|

시장보고서

상품코드

1628841

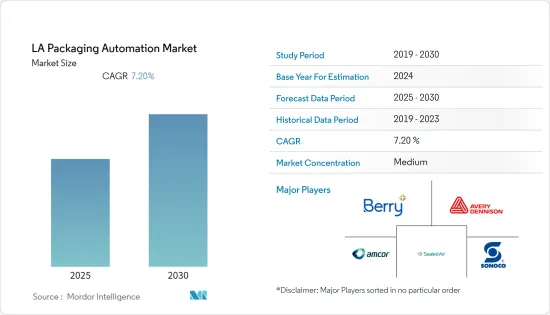

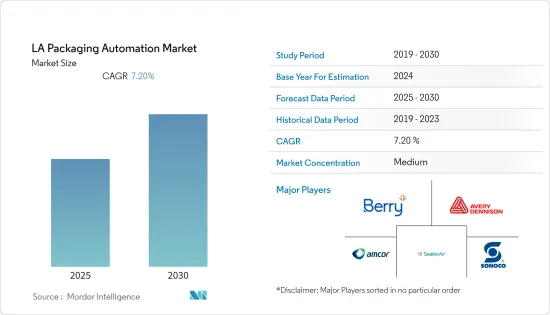

라틴아메리카의 포장 자동화 : 시장 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)LA Packaging Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

라틴아메리카의 포장 자동화 시장은 예측 기간 동안 CAGR 7.2%를 기록할 것으로 예상됩니다.

주요 하이라이트

- 포장 자동화가 이 분야에 영향을 미치기 전에 포장은 전적으로 수작업으로 이루어졌습니다. 경쟁이 치열해짐에 따라 제조업체들은 포장 비용을 줄이기 위해 다양한 수작업 공정을 자동화하고 반자동화 공정의 수준을 높여 비용 절감 조치를 취했습니다.

- 오늘날 라틴아메리카에서는 소비자와 정부의 환경에 대한 관심이 높아지면서 더 가볍고 재활용 및 재사용이 가능한 포장에 대한 관심이 높아지고 있습니다. 특히 식음료, 베이커리 및 의료 시장은 새로운 라벨링 규칙을 따라야 합니다.

- 멕시코에서는 기업들이 포장 제품 혁신에 주력하고 있습니다. 예를 들어, 2021년 11월 페스트와 하이바냐 인더스트리얼은 다논과 다냅 요구르트 멀티팩을 위한 자동 포장 솔루션을 개발했습니다.

- 멕시코에 요구르트 포장 산업이 탄생하기 전에는 멕시코에 이러한 유형의 다중 분류 포장을 처리할 수 있는 장비가 없었기 때문에 멕시코의 요구르트 포장 산업은 획기적인 사건이었습니다. 이러한 유형의 공정은 각 라인에서 제품을 꺼내 포장기계에 공급하는 작업자가 수작업으로 수행했습니다.

- 브라질, 멕시코, 아르헨티나는 충진, 라벨링, 백 에깅, 팔레타이징, 캡핑 등의 자동화 공정을 갖춘 이 지역의 주요 견인차 역할을 하고 있습니다. 식품, 제약, 화장품, 퍼스널케어, 식음료, 창고 등 다양한 기업들이 비즈니스 프로세스를 최적화하고 운영 비용을 절감하기 위해 이러한 자동화 솔루션을 점점 더 많이 활용하고 있습니다.

라틴아메리카의 포장 자동화 시장 동향

음료 및 식품 부문이 가장 큰 영업비용을 차지

기술의 발전으로 기업은 더욱 유연하고 구성이 가능해지면서 물류와 품질을 개선하고 있습니다. 자동화는 공급망 전체, 그리고 고객의 문 앞까지 식음료 제조 기업을 계속 변화시킬 것으로 보입니다.

소비자용 포장 제품 기업들은 정확하고 반복 가능한 포장 공정을 필요로 합니다. 고주기의 개별 포장 작업은 까다롭기 때문에 로봇을 포장 라인에 사용하는 기업은 처리량, 효율성 및 품질을 향상시킬 수 있습니다. 원재료 취급부터 1차 포장, 2차 포장, 팔레타이징에 이르기까지 로봇은 높은 투자 대비 효과를 입증하고 있습니다.

