|

시장보고서

상품코드

1631574

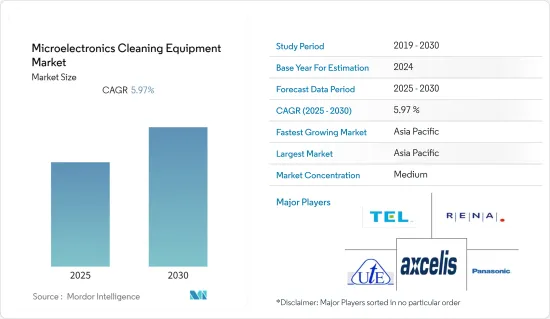

마이크로일렉트로닉스 세정 장비 : 시장 점유율 분석, 산업 동향 및 통계, 성장 예측(2025-2030년)Microelectronics Cleaning Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

마이크로일렉트로닉스 세정 장비 시장은 예측 기간 동안 CAGR 5.97%를 기록할 것으로 예상됩니다.

웨이퍼, MEMS, IC, PCB와 같은 마이크로 전자 장치는 거의 모든 전자 장치의 구성요소로 간주되며, 성능과 신뢰성을 유지하기 위해 세척 공정이 필요합니다. 따라서 마이크로일렉트로닉스의 세정은 반도체 산업에서 모든 전자 장치의 기능에 있어 중요한 단계입니다. 이러한 장치의 세척에 대한 수요가 증가하고 있으며, 예측 기간 동안 시장 성장을 주도하고 있습니다.

주요 하이라이트

- 세계 반도체 무역 통계(WSTS)에 따르면, 세계 반도체 시장 규모는 2019년 4,123억 달러에서 2021년 4,600억 달러에 달할 것으로 예상됩니다. 반도체 시장을 주도하는 것은 전체 전자기기의 전력 관리 요구의 증가와 소형화입니다.

- 스마트폰, 태블릿, TV, 노트북, 노트북, 아이팟, 카메라, 세탁기, 프린터, 음악 시스템 등 가전제품에 반도체의 통합으로 인한 반도체 산업의 성장 증가에 따라 마이크로일렉트로닉스 세정장치는 실리콘 웨이퍼, 화합물 반도체 소자 웨이퍼 등 세척에 사용되기 때문에 시장이 크게 성장하고 있습니다.

- 또한, 자동화 도입이 진행됨에 따라 생산 시 세척 방법이 증가하고 실리콘 기반 센서에 대한 수요가 증가함에 따라 마이크로일렉트로닉스 세정 장비에 대한 수요가 증가하고 있습니다. 또한, 마이크로일렉트로닉스 세정 장비의 주요 용도는 IC 제조 산업이며, 제조 공정의 상당 부분이 웨이퍼 세정이 이루어지고 있습니다.

- 또한, 전자 제품의 기능 및 성능을 저해하는 표면 오염 및 결함의 부정적인 영향에 대한 인식이 높아지면서 시장 성장을 촉진하는 중요한 요인이 되고 있습니다. 또한, ISO 14000의 도입으로 인해 기술 프로세스의 다양한 부분에서 세척이 더욱 중요해졌습니다. 그러나 화학제품 및 독성 가스와 관련된 환경 문제의 증가와 숙련된 노동자의 부족은 시장 성장을 저해하는 요인으로 작용하고 있습니다.

- COVID-19는 반도체 산업에 부정적인 영향을 미치고 있으며, 정부의 봉쇄로 인해 공급망에 큰 혼란이 발생하여 제조에 영향을 미치고 반도체 장치에 대한 소비자 수요를 감소시키고 있습니다. 또한, 중소기업들은 시장에서 살아남기 위해 고군분투하고 있습니다.

마이크로일렉트로닉스 세정 장비 시장 동향

미세전자기계시스템(MEMS)이 시장 성장을 견인

- 미세전자기계시스템(MEMS) 센서는 정밀도와 신뢰성, 전자기기 소형화 가능성 등 여러 가지 장점을 가지고 있습니다. 그 결과, MEMS 센서는 최근 몇 년 동안 큰 주목을 받고 있습니다. 산업 자동화, 웨어러블 및 IoT 연결 장치와 같은 소형화된 소비자용 장치에 대한 수요는 지역에 따라 다르지만, MEMS 센서를 견인하는 중요한 요소 중 하나입니다.

