|

시장보고서

상품코드

1822581

유축기 시장 : 기회, 성장 촉진요인, 산업 동향 분석과 예측(2025-2034년)Milking Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

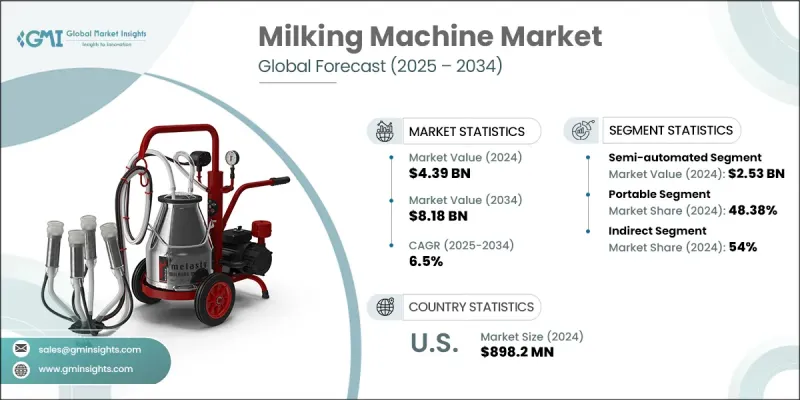

세계의 유축기 시장은 2024년에는 43억 9,000만 달러로 평가되었고, CAGR 6.5%로 성장하여 2034년에는 81억 8,000만 달러에 이를 것으로 예측되고 있습니다.

농촌의 노동력이 고령화되고 도시로의 이주가 계속되고 있는 가운데, 농업부문은 노동력에 관한 큰 과제에 직면하고 있습니다. 이러한 움직임으로 인해 세계 낙농가들은 생산성과 수익성을 유지하기 위해 착유의 자동화를 추진하려고 합니다. 수작업으로 인한 착유는 숙련된 노동력을 필요로 할뿐만 아니라 일관성 부족, 비위생 및 동물 스트레스의 위험을 증가시킵니다. 대조적으로, 자동화된 로봇 시스템은 인간 오류를 줄이고 동물의 복지를 향상시키고 전반적인 유질을 향상시킵니다. 이 기계는 일관된 착유 패턴을 제공하고 유방염을 억제하며 착유 과정의 청결을 보장함으로써 동물의 건강 기준과 현대 낙농장의 요구를 모두 충족합니다. 자동화는 더 이상 사치품이 아니며 지속 가능한 낙농 경영에 필수적입니다. AI 구동 추적 시스템과 IoT 대응 센서 등의 첨단 기술을 통해 낙농가는 무리의 건강 상태와 기기의 성능을 실시간으로 파악할 수 있게 되었습니다. 이 데이터 중심의 접근 방식은 적시에 개입을 가능하게 하여 농장 관리를 더욱 제어할 수 있게 되었습니다. 그 결과 스마트 자동화는 낙농 생산을 보다 정확하고 생산성이 높은 지속 가능한 산업으로 전 세계적으로 변화하고 있습니다.

| 시장 범위 | |

|---|---|

| 시작 연도 | 2024년 |

| 예측 연도 | 2025-2034년 |

| 시장 규모 | 43억 9,000만 달러 |

| 예측 금액 | 81억 8,000만 달러 |

| CAGR | 6.5% |

자동 착유 시스템 분야는 뛰어난 효율성과 24시간 가동을 통해 2024년에 주목할 만한 수익을 올렸습니다. 이 시스템은 독립적으로 작동하여 균일한 흡입, 타이밍 및 수율을 실현하고 우유의 양과 품질을 크게 향상시킵니다. 로봇 착유 유닛은 노동력 부족으로 고민하는 낙농장이나 생산 규모의 확대를 목표로 하는 낙농장에 특히 매력적입니다. 이 장비는 수작업의 개입을 줄이고 가축에 대한 스트레스를 최소화하고 AI와 IoT 기능을 갖추고 있기 때문에 낙농가는 소의 행동, 유량 및 장비의 효율성을 원격으로 모니터링 할 수 있습니다. 이러한 수준의 관리는 무리의 건강 상태를 개선하고, 감염을 예방하는 데 도움이 되며, 식품 안전 지침을 엄격하게 준수하고, 자동화 시스템을 최신 낙농 시설에 필수적인 요소로 만듭니다.

