|

시장보고서

상품코드

1628817

중동 및 아프리카의 의약품 포장 : 시장 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)MEA Pharmaceutical Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

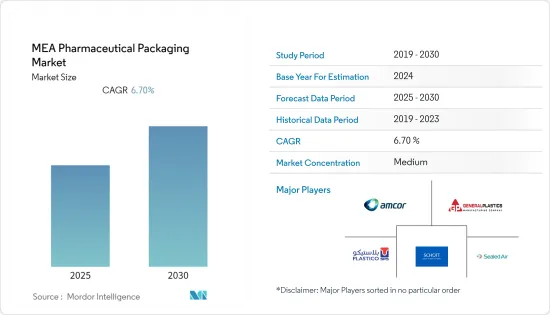

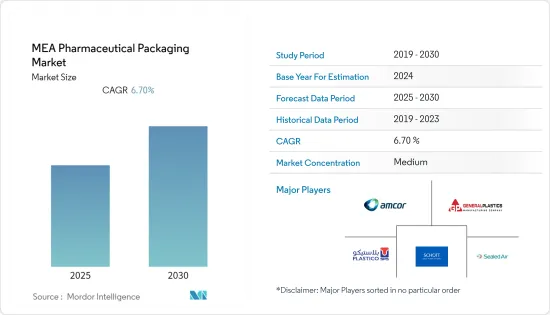

중동 및 아프리카의 의약품 포장 시장은 예측 기간 동안 CAGR 6.7%를 기록할 것으로 예상됩니다.

주요 하이라이트

- 중동 지역은 전체 의약품 포장 시장의 3.5%에 불과합니다. 최근 몇 년 동안 플라스틱이 제약 시장에서 가장 널리 사용되는 포장재로 부상한 것은 단계적인 기술 혁신과 제약 분야에서 제네릭 의약품 및 특수 의약품의 증가로 인해 플라스틱이 가장 널리 사용되는 포장 재료로 부상했습니다. 환자의 이익을 보호하기 위해 위조 방지 기술에 대한 요구가 증가함에 따라 의약품 포장의 성장이 더욱 강화되고 있습니다.

- 이 조사 시장의 성장 전망은 GCC 및 기타 인근 지역의 제약 및 의료 분야의 전반적인 성장에 따라 좌우될 것으로 예상됩니다. 고령화 인구의 증가와 함께 전반적인 생활수준의 상승, 의료 부문의 개선을 위한 여러 정부의 노력은 이 지역의 제약 부문 성장에 기여하는 주요 요인으로 볼 수 있습니다. 또한, 제약 부문에서 포장재의 역할은 지난 수십 년 동안 크게 발전해 왔습니다.

- 현재 여러 가지 규제 기준을 준수하고 제품 정보를 제공하고 자가 투여 의약품의 경우 적절한 약물전달을 보장하기 위해 여러 가지 규제 기준을 준수해야 합니다. 의약품 포장재는 1차 포장, 2차 포장 및 폐쇄 시스템으로 명확하게 분류됩니다. 제약 회사는 플라스틱 포장재를 선택할 때 대상 환자층, 제품 안정성 요구 사항, 상업적 실행 가능성 및 규제 고려 사항을 염두에 두어야 합니다.

- 이 시장의 성장 촉진요인으로는 이 지역의 건강 인식 증가, 위조품에 대한 적극적인 대응, 제약 분야에서 나노기술과 바이오기술의 기여도 증가 등을 꼽을 수 있습니다.

- 풍토병, 호흡기질환 및 기타 전염병에 대응하기 위한 새로운 건강 관리 의약품 및 장치의 출현은 제약 플라스틱 포장 시장의 성장을 촉진하는 주요 요인 중 하나입니다. 반대로 플라스틱 사용과 관련된 환경 문제와 지속적인 규정 준수 기준의 변화는 이 시장의 성장을 저해할 것으로 예상됩니다.

- 중동 및 아프리카, 특히 남아공에서 전례없는 수의 COVID-19 사건이 발생하여 의약품 포장 사업이 중단되었습니다. 다른 의료 제품 생산 부문의 감소는 2020년 첫 달 의료 포장 수요에 부정적인 영향을 미쳤습니다. 또한 포장재 총 생산량 감소로 인해 의약품 포장재 생산 프로젝트가 종료되어 의약품 포장재에 대한 수요가 감소했습니다. 중동 및 아프리카의 다른 국가, 즉 사우디아라비아 및 아랍에미리트(UAE)에서도 유사한 추세가 나타났습니다. 그러나 사우디아라비아는 이러한 수요 감소를 극복하고 특히 2021년 초에 경제 활동이 회복될 것으로 예상됩니다.

