|

시장보고서

상품코드

1626292

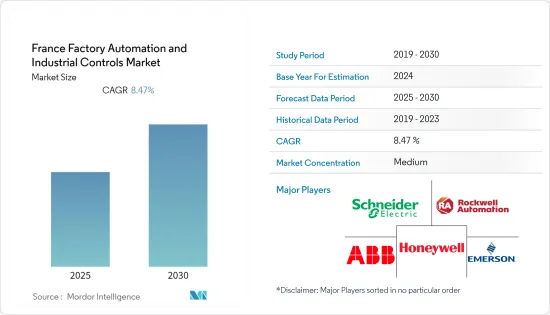

프랑스의 공장 자동화 및 산업 제어 장비: 시장 점유율 분석, 산업 동향, 통계 및 성장 예측(2025-2030년)France Factory Automation and Industrial Controls - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

프랑스의 공장 자동화 및 산업 제어 장비 시장은 예측 기간 동안 8.47%의 연평균 복합 성장률(CAGR)을 나타낼 것으로 예상됩니다.

주요 하이라이트

- 프랑스의 산업 부문은 GDP의 약 17%를 차지하고 있으며, 그 중 제조업은 가장 중요한 부분 중 하나입니다. 프랑스는 IoT와 M2M을 통해 고도로 산업화된 경제로 전환함으로써 인더스트리 4.0에 적응하고 있습니다. 이는 제조 부문이 효율성을 높이고, 시스템 오류를 줄이며, 분석적 통찰력과 낭비 감소를 통해 비용을 최적화하는 데 도움이 되고 있습니다.

- 프랑스는 현재 제조업 생산량 세계 8위를 차지하고 있으며, 제조업의 주요 분야는 식음료, 기계 및 설비용품, 항공기, 자동차, 금속 및 금속 가공품, 선박 및 철도 등입니다.

- 이러한 제조업 시장 점유율은 산업 장비 제어에 사용되는 소프트웨어 용도의 사용 증가로 인해 크게 증가할 것으로 예상됩니다.

- 또한 화학, 화장품, 제약, 자동차 산업 인프라에서 산업용 로봇에 대한 투자가 꾸준히 증가하고 있습니다. 자재 취급은 픽앤플레이스 로봇 증가에 중요한 역할을 하고 있습니다.

- 그러나 자동화 생산라인에는 항상 높은 초기 투자가 필요하고, 프랑스 경제의 성장 정체는 자동화 도입에 걸림돌이 되고 있습니다.

프랑스 공장자동화 및 산업제어기기 시장 동향

프랑스 공장자동화 및 산업제어기기 시장 동향프로그래머블 로직 컨트롤러의 채택이 크게 증가할 전망

- 프로그래머블 로직 컨트롤러는 산업 자동화를 위해 열악한 산업 환경에서 작동하도록 설계된 산업용 디지털 컴퓨터입니다. 이 컴퓨터는 주로 산업에서 제조 공정을 제어하는 데 사용되며 로봇 장비, 기계 및 조립 라인을 PLC로 쉽고 자율적으로 제어 할 수 있습니다.

- PLC는 필요한 매개 변수가 미리 프로그래밍되어 있으며, 수신된 데이터를 처리하고 분석하여 필요에 따라 출력을 트리거하며, 기계 생산성, 온도, 자동 시동 및 정지 프로세스, 기계 고장 시 경보 발생 등 런타임 데이터를 쉽게 기록하고 모니터링할 수 있습니다. 모니터링합니다.

- 또한 설비 및 프로그램 상태를 확인할 수 있는 기능도 갖추고 있어 문제나 오류가 발생했을 때 다른 제어장치에 비해 빠르게 수리할 수 있습니다. 입력 및 출력 표시기는 시스템 내에서 쉽게 식별할 수 있습니다.

- 프랑스의 자동차 산업이 성장함에 따라 로봇에 의한 자율 제조 조립의 필요성이 증가하고 있으며, PLC는 견고성, 유연성 및 쉬운 프로그래밍 가능성으로 인해 제조 공정 제어에 중요한 역할을 하고 있습니다.

- PLC의 고급 기능은 웹 브라우저를 통해 데이터를 통신하고 클라우드와 데이터를 연결할 수 있기 때문에 공장에서 산업용 사물 인터넷과 인더스트리 4.0을 쉽게 채택할 수 있습니다.