휴대용 유축기 부문은 2024년에 48.38%의 점유율을 차지했으며, 2025년부터 2034년에 걸쳐 CAGR은 8%를 보일 것으로 예측됩니다. 휴대용 유축기는 다재다능하고 가격이 저렴하며 조작이 쉽기 때문에 특히 개발 도상 지역의 중소규모의 낙농장에 매우 매력적입니다. 이 경량 유닛은 가축이 분산되거나 여러 목초지에 방목되는 경영에 이상적입니다. 고가의 고정식 시스템을 도입할 수 없는 낙농장에 있어서, 휴대용 유축기는 효율적인 생산을 유지하면서 노동력에 대한 의존도를 낮추는 비용 효율적인 옵션이 됩니다. 또한 이동식이기 때문에 다양한 가축의 유형이나 장소에서 사용할 수 있어 혼목 모델이나 농장의 레이아웃이 분산되어 있는 지역에서도 매력적입니다.

미국 유축기 시장은 73.8%의 점유율을 차지하며, 2024년에는 8억 9,820만 달러의 수익을 올렸습니다. 노동비용 상승, 숙련 낙농가 접근 제한, 농촌 인구 고령화로 미국 낙농장은 자동화 도입을 추진하고 있습니다. 미국에서는 대규모 상업 낙농이 시장을 독점하고 있으며 수익성을 보장하기 위해 고효율 솔루션이 필요합니다. 스마트 착유 시스템은 품질을 확보하면서 유량을 늘릴 수 있기 때문에 보급되고 있습니다. IoT 지원 기술은 이러한 시스템을 더욱 지원하여 낙농가가 가축의 건강, 유량 및 환경 상태를 실시간으로 추적할 수 있도록 합니다. 이 기술 첨단 접근법은 식품의 안전성, 추적성, 동물 복지에 중점을 둔 국가의 자세를 지원하는 것입니다.

세계의 유축기 시장을 형성하고 있는 유력 기업으로는 DeLaval, Boumatic, Lely, GEA Group, Fullwood Packo, Afimilk, Lusna, Agrifac Machinery, Prompt Dairy Tech, AMS-Galaxy USA, Melasty, Milkplan Farming Technologies, Kanters Holland, SA Chris등이 있습니다. 경쟁 우위를 확보하기 위해 시장 경쟁을 전개하는 기업은 제품 혁신, 실시간 모니터링 기능 및 AI 통합 시스템에 주력하고 있습니다. 시장 리더는 소규모 농장에서 대규모 낙농 경영까지 확장 가능한 솔루션을 제공하기 위해 자동화 및 로봇 공학에 많은 투자를 하고 있습니다. 기술 기업과의 전략적 제휴를 통해 기업은 건강 상태 추적, 수율 예측 및 자동 세척을 제공하는 IoT 지원 시스템을 개발하고 있습니다. 많은 기업들이 지역 유통업체와 제휴하고 지역 농업 요구에 맞게 제품을 조정함으로써 세계 사업을 확대하고 있습니다.

목차

제1장 조사 방법과 범위

제2장 주요 요약

제3장 업계 인사이트

- 생태계 분석

- 공급자의 상황

- 이익률

- 각 단계에서의 부가가치

- 밸류체인에 영향을 주는 요인

- 업계에 미치는 영향요인

- 성장 촉진요인

- 노동력 부족과 비용 상승

- 동물복지와 위생에 초점

- 신흥 시장에서 중소규모의 낙농장 성장

- 업계의 잠재적 위험 및 과제

- 높은 초기 투자액

- 지방에서의 기술 스킬의 부족

- 기회

- 아시아태평양 및 아프리카에서의 도입 증가

- AI와 IoT의 통합

- 성장 촉진요인

- 성장 가능성 분석

- 장래 시장 동향

- 기술과 혁신의 상황

- 규제 환경

- 밸류체인 분석

- 원재료 공급업체 및 부품 제조업체

- 기기 제조업체 및 OEM

- 유통 채널과 판매 네트워크

- 최종 용도 부문 및 용도

- 애프터 서비스 제공업체

- 가격 동향

- 지역별

- 기종별

- 규제 상황

- 표준 및 컴플라이언스 요건

- 지역 규제 틀

- 인증기준 무역 통계(HS코드-84341000)

