|

시장보고서

상품코드

1636442

미국의 EV용 배터리 분리막 시장 : 점유율 분석, 산업 동향, 성장 예측(2025-2030년)United States Electric Vehicle Battery Separator - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

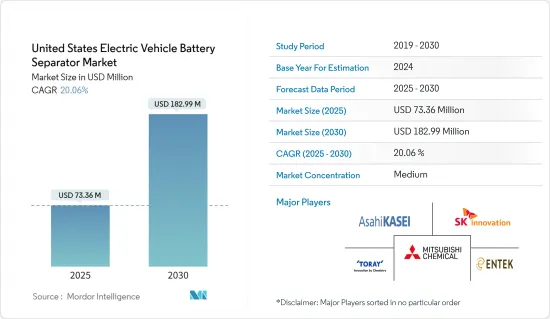

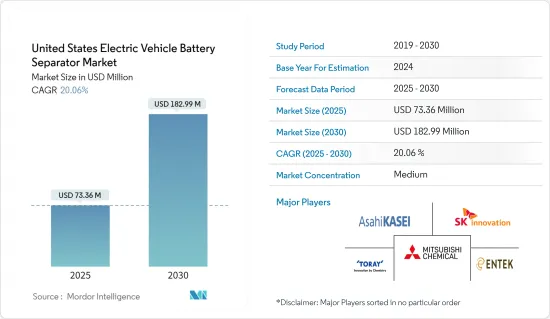

미국의 EV용 배터리 분리막 시장 규모는 2025년 7,336만 달러, 2030년 1억 8,299만 달러로 추정되며, 예측기간(2025-2030년)중 CAGR 20.06%에 달할 것으로 예측됩니다.

주요 하이라이트

- 중기적으로는 전기자동차의 보급과 리튬 이온 배터리의 저가격화가 미국의 EV용 배터리 분리막 시장을 견인할 것으로 예측됩니다.

- 한편, 원료 부족이나 유통의 병목 등, 배터리 재료공급 체인 갭은 미국의 EV용 배터리 분리막 시장의 향후의 성장을 억제할 것으로 예상됩니다.

- 그럼에도 불구하고 고체 배터리, 첨단 리튬 이온 화학, 나트륨 이온 배터리 등 다른 배터리 화학의 연구 개발이 진행되고 있어 향후 시장에 기회를 가져올 것으로 예상됩니다.

미국 EV용 배터리 분리막 시장 동향

리튬 이온 배터리 부문이 시장을 독점할 전망

- 리튬 이온 배터리에는 다공성 막인 배터리 분리막이 필수적입니다. 캐소드와 애노드를 분리하고 리튬 이온만을 통과시킴으로써 전기적 단락을 방지합니다.

- 처음에는 리튬 이온 배터리는 주로 소비자 전자 장치 분야에서 사용되었습니다. 그러나 시간이 지남에 따라 전기자동차(EV) 제조업체는 주요 소비자가 되었으며 특히 플러그인 하이브리드 전기자동차(PHEV)의 EV 판매량 증가에 견인했습니다. 이 배터리는 높은 에너지 밀도, 비교적 긴 사이클 수명 및 효율성의 이점을 제공합니다.

- 국제에너지기구(IEA)에 따르면 EV용 배터리 수요는 2023년 750GWh를 넘어 2022년부터 40% 증가했습니다. 미국은 이 수요 중 100GWh 가까이를 차지하고 있습니다. EV용 리튬 이온 배터리의 용도 확대에 따라, 분리막 수요도 증가의 일도를 따르고 있습니다.

- 게다가 리튬 이온 배터리의 가격이 하락함에 따라 전기자동차 채용이 증가하고 배터리 분리기 수요도 증가하고 있습니다. 2023년 리튬이온 배터리 팩 가격은 전년 대비 14% 하락해 139달러/kWh에 정착합니다.

- 2023년 7월 플로리다 주 포트 로더데일의 Nuvola Technologies Inc.가 직접 증착 폴리머 분리기 기술을 발표했습니다. 이 기술 혁신은 리튬 이온 배터리의 주요 발화 위험을 대상으로 합니다. 이 특허 기술은 기존의 필름 분리기를 대체하는 보다 안전하고 효율적인 우수한 기술입니다.