산업용 로봇이 시장을 장악할 전망

- 산업용 로봇 분야는 다관절 로봇, 직교 로봇, 스칼라 로봇, 협동 로봇(코봇), 병렬 로봇, 피스 피킹 로봇 등으로 구성됩니다. 산업용 로봇은 정확성, 유연성, 제품 손상 감소, 속도 및 작업 효율을 향상시키기 위해 대부분의 최종 사용자와 용도에서 채택이 증가하고 있습니다.

- 협동 로봇과 코봇의 사용은 환경 변화에 신속하고 안전하게 대응하고 효율성을 높이는 데 도움이 되는 첨단 센서, 소프트웨어 및 암 종단 툴을 활용하기 때문에 빠르게 증가하고 있습니다.

- 산업용 로봇에 인공지능이 탑재되면서 자동차 부문의 조립 라인은 생산성, 효율성 및 비용 효율성이 향상되고 있습니다. 현장 산업용 로봇, 특히 원통형 로봇은 제조 공정을 자동화함으로써 자동차 생산에 큰 변화를 가져왔습니다.

- 프랑스에는 에어버스, 다에르, 르노 그룹, 나발 그룹 등 명성이 높은 제조 기업이 많이 있습니다. 또한 ID 4 Car, EMC2, Clarte, Proxinnov 등 혁신 클러스터 및 혁신 플랫폼이 있습니다.

- 이렇듯 이 나라의 산업 부문은 성장 잠재력이 매우 큽니다. 따라서 이러한 제조 공장을 자동화하기 위한 공장 자동화 및 현장 장치의 필요성이 증가하고 있습니다. 산업용 로봇은 제조업 자동화에 있어 중요한 역할을 하고 있습니다.

프랑스 공장자동화 및 산업제어기기 산업 개요

프랑스 공장자동화 및 산업제어기기 산업 개요

- 산업용 로봇 분야는 다관절 로봇, 직교 로봇, 스칼라 로봇, 협동 로봇(코봇), 병렬 로봇, 피스 피킹 로봇 등으로 구성됩니다. 산업용 로봇은 정확성, 유연성, 제품 손상 감소, 속도 및 작업 효율을 향상시키기 위해 대부분의 최종 사용자와 용도에서 채택이 증가하고 있습니다.

- 협동 로봇과 코봇의 사용은 환경 변화에 신속하고 안전하게 대응하고 효율성을 높이는 데 도움이 되는 첨단 센서, 소프트웨어 및 암 종단 툴을 활용하기 때문에 빠르게 증가하고 있습니다.

- 산업용 로봇에 인공지능이 탑재되면서 자동차 부문의 조립 라인은 생산성, 효율성 및 비용 효율성이 향상되고 있습니다. 현장 산업용 로봇, 특히 원통형 로봇은 제조 공정을 자동화함으로써 자동차 생산에 큰 변화를 가져왔습니다.

- 프랑스에는 에어버스, 다에르, 르노 그룹, 나발 그룹 등 명성이 높은 제조 기업이 많이 있습니다. 또한 ID 4 Car, EMC2, Clarte, Proxinnov 등 혁신 클러스터 및 혁신 플랫폼이 있습니다.

- 이렇듯 이 나라의 산업 부문은 성장 잠재력이 매우 큽니다. 따라서 이러한 제조 공장을 자동화하기 위한 공장 자동화 및 현장 장치의 필요성이 증가하고 있습니다. 산업용 로봇은 제조업 자동화에 있어 중요한 역할을 하고 있습니다.

프랑스 공장자동화 및 산업제어기기 산업 개요

프랑스 공장자동화 및 산업제어기기 산업 개요프랑스 공장 자동화 및 산업 제어 장비 시장은 크고 작은 다양한 기업이 존재하며 적당히 단편화 된 시장입니다. 많은 기업들이 산업 자동화 및 산업 제어 장비의 첨단 기술에 종사하고 있으며, 시장은 적당히 통합되어 있습니다. 자동화가 진행됨에 따라 각 기업은 다른 자동화 기업과 제휴하여 이 시장에 투자하고 있습니다.

- 2021년 9월 - 오렌지 비즈니스 서비스와 지멘스는 데이터 분석, 프라이빗 5G 네트워크, 산업용 IoT, 사이버 보안, 클라우드, 엣지 컴퓨팅 분야에서 협력하여 프랑스 제조업의 인더스트리 4.0 분야를 확대합니다.

- 2021년 5월 - 슈나이더일렉트릭은 Roca Group과 파트너십을 맺고 탈탄소화를 가속화합니다. 탈탄소화를 위한 새로운 로드맵을 정의하는 제품 설계, 생산 및 상용화 분야에서 세계를 선도하는 로카 그룹은 그룹 전체에 걸쳐 단일 세계 전략을 수립하고 있습니다.