포장 자동화에는 재활용, 생분해성, 리필 가능과 같은 환경 친화적인 솔루션도 포함됩니다. 조사에 따르면, 라틴아메리카는 식기세척기 보급률이 낮고 손 씻기가 주류를 이루고 있으며, 플라스틱 페트병이 이 지역의 주요 제품 팩으로 수량 기준으로 성장하고 있는 것으로 나타났습니다.

또한, 브라질의 코카콜라는 재사용 가능한 PET 병 디자인을 도입하고 2030년까지 재사용 가능한 포장재를 대폭 확대하겠다는 야망의 일환으로 재사용 인프라를 확장하는 데 투자했습니다. 모든 브랜드에 공통된 병 디자인은 세척, 충전 및 반송에 드는 물류 비용을 크게 절감할 수 있습니다.

육류 산업과 제품별 육류 산업은 대륙의 중요한 부문입니다. 소비자들이 육류 생산과 가공에 대한 관심이 높아짐에 따라 기업들은 새로운 도전에 직면하고 있으며, HPP 기술을 통해 고품질의 생고기 및 조리된 제품을 더 오래 보관할 수 있고, 다른 국가로의 수출 가능성을 넓힐 수 있습니다.

라틴아메리카의 소비자들은 더 깨끗한 첨가물, 더 지속가능하고 소비하기 쉬운 제품을 요구하며 새로운 지평을 열어가고 있습니다. 다른 시장에서도 소비자들은 자신이 구매하는 제품에 더 안전하고 지속가능하며 안전한 포장을 원하고 있으며, 이에 따라 기업들은 새로운 기술 혁신을 통해 새로운 제품을 개발하고 있습니다.

산업적으로 크게 성장하고 있는 멕시코

기술 혁신, 지속가능성에 대한 관심, 매력적인 경제성 등이 지난 몇 년 동안 이 지역에서 포장 자동화가 크게 성장한 이유 중 일부이며, 소비자가 패키징을 보고 대하는 방식도 변화하고 있습니다.

- 멕시코는 포장 기술의 현대화를 향해 나아가고 있습니다. 현재 경제, 상업 및 정치 상황의 안정성과 국가의 예상 성장을 고려할 때 포장 장비 수입은 가까운 장래에 계속 성장할 것으로 예상됩니다.

- 성장의 원동력은 강력한 국내외 수요와 효율성과 경쟁력을 향상시키기 위해 업무를 현대화하려는 많은 기업의 관심 등이 주요 요인으로 작용할 것으로 예상됩니다.

- 포장기계를 사용하는 일부 다국적 기업 및 기업 그룹은 정치적 결정이 사업 운영에 미치는 영향을 이해하면서 멕시코에 대한 투자를 계속할 의향이 있음을 보여주었습니다. 기업들은 멕시코의 현실에 적응하고 있으며, 현재 멕시코의 수요 전망과 성장은 안정적입니다.

- 식품, 음료, 퍼스널케어, 제약 산업이 포장기계 수요의 대부분을 차지합니다. 젊은 층의 높은 비율과 중산층의 증가가 식품 수요를 주도하고 있습니다. 음료 부문은 청량음료, 생수, 맥주, 증류주 등의 제품에서 특히 강세를 보이고 있습니다.

- 또한 제약 업계는 제네릭 의약품과의 경쟁 심화 및 낮은 수준의 신규 투자에도 불구하고 제약 부문은 경쟁력을 유지하고 있으며, 포장기계에 대한 수요가 증가하고 있습니다.

라틴아메리카의 포장 자동화 산업 개요

라틴아메리카의 포장 자동화 산업은 Amcor Flexibles MX, Avery Dennison Corporation, Berry Global Inc, Sonoco Products Company 등의 대기업이 존재하며, 적당히 파편화되어 있습니다. 이들 기업은 제품 혁신을 위한 연구개발에 투자하고 성장을 위해 새로운 기술 혁신에 대응하고 있습니다.

- 2020년 9월 - 에이버리데니슨(Avery Dennison Corporation)은 토양 생물에 노출되면 1년 이내에 분해되어 플라스틱을 대체할 수 있는 생분해성 의류 태그 패스너를 출시했습니다. 이 새로운 에코터치 바이오 PP 패스너는 환경에 유해한 물질인 미세 플라스틱을 남기지 않고 분해됩니다.

- 2021년 10월-암코는 콜롬비아에서 재활용 원료로만 만든 식용유 병을 제공했습니다. Amcor는 Alianza 팀과 협력하여 콜롬비아에서 처음으로 재활용 재료로 만든 식용유 병을 출시했으며, Amcor Rigid Packaging(ARP)은 안전, 맛의 변화 및 투명성을 보장하기 위해 병을 개선했습니다.