- 2023년 2월, 미국의 유명한 리튬 이온 배터리용 분리막 기업인 ENTEK와 Brookner Group은 18개의 배터리용 분리막 필름 생산 라인에 대한 계약을 체결하고 파트너십을 강화했습니다. 미국에서 전기차와 에너지 저장 수요 증가에 대응하기 위해 ENTEK는 연간 14억 평방미터를 목표로 하는 선행 프로젝트 외에 대폭적인 생산 능력 확대를 발표했습니다.

- BloombergNEF에 따르면 미국의 리튬 이온 배터리의 생산 능력은 2016년부터 급증하고 2023년까지 약 3배가 됩니다. 2023년 생산 능력은 114GWh에 이르렀으며, 2022년 89GWh에서 증가하여 미국 EV용 배터리 분리기 시장의 견조한 성장을 뒷받침하고 있습니다.

- 리튬 이온 배터리 분리막의 용량이 확대되고 전기자동차용 기술이 진보하고 있기 때문에 리튬 이온 부문이 미국의 EV용 배터리 분리막 시장을 독점할 전망입니다.

전기자동차의 보급이 EV용 배터리 분리막 시장을 견인

- 최근 미국에서는 전기자동차(EV)용 배터리 시장이 크게 급성장하고 있습니다. 이 기세는 정부 인센티브, 엄격한 배기 가스 규제, 소비자 환경 의식 증가, 국내외 기업에 의한 다수의 EV 배터리 제조 공장의 설립, EV 충전 인프라의 진보 등 다양한 요인이 겹쳤기 때문입니다. 이러한 요소는 종합적으로 미국의 EV용 배터리 분리막 시장을 강화하고 있습니다.

- 정부는 일련의 정책과 인센티브를 통해 EV 도입을 추진하고 있습니다. 여기에는 세액 공제, 보조금, 리베이트, 충전 인프라에 대한 많은 투자가 포함됩니다. 이러한 노력으로 소비자의 EV에 대한 관심이 높아지고 배터리 팩 수요도 증가하고 있습니다. 이에 따라 대형 자동차 제조업체나 배터리 제조업체는 이 지역에서 EV용 배터리 팩의 생산 능력을 증강하고 있습니다.

- 국제에너지기구(IEA)의 데이터에 따르면 미국에서의 배터리식 전기자동차의 판매량은 견조한 성장을 보이고 있으며, 2022년 80만대에서 2023년에는 110만대로 급증하여 37.5% 증가라는 현저한 성장을 보이고 있습니다.

- 2023년 1월, Tesla는 네바다에 있는 리튬 이온 배터리 조립 공장의 대폭 강화를 발표했습니다. 36억 달러의 거액 투자로 Tesla는 최첨단 배터리 셀 생산을 강화하고 Cybertruck BEV의 전용 공장을 설립하는 것을 목표로 하고 있습니다. 이 투자에는 혁신적인 4680 리튬 이온 셀 공장과 Cybertruck 전용 시설이 포함됩니다.

- 2023년 11월, Toyota는 노스캐롤라이나에 있는 Toyota Battery Manufacturing facility(TBNMA)에 80억 달러를 투자할 것이라고 밝혔습니다. 이로 인해 이 공장의 총 투자액은 139억 달러에 달할 전망입니다. 또한 Toyota는 앞서 발표된 2개의 배터리 라인에 더해 EV용 리튬 이온 배터리의 생산에 특화된 8개의 배터리 라인을 신설하여 생산 능력을 확대합니다.

- 신흥 EV용 배터리 공장에 대한 투자 증가, 정부 지원 정책, 전기자동차의 급속한 보급을 감안할 때 미국의 EV용 배터리 분리막 시장은 유망할 것으로 보입니다.

미국 전기자동차 배터리 분리기 산업 개요

미국의 EV용 배터리 분리막 시장은 반고착화되고 있습니다. 이 시장의 주요 기업(순부동)에는 Entek International, SK Innovation, Asahi Kasei, Sumitomo Chemical, Toray, Nuvola Technology, Celgard LLC, SEMCORP Advanced Materials Group, Sepion Technologies 등이 있습니다.

