|

시장보고서

상품코드

1478712

LED 조명 및 OLED 조명 : 시장 분석 및 제조 동향LED and OLED Lighting: Market Analysis and Manufacturing Trends |

||||||

빠르게 진화하는 조명 기술 속에서 LED(발광 다이오드)와 OLED(유기 발광 다이오드) 조명은 효율성, 지속가능성, 디자인 유연성의 새로운 시대를 여는 최전선에 서 있습니다.

에너지 효율과 이산화탄소 배출량을 줄이기 위한 전 세계적인 움직임이 강화되면서 LED와 OLED 조명 솔루션은 매우 중요한 제품으로 부상하고 있습니다. 특히 에너지 효율, 긴 수명, 우수한 광 품질 등 고유한 특성으로 인해 기존 조명 솔루션을 대체할 뿐만 아니라 주거 및 상업 시설에서 산업 및 건축에 이르기까지 다양한 분야에서 선호되는 대안으로 각광받고 있습니다.

LED(발광 다이오드)와 OLED(유기 발광 다이오드) 기술의 급속한 발전과 채택으로 조명 산업은 큰 변화의 시기를 맞이하고 있습니다. 이러한 변화는 공간을 조명하는 방식뿐만 아니라 조명 솔루션을 설계, 제조하고 현대 디지털 생태계에 통합하는 방식에도 변화를 가져오고 있습니다.

이 보고서는 LED 조명 및 OLED 조명 시장을 조사하고 주요 성장 동인, 과제 및 기회를 분석합니다. 또한, 시장 상황을 형성하는 데 중요한 역할을 해온 각 지역의 규제 프레임워크와 환경 관련 의무에 대해 자세히 알아보고, 정책 변화가 수요 패턴과 기술 발전에 어떤 영향을 미치는지 알아보고자 합니다.