중동 및 아프리카의 의약품 포장 시장 동향

병 포장 부문이 가장 큰 영업비용을 차지

이 지역에서는 다양한 종류의 의약품 포장에 유리병과 플라스틱 병이 사용되고 있습니다. 상당수의 의약품이 유리 용기를 사용하여 포장되어 있으며, 일반적으로 유리 용기가 포장 재료의 첫 번째 선택이 되고 있습니다.

- 병은 정제 및 캡슐 포장에 주로 사용되어 왔습니다. 또한 시럽제, 점비제, 점안제 등 액체 제제의 포장에도 사용됩니다. 플라스틱 병은 경구용 의약품의 대량 포장 및 처방량 포장, 고체량 경구용 일반 의약품의 대량 포장에 사용되는 것을 반영하여 일차 의약품 용기 중 가장 높은 시장 점유율을 유지할 것으로 예상됩니다.

- 의약품 포장용 플라스틱 재료에는 PVC, PE, PE, PP, PS, PET, 나일론 등 많은 종류의 플라스틱 재료가 있으며, PE, PP, PET의 비율이 가장 높지만 PVC의 양은 감소하고 있습니다. 플라스틱 병 중 가장 큰 비중을 차지하는 것은 타원형, 정사각형 및 원형 용기로 다양한 폐쇄에 맞게 설계된 나사식 목이 장착된 타원형, 정사각형 및 원형 용기입니다.

- 그러나 플라스틱 병이 시장을 점유하고 있습니다. 고밀도 폴리에틸렌(HDPE) 또는 폴리에틸렌 테레프탈레이트(PET)를 사용하여 제조 된 플라스틱 병은 유리보다 의약품 포장에 더 많이 사용됩니다. 그 이유는 높은 내열성과 내충격성, 가스와 수분에 대한 우수한 차단성, 투명성과 불투명성 때문입니다.

- 또한, 이 지역에서 처방전을 통해 유통되는 경구용 의약품에는 병이 대량으로 사용됩니다. 약국에 우편으로 발송되는 대량 복용량은 편리한 플라스틱 병에 포장되어 있습니다.

- 따라서 요구 사항과 용도에 따라 다양한 종류의 병이 만들어집니다. 제약 포장 산업에서 플라스틱 병의 사용 편의성과 높은 수요는 시장 성장을 촉진하고 2021-2026년 예측 기간 동안 시장 점유율 1위를 차지할 것으로 예상됩니다.

사우디아라비아, 수익성 높은 시장 점유율을 차지

사우디아라비아는 의약품 포장 부문에서 가장 유리한 시장 중 하나로 부상하고 있습니다. 증가하는 국내 수요를 충족시키기 위해 외부 시장에 크게 의존하고 있으며, 의약품 수입이 시장의 80% 이상을 차지하고 있습니다. 의약품 포장재는 이 지역에서 가공된 반제품 의약품의 재포장 및 수출에 널리 사용되고 있습니다. 이러한 재포장된 의약품은 인근 국가에서 상업적으로 판매되어 수요와 공급 패러다임에 대응하고 있습니다.

- 보건의료에 대한 공공 지출은 지난 몇 년 동안 상당히 개선되었습니다. 만성질환, 특히 COVID-19 및 기타 건강 질환의 증가는 제약 부문의 성장에 기여하고 있습니다. 이 지역에서는 특수 의약품의 사용이 높은 성장세를 보일 것으로 예상됩니다.

- 사우디아라비아는 중동에서 의약품 제조의 핫스팟으로 널리 알려져 있습니다. 사우디는 GCC 의약품 시장의 절반 이상을 차지하는 것으로 추정됩니다. 사우디 정부는 석유와 원유에 크게 의존하는 국내 부문을 다각화하기 위해 몇 가지 적극적인 조치를 취하고 있습니다. 사우디의 의료 부문은 가장 정교한 의료 네트워크 중 하나로 세계적으로 유명합니다.

- 또한, 4개의 "경제" 도시(즉, KAEC, PABMEC, KEC, JEC)의 개발은 이 지역에 의약품 가공 시설을 설립할 수 있는 새로운 기회를 창출할 것으로 기대됨. 화이자(Pfizer)와 같은 거대 제약회사들은 GCC 지역에서의 입지를 강화하기 위해 사업 확장에 큰 관심을 보이고 있습니다.