- 따라서 MEMS의 수요 확대에 따라 시장도 성장할 가능성이 높습니다. 웨이퍼의 불순물이나 공정의 미립자는 MEMS 디바이스의 고장의 주요 원인 중 하나입니다. 따라서 MEMS 분야에서는 여전히 세정이 중요한 공정으로 자리 잡고 있습니다.

- 또한, 각 지역의 군사비 증가는 드론/무인항공기(UAV)와 같은 MEMS 센서에 대한 길을 열어주고 있습니다. 하이엔드 내비게이션 시스템을 장착한 기존 전투기에는 MEMS 압력 센서의 사용이 크게 증가하고 있습니다. 애플리케이션에 따라 최소한의 표준화된 MEMS 솔루션은 고도의 커스터마이징이 가능합니다.

- 독일, 미국, 중국, 인도 등 각국 정부는 커넥티드 자동화 환경을 구축하고 운영 효율성을 향상시키기 위해 자동화 및 산업 제어 시스템(ICS)을 증가시켜 스마트 제조 기술에 집중하고 있습니다. 공정 제어 외에도 MEMS 센서는 자동차 검사, 냉장고 상태 모니터링, HVAC 제어, 누출 감지, 압력 강하 등의 용도가 있습니다. 이러한 사례들이 시장 성장을 촉진할 가능성이 높습니다.

아시아태평양이 가장 높은 시장 점유율을 차지합니다.

- 아시아태평양의 반도체 산업은 중국, 일본, 대만, 한국이 주도하고 있으며, 전 세계 개별 반도체 시장의 약 65%를 차지하고 있습니다. 반면, 베트남, 태국, 말레이시아, 싱가포르와 같은 다른 국가들도 그 지배력에 크게 기여하고 있습니다.

- 인도, 중국, 일본, 싱가포르와 같은 국가에서 스마트폰 및 기타 소비자 전자제품에 대한 큰 수요로 인해 많은 업체들이 이 지역에 생산 시설을 설립하고 있습니다. 풍부한 원자재 가용성, 저렴한 설립 비용과 인건비도 기업들이 이 지역에 생산기지를 설립하는 데 도움이 되고 있습니다.

- 아시아태평양은 자동차, 가전, 산업 등의 산업에서 마이크로일렉트로닉스에 대한 수요를 목격하고 있습니다. 파나소닉(Panasonic Corporation), 다이니폰 스크린 제조(Dainippon Screen Manufacturing Corporation)와 같은 업체들이 이 지역에 본사를 두고 있습니다. 다른 여러 개별 반도체 제조업체들도 저비용 제조의 이점으로 인해 이 지역에 강력한 생산기지를 두고 있습니다.

- 또한, 대만은 혁신적인 마이크로일렉트로닉스 제조 강국으로 알려져 있으며, 노트북 PC, LCD 모니터, 칩 테스트, 칩 파운드리 서비스 분야에서 세계 최고의 생산국 중 하나로 여겨지고 있습니다. 따라서 이 지역은 시장 잠재력이 매우 큰 지역입니다.

마이크로일렉트로닉스 세정 장비 산업 개요

마이크로일렉트로닉스 세정 장비 시장은 상당히 세분화되어 있습니다. 이 시장의 기업들은 전략적 제휴, 합병, 인수를 채택하고 반도체 산업의 높은 수요를 충족시키기 위해 제품 제공을 개선하기 위해 투자하고 있습니다. 최근 몇 가지 시장 개척 동향을 소개하고자 합니다:

- 2020년 5월 - 파나소닉과 엔드투엔드 공급망 소프트웨어 제공업체인 블루욘더(Blue Yonder)가 자율 공급망을 가속화하기 위해 전략적 파트너십을 연장했습니다.

기타 특전:

- 엑셀 형식의 시장 예측(ME) 시트

- 3개월간 애널리스트 지원

목차

제1장 소개

- 조사 가정과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 역학

- 시장 개요

- 산업 밸류체인 분석

- 업계의 매력 - Porter's Five Forces 분석

- 공급 기업의 교섭력

- 소비자의 협상력

- 신규 참여업체의 위협

- 대체품의 위협

- 경쟁 기업 간의 경쟁 관계

- 시장 성장 촉진요인

- 반도체 웨이퍼 산업의 성장

- MEMS 이용 증가

- 스마트폰과 태블릿 수요 증가

- 시장 과제

- 마이크로일렉트로닉스 세정 장비 시장에 대한 COVID-19의 영향

제5장 시장 세분화

- 유형별

- 싱글 시스템

- 매엽식 저온 시스템

- 매엽식 스프레이 시스템

- 배치 시스템

- 배치 침지 세정 시스템

- 배치식 스프레이 세정 시스템

- 싱글 시스템

- 기술별(정성 동향 분석)