기타 혜택:

- 엑셀 형식의 시장 예측(ME) 시트

- 3개월간의 애널리스트 지원

목차

제1장 소개

- 조사 가정과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 인사이트

- 시장 개요

- 산업 밸류체인 분석

- 업계의 매력 - Porter's Five Forces 분석

- 공급 기업의 교섭력

- 구매자의 교섭력

- 신규 참여업체의 위협

- 대체품의 위협

- 경쟁 기업 간의 경쟁 강도

- COVID-19의 시장에 대한 영향 평가

제5장 시장 역학

- 시장 성장 촉진요인과 시장 성장 억제요인 소개

- 시장 성장 촉진요인

- 제조업체에 대한 운전 비용 절감 압력 상승

- 기계 다운타임과 제품 낭비를 절감

- 신흥 시장의 대두에 의한 저비용 노동력과 경쟁 증가

- 시장 성장 억제요인

- 고액의 초기 투자

제6장 시장 세분화

- 사업 유형별

- B2B E-Commerce 소매업체

- B2C E-Commerce 소매 기업

- 옴니채널 소매업체

- 도매업체

- 제조업체

- 개인용 문서 발송업체

- 기타

- 최종 이용 업계별

- 식품

- 의약품

- 화장품

- 가정용

- 음료

- 화학제품

- 제과

- 창고

- 기타

- 제품 유형별

- 충전

- 라벨링

- 수평/수직 필로우

- 케이스 포장

- 봉입

- 팔레타이징

- 캡핑

- 랩핑

제7장 경쟁 구도

- 기업 개요

- Amcor PLC

- Klabin SA

- Printpack Inc.

- Berry Global Inc.

- Westrock Company

- Constantia Flexibles

- Sealed Air Corporation

- Transcontinental Mexico

- Sonoco Products Company

- Avery Dennison Corporation

- Clifton Packaging Packaging SA de CV

제8장 투자 분석

제9장 시장 전망

ksm 25.01.16The LA Packaging Automation Market is expected to register a CAGR of 7.2% during the forecast period.

Key Highlights

- Before packaging automation made an impact in the region, packaging was a completely manual process. As competition increased, manufacturers took steps to reduce packaging costs and took measures to reduce costs by automating a variety of manual processes and raising the level of semi-automated processes.

- In Latin America today, consumers and governments are increasingly concerned about the environment and are increasingly interested in lighter, recyclable and reusable packaging. New labeling rules must be followed, especially in the food and beverage, bakery, and medical markets.

- In Mexico, companies are focusing on innovations in packaging products. For instance, in November 2021, Festo and Hybernya Industrial developed an automated packaging solution for multi-packs for Danone and Danup yogurts.

- Prior to the creation of the yogurt packaging industry in Mexico, it was a milestone for the Mexican yogurt packaging industry, given that there was no equipment in the country capable of processing this type of multi-sort packaging. This type of process was done manually by operators who took the product from each line and delivered it to the packaging machine.

- Brazil, Mexico, and Argentina are the main drivers for the region, with automated processes such as filling, labeling, bag egging, palletizing, and capping. Various businesses in food, pharmaceutical, cosmetic, personal care, beverage, and even warehouse are increasingly using these automation solutions to optimize business processes and reduce operating costs.

Latin America Packaging Automation Market Trends

Food and Beverage segment to hold biggest operating expense

As technology advances to become more flexible and configurable, companies are improving logistics and quality. Automation will continue to transform food and beverage manufacturing companies throughout the supply chain and to their customer's doors.

Consumer packaged goods companies need accurate and repeatable packaging processes. Individual packaging at high-cycle rates can be challenging, so companies that use robotics in their packaging lines can improve their throughput, efficiency, and quality. From raw product handling to primary packaging, secondary packaging, and palletizing, robotics has proven a high return on investment.

Packaging automation also involves greener solutions like recyclable, biodegradable, and refillable methods in the region. According to research conducted, Latin America has a low penetration for dishwashers, and hand washing is dominant where the plastic PET bottle is a dominant product pack and has increased its growth in terms of volume in this region.

Further, Coca-Cola company in Brazil invested in expanding the reuse infrastructure as part of its ambition to incorporate the design of reusable PET bottles and significantly expand reusable packaging by 2030. Universal bottle design for all brands significantly reduces cleaning, filling, and return logistics costs.