목차

제1장 소개

제2장 고휘도 LED 기술과 응용의 최근 진보

제3장 처리 장비

- 소개

- 증착

- 화학 기계 평탄화

- 결함 검사와 테스트

- 리소그래피

제4장 건축자재

- 소개

- 일반 조명용 GaN 기반 LED

- LED 형광체 제조 문제

제5장 고휘도 LED 패키징과 조립 문제

- HB LED 패키지

- 웨이퍼 레벨 패키징 HB LED

- 열 문제

- 테스트와 검사

제6장 혁신 원동력으로서의 국가 프로그램

- DOE 고체 조명 제조 이니셔티브

- DOE 고체 조명 프로그램 사명과 목표

- LED에 관한 주요 국가 조사 프로그램

- SSL 제조가 직면하는 과제

제7장 OLED 조명

- 조명기구 제조업체에 대한 기회

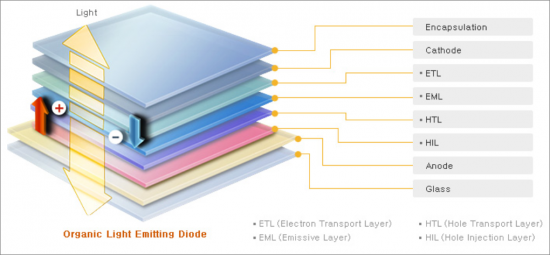

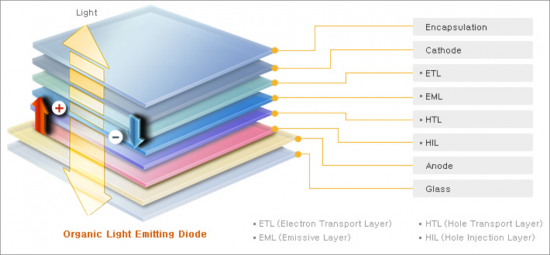

- OLED 구조

- OLED 조명과 OLED 디스플레이의 차이

- OLED 조명 기술의 이점

- OLED 퍼포먼스 지표

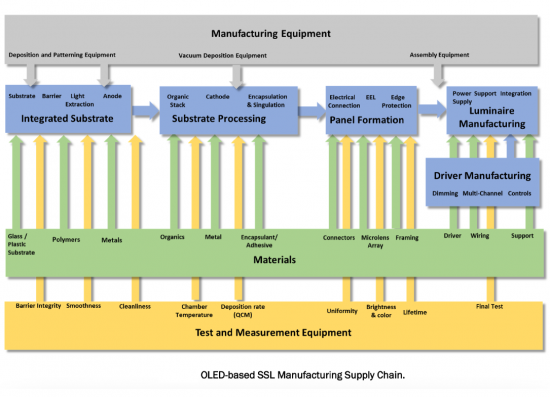

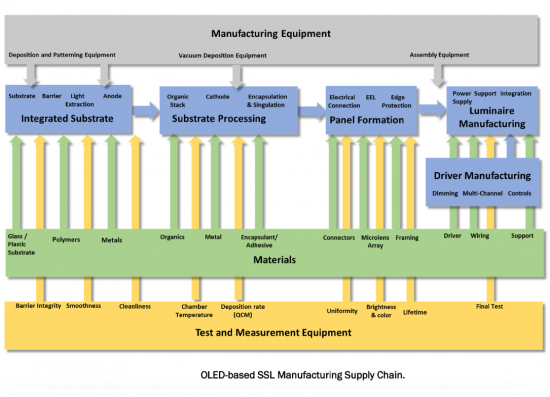

제8장 OLED 제조

- OLED 조명용 증착 장비와 프로세스

- 일반적인 OLED 제조 비용 검토

- 리소그래피

- 기판과 캡슐화

- 검사와 품질 관리

제9장 세계의 OLED 시장 전망

- 소개

- 패시브 매트릭스 용량과 수요

- 액티브 매트릭스 용량과 수요

- OLED 조명 비용 과제

제10장 세계의 고휘도 LED 시장 전망

- 고휘도 LED 기술

- 고휘도 LED 시장 개요와 동향

In the rapidly evolving landscape of lighting technology, LED (Light Emitting Diode) and OLED (Organic Light Emitting Diode) lighting stand at the forefront, heralding a new era of efficiency, sustainability, and design flexibility. The "LED and OLED Lighting: Market Analysis and Manufacturing Trends" report offers an in-depth exploration of these two pivotal technologies, providing a comprehensive overview of their current market status, growth trajectories, and the technological innovations that drive them.

As the global push towards energy efficiency and reduced carbon footprints intensifies, LED and OLED lighting solutions have emerged as pivotal players. Their unique attributes-notably, their energy efficiency, longer lifespans, and superior light quality-have propelled them into the spotlight, not just as alternatives to traditional lighting solutions, but as the preferred choice in a wide range of applications, from residential and commercial to industrial and architectural.

This report begins by dissecting the market dynamics of the LED and OLED sectors, analyzing key growth drivers, challenges, and opportunities. It delves into the regulatory frameworks and environmental mandates across different regions that have been instrumental in shaping the market landscape, highlighting how policy shifts are influencing demand patterns and technological advancements.

Technological innovation remains at the heart of LED and OLED development, with ongoing research and development efforts pushing the boundaries of what's possible in lighting technology. The report examines the latest advancements in material science, including novel phosphors and organic materials, that are enhancing the performance and efficiency of LED and OLED lights. It also explores the evolution of design trends, from the miniaturization of components to the integration of smart technology, which are expanding the applications and appeal of these lighting solutions.

The manufacturing landscape for LED and OLED technologies is also a focal point of this report. It assesses the impact of global supply chains, the role of economies of scale, and the strategic moves by leading manufacturers as they navigate the complexities of production, from cost considerations to the adoption of sustainable manufacturing practices.

Furthermore, the report provides a detailed analysis of the competitive environment, identifying key players, their market positioning, and strategies for innovation and growth. It also offers insights into the emerging markets and sectors that represent growth opportunities for LED and OLED technologies, including automotive lighting, horticultural applications, and wearable electronics.

Looking ahead, the report forecasts the future directions of the LED and OLED markets, considering factors such as potential technological breakthroughs, emerging economic trends, and shifts in consumer preferences. It identifies challenges that could impede growth, such as material shortages or competitive pressures, and opportunities that could fuel expansion, such as the increasing demand for smart and connected lighting systems.

In conclusion, the "LED and OLED Lighting: Market Analysis and Manufacturing Trends" report serves as an essential resource for stakeholders across the lighting industry spectrum, offering strategic insights and actionable intelligence to navigate the complexities of the market, leverage emerging opportunities, and shape the future of lighting technology.

Trends in LED and OLED Lighting

The lighting industry is undergoing a significant transformation, driven by the rapid advancements and adoption of LED (Light Emitting Diode) and OLED (Organic Light Emitting Diode) technologies. These shifts are not only changing the way spaces are illuminated but also how lighting solutions are designed, manufactured, and integrated into the modern digital ecosystem.

The key trends shaping the LED and OLED lighting markets include:

- Energy Efficiency and Sustainability: As global awareness and regulations around energy conservation and environmental sustainability intensify, LED and OLED lights, known for their low power consumption and long service life, are becoming increasingly popular. These technologies are central to green building designs and energy-saving initiatives across residential, commercial, and industrial applications.

- Smart and Connected Lighting: The integration of LED and OLED lighting with IoT (Internet of Things) technologies is a growing trend. Smart lighting systems, capable of being controlled via smartphones or voice-activated devices, are becoming commonplace in smart homes and cities. These systems offer not just convenience but also efficiency, as they can adjust lighting based on presence, ambient light levels, or time of day.

- Human-Centric and Health-Focused Lighting: There is an increasing focus on the impact of lighting on human health and well-being. LED and OLED technologies allow for the creation of lighting solutions that mimic natural light patterns, potentially improving sleep cycles, mood, and productivity. This trend is gaining traction in both residential settings and workplaces.