기타 혜택:

- 엑셀 형식 시장 예측(ME) 시트

- 3개월간의 애널리스트·지원

목차

제1장 서론

- 조사 범위

- 시장의 정의

- 조사의 전제

제2장 주요 요약

제3장 조사 방법

제4장 시장 개요

- 소개

- 2029년까지 시장 규모 및 수요 예측(단위: 달러)

- 최근 동향과 개발

- 정부의 규제와 정책

- 시장 역학

- 성장 촉진요인

- 전기자동차의 보급 확대

- 리튬 이온 배터리의 가격 저하

- 억제요인

- 공급 체인의 갭

- 성장 촉진요인

- 공급망 분석

- PESTLE 분석

- 투자 분석

제5장 시장 세분화

- 배터리 유형별

- 리튬 이온

- 납축배터리

- 기타 배터리 유형

- 재료 유형별

- 폴리프로필렌

- 폴리에틸렌

- 기타 재료 유형

제6장 경쟁 구도

- M&A, 합작사업, 제휴, 협정

- 주요 기업의 전략

- 기업 프로파일

- Entek International,

- SK Innovation Co. Ltd.

- Asahi Kasei Corporation

- Hitachi Chemical Company Ltd

- Sumitomo Chemical Co., Ltd.

- Toray Industries Inc

- Nuvola Technology

- SEMCORP Advanced Materials Group

- Celgard LLC

- Sepion Technologies

- List of Other Prominent Companies

- Market Ranking/Share(%) Analysis

제7장 시장 기회와 앞으로의 동향

- 리튬 이온 배터리 분리막 재료의 지속적인 조사와 진보

The United States Electric Vehicle Battery Separator Market size is estimated at USD 73.36 million in 2025, and is expected to reach USD 182.99 million by 2030, at a CAGR of 20.06% during the forecast period (2025-2030).

Key Highlights

- Over the medium period, the growing adoption of electric vehicles and the decreasing price of lithium-ion batteries is expected to drive the United States Electric Vehicle Battery Separator Market.

- On the other hand, the supply chain gap in battery materials, such as ingredient shortages or distribution bottlenecks, is expected to restrain the United States Electric Vehicle Battery Separator Market growth in the future.

- Nevertheless, the increasing research and development of other battery chemistries like solid-state batteries, advanced lithium-ion chemistry, Sodium-ion batteries, etc, are expected to create an opportunity for the market in the future.

United States Electric Vehicle Battery Separator Market Trends

Lithium-ion Battery Segment is Expected to Dominate the Market

- A battery separator, a porous membrane, is vital in lithium-ion batteries. It prevents electrical short circuits by isolating the cathode and anode, allowing only lithium ions to pass through.

- Initially, lithium-ion batteries primarily served the consumer electronics sector. However, over time, electric vehicle (EV) manufacturers became the leading consumers, driven by rising EV sales, especially in plug-in hybrid electric vehicles (PHEVs). These batteries offer advantages like high energy density, a relatively long cycle life, and efficiency.

- As per the International Energy Agency, the demand for EV batteries surpassed 750 GWh in 2023, marking a 40% increase from 2022. The United States accounted for nearly 100 GWh of this demand. With the rising application of lithium-ion batteries in EVs, the demand for their separators is poised to grow in tandem.

- Moreover, as lithium-ion battery prices decline, their adoption in electric vehicles is set to rise, subsequently boosting the demand for battery separators. In 2023, lithium-ion battery pack prices dropped by 14% from the previous year, settling at USD 139/kWh.

- In July 2023, Fort Lauderdale, Florida's Nuvola Technologies Inc. unveiled a direct deposition polymer separator technology. This innovation targets the primary fire risk in lithium-ion batteries. The patented technology is touted as a superior, safer, and more efficient alternative to conventional film separators.

- In February 2023, ENTEK, a prominent United States lithium-ion battery separator firm, and Bruckner Group strengthened their partnership by signing agreements for 18 battery separator film production lines. Responding to the rising demand for electric vehicles and energy storage in the United States, ENTEK announced a significant production capacity expansion, building on a prior project aiming for 1.4 billion square meters annually.