- 그러나 세계 기업들은 품질 기준을 충족하고 지역 규정을 준수해야 하기 때문에 현지 기업과의 협력은 여전히 큰 도전이 되고 있습니다. 사우디아라비아 식품의약청은 다른 GCC 회원국과 함께 이 지역의 의약품 가격 책정을 담당하고 있습니다. 의약품 포장 회사는 전체 제조 비용을 낮추기 위해 의약품 제조업체로부터 가격 인하를 요구받을 수 있습니다.

- 이 지역은 현재 유가 변동으로 인한 과도기를 겪고 있지만, 강력한 경제적 여유가 있기 때문에 단기적으로 유가 하락의 영향을 상쇄할 수 있을 것으로 예상됩니다. 이러한 거시 경제의 변화는 의약품 포장 시장에 간접적인 영향을 미칠 것으로 예상됩니다. 그러나 전반적인 수요는 보고서 기간 동안 상당히 높은 수준을 유지할 것으로 예상됩니다.

중동 및 아프리카의 의약품 포장 산업 개요

중동 및 아프리카의 의약품 포장 시장은 Indevco group, Amcor Worldwide, General Plastics, Saudi Arabia Plastic Packaging Systems Co. Sealed Air Corporation 등 주요 기업들이 존재하기 때문에 세분화되어 있으며, 이들 기업들은 모두 새로운 기술 혁신과 산업 규모 확대를 위한 연구개발에 투자하고 있습니다.

- 2021년 4월 - Amcor는 획기적인 재활용 가능한 헬스케어 패키징인 새로운 AmSky 블리스터 시스템(AmSky Blister System)을 개발했습니다. 이는 헬스케어 패키징의 지속가능성을 변화시키는 최근의 혁신으로, 블리스터 포장에 PVC를 제거하여 Amcor 헬스케어의 재활용 가능성을 향상시킬 수 있습니다. 이 혁신은 의약품 포장에 소아 내성 및 노인 친화적인 솔루션을 제공합니다.

- 2021년 9월 - SCHOTT AG는 애리조나에 본사를 둔 마이크로어레이 솔루션 회사를 인수하여 회사의 입지를 확장하고 생명과학 분야의 역량을 강화했습니다. 이번 인수를 통해 고객은 고밀도 마이크로어레이 인쇄를 포함한 향상된 개발 및 제조 능력의 혜택을 누릴 수 있습니다.

- 2021년 11월 - INDEVCO는 중동 및 북아프리카 지역의 플라스틱 폐기물 감소를 지원하기 위해 플라스틱 폐기물 퇴치 동맹과 협력하여 중동 및 북아프리카(MENA) 지역 태스크 그룹인 AEPW(Alliance to End Plastic Waste)의 공동 의장을 맡았습니다. AEPW 지역 태스크그룹(RTG)의 목적은 플라스틱 폐기물 근절을 위한 세계 전략을 지역 자원, 과제 및 필요에 맞는 지역 전략으로 전환하는 것입니다.

기타 혜택:

- 엑셀 형식의 시장 예측(ME) 시트

- 3개월간의 애널리스트 지원

목차

제1장 소개

- 조사 가정과 시장 정의

- 조사 범위

제2장 주요 요약

제3장 조사 방법

제4장 시장 역학

- 시장 개요

- 시장 성장 촉진요인

- 환경 문제에 대한 인식 확산과 새로운 규제 기준 채용

- 만성질환 환자 급증

- 시장 성장 억제요인

- 공급 기업의 교섭력에 의한 원자재 비용 변동

- 밸류체인/공급망 분석

- Porter's Five Forces 분석

- 신규 참여업체의 위협

- 구매자의 교섭력

- 공급 기업의 교섭력

- 대체품의 위협

- 경쟁 기업 간의 경쟁 강도

- COVID-19의 업계에 대한 영향 평가

제5장 시장 세분화

- 재료 유형별

- 플라스틱

- 유리

- 기타(종이·판지, 금속)

- 제품 유형별

- 보틀

- 바이알·앰플

- 시린지

- 튜브

- 뚜껑 및 마개

- 파우치

- 라벨

- 기타 제품 유형

제6장 경쟁 구도

- 기업 개요

- Indevco Group

- Amcor Worldwide

- Rexam PLC

- Schott AG

- Sealed Air Corporation

- Saudi Arabia plastic Packaging Systems Co.