- 2021년 4월 - 지멘스와 구글 클라우드가 생산 현장의 효율성을 높이기 위한 생산 운영 효율화를 위해 협력한다고 발표했습니다. 지멘스는 구글 클라우드의 최고 데이터 클라우드와 인공지능/머신러닝(AI/ML) 기능을 자사의 공장 자동화 솔루션에 통합하여 제조업계의 제조 공정을 지원할 계획.

기타 혜택 :

기타 혜택- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트 지원

목차

제1장 서론

- 조사의 전제조건과 시장 정의

- 조사 범위

제2장 조사 방법

제3장 주요 요약

제4장 시장 개요

- 시장 개요

- 산업 밸류체인 분석

- 업계의 매력 - Porter의 Five Forces 분석

- 공급 기업의 교섭력

- 소비자의 교섭력

- 신규 진출업체의 위협

- 대체품의 위협

- 경쟁 기업간 경쟁 관계

- COVID-19의 업계에 대한 영향 평가

제5장 시장 역학

- 시장 성장 촉진요인

- 자동화 기술 부상

- 머신 투 머신(M2M) 기술 도입 확대

- 시장이 해결해야 할 과제

- 높은 설치 비용

- 업계 규제와 정책

- 기술 현황

제6장 시장 세분화

- 유형별

- 산업 제어 시스템

- 분산형 제어 시스템(DCS)

- 프로그래머블 로직 컨트롤러(PLC)

- 감시제어·데이터 수집(SCADA)

- 제품수명주기관리(PLM)

- 제조 실행 시스템(MES)

- 휴먼·머신·인터페이스(HMI)

- 기타 산업 제어 시스템

- 필드 기기

- 머신 비전

- 산업용 로봇

- 모터와 드라이브

- 안전 시스템

- 센서&트랜스미터

- 기타 필드 기기

- 산업 제어 시스템

- 최종사용자 산업별

- 석유 및 가스

- 화학제품 및 석유화학제품

- 전력 및 유틸리티

- 식품 및 음료

- 자동차 및 운송

- 제약

- 기타 최종사용자 산업

제7장 경쟁 구도

- 기업 개요

- Schneider Electric SE

- Rockwell Automation Inc.

- Honeywell International Inc.

- Emerson Electric Company

- ABB Ltd

- Mitsubishi Electric Corporation

- Siemens AG

- Omron Corporation

- Yokogawa Electric Corporation

- Fanuc Corporation

제8장 투자 분석

제9장 향후 전망

LSH 25.01.15The France Factory Automation and Industrial Controls Market is expected to register a CAGR of 8.47% during the forecast period.

Key Highlights

- The country's industrial sector contributes nearly 17% to the GDP, in which manufacturing is one of the most important parts. France is adapting to industry 4.0 by moving a highly industrialized economy through IoT and M2M. This is helping the manufacturing sector to increase its efficiency, reduce system failures and optimize the cost through analytical insight and cutting down on wastage.

- France is currently ranked eighth in the world for manufacturing output, the biggest segments in manufacturing sector includes food products and beverages, machinery and equipment goods, aircrafts, automobiles, metals and fabricated metal products, ships and trains.

- The market share of these manufacturing industries is expected to grow to a significant extent due to increase in use of software applications that are used to control industrial devices.

- Alslo, there has been increase in industrial robot investment at steady rate in chemical, cosmetic, pharmaceutical industries and in the infrastructure of automotive industry. Material handling has played the important role to increase pick and place robots.

- However, there is always a high initial investment requirement for automated production line which hinders the automation adoption in France due to the stagnated growth in the economy of the country.

France Factory Automation & Industrial Controls Market Trends

Programable Logic Controller Expected to Witness Signifcant Growth in the Adoption

- Programable Logic Controller is an industrial digital computer which is designed to operate in tough industrial environment for industrial automation. These computers are mainly used to control manufacturing process in industry, robotic devices, machines, assembly lines can be easily and autonomously controlled with PLC.

- PLCs are pre-programmed with required parameters; they process and analyse the received data and trigger outputs as per need. PLC easily records and monitors runtime data like machine productivity, temperature, automatic start and stop processes, generation of alarms when a machine fails and many more.

- It also provides a function that can check the state of facilities and programs so that if there are problems or errors, it is possible to make repairs quickly compared to other control units. Input and output indicators are easily identifiable in a system.