- 주요 수입국

- 주요 수출국

- Porter's Five Forces 분석

- PESTEL 분석

제4장 경쟁 구도

- 소개

- 기업의 시장 점유율 분석

- 지역별

- 기업 매트릭스 분석

- 주요 시장 기업의 경쟁 분석

- 경쟁 포지셔닝 매트릭스

- 주요 발전

- 합병과 인수

- 파트너십 및 협업

- 신제품 발매

- 확장 계획

제5장 시장 추정 및 예측 : 기종별, 2021-2034

- 주요 동향

- 자동

- 반자동

제6장 시장 추정 및 예측 : 모델별, 2021-2034

- 주요 동향

- 휴대용

- Stationery

- 기타

제7장 시장 추정 및 예측 : 가축별, 2021-2034

- 주요 동향

- 소

- 양

- 염소

- 기타

제8장 시장 추정 및 예측 : 최종 용도별, 2021-2034

- 주요 동향

- 소규모 낙농장

- 매크로 낙농장

- 기타

제9장 시장 추정 및 예측 : 유통채널별 2021-2034

- 주요 동향

- 직접 판매

- 간접판매

제10장 시장 추정 및 예측 : 지역별, 2021-2034

- 주요 동향

- 북미

- 미국

- 캐나다

- 유럽

- 영국

- 독일

- 프랑스

- 이탈리아

- 스페인

- 러시아

- 아시아태평양

- 중국

- 인도

- 일본

- 호주

- 한국

- 라틴아메리카

- 브라질

- 멕시코

- 중동 및 아프리카

- 아랍에미리트(UAE)

- 남아프리카

- 사우디아라비아

제11장 기업 프로파일

- Afimilk

- Agrifac Machinery

- AMS-Galaxy USA

- Boumatic

- DeLaval

- Fullwood Packo

- GEA Group

- Kanters Holland

- Lely

- Lusna

- Melasty

- Milkplan Farming Technologies

- Prompt Dairy Tech

- SA Christensen

- Yue Jiang Mechanical

The Global Milking Machine Market was valued at USD 4.39 billion in 2024 and is estimated to grow at a CAGR of 6.5% to reach USD 8.18 billion by 2034.

As rural workforces age and urban migration continues, the agricultural sector is facing significant labor challenges. These dynamics are pushing dairy farmers worldwide to turn to milking automation to maintain productivity and profitability. Manual milking not only demands skilled labor but also increases the risk of inconsistencies, poor hygiene, and animal stress. In contrast, automated and robotic systems reduce human error, enhance animal welfare, and improve overall milk quality. These machines offer consistent milking patterns, help control mastitis, and ensure the cleanliness of the milking process, aligning both animal health standards and modern dairy farm needs. Automation is no longer a luxury-it's a necessity for sustainable dairy operations. With advanced technologies such as AI-driven tracking systems and IoT-enabled sensors, farmers now have real-time insights into herd health and equipment performance. This data-centric approach allows for timely interventions and greater control over farm management. As a result, smart automation is transforming dairy production into a more precise, productive, and sustainable industry on a global scale.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $4.39 Billion |

| Forecast Value | $8.18 Billion |

| CAGR | 6.5% |

The automated milking systems segment generated notable revenues in 2024 owing to their superior efficiency and round-the-clock operation. These systems function independently and deliver uniform suction, timing, and yield, significantly improving both the quantity and quality of milk. Robotic milking units have become particularly attractive to farms dealing with labor shortages or looking to scale up production. These devices reduce manual intervention, minimize stress on livestock, and are equipped with AI and IoT capabilities that allow farmers to monitor cow behavior, milk output, and equipment efficiency remotely. This level of control ensures better herd health, helps prevent infections, and supports strict compliance with food safety guidelines, making automated systems essential for modern dairy facilities.

The portable milking machines segment held 48.38% share in 2024 and is forecasted to grow at a CAGR of 8% from 2025 to 2034. Their versatility, affordability, and ease of operation make them highly attractive to small and mid-sized dairy farms, especially in developing regions. These lightweight units are ideal for operations where livestock is scattered or grazing across multiple pastures. For farms that cannot afford expensive, fixed systems, portable milking machines offer a cost-effective alternative to reduce labor dependence while maintaining efficient production. Their mobile nature also enables their use across various animal types and locations, adding to their appeal in regions with mixed-grazing models and decentralized farm layouts.

U.S. Milking Machine Market held 73.8% share and generated USD 898.2 million in 2024. Rising labor costs, limited access to skilled farmhands, and an aging rural demographic are pushing American dairy farms to adopt more automation. Large-scale commercial dairies dominate the market in the U.S., and as such, they require high-efficiency solutions to ensure profitability. Smart milking systems are becoming widespread due to their ability to increase milk yield while ensuring quality. IoT-enabled technologies further support these systems, allowing farmers to track the health, milk production, and environmental conditions of their animals in real time. This tech-forward approach supports the country's emphasis on food safety, traceability, and animal welfare.