- General Plastics Limited

- Medical Packaging(S.A.E)

- Frank NOE Limited

- Rose Plastics Medical Packaging

제7장 투자 분석

제8장 시장 전망

ksm 25.01.16The MEA Pharmaceutical Packaging Market is expected to register a CAGR of 6.7% during the forecast period.

Key Highlights

- The Middle East region accounts for a meager portion of 3.5% of the overall pharmaceutical packaging market. Over the last few years, plastics have emerged as the most widely used packaging materials in the pharmaceutical market owing to incremental technological changes and growth in generic and specialty drugs in the pharmaceutical sector. The increasing need for anti-counterfeiting techniques to protect the interests of patients has further strengthened the growth of pharmaceutical packaging.

- The growth prospects of the study market are expected to be dependent on the overall growth of the pharmaceutical and healthcare sector in GCC and other neighboring regions. An overall rise in living standards, coupled with an increase in the aging population and the endeavors of several governments towards improving their healthcare sector, can be seen as major factors contributing to the growth of the pharmaceutical sector in this region. Moreover, the role of packaging materials in the pharma sector has greatly evolved over the last few decades.

- They are now expected to comply with several regulatory standards and provide product information and ensure proper drug delivery in case of self-administering drugs. The pharmaceutical packaging materials have been distinctly categorized into primary, secondary, and closure systems. Pharmaceutical companies have to be mindful of their target patient base, product stability requirements, commercial viability, and regulatory considerations while opting for plastic packaging materials.

- The major drivers for growth in this market include growing health awareness in the region, proactive measures against counterfeit products, and increased contribution of nanotechnology and biotechnology practices in the pharmaceutical sector.

- The advent of new healthcare medicines and devices to counter endemics, respiratory diseases, and other prevalent ailments is one of the major drivers for growth in the pharmaceutical plastic packaging market. Conversely, environmental concerns related to the use of plastics and constant changes in compliance standards are expected to impede the growth in this market.

- In the Middle East and Africa, particularly South Africa, an unprecedented number of COVID-19 cases have resulted in the suspension of the medical packaging business. The decline in other medical product production sectors had a negative impact on medical packaging demand in the first month of 2020. Moreover, the decrease in the total production of packaging materials led to the termination of the medical packaging material production project, which led to a decrease in the demand for medical packaging materials. Similar trends were observed in other countries in the Middle East and Africa, namely Saudi Arabia and the UAE. However, the country is likely to overcome the decline in demand in this way, and economic activity is expected to recover, especially in early 2021.

MEA Pharmaceutical Packaging Market Trends

Bottle Packaging segment to hold biggest operating expense

Glass and Plastic Bottles are used for various kinds of drug packaging in the region. A considerable number of pharmaceutical formulations have been packaged using glass containers, and they are usually the first choice of packaging materials.

- Bottles have been the preferred mode of packaging tablets and capsules. They are also used for packaging liquid dosages like syrups, nasal and ophthalmic medications. Plastic bottles will continue to have the highest market share among primary pharmaceutical containers, reflecting the usage in the bulk and prescription dose packaging of oral ethical drugs and the packaging of solid dose oral over-the-counter medicines in large quantities.

- There are many kinds of medicine packaging plastic materials, including PVC, PE, PP, PS, PET, nylon, etc. The PE, PP, and PET account for the largest proportion; however, the amount of PVC is reducing. The largest share within plastic bottles is for ovals, square and round containers with threaded necks designed to fit a wide variety of closures.

- However, the market is getting progressively occupied by Plastic bottles. Plastic bottles manufactured using high-density polyethene (HDPE) and polyethene terephthalate (PET) are being used to pack pharmaceuticals than glass. This is due to high temperature and impact resistance, the excellent barrier to gas and moisture, and transparency and opacity properties.

- Moreover, bottles are used in large quantities for oral drugs that are distributed through prescription in the region. Bulk dose volumes that are mailed to pharmacies are conveniently packed in plastic bottles.

- Hence, based on the requirement and usage, the types of bottles are made. The ease of use and high demand for plastic bottles in the pharmaceutical packaging industry will help the market grow, and it will be the highest market shareholder in the forecast period of 2021-2026.

Saudi Arabia to hold profitable market share

Saudi Arabia has emerged as one of the most lucrative markets for the pharmaceutical packaging sector. Drug imports account for more than 80% of the market, as it heavily relies on external markets for meeting the ever-growing domestic demand. Pharmaceutical packaging materials are widely used for the repackaging and export of semi-finished medicaments processed in this region. These repackaged drugs are commercially sold in neighboring countries to address the demand-supply paradigm.