- The automobile industry in France in growing and with it the need of autonomous manufacturing assembly controlled by robots is also increasing. PLC plays an important role in controlling manufacturing processes due to their rugged, flexible and easily programmable features.

- The advanced features of PLC can communicate data through web browser and connect data with clouds, this enables easy adoption of Industrial Internet of Things and Industry 4.0 in a factory.

Industrial Robotics are expected to dominate the market

- The industrial robotics segment consists of articulated robots, cartesian robots, SCARA robots, collaborative industry robots (cobots), parallel robots, piece picking robots, etc. The adoption of industrial robots has been increasing in most end-users and applications as these robots enhance accuracy, flexibility, reduced product damage, speed, and ultimately the efficiency of operations.

- The use of collaborative robots or cobots is increasing rapidly as they are utilizing advanced sensors, software, and end-of-arm tooling that quickly and safely respond to the changes in the environment and assist in improving efficiency.

- With the help of artificial intelligence in industrial robots, the automotive sector's assembly lines have become more productive, efficient, and cost-effective. Industrial robotics on the shop floor, especially cylindrical robots, transformed automobile production by automating the manufacturing process.

- France is home to many reputable manufacturing companies that include Airbus, Daher, Groupe Renault, naval Group, and many others. Furthermore, the presence of innovation cluster and innovation platforms include ID 4 Car, EMC2, and other, Clarte, Proxinnov, and others.

- Thus, there is a huge potential for the growth of the country's industrial sector. This increases the need for factory automation and field devices to automate such manufacturing factories. Industrial Robots play important role in automation in manufacturing industry.

France Factory Automation & Industrial Controls Industry Overview

The France Factory Automation and Industrial Controls Market is a moderately fragmented market, with presence of many small and large players. Many companies are engaged in industrial automation and advanced technologies in industrial control devices, the market is moderately consolidated. Considering the increasing automation, companies are investing in the same, by partnering with other automation companies.

- September 2021 - Orange Business Services and Siemens struck a deal to combine in data analytics, private 5G networks, industrial IoT, cybersecurity, cloud and edge computing to expand the industry 4.0 space in French manufacturing sector.

- May 2021 - Schneider Electric partnered with Roca Group to accelerate decarbonization. Roca Group, a world leader in the design, production, and commercialization of products to define a new roadmap toward decarbonization, has been establishing a single, global strategy across the group.

- April 2021 - Siemens and Google Cloud announced their collaboration to streamline production operations for boosting shop floor efficiency. Siemens plans to integrate Google Cloud's top data cloud and artificial intelligence/machine learning (AI/ML) capabilities with its factory automation solutions to assist manufacturers in the manufacturing process.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGTHS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Force Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitutes

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of COVID -19 impact on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Gaining Prominence for Automation Technologies

- 5.1.2 Increasing Deployment of Machine-to-Machine (M2M) Technologies

- 5.2 Market Challenges

- 5.2.1 High Installation Costs

- 5.3 Industry Policies and Regulations

- 5.4 Technology Snapshot

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Industrial Control Systems

- 6.1.1.1 Distributed Control System (DCS)

- 6.1.1.2 Programable Logic Controller (PLC)

- 6.1.1.3 Supervisory Control and Data Acquisition (SCADA)

- 6.1.1.4 Product Lifecycle Management (PLM)

- 6.1.1.5 Manufacturing Execution System (MES)

- 6.1.1.6 Human Machine Interface (HMI)

- 6.1.1.7 Other Industrial Control Systems

- 6.1.2 Field Devices

- 6.1.2.1 Machine Vision

- 6.1.2.2 Industrial Robotics

- 6.1.2.3 Motors and Drives

- 6.1.2.4 Safety Systems

- 6.1.2.5 Sensors & Transmitters

- 6.1.2.6 Other Field Devices

- 6.1.1 Industrial Control Systems

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemical and Petrochemical

- 6.2.3 Power and Utilities

- 6.2.4 Food and Beverage

- 6.2.5 Automotive and Transportation

- 6.2.6 Pharmaceutical

- 6.2.7 Other End-user Industries

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Schneider Electric SE

- 7.1.2 Rockwell Automation Inc.

- 7.1.3 Honeywell International Inc.

- 7.1.4 Emerson Electric Company

- 7.1.5 ABB Ltd

- 7.1.6 Mitsubishi Electric Corporation

- 7.1.7 Siemens AG

- 7.1.8 Omron Corporation

- 7.1.9 Yokogawa Electric Corporation

- 7.1.10 Fanuc Corporation