Prominent players shaping the Global Milking Machine Market include DeLaval, Boumatic, Lely, GEA Group, Fullwood Packo, Afimilk, Lusna, Agrifac Machinery, Prompt Dairy Tech, AMS-Galaxy USA, Melasty, Milkplan Farming Technologies, Kanters Holland, S. A. Christensen, and Yue Jiang Mechanical. To gain a competitive edge, companies operating in the milking machine market are focusing on product innovation, real-time monitoring features, and AI-integrated systems. Market leaders are investing heavily in automation and robotics to offer solutions that are scalable for both small farms and large dairy operations. Strategic collaborations with technology firms have helped companies develop IoT-enabled systems that offer health tracking, yield forecasting, and automated cleaning. Many firms are expanding globally by partnering with regional distributors and tailoring products to local farming needs.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.3 Data collection methods

- 1.4 Data mining sources

- 1.4.1 Global

- 1.4.2 Regional/Country

- 1.5 Base estimates and calculations

- 1.5.1 Base year calculation

- 1.5.2 Key trends for market estimation

- 1.6 Primary research and validation

- 1.6.1 Primary sources

- 1.7 Forecast model

- 1.8 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Machine type

- 2.2.3 Model type

- 2.2.4 Livestock

- 2.2.5 End use

- 2.2.6 Distribution channel

- 2.3 CXO perspectives: strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factors affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Labor shortages & rising costs

- 3.2.1.2 Animal welfare & hygiene focus

- 3.2.1.3 Growth of small & medium dairy farms in emerging markets

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment

- 3.2.2.2 Lack of technical skills in rural areas

- 3.2.3 Opportunities

- 3.2.3.1 Rising adoption in Asia-Pacific & Africa

- 3.2.3.2 Integration of AI & IoT

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.6 Regulatory environment

- 3.7 Value chain analysis

- 3.7.1 Raw material suppliers and component manufacturers

- 3.7.2 Equipment manufacturers and OEMs

- 3.7.3 Distribution channels and sales networks

- 3.7.4 end use segments and applications

- 3.7.5 After-sales service providers

- 3.8 Price trends

- 3.8.1 By region

- 3.8.2 By machine type

- 3.9 Regulatory landscape

- 3.9.1 standards and compliance requirements

- 3.9.2 Regional regulatory frameworks

- 3.10 Certification standards Trade statistics (HS code -84341000)

- 3.10.1 Major importing countries

- 3.10.2 Major exporting countries

- 3.11 Porter's analysis

- 3.12 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Machine Type, 2021 - 2034 ($Mn, Units)

- 5.1 Key trends

- 5.2 Automatic

- 5.3 Semi-automatic

Chapter 6 Market Estimates & Forecast, By Model Type, 2021 - 2034 ($Mn, Units)

- 6.1 Key trends

- 6.2 Portable

- 6.3 Stationery

- 6.4 Others

Chapter 7 Market Estimates & Forecast, By Livestock, 2021 - 2034 ($Mn, Units)

- 7.1 Key trends

- 7.2 Cow

- 7.3 Ship

- 7.4 Goat

- 7.5 Others

Chapter 8 Market Estimates & Forecast, By end use, 2021 - 2034 ($Mn, Units)

- 8.1 Key trends

- 8.2 Micro dairy farm

- 8.3 Macro dairy farm

- 8.4 Others

Chapter 9 Market Estimates & Forecast, By Distribution Channel 2021 - 2034 ($Mn, Units)

- 9.1 Key trends

- 9.2 Direct sales

- 9.3 Indirect sales

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 ($Mn, Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 UAE

- 10.6.2 South Africa

- 10.6.3 Saudi Arabia

Chapter 11 Company Profiles

- 11.1 Afimilk

- 11.2 Agrifac Machinery

- 11.3 AMS-Galaxy USA

- 11.4 Boumatic

- 11.5 DeLaval

- 11.6 Fullwood Packo

- 11.7 GEA Group

- 11.8 Kanters Holland

- 11.9 Lely

- 11.10 Lusna

- 11.11 Melasty

- 11.12 Milkplan Farming Technologies

- 11.13 Prompt Dairy Tech

- 11.14 S. A. Christensen

- 11.15 Yue Jiang Mechanical