- Public spending on healthcare has improved considerably over the last few years; the rise in chronic diseases, especially COVID-19 and other health ailments, has contributed to the growth of the pharmaceutical sector. The use of specialty pharma drugs is expected to witness high growth in this region.

- Saudi Arabia is widely known as a pharma manufacturing hot spot in the Middle East. The country has been estimated to account for more than half of the GCC pharmaceuticals market. The Saudi government has been taking several proactive measures to diversify the domestic sector, which is heavily reliant on petroleum and oil. The Saudi Arabian healthcare sector is world-renowned as one of the most sophisticated healthcare networks.

- Moreover, the development of four 'economic' cities (namely KAEC, PABMEC, KEC, and JEC) is expected to create new opportunities for the establishment of pharmaceutical processing units in this region. Pharma giants like Pfizer have taken a keen interest in expanding their operations in a bid to gain more ground in the GCC region.

- However, collaborating with local companies remains a considerable challenge for global companies, as they are required to meet their quality standards and comply with regional regulations. The Saudi Food and Drug Authority, in conjunction with other GCC member countries, is responsible for the pricing of pharmaceutical products in this region. Pharmaceutical packaging companies could be prompted to cut down on their prices by drug manufacturers in a bid to keep the overall production costs under check.

- This region is currently growing through a transition due to the fluctuations in the oil prices; however, strong economic reserves are expected to offset the impact of the reduction in oil prices in the short term. These macroeconomic changes are anticipated to have an indirect impact on the pharmaceutical packaging market. However, the overall demand shall remain fairly high over the reporting period.

MEA Pharmaceutical Packaging Industry Overview

The Middle East and Africa Pharmaceutical Packaging Market are fragmented due to the presence of key players like Indevco group, Amcor Worldwide, General Plastics, Saudi Arabia Plastic Packaging Systems Co., and Sealed Air Corporation; all these players are investing in new innovations and for R&D upscaling the industry.

- April 2021 - Amcor developed breakthrough recyclable healthcare packaging, the new AmSky blister system, the recent innovation to transform the sustainability of healthcare packaging and to eliminate PVC from blister packaging, enabling Amcor healthcare to improve its recyclability. This innovation offers child-resistant and senior-friendly solutions for pharmaceutical packaging.

- Sep 2021 - SCHOTT AG acquired the Arizona-based microarray solutions compnay extending the companies presence and strengthening its bioscience capabilities. This acquisition helps customers to benefit from enhanced development and manufacturing capabilities, including high-density microarray printing.

- Nov 2021 - INDEVCO partners with the Alliance to End Plastic Waste to help reduce plastic waste in the Middle East and North Africa region. INDEVCO took on the role of Co-Chair to the Alliance to End Plastic Waste (AEPW), the Middle East & North Africa (MENA) Regional Task Group. The objective of the AEPW Regional Task Group (RTG) is to translate its global strategy for eliminating plastic waste into a regional strategy that tailors to the local resources, challenges, and needs.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising Awareness of Environmental Issues and Adoption of New Regulatory Standards

- 4.2.2 Surging Number of Chronic Disease Cases

- 4.3 Market Restraints

- 4.3.1 Fluctuations in Raw Material Cost Due to Suppliers Bargaining Power

- 4.4 Value Chain / Supply Chain Analysis

- 4.5 Porter's Five Force Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

- 4.6 Assessment of COVID-19 Impact on the Industry

5 MARKET SEGMENTATION

- 5.1 Material Type

- 5.1.1 Plastic

- 5.1.2 Glass

- 5.1.3 Others (Paper and Paperboard, Metal)

- 5.2 Product Type

- 5.2.1 Bottles

- 5.2.2 Vials and Ampoules

- 5.2.3 Syringes

- 5.2.4 Tubes

- 5.2.5 Caps and Closures

- 5.2.6 Pouches

- 5.2.7 Labels

- 5.2.8 Other Product Types

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Indevco Group

- 6.1.2 Amcor Worldwide

- 6.1.3 Rexam PLC

- 6.1.4 Schott AG

- 6.1.5 Sealed Air Corporation

- 6.1.6 Saudi Arabia plastic Packaging Systems Co.

- 6.1.7 General Plastics Limited

- 6.1.8 Medical Packaging ( S.A.E)

- 6.1.9 Frank NOE Limited

- 6.1.10 Rose Plastics Medical Packaging