- 웨트

- RCA 세정

- 황산 솔루션

- HF산용액

- 수성

- FEOL 세정액

- BEOL 세정액

- 신흥 수용액

- 극저온 세정 솔루션

- 드라이

- 기상 세정 솔루션

- 플라즈마 세정 솔루션

- 신규 솔루션

- 레이저 세정

- 화학 치료 솔루션

- 건식 입자 솔루션

- 물순도 솔루션

- 웨트

- 용도별

- 인쇄회로기판(PCB)

- 미세전자기계 시스템(MEMS)

- 집적회로(IC)

- 디스플레이

- 하드 디스크·드라이브(HDD)

- 기타

- 지역별

- 북미

- 유럽

- 아시아태평양

- 세계 기타 지역

제6장 경쟁 구도

- 기업 개요

- TEL FSI Inc.

- Panasonic Corporation

- RENA Technologies GmbH

- Axcelis Technologies Inc.

- Ultra t Equipment Company, Inc.

- NAURA Akrion Inc

- Quantum Global Technologies, LLC

- Dainippon Screen Mfg. Co., Ltd.

- Speedline Technologies, Inc

- Axus Technology LLC

제7장 투자 분석

제8장 시장 전망

ksm 25.02.06The Microelectronics Cleaning Equipment Market is expected to register a CAGR of 5.97% during the forecast period.

Microelectronics devices such as wafers, MEMS, ICs, and PCBs, which are considered building blocks of almost all the electronic devices, require the cleaning process to maintain performance and reliability. Hence, microelectronics cleaning is a crucial step concerning the functioning of any electronic device in the semiconductor industry. The demand for cleaning such devices is rising, thereby driving the market growth during the forecast period.

Key Highlights

- According to World Semiconductor Trade Statistics (WSTS), the global semiconductor market size is expected to reach USD 460 billion by 2021, compared to USD 412.3 billion in 2019. The semiconductor market is driven by the increasing need to manage power across electronics and miniaturization.

- With the increase in the growth of the semiconductor industry due to the integration of semiconductors into consumer electronics devices, such as smartphones, tablets, television, laptops, iPods, cameras, washing machines, printers, music systems, and others, the market is experiencing significant growth as microelectronics cleaning equipment are used to clean silicon wafers, compound semiconductor device wafers, etc.

- Moreover, the growing adoption of automation has led to an increase in the number of cleaning methods during production and high demand for silicon-based sensors, which is likely to trigger the need for microelectronics cleaning equipment. Also, the primary application of microelectronics cleaning equipment is in the IC fabrication industry, where a significant percentage of the fabrication process involves cleaning the wafers.

- Further, rising awareness about the adverse effect of surface contamination & defects on an electronic product that hampers functioning & performance is the significant factor that propels the market growth. Furthermore, with the introduction of ISO 14000, the cleaning has become more important for different parts of technological processes. However, growing environmental concerns regarding chemicals & toxic gasses and lack of skilled workforce are the factors that are hindering the market growth.

- The Outbreak of COVID-19 has an adverse effect on the semiconductor industry with massive disruptions in the supply chain due to lockdown imposed by the governments that have affected manufacturing and hauled consumer demand for semiconductor devices. Moreover, small and medium scale companies are struggling to sustain in the market.

Microelectronics Cleaning Equipment Market Trends

Microelectromechanical Systems (MEMS) to Drive the Market Growth

- Microelectromechanical system (MEMS) sensors offer several advantages, such as accuracy and reliability, and the potential to make smaller electronic devices. As a result, they have gained significant traction in the past few years. Industrial automation and demand for miniaturized consumer devices, such as wearables and IoT-connected devices, among others, across regions, are among the significant factors driving the MEMS sensors.

- Hence, with the growing demand for MEMS, the market is likely to grow. Wafer impurities and process particulates are one of the prime reasons for MEMS device failure. Therefore cleaning remains the crucial process in the MEMS domain.

- Moreover, the increasing military spending across regions is paving the way for MEMS sensors, like drones/unmanned aerial vehicles (UAVs). The usage of MEMS pressure sensors in traditional fighter jets, with high-end navigation systems, is increasing significantly. MEMS solutions that have minimum standardization, based on applications, are highly customizable.

