acquisitions are the prime growth strategies adopted by the companies in the region to sustain the intense competition.

- August 2021 - Keyence Corporation introduced a customizable vision system XG-X series Advanced programming interface with 3D and linescan capabilities for high-quality, high-speed inspection and control. The XG-X Series provides high-speed, high-resolution cameras for high-accuracy inspection, providing robust solutions to a wide range of manufacturing problems.

- January 2021 - Cognex Corporation announced In-Sight 3D-L4000 embedded vision system. The smart camera, which features 3D laser displacement technology, enables engineers to quickly, effectively, and cost-effectively solve a variety of inspections and testing on automated production lines.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Assessment of the Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Need for Quality Inspection and Automation

- 5.1.2 Rising Demand for Accurate Defect Detection

- 5.2 Market Challenges

- 5.2.1 Complications in the Implementation of Mv Systems

6 MARKET SEGMENTATION

- 6.1 By Component

- 6.1.1 Hardware

- 6.1.1.1 Vision Systems

- 6.1.1.2 Cameras

- 6.1.1.3 Optics and Illumination Systems

- 6.1.1.4 Frame Grabber

- 6.1.1.5 Other Types of Hardware

- 6.1.2 Software

- 6.1.1 Hardware

- 6.2 By Product

- 6.2.1 PC-based

- 6.2.2 Smart Camera-based

- 6.3 By End-User Industry

- 6.3.1 Food and Beverage

- 6.3.2 Healthcare and Pharmaceutical

- 6.3.3 Logistic and Retail

- 6.3.4 Automotive

- 6.3.5 Electronics and Semiconductors

- 6.3.6 Other End-user Industries

- 6.4 By Country

- 6.4.1 United Kingdom

- 6.4.2 Germany

- 6.4.3 Italy

- 6.4.4 Rest of Europe

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Cognex Corporation

- 7.1.2 Keyence Corporation

- 7.1.3 Omron Corporation

- 7.1.4 Basler AG

- 7.1.5 National Instruments Corporation

- 7.1.6 Teledyne DALSA

- 7.1.7 Datalogic SpA

- 7.1.8 Perceptron Inc

- 7.1.9 Uss Vision Inc

- 7.1.10 IDS Imaging Development Systems GmbH

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

샘플 요청 목록