- Innovative Design and Flexibility: OLED technology, in particular, allows for flexible, thin, and even transparent lighting panels that can be integrated into various surfaces and materials. This opens up new avenues for innovative lighting designs and applications, from architectural features to wearable technology.

- Advancements in Light Quality and Color Rendering: Continuous improvements in LED and OLED technologies have led to better color rendering and the ability to produce a wide spectrum of light. This not only enhances the aesthetic appeal of illuminated spaces but also finds applications in sectors such as retail, where accurate color representation is critical.

- Decreasing Costs and Increasing Accessibility: As manufacturing processes mature and economies of scale are achieved, the costs of LED and OLED lighting solutions continue to decrease. This trend is making these technologies more accessible to a broader market, driving their adoption in regions and sectors where cost was previously a barrier.

- Growth in Automotive and Specialty Applications: Beyond traditional lighting, LEDs and OLEDs are increasingly used in automotive lighting, including headlights, interior lights, and displays, as well as in specialized applications such as horticultural lighting, where specific light spectra can enhance plant growth.

Table of Contents

Chapter 1. Introduction

Chapter 2. Recent Progress in High Brightness LED Technology and Applications

- 2.1. LED: Theory of Operation

- 2.2. Intellectual Property Map

- 2.3. LED Manufacturing Technologies & Costs

- 2.4. LED Market General Illumination

Chapter 3. Processing Equipment

- 3.1. Introduction

- 3.2. Deposition

- 3.2.1. MOCVD for SSL - Productivity Challenges and Solutions

- 3.2.2. Low temperature Remote Plasma Chemical Vapor Deposition (RPCVD)

- 3.3. Chemical Mechanical Planarization

- 3.4. Defect Inspection and Testing

- 3.5. Lithography

- 3.5.1. Steppers

Chapter 4. Materials of Construction

- 4.1. Introduction

- 4.2. GaN-based LED for General Lighting

- 4.2.1. Methods to Improve White LED Efficiency

- 4.2.2. Time-to-Market for LED substrates

- 4.3. LED Phosphor Manufacturing Issues

- 4.3.1. Current LED Phosphor Manufacturing

- 4.3.2. LED Phosphor Cost

Chapter 5. Packaging and Assembly Issues for High Brightness LEDs

- 5.1. Packaging for HB LEDs

- 5.1.1. Bonding

- 5.1.2. Die/Ball Bonding

- 5.1.3. Scribing

- 5.2. Wafer Level Packaging HB LEDs

- 5.3. Thermal Issues

- 5.4. Test and Inspection

Chapter 6. National Programs As Innovation Drivers

- 6.1. DOE Solid-State Lighting Manufacturing Initiative

- 6.2. DOE Solid-State Lighting Program Mission and Goal

- 6.3. Major National Research Programs Pertaining to LEDs

- 6.4. Challenges Facing SSL Manufacturing

Chapter 7. OLED Lighting

- 7.1. Opportunities for Luminaire Manufacturers

- 7.2. How Does an OLED Work

- 7.3. Differences Between OLED Lighting and OLED Display

- 7.4. Benefits of OLED Lighting Technology

- 7.5. OLED Performance Metrics

Chapter 8. OLED Manufacturing

- 8.1. Deposition Equipment and Processes for OLED Lighting

- 8.1.1. Vacuum Deposition Or Vacuum Thermal Evaporation (VTE)

- 8.1.2. Organic Vapor Deposition (OVPD)

- 8.1.3. Inkjet Printing

- 8.1.4. Roll-to-Roll (R2R)

- 8.2. General OLED Manufacturing Cost Considerations

- 8.3. Lithography

- 8.4. Substrates and Encapsulation

- 8.4.1. Substrate and Encapsulation Material Selection

- 8.4.2. Substrate Coatings

- 8.4.3. Transparent Electrodes

- 8.4.4. Encapsulation

- 8.5. Inspection and Quality Control

Chapter 9. Outlook for the Worldwide OLED Market

- 9.1. Introduction

- 9.2. Passive Matrix Capacity and Demand

- 9.3. Active Matrix Capacity and Demand

- 9.4. Cost Challenges for OLED Lighting

Chapter 10. Outlook for the Worldwide High-Brightness LED Market

- 10.1. HB LED Technology

- 10.2. HB LED Market Overview and trends

- 10.2.1. Market Drivers for SSL

- 10.2.2. LED Backlights for Notebook PCs

- 10.2.3. LED Backlights for LCD TVs

- 10.2.4. LED Backlights for Other Applications

- 10.2.5. LED Lighting Market

- 10.2.6. LED Active Outdoor Display Market

- 10.2.7. LED Signal Market

- 10.2.8. LED Automotive Market

- 10.2.9. LED Mobile Market