- Governments are focusing on smart manufacturing techniques by increasing automation and industrial control systems (ICS), to create a connected automated environment and improve the operational efficiencies across regions, such as Germany, the United States, China, and India. In addition to process control, the MEMS sensors find applications, such as automotive testing, condition monitoring of refrigerators, HVAC control, leak detection, pressure drops, etc. Such instances are likely to boost the market growth.

Asia-Pacific Holds Highest Market Share

- Asia-Pacific's semiconductor industry is driven by China, Japan, Taiwan, and South Korea, constituting around 65% of the global discrete semiconductor market. In contrast, others like Vietnam, Thailand, Malaysia, and Singapore also contribute significantly to its dominance.

- Significant demand for smartphones and other consumer electronics devices from countries like India, China, Japan, and Singapore encourages many vendors to set up production establishments in the region. The abundant availability of raw materials and the low establishment and labor costs have also helped companies launch their production centers in the region.

- Asia-pacific is witnessing demand for microelectronics from industries, such as automotive, consumer electronics, and industrial. Vendors operating in the market studied, such as Panasonic Corporation, Dainippon Screen Mfg. Co., Ltd. is headquartered in the region. Several other discrete semiconductor companies have a strong production base in the region due to the low-cost manufacturing benefit.

- Moreover, Taiwan is known for microelectronics manufacturing powerhouse for innovations and considered as one of the best producers of notebook PCs, LCD monitors, chip-testing, and chip-foundry services worldwide. Hence, the region has a vast scope for the market.

Microelectronics Cleaning Equipment Industry Overview

The microelectronics cleaning equipment market is moderately fragmented. Players in the market are adopting strategic partnerships, mergers, and acquisitions and investing in improving their product offering to cater to the high demands from the semiconductor industry. Some of the recent developments in the market are:

- In May 2020 - Panasonic Corporation and Blue Yonder, an end-to-end supply chain software provider, extended its strategic partnership to accelerate the autonomous supply chain.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Market Drivers

- 4.4.1 Growth in the Semiconductor Wafer Industry

- 4.4.2 Increasing use of MEMS

- 4.4.3 Increasing Demand for Smartphones & Tablets

- 4.5 Market Challenges

- 4.6 Impact of COVID-19 on the Microelectronics Cleaning Equipment Market

5 MARKET SEGMENTATION

- 5.1 By Type

- 5.1.1 Single System

- 5.1.1.1 Single-Wafer Cryogenic Systems

- 5.1.1.2 Single-Wafer Spray Systems

- 5.1.2 Batch System

- 5.1.2.1 Batch Immersion Cleaning Systems

- 5.1.2.2 Batch Spray Cleaning Systems

- 5.1.1 Single System

- 5.2 By Technology (Qualitative Trend Analysis)

- 5.2.1 Wet

- 5.2.1.1 RCA Cleaning

- 5.2.1.2 Sulphuric Acid Solutions

- 5.2.1.3 HF Acid Solutions

- 5.2.2 Aqueous

- 5.2.2.1 FEOL Cleaning Solutions

- 5.2.2.2 BEOL Cleaning Solutions

- 5.2.2.3 Emerging Aqueous Solutions

- 5.2.2.4 Cryogenic Cleaning Solutions

- 5.2.3 Dry

- 5.2.3.1 Vapor-Phase Cleaning Solution

- 5.2.3.2 Plasma Cleaning Solution

- 5.2.4 Emerging Solutions

- 5.2.4.1 Laser Cleaning

- 5.2.4.2 Chemical Treatment Solutions

- 5.2.4.3 Dry Particle Solutions

- 5.2.4.4 Water Purity Solutions

- 5.2.1 Wet

- 5.3 By Application

- 5.3.1 Printed Circuit Board (PCB)

- 5.3.2 Microelectromechanical Systems (MEMS)

- 5.3.3 Integrated Circuit (ICs)

- 5.3.4 Display

- 5.3.5 Hard Disk Drives (HDD)s

- 5.3.6 Others

- 5.4 By Geography

- 5.4.1 North America

- 5.4.2 Europe

- 5.4.3 Asia Pacific

- 5.4.4 Rest of the World

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 TEL FSI Inc.

- 6.1.2 Panasonic Corporation

- 6.1.3 RENA Technologies GmbH

- 6.1.4 Axcelis Technologies Inc.

- 6.1.5 Ultra t Equipment Company, Inc.

- 6.1.6 NAURA Akrion Inc

- 6.1.7 Quantum Global Technologies, LLC

- 6.1.8 Dainippon Screen Mfg. Co., Ltd.

- 6.1.9 Speedline Technologies, Inc

- 6.1.10 Axus Technology LLC