The meat industry and its by-products are an important sector on the continent. Companies are facing new challenges as more and more consumers are concerned about the origin and processing of meat. HPP technology allows obtaining high-quality raw or cooked products with a longer shelf life, opening up export possibilities to other countries.

Latin American consumers take on new horizons for cleaner additives, more sustainable, and easy to consume. In other markets, consumers are looking for more secure, sustainable, and safe packaging for the products purchased, and for that reason, companies are innovating new products with new technological innovations.

Mexico to grow significantly in the industry

Technological innovation, sustainability concerns, and attractive economies are some of the reasons packaging automation has grown significantly over the last few years in this region and the way consumers view and interact with packages is also changing.

- Mexico is moving towards modernization for its packaging technologies; considering the stability of the current economic, commercial and political situation and the expected growth of the country; it can be expected that packaging equipment imports will continue to grow in the near future.

- Growth is expected to be driven by key factors such as strong domestic and international demand and the interest of many companies to modernize their operations to improve efficiency and competitiveness.

- Several multinational companies and business groups using packaging machines have indicated that they will continue to invest in Mexico, understanding the impact of political decisions on their operations. Businesses are adapting to the country's realities, and for now, demand prospects and growth in Mexico are stable.

- The food, beverage, personal care, and pharmaceutical industries account for the majority of packaging machinery demand. A high proportion of young people and a growing middle class are driving food demand. The beverage sector performs particularly well in products such as soft drinks, bottled water, beer, and spirits, respectively.

- Further, in the pharmaceutical industry, despite the intensifying competition from generic drugs and low levels of new investments, the pharmaceutical sector continues to keep its sector competitive and in demand for packaging machinery.

Latin America Packaging Automation Industry Overview

Latin America automation packaging is moderately fragmented with the presence of major players in the industry such as Amcor Flexibles MX, Avery Dennison Corporation, Berry Global Inc., Sonoco Products Company, and more. These companies are investing in R&D for product innovations and adapting to new technological innovations for growth.

- September 2020 - Avery Dennison Corporation launched biodegradable apparel tag fasteners made of material that degrades within one year of exposure to soil organisms, replacing the plastic. This new Ecotach bio-PP Fastener degrades without leaving behind microplastics, which are harmful substances for the environment.

- October 2021 - Amcor offered cooking oil bottles made entirely from recycled content in Colombia. Amcor worked with Alianza Team to launch the first bottle in Colombia for cooking oil made with all recycled content. Amcor Rigid Packaging (ARP) refined its bottles to ensure it is safe, causes no change in taste, and is transparent - while maintaining Gourmet's visual branding.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Force Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of the Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Introduction to Market Drivers and Restraints

- 5.2 Market Drivers

- 5.2.1 Increasing Pressure on Manufacturers to Cut Down Operating Costs

- 5.2.2 Reduces Machine Downtime and Product Waste

- 5.2.3 Emerging Markets are Emerging as Low Cost Labor and Increased Competition

- 5.3 Market Restraints

- 5.3.1 High Initial Investment

6 MARKET SEGMENTATION

- 6.1 Businesses Type

- 6.1.1 B2B e-commerce retailers

- 6.1.2 B2C e-commerce retailers

- 6.1.3 Omni Channel Retailers

- 6.1.4 Wholesale Distributors

- 6.1.5 Manufacturers

- 6.1.6 Personal Document Shippers

- 6.1.7 Others

- 6.2 End-User Vertical

- 6.2.1 Food

- 6.2.2 Pharmaceuticals

- 6.2.3 Cosmetics

- 6.2.4 Household

- 6.2.5 Beverages

- 6.2.6 Chemical

- 6.2.7 Confectionery

- 6.2.8 Warehouse

- 6.2.9 Others

- 6.3 Product Type

- 6.3.1 Filling

- 6.3.2 Labelling

- 6.3.3 Horizontal/Vertical Pillow

- 6.3.4 Case Packaging

- 6.3.5 Bagging

- 6.3.6 Palletizing

- 6.3.7 Capping

- 6.3.8 Wrapping

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Amcor PLC

- 7.1.2 Klabin SA

- 7.1.3 Printpack Inc.

- 7.1.4 Berry Global Inc.

- 7.1.5 Westrock Company

- 7.1.6 Constantia Flexibles

- 7.1.7 Sealed Air Corporation

- 7.1.8 Transcontinental Mexico

- 7.1.9 Sonoco Products Company

- 7.1.10 Avery Dennison Corporation

- 7.1.11 Clifton Packaging Packaging SA de CV