|

시장보고서

상품코드

1685751

형상 기억 폴리머 : 시장 점유율 분석, 산업 동향, 통계, 성장 예측(2025-2030년)Shape-memory Polymer - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

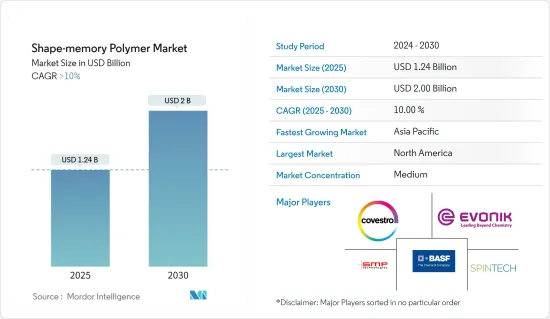

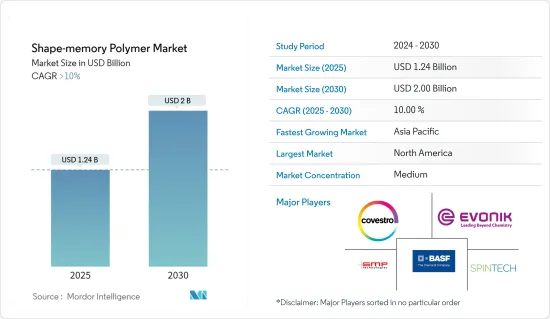

형상 기억 폴리머 시장 규모는 2025년에 12억 4,000만 달러, 2030년에는 20억 달러에 이를 것으로 예측됩니다. 예측기간 중(2025-2030년) CAGR은 10%를 나타낼 것으로 예상됩니다.

주요 하이라이트

- 헬스케어 산업에서의 형상 기억 폴리머의 용도 확대와 아시아태평양 건설 업계 수요 증가는 예측기간 중 시장 성장의 주요 촉진요인이 될 것으로 예상됩니다.

- 형상 기억 중합체의 강성 값이 비교적 낮다는 것은 시장 성장을 억제할 것으로 예상됩니다.

- 형상 기억 폴리머의 생의학 응용 분야에서의 개발과 혁신은 시장 성장 기회를 제공할 것으로 예상됩니다.

- 예측 기간 동안 시장은 아시아태평양에서 가장 빠른 성장률을 보일 것으로 예상됩니다.

형상 기억 폴리머 시장 동향

온도 유도 부문이 시장을 독점할 전망

- 열 유도형 또는 온도-유도형 형상 기억 중합체(SMP)는 직접 열을 가함으로써 활성화되는 SMP 중에서 가장 연구된 유형입니다. 가해지는 온도가 중합체의 전이 온도보다 높으면 일시적인 형상을 SMP에 프로그래밍 할 수 있습니다.

- 열에 의해 유도된 SMP의 메커니즘은 용융 온도와 유리 전이 온도라는 두 가지 열 전이를 기반으로 합니다.

- 가장 흔한 융점 기반 SMP는 폴리올레핀, 폴리에테르, 폴리에스테르이며, 이들은 융점이 낮은 부드러운 상과 고온에서도 변하지 않는 결정성 하드상을 나타냅니다.

- 유리 전이 온도가 25℃ 이상의 SMP는 유리 전이 온도계 재료라고 불리며, 융점계 SMP에 비해 형상 회복이 느립니다. 그러나 느린 형상 회복은 치열 교정과 같은 임상 목적뿐만 아니라 삽입으로 인한 조직 손상을 피하기 위해 바람직하기 때문에 생체 의료 용도에서 중요한 특성입니다.

- Shape Memory Polymeric Materials for Biomedical Applications라는 제목의 논문에 따르면, 바이오메디컬 용도의 SMP는 일반 의료, 약물전달, 재생 의료, 치과, 신경의료, 암 치료, 정형외과, 부식 방지 등의 분야에서 폭넓게 응용이 가능합니다. 그러므로 바이오메디컬 분야의 성장은 향후 온도 유도형 SMP에 이익을 가져올 것으로 보입니다.