- BloombergNEF reports that the United States lithium-ion battery manufacturing capacity surged from 2016, nearly tripling by 2023. In 2023, the capacity reached 114 GWh, up from 89 GWh in 2022, underscoring robust growth for the U.S. electric vehicle battery separator market.

- Given the expanding capacities for lithium-ion battery separators and advancements in their technology for electric vehicles, the lithium-ion segment is poised to dominate the U.S. electric vehicle battery separator market.

Growing Adoption of Electric Vehicles Driving the EV Battery Separator Market

- In recent years, the United States has witnessed a significant surge in its electric vehicle (EV) batteries market, primarily fueled by the growing adoption of electric vehicles. This momentum can be attributed to a confluence of factors: government incentives, stringent emission regulations, heightened environmental consciousness among consumers, the establishment of numerous EV battery manufacturing plants by both domestic and foreign entities, and advancements in EV charging infrastructure. These elements collectively bolster the United States Electric Vehicle Battery Separator Market.

- The government is championing EV adoption through a suite of policies and incentives. These encompass tax credits, grants, rebates, and substantial investments in charging infrastructure. Such initiatives have amplified consumer interest in EVs, subsequently driving up the demand for battery packs. In response, leading automakers and battery manufacturers are ramping up their production capacities for EV battery packs within the region.

- Data from the International Energy Agency (IEA) highlights a robust growth in battery electric vehicle sales in the U.S., with figures jumping from 800,000 vehicles in 2022 to 1,100,000 in 2023, marking a remarkable 37.5% increase.

- In January 2023, Tesla announced a major enhancement to its Li-ion battery assembly plant in Nevada. With a substantial investment of USD 3.6 billion, Tesla aims to boost production of a cutting-edge battery cell and set up a dedicated factory for its Cybertruck BEV. This investment includes a plant for the innovative 4680 lithium-ion cells and a specialized facility for the Cybertruck.

- In November 2023, Toyota revealed an ambitious investment of USD 8 billion in its North Carolina-based Toyota Battery Manufacturing facility (TBNMA), which is still under construction. This move elevates the plant's total investment to a staggering USD 13.9 billion. Furthermore, Toyota is expanding its production capabilities by adding eight new battery lines, complementing the two previously announced, all dedicated to producing lithium-ion batteries for electric vehicles.

- Given the escalating investments in emerging EV battery plants, supportive government policies, and the surging adoption of electric vehicles, the trajectory for the U.S. Electric Vehicle Battery Separator Market looks promising.

United States Electric Vehicle Battery Separator Industry Overview

The United States Electric Vehicle Battery Separator Market is semi-consolidated. Some of the major players in the market (in no particular order) include Entek International, SK Innovation Co. Ltd., Asahi Kasei Corporation, Sumitomo Chemical Co., Ltd., Toray Industries Inc, Nuvola Technology, Celgard LLC, SEMCORP Advanced Materials Group, Sepion Technologies, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 The Growing Adoption of Electric Vehicles

- 4.5.1.2 Decreasing Price of Lithium-ion Batteries

- 4.5.2 Restraints

- 4.5.2.1 The Supply Chain Gap

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE Analysis

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery Type

- 5.1.1 Lithium-ion

- 5.1.2 Lead-acid

- 5.1.3 Other Battery Type

- 5.2 Material Type

- 5.2.1 Polypropylene

- 5.2.2 Polyethylene

- 5.2.3 Other Material Types

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Entek International,

- 6.3.2 SK Innovation Co. Ltd.

- 6.3.3 Asahi Kasei Corporation

- 6.3.4 Hitachi Chemical Company Ltd

- 6.3.5 Sumitomo Chemical Co., Ltd.

- 6.3.6 Toray Industries Inc

- 6.3.7 Nuvola Technology

- 6.3.8 SEMCORP Advanced Materials Group

- 6.3.9 Celgard LLC

- 6.3.10 Sepion Technologies

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking/Share (%) Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Ongoing Research and Advancement in Li-ion Battery Separator Material