- Evaluate Ltd에 따르면 전 세계 의약 연구 개발에 대한 총 지출은 2028년까지 3,020억 달러에 이를 것으로 예측되며, 2022년 2,440억 달러에서 24%의 가치 성장을 이룰 것으로 예상됩니다.

- Mediobanca에 따르면 2024년 말까지 의료기술산업의 세계 매출은 약 6,820억 달러에 달할 전망입니다. 의료기술산업의 지속적인 성장은 온도유도형 SMP에 대한 수요도 높일 것으로 보입니다.

- 온도 유도형 SMP는 경량, 복원 가능한 변형 능력, 생체 적합성 등의 장점에서 항공우주 산업에서도 널리 사용되고 있습니다. 항공우주 산업에서 SMP를 사용하면 연비 향상, 배출 가스 절감, 성능 향상으로 이어집니다.

- 2023년 6월 보잉은 2042년까지 신형 민간 제트기 수요가 42,600대에 이르고 8조 달러에 달할 것으로 예측했습니다. 게다가, 이러한 납품기의 약 절반은 배출량 감소를 위해 더 연비가 좋은 모델로 대체됩니다. 이는 예측 기간 동안 온도 유도형 SMP 수요를 높일 것으로 예상됩니다.

- 따라서 위의 요인들로부터 온도유도형 SMP는 예측기간 동안 시장 우위를 유지하면서 주요 시장 점유율을 차지할 것으로 보입니다.

아시아태평양이 가장 높은 성장률을 보여줄 전망

- 아시아태평양은 중국, 인도, 일본과 같은 국가에서 수요가 증가함에 따라 형상 기억 폴리머(SMP) 수요가 크게 늘어날 것으로 예상됩니다.

- 이 지역에는 자동차, 건설, 헬스케어, 섬유 등의 산업이 활발한 나라가 있습니다. 예를 들어, 중국은 세계 최대의 건설, 자동차, 섬유 시장입니다.

- 게다가 국제자동차공업회(OICA)에 따르면 2022년에는 중국, 일본, 인도, 한국이 승용차와 상용차 생산 대수로 주요 5개국에 들어갔습니다. 예를 들어 중국은 2023년에 3,000만대 이상의 승용차 및 상용차를 생산했습니다.

- 세계의 사륜차 보유 수요가 증가하고, 배터리 구동의 전기자동차로의 전환 동향도 확대하고 있기 때문에 신차 생산 대수는 해마다 증가하고 있습니다. 중국 자동차 공정 학회에 따르면 2030년 자동차 판매 대수는 3,800만대에 이를 전망이며, 그 중 EV의 판매 대수는 1,500만대, 40%에 이를 것으로 추정되고 있습니다. 이로 인해 SMP 수요가 증가하고 아시아태평양에서 급성장할 수 있습니다.

- 또한 SMP는 건설 업계에서도 널리 채택되고 있습니다. 중국과 인도의 건설 업계는 향후 수년간 급성장이 예상되고 있으며, 이 지역 시장 성장에 크게 기여할 것으로 기대됩니다. 옥스포드 이코노믹스에 따르면 중국, 미국, 인도는 2037년까지 세계 건설 공사의 51%를 차지할 것이며, 그 규모는 13조 9,000억 달러에 이를 것으로 예측됩니다.

- 따라서 위의 이유로 아시아태평양은 예측 기간 동안 가장 높은 성장을 이룰 가능성이 높습니다.

형상 기억 폴리머 산업 개요

세계의 형상 기억 폴리머 시장은 시장 점유율의 대부분이 소수의 기업로 나뉘어져 있기 때문에 적당히 통합되어 있습니다. 시장의 주요 기업으로는 BASF SE, Covestro AG, Evonik Industries AG, SMP Technologies Inc., Spintech Holdings Inc. 등이 있습니다.

기타 혜택

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트 서포트

목차

제1장 서론

- 조사의 전제조건

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 역학

- 성장 촉진요인

- 헬스케어 분야에서의 용도 확대

- 아시아태평양의 건설 업계로부터 수요 증가

- 기타

- 억제요인

- 강성값이 비교적 낮은

- 업계 밸류체인 분석

- Porter's Five Forces 분석

- 공급기업의 협상력

- 소비자의 협상력

- 신규 참가업체의 위협

- 대체품의 위협

- 경쟁도

제5장 시장 세분화

- 자극 유형

- 온도유발형

- 광 유도형

- 전기 자극

- 기타 자극 유형

- 최종 사용자 산업

- 항공우주

- 자동차

- 건설

- 헬스케어

- 기타 최종 사용자 산업

- 지역

- 아시아태평양

- 중국

- 인도

- 일본

- 한국

- 베트남

- 태국

- 인도네시아

- 말레이시아

- 기타 아시아태평양

- 북미

- 미국

- 캐나다

- 멕시코

- 유럽

- 독일

- 영국

- 프랑스

- 이탈리아

- 러시아

- 노르딕

- 터키

- 스페인

- 기타 유럽

- 남미

- 브라질

- 아르헨티나

- 콜롬비아

- 기타 남미

- 중동 및 아프리카

- 사우디아라비아

- 나이지리아

- 카타르

- 아랍에미리트(UAE)

- 이집트

- 남아프리카

- 기타 중동 및 아프리카

- 아시아태평양

제6장 경쟁 구도

- M&A, 합작사업, 제휴, 협정

- 시장 점유율/랭킹 분석

- 주요 기업의 전략

- 기업 프로파일

- BASF SE

- Covestro AG

- Evonik Industries AG

- Spintech Holdings Inc.

- EndoShape Inc.

- Nanoshel LLC

- SMP Technologies Inc.

- Asahi Kasei Corporation

- Composite Technology Development Inc.

- Shape Memory Medical

- MedShape Inc.

제7장 시장 기회와 앞으로의 동향

- 형상 기억 폴리머의 바이오 메디컬 용도에 있어서의 개발과 혁신

The Shape-memory Polymer Market size is estimated at USD 1.24 billion in 2025, and is expected to reach USD 2.00 billion by 2030, at a CAGR of greater than 10% during the forecast period (2025-2030).

Key Highlights

- The increasing application of shape-memory polymers in the healthcare industry and the growing demand from the Asia-Pacific construction industry are expected to be the primary drivers of market growth during the forecast period.

- The relatively low stiffness value of shape-memory polymers is expected to restrain market growth.

- Development and innovation in the biomedical uses or applications of shape-memory polymers are expected to offer market growth opportunities.

- The market is expected to witness the fastest growth rate in the Asia-Pacific region during the forecast period.

Shape Memory Polymer Market Trends

The Temperature-induced Segment is Expected to Dominate the Market

- Thermally-induced or temperature-induced types of shape-memory polymers (SMPs) are the most studied type of SMPs that can be activated by direct thermal application. When the temperature applied is higher than the polymer transition temperature, a transitory shape can be programmed to an SMP.

- The thermally-induced SMP mechanism is based on two thermal transitions: melting temperature and glass transition temperature.

- The most common melting temperature-based SMPs are polyolefins, polyethers, and polyesters, which show a low melting temperature soft phase and a crystalline hard phase that remains unchanged at high temperatures.

- SMPs whose glass transition temperature is above 25 °C are referred to as glass transition temperature-based materials, and they show a slow shape recovery compared to melting temperature-based SMPs. However, slow shape recovery is a significant property for biomedical applications because it is preferred not only for clinical purposes such as orthodontic applications but also for avoiding insertion-induced tissue damage.

- According to the article titled Shape Memory Polymeric Materials for Biomedical Applications, SMPs for biomedical applications have wide applicability in the fields of general medicine, drug delivery, regenerative medicine, dentistry, neuromedicine, cancer therapy, orthopedics, and corrosion protection. Therefore, the growth in the field of biomedical will benefit the temperature-induced type of SMPs in the future.

- According to Evaluate Ltd, the gross spending on pharmaceutical research and development worldwide will reach USD 302 billion by 2028, making a 24% growth in value over USD 244 billion in 2022.

- By the end of 2024, the worldwide revenue of the medical technology industry will likely be around USD 682 billion, according to Mediobanca. The continuous growth in the medical technology industry will also boost the demand for temperature-induced SMPs.

- Temperature-induced SMPs are also widely used in the aerospace industry because of their advantages, such as their light weight, large recoverable deformation capability, and biocompatibility. The use of SMPs in the aerospace industry leads to improved fuel efficiency, reduced emissions, and enhanced performance.

- In June 2023, Boeing forecasted that the demand for new commercial jets by 2042 will likely reach 42,600, valued at USD 8 trillion. Additionally, about half of those deliveries will replace older jets with more fuel-efficient models for reducing emissions. This is expected to boost the demand for temperature-induced SMPs during the forecast period.

- Hence, owing to the above-mentioned factors, temperature-induced SMPs are likely to account for the major market share while maintaining their market dominance during the forecast period.

Asia-Pacific is Expected to Witness the Highest Growth Rate

- Asia-Pacific is expected to witness major growth in the demand for shape-memory polymers (SMPs) owing to the increasing demand from countries like China, India, and Japan.

- The region has countries with substantially large automotive, construction, healthcare, textile, and other industries. For instance, China is the world's largest construction, automotive, and textile market.

- Moreover, according to the International Organization of Motor Vehicle Manufacturers (OICA), in 2022, China, Japan, India, and South Korea were among the top 5 countries in terms of the production volume of passenger cars and commercial vehicles. For instance, China manufactured over 30 million units of passenger cars and commercial vehicles in 2023.

- As the global demand for owning a personal four-wheeler vehicle is increasing and the trend of switching over to battery powered electric cars is expanding, the production of new cars will increase year-on-year. According to the Society of Automotive Engineering of China, car sales in 2030 are expected to reach 38 million, of which the sales of EVs are estimated to amount to 15 million, or 40%. Such factors will increase the demand for SMPs, leading to rapid growth in the Asia-Pacific.

- Also, SMPs are widely being adopted in the construction industry. With the construction industries of China and India expected to witness rapid growth in the coming years, a significant contribution to the market growth in the region is expected to be made. According to Oxford Economics, China, the United States, and India will account for 51% of global construction work done by 2037, valued at USD 13.9 trillion.

- Hence, owing to the reasons mentioned above, Asia-Pacific is likely to witness the highest growth during the forecast period.

Shape Memory Polymer Industry Overview

The global shape-memory polymer market is moderately consolidated as the majority of the market share is divided among a few players. Some of the key players in the market include BASF SE, Covestro AG, Evonik Industries AG, SMP Technologies Inc., and Spintech Holdings Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Applications in Healthcare

- 4.1.2 Growing Demand From the Construction Industry in Asia-Pacific

- 4.1.3 Others

- 4.2 Restraints

- 4.2.1 Relatively Low Stiffness Values

- 4.3 Industry Value-chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION

- 5.1 Stimulus Type

- 5.1.1 Temperature-induced

- 5.1.2 Light-induced

- 5.1.3 Electricity-induced

- 5.1.4 Other Stimulus Types

- 5.2 End-user Industry

- 5.2.1 Aerospace

- 5.2.2 Automotive

- 5.2.3 Construction

- 5.2.4 Healthcare

- 5.2.5 Other End-user Industries

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Vietnam

- 5.3.1.6 Thailand

- 5.3.1.7 Indonesia

- 5.3.1.8 Malaysia

- 5.3.1.9 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Russia

- 5.3.3.6 NORDIC

- 5.3.3.7 Turkey

- 5.3.3.8 Spain

- 5.3.3.9 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colmbia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 Nigeria

- 5.3.5.3 Qatar

- 5.3.5.4 United Arab Emirates

- 5.3.5.5 Egypt

- 5.3.5.6 South Africa

- 5.3.5.7 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 BASF SE

- 6.4.2 Covestro AG

- 6.4.3 Evonik Industries AG

- 6.4.4 Spintech Holdings Inc.

- 6.4.5 EndoShape Inc.

- 6.4.6 Nanoshel LLC

- 6.4.7 SMP Technologies Inc.

- 6.4.8 Asahi Kasei Corporation

- 6.4.9 Composite Technology Development Inc.

- 6.4.10 Shape Memory Medical

- 6.4.11 MedShape Inc.

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Development and Innovation in The Biomedical Use of Shape